Flotation process on:

[Wikipedia]

[Google]

[Amazon]

Froth flotation is a process for selectively separating

Increasing the energy efficiency of grinding

" Presented at: ''Crushing and Grinding, Brisbane, September 2007.'' Accessed 24 May 2013.

"Removal of organic carbon with a Jameson Cell at Red Dog Mine,"

in: ''Proceedings of the 40th Annual Meeting of the Canadian Mineral Processors, Ottawa, Ontario, 22–24 January 2008'' The rougher concentrate is normally subjected to further stages of flotation to reject more of the undesirable minerals that also reported to the froth, in a process known as ''cleaning''. The resulting material is often subject to further grinding (usually called ''regrinding''). Regrinding is often undertaken in specialized ''regrind mills'', such as the IsaMill.. The rougher flotation step is often followed by a ''scavenger'' flotation step that is applied to the rougher tailings to further recover any of the target minerals.

Mechanical cells use a large mixer and diffuser mechanism at the bottom of the mixing tank to introduce air and provide mixing action. Flotation columns use air

Mechanical cells use a large mixer and diffuser mechanism at the bottom of the mixing tank to introduce air and provide mixing action. Flotation columns use air

"Fundamentals of Jameson Cell operation including size–yield response,"

in: ''Sixth Australian Coal Preparation Conference, Mackay, Queensland, 6–9 September 1993'' (The Australasian Institute of Mining and Metallurgy: Melbourne, 1993). In a conventional mechanically-agitated cell, the void fraction (i.e. volume occupied by air bubbles) is low (5 to 10 percent) and the bubble size is usually greater than 1 mm. This results in a relatively low interfacial area and a low probability of particle–bubble contact.B W Atkinson, C J Conway and G J Jameson, "High-efficiency flotation of coarse and fine coal," in: ''High-efficiency Coal Preparation: An International Symposium,'' (Society of Mining, Metallurgy and Exploration: Littleton, Colorado, 1995). Consequently, several cells in series are required to increase the particle residence time, thus increasing the probability of particle–bubble contact.

Google Books preview

{{DEFAULTSORT:Froth Flotation Industrial processes Water treatment Metallurgical processes Australian inventions

hydrophobic

In chemistry, hydrophobicity is the physical property of a molecule that is seemingly repelled from a mass of water (known as a hydrophobe). In contrast, hydrophiles are attracted to water.

Hydrophobic molecules tend to be nonpolar and, ...

materials from hydrophilic

A hydrophile is a molecule or other molecular entity that is attracted to water molecules and tends to be dissolved by water.Liddell, H.G. & Scott, R. (1940). ''A Greek-English Lexicon'' Oxford: Clarendon Press.

In contrast, hydrophobes are n ...

. This is used in mineral processing, paper recycling and waste-water treatment industries. Historically this was first used in the mining industry, where it was one of the great enabling technologies of the 20th century. It has been described as "the single most important operation used for the recovery and upgrading of sulfide ores". The development of froth flotation has improved the recovery of valuable minerals

In geology and mineralogy, a mineral or mineral species is, broadly speaking, a solid chemical compound with a fairly well-defined chemical composition and a specific crystal structure that occurs naturally in pure form.John P. Rafferty, ed ...

, such as copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pink ...

- and lead

Lead is a chemical element with the symbol Pb (from the Latin ) and atomic number 82. It is a heavy metal that is denser than most common materials. Lead is soft and malleable, and also has a relatively low melting point. When freshly cut, ...

-bearing minerals. Along with mechanized mining, it has allowed the economic recovery of valuable metals from much lower grade ore than previously.

Industries

Froth flotation is applied to a wide range of separations. An estimated 1B tons of materials are processed in this manner annually.Mineral processing

Froth flotation is a process for separating minerals from gangue by exploiting differences in their hydrophobicity. Hydrophobicity differences between valuable minerals and waste gangue are increased through the use of surfactants and wetting agents. The flotation process is used for the separation of a large range ofsulfide

Sulfide (British English also sulphide) is an inorganic anion of sulfur with the chemical formula S2− or a compound containing one or more S2− ions. Solutions of sulfide salts are corrosive. ''Sulfide'' also refers to chemical compounds la ...

s, carbonate

A carbonate is a salt of carbonic acid (H2CO3), characterized by the presence of the carbonate ion, a polyatomic ion with the formula . The word ''carbonate'' may also refer to a carbonate ester, an organic compound containing the carbonate ...

s and oxides prior to further refinement. Phosphates and coal

Coal is a combustible black or brownish-black sedimentary rock, formed as rock strata called coal seams. Coal is mostly carbon with variable amounts of other elements, chiefly hydrogen, sulfur, oxygen, and nitrogen.

Coal is formed when ...

are also upgraded (purified) by flotation technology. "Grade-recovery curves" are tools in weighing the trade-off of producing a high grade of concentrate vs cost. These curves only compare the grade-recovery relations of a specific feed grade and feed rate.

Waste water treatment

The flotation process is also widely used in industrial waste water treatment plants, where it removes fats, oil, grease and suspended solids from waste water. These units are called dissolved air flotation (DAF) units. In particular, dissolved air flotation units are used in removing oil from the wastewater effluents ofoil refineries

An oil refinery or petroleum refinery is an industrial process plant where petroleum (crude oil) is transformed and refined into useful products such as gasoline (petrol), diesel fuel, asphalt base, fuel oils, heating oil, kerosene, li ...

, petrochemical

Petrochemicals (sometimes abbreviated as petchems) are the chemical products obtained from petroleum by refining. Some chemical compounds made from petroleum are also obtained from other fossil fuels, such as coal or natural gas, or renewabl ...

and chemical plant

A chemical plant is an industrial process plant that manufactures (or otherwise processes) chemicals, usually on a large scale. The general objective of a chemical plant is to create new material wealth via the chemical or biological transfo ...

s, natural gas processing plants and similar industrial facilities.

Principle of operation

The ore to be treated is ground into particles (comminution

Comminution is the reduction of solid materials from one average particle size to a smaller average particle size, by crushing, grinding, cutting, vibrating, or other processes. In geology, it occurs naturally during faulting in the upper part ...

). In the idealized case, the individual minerals are physically separated, a process known as full ''liberation''. The particle sizes are typically in the range 2-500 microns in diameter. For froth flotation, an aqueous slurry of the ground ore is treated with the frothing agent. An example is sodium ethyl xanthate as a collector in the flotation of galena

Galena, also called lead glance, is the natural mineral form of lead(II) sulfide (PbS). It is the most important ore of lead and an important source of silver.

Galena is one of the most abundant and widely distributed sulfide minerals. It cr ...

(lead sulfide) to separate it from sphalerite (zinc sulfide). The polar part of xanthate anion attaches to the ore particles and the non-polar hydrocarbon part forms a hydrophobic layer. The particles are brought to the water surface by air bubbles. About 300 g/tonne of ore is required for efficient separation. The efficiency of the hydrophobic action increases, but the selectivity to ore type decreases with increasing length of the hydrocarbon chain in xanthates. The chain is shortest in sodium ethyl xanthate that makes it highly selective to copper, nickel, lead, gold, and zinc ores. Aqueous solutions (10%) with pH=7–11 are normally used in the process.Report 5 (1995) p. 13 This slurry (more properly called the ''pulp'') of hydrophobic particles and hydrophilic particles is then introduced to tanks known as ''flotation cells'' that are aerated to produce bubbles. The hydrophobic particles attach to the air bubbles, which rise to the surface, forming a froth. The froth is skimmed from the cell, producing a concentrate ("conc") of the target mineral.

The minerals that do not float into the froth are referred to as the ''flotation tailings'' or ''flotation tails''. These tailings may also be subjected to further stages of flotation to recover the valuable particles that did not float the first time. This is known as ''scavenging''. The final tailings after scavenging are normally pumped for disposal as mine fill or to tailings disposal facilities for long-term storage.

Flotation is normally undertaken in several stages to maximize the recovery of the target mineral or minerals and the concentration of those minerals in the concentrate, while minimizing the energy input.J Pease,Increasing the energy efficiency of grinding

" Presented at: ''Crushing and Grinding, Brisbane, September 2007.'' Accessed 24 May 2013.

Flotation stages

The first stage is called ''roughing'', which produces a ''rougher concentrate''. The objective is to remove the maximum amount of the valuable mineral at as coarse a particle size as practical. Grinding costs energy. The goal is to release enough gangue from the valuable mineral to get a high recovery. Some concentrators use a ''preflotation'' step to remove low density impurities such as carbonaceous dust.T Smith, D Lin, B Lacouture and G Anderson"Removal of organic carbon with a Jameson Cell at Red Dog Mine,"

in: ''Proceedings of the 40th Annual Meeting of the Canadian Mineral Processors, Ottawa, Ontario, 22–24 January 2008'' The rougher concentrate is normally subjected to further stages of flotation to reject more of the undesirable minerals that also reported to the froth, in a process known as ''cleaning''. The resulting material is often subject to further grinding (usually called ''regrinding''). Regrinding is often undertaken in specialized ''regrind mills'', such as the IsaMill.. The rougher flotation step is often followed by a ''scavenger'' flotation step that is applied to the rougher tailings to further recover any of the target minerals.

Science of flotation

To be effective on a given ore slurry, the collectors are chosen based upon their selective wetting of the types of particles to be separated. A good collector will adsorb, physically or chemically, with one of the types of particles. The wetting activity of a surfactant on a particle can in principle be quantified by measuring the contact angles of the liquid/bubble interface. Another important measure for attachment of bubbles to particles is induction time, the time required for the particle and bubble to rupture the thin film separating the particle and bubble. This rupturing is achieved by the surface forces between the particle and bubble. The mechanisms for the bubble-particle attachment is complex but is viewed as consisting of three steps: collision, attachment, and detachment. The collision is achieved by particles being within the collision tube of a bubble and this is affected by the velocity of the bubble and radius of the bubble. The collision tube corresponds to the region in which a particle will collide with the bubble, with the perimeter of the collision tube corresponding to the grazing trajectory. The attachment of the particle to the bubble is controlled by the induction time of the particle and bubble. The particle and bubble need to bind and this occurs if the time in which the particle and bubble are in contact with each other is larger than the required induction time. This induction time is affected by the fluid viscosity, particle and bubble size and the forces between the particle and bubbles. The detachment of a particle and bubble occurs when the force exerted by the surface tension is exceeded by shear forces and gravitational forces. These forces are complex and vary within the cell. High shear will be experienced close to the impeller of a mechanical flotation cell and mostly gravitational force in the collection and cleaning zone of a flotation column. Significant issues of entrainment of fine particles occurs as these particles experience low collision efficiencies as well as sliming and degradation of the particle surfaces. Coarse particles show a low recovery of the valuable mineral due to the low liberation and high detachment efficiencies.Flotation equipment

Flotation can be performed in rectangular or cylindrical mechanically agitated cells or tanks, flotation columns, Jameson Cells or deinking flotation machines. Classified by the method of air absorption manner, it is fair to state that two distinct groups of flotation equipment have arisen:pneumatic and mechanical machines. Generally pneumatic machines give a low-grade concentrate and little operating troubles. Mechanical cells use a large mixer and diffuser mechanism at the bottom of the mixing tank to introduce air and provide mixing action. Flotation columns use air

Mechanical cells use a large mixer and diffuser mechanism at the bottom of the mixing tank to introduce air and provide mixing action. Flotation columns use air sparger

In chemistry, sparging, also known as gas flushing in metallurgy, is a technique in which a gas is bubbled through a liquid in order to remove ''other'' dissolved gas(es) and/or dissolved volatile liquid(s) from that liquid. It is a method of ...

s to introduce air at the bottom of a tall column while introducing slurry above. The countercurrent motion of the slurry flowing down and the air flowing up provides mixing action. Mechanical cells generally have a higher throughput rate, but produce material that is of lower quality, while flotation columns generally have a low throughput rate but produce higher quality material.

The Jameson cell uses neither impellers nor spargers, instead combining the slurry with air in a downcomer where high shear creates the turbulent conditions required for bubble particle contacting.

Chemicals of flotation

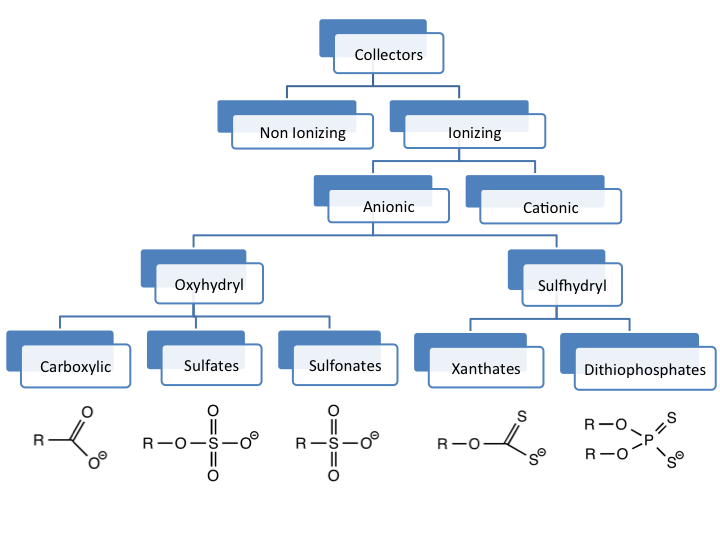

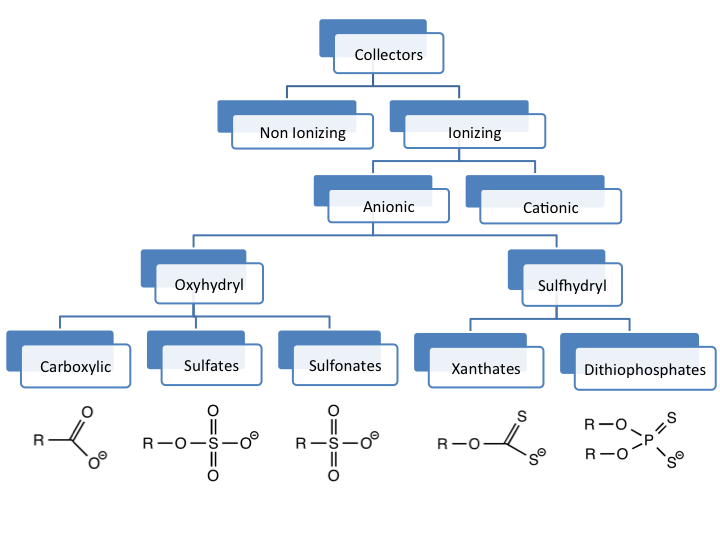

Collectors

For many ores (e.g. those of Cu, Mo, W, Ni), the collectors are anionic sulfur ligands. Particularly popular for sulfide minerals are xanthate salts, including potassium amyl xanthate (PAX), potassium isobutyl xanthate (PIBX), potassium ethyl xanthate (KEX), sodium isobutyl xanthate (SIBX), sodium isopropyl xanthate (SIPX), sodium ethyl xanthate (SEX). Related collectors include related sulfur-based ligands:dithiophosphate

Sodium dithiophosphate is the salt with the formula Na3PS2O2. It is usually supplied as the hydrated solid or as an aqueous solution together with other thiophosphates such as sodium monothiophosphate and sodium trithiophosphate. It is a color ...

s, dithiocarbamates. Still other classes of collectors include the thiourea thiocarbanilide. Fatty acid

In chemistry, particularly in biochemistry, a fatty acid is a carboxylic acid with an aliphatic chain, which is either saturated or unsaturated. Most naturally occurring fatty acids have an unbranched chain of an even number of carbon atoms, f ...

carboxylates, alkyl sulfates, and alkyl sulfonate

Alkyl sulfonates are esters of alkane sulfonic acids with the general formula R-SO2-O-R'. They act as alkylating agents, some of them are used as alkylating antineoplastic agents in the treatment of cancer, e.g. Busulfan

Busulfan (Myleran, G ...

s have also been used for oxide minerals.

For some minerals (e.g., sylvinite for KCl), fatty amines are used as collectors.

Frothers

A variety of compounds are added to stabilize the foams. These additives include pine oil, various alcohols ( methyl isobutyl carbinol (MIBC)), polyglycols, xylenol (cresylic acid).Modifiers

A variety of other compounds are added to optimize the separation process, these additives are called modifiers. Modifying reagents react either with the mineral surfaces or with collectors and other ions in the flotation pulp, resulting in a modified and controlled flotation response. * pH modifiers include lime (used as quicklime CaO, or more commonly as slaked lime, a slurry of Ca(OH)2), Soda ash (Na2CO3), Caustic soda (NaOH),sulfuric

Sulfur (or sulphur in British English) is a chemical element with the symbol S and atomic number 16. It is abundant, multivalent and nonmetallic. Under normal conditions, sulfur atoms form cyclic octatomic molecules with a chemical formula ...

and hydrochloric acid

Hydrochloric acid, also known as muriatic acid, is an aqueous solution of hydrogen chloride. It is a colorless solution with a distinctive pungent smell. It is classified as a strong acid. It is a component of the gastric acid in the dige ...

(H2SO4, HCl).

* Anion

An ion () is an atom or molecule with a net electrical charge.

The charge of an electron is considered to be negative by convention and this charge is equal and opposite to the charge of a proton, which is considered to be positive by conve ...

ic modifiers include phosphates, silicates, and carbonates.

* Organic modifiers include the thickeners dextrin, starch

Starch or amylum is a polymeric carbohydrate consisting of numerous glucose units joined by glycosidic bonds. This polysaccharide is produced by most green plants for energy storage. Worldwide, it is the most common carbohydrate in human die ...

, glue, and CMC.

Specific applications

Sulfide ores

Copper (seecopper extraction

Copper extraction refers to the methods used to obtain copper from its ores. The conversion of copper consists of a series of physical and electrochemical processes. Methods have evolved and vary with country depending on the ore source, loca ...

) and copper- molybdenum Sebenik, Roger F. ''et al''. (2005) "Molybdenum and Molybdenum Compounds" in ''Ullmann's Encyclopedia of Chemical Technology''. Wiley-VCH, Weinheim. Lead

Lead is a chemical element with the symbol Pb (from the Latin ) and atomic number 82. It is a heavy metal that is denser than most common materials. Lead is soft and malleable, and also has a relatively low melting point. When freshly cut, ...

-Zinc

Zinc is a chemical element with the symbol Zn and atomic number 30. Zinc is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed. It is the first element in group 12 (IIB) of the periodi ...

Prior to 1907, nearly all the copper mined in the US came from underground vein deposits, averaging 2.5 percent copper. By 1991, the average grade of copper ore mined in the US had fallen to only 0.6 percent.

Nonsulfide ores

Flotation is used for purification of potassium chloride fromsodium chloride

Sodium chloride , commonly known as salt (although sea salt also contains other chemical salts), is an ionic compound with the chemical formula NaCl, representing a 1:1 ratio of sodium and chloride ions. With molar masses of 22.99 and 35. ...

and clay minerals. The crushed mineral is suspended in brine in the presence of fatty ammonium salts. Because the ammonium head group and K+ have very similar ionic radii (ca. 0.135, 0.143 nm respectively), the ammonium centers exchange for the surface potassium sites on the particles of KCl, but not on the NaCl particles. The long alkyl

In organic chemistry, an alkyl group is an alkane missing one hydrogen.

The term ''alkyl'' is intentionally unspecific to include many possible substitutions.

An acyclic alkyl has the general formula of . A cycloalkyl is derived from a cycloa ...

chains then confer hydrophobicity to the particles, which enable them to form foams.Elizabeth R. Burkhardt "Potassium and Potassium Alloys" in Ullmann's Encyclopedia of Industrial Chemistry, Wiley-VCH, 2006.

Coal

Waste water treatment

Chemical compounds for deinking of recycled paper

Froth flotation is one of the processes used to recover recycled paper. In the paper industry this step is called deinking or just flotation. The target is to release and remove the hydrophobic contaminants from the recycled paper. The contaminants are mostly printing ink and stickies. Normally the setup is a two-stage system with 3,4 or 5 flotation cells in series. * pH control:sodium silicate

Sodium silicate is a generic name for chemical compounds with the formula or ·, such as sodium metasilicate , sodium orthosilicate , and sodium pyrosilicate . The anions are often polymeric. These compounds are generally colorless transparent ...

and sodium hydroxide

* Calcium

Calcium is a chemical element with the symbol Ca and atomic number 20. As an alkaline earth metal, calcium is a reactive metal that forms a dark oxide-nitride layer when exposed to air. Its physical and chemical properties are most similar ...

ion source: hard water, lime or calcium chloride

* Collector: fatty acid

In chemistry, particularly in biochemistry, a fatty acid is a carboxylic acid with an aliphatic chain, which is either saturated or unsaturated. Most naturally occurring fatty acids have an unbranched chain of an even number of carbon atoms, f ...

, fatty acid emulsion

An emulsion is a mixture of two or more liquids that are normally immiscible (unmixable or unblendable) owing to liquid-liquid phase separation. Emulsions are part of a more general class of two-phase systems of matter called colloids. Alth ...

, fatty acid soap

Soap is a salt of a fatty acid used in a variety of cleansing and lubricating products. In a domestic setting, soaps are surfactants usually used for washing, bathing, and other types of housekeeping. In industrial settings, soaps are us ...

and/or organo-modified siloxane

Environmental considerations

As in any technology that has long been conducted on the multi-million ton per year scale, flotation technologies have the potential for threatening the environment beyond the disruption of the mining. Froth flotation employs a host of organic chemicals and relies of elaborate machinery. Some of the chemicals (cyanide) are acutely toxic but hydrolyze to innocuous products. Naturally occurring fatty acids are widely used. Tailings and effluents are contained in lined ponds. Froth flotation is "poised for increased activity due to their potential usefulness in environmental site cleanup operations" including recycling of plastics and metals, not to mention water treatment.History

Flotation process are described in ancient Greek and Persian literature. During the late 19th century, the process basics were discovered through a slow evolutionary phase. During the first decade of the 20th century, a more rapid investigation of oils, froths, and agitation led to proven work-place applications, especially at Broken Hill, Australia, that brought the technological innovation known as “froth flotation.” During the early 20th century, froth flotation revolutionized mineral processing. Initially, naturally occurring chemicals such asfatty acid

In chemistry, particularly in biochemistry, a fatty acid is a carboxylic acid with an aliphatic chain, which is either saturated or unsaturated. Most naturally occurring fatty acids have an unbranched chain of an even number of carbon atoms, f ...

s and oils were used as flotation reagents in a large quantity to increase the hydrophobicity of the valuable minerals. Since then, the process has been adapted and applied to a wide variety of materials to be separated, and additional collector agents, including surfactants and synthetic compounds have been adopted for various applications.

19th century

Englishman William Haynes patented a process in 1860 for separatingsulfide

Sulfide (British English also sulphide) is an inorganic anion of sulfur with the chemical formula S2− or a compound containing one or more S2− ions. Solutions of sulfide salts are corrosive. ''Sulfide'' also refers to chemical compounds la ...

and gangue minerals using oil. Later writers have pointed to Haynes's as the first "bulk oil flotation" patent, though there is no evidence of its being field tested, or used commercially. In 1877 the brothers Bessel (Adolph and August) of Dresden, Germany, introduced their commercially successful oil and froth flotation process for extracting graphite

Graphite () is a crystalline form of the element carbon. It consists of stacked layers of graphene. Graphite occurs naturally and is the most stable form of carbon under standard conditions. Synthetic and natural graphite are consumed on la ...

, considered by some the root of froth flotation. However, the Bessel process became uneconomical after the discovery of high-grade graphite in Sri Lanka

Sri Lanka (, ; si, ශ්රී ලංකා, Śrī Laṅkā, translit-std=ISO (); ta, இலங்கை, Ilaṅkai, translit-std=ISO ()), formerly known as Ceylon and officially the Democratic Socialist Republic of Sri Lanka, is an ...

and was largely forgotten.

Inventor Hezekiah Bradford of Philadelphia invented a "method of saving floating material in ore-separation” and received US patent No. 345951 on July 20, 1886. He would later go on to patent the Bradford Breaker, currently in use by the coal industry, in 1893. His "Bradford washer," patented 1870, was used to concentrate iron, copper and lead-zinc ores by specific gravity, but lost some of the metal as float off the concentration process. The 1886 patent was to capture this "float" using surface tension, the first of the skin-flotation process patents that was eclipsed by oil froth flotation.

On August 24, 1886, Carrie Everson

Carrie Jane Everson (born Rebecca Jane Billings; 27 August 1842–3 November 1914) was an American who invented and patented processes for extracting valuable minerals from ore using froth floatation. ''The Mining Journal'' noted in 1916 that ...

received a patent for her process calling for oil but also an acid or a salt, a significant step in the evolution of the process history. By 1890, tests of the Everson process had been made at Georgetown and Silver Cliff, Colorado, and Baker, Oregon. She abandoned the work upon the death of her husband, and before perfecting a commercially successful process. Later, during the height of legal disputes over the validity of various patents during the 1910s, Everson's was often pointed to as the initial flotation patent - which would have meant that the process was not patentable again by later contestants. Much confusion has been clarified recently by historian Dawn Bunyak.

First commercial flotation process

The generally recognized first successful commercial flotation process for ''mineral'' sulphides was invented by Frank Elmore who worked on the development with his brother, Stanley. The Glasdir copper mine at Llanelltyd, near Dolgellau inNorth Wales

North Wales ( cy, Gogledd Cymru) is a regions of Wales, region of Wales, encompassing its northernmost areas. It borders Mid Wales to the south, England to the east, and the Irish Sea to the north and west. The area is highly mountainous and rural, ...

was bought in 1896 by the Elmore brothers in conjunction with their father, William. In 1897, the Elmore brothers installed the world's first industrial size commercial flotation process for mineral beneficiation at the Glasdir mine. The process was not froth flotation but used oil to agglomerate (make balls of) pulverised sulphides and buoy

A buoy () is a floating device that can have many purposes. It can be anchored (stationary) or allowed to drift with ocean currents.

Types

Navigational buoys

* Race course marker buoys are used for buoy racing, the most prevalent form of y ...

them to the surface, and was patented in 1898 (revised 1901). The operation and process was described in the April 25, 1900 ''Transactions'' of the Institution of Mining and Metallurgy of England, which was reprinted with comment, June 23, 1900, in the ''Engineering and Mining Journal'', New York City. By this time they had recognized the importance of air bubbles in assisting the oil to carry away the mineral particles. As modifications were made to improve the process, it became a success with base metal ores from Norway to Australia.

The Elmores had formed a company known as the Ore Concentration Syndicate Ltd to promote the commercial use of the process worldwide. In 1900, Charles Butters of Berkeley, California, acquired American rights to the Elmore process after seeing a demonstration at Llanelltyd, Wales. Butters, an expert on the cyanide process, built an Elmore process plant in the basement of the Dooley Building, Salt Lake City, and tested the oil process on gold ores throughout the region and tested the tailings of the Mammoth gold mill, Tintic district, Utah, but without success. Because of Butters’ reputation and the news of his failure, as well as the unsuccessful attempt at the LeRoi gold mine at Rossland, B. C., the Elmore process was all but ignored in North America.

Developments elsewhere, particularly in Broken Hill, Australia

Broken Hill is an inland mining city in the far west of outback New South Wales, Australia. It is near the border with South Australia on the crossing of the Barrier Highway (A32) and the Silver City Highway (B79), in the Barrier Range. It is ...

by Minerals Separation, Limited Minerals Separation Ltd, was a small London-based company involved in developing a technique of ore extraction.

History

Organized in 1903 by South African John Ballot, the firm moved to experiment with new processes as well as acquire patents of ot ...

, led to decades of hard-fought legal battles and litigations for the Elmores who, ultimately, lost as the Elmore process was superseded by more advanced techniques. Another flotation process was independently invented in the early 1900s in Australia by Charles Vincent Potter and around the same time by Guillaume Daniel Delprat

Guillaume Daniel Delprat CBE (1 September 1856 – 15 March 1937) was a Dutch- Australian metallurgist, mining engineer, and businessman. He was a developer of the froth flotation process for separating minerals.

Delprat was born in Delft, th ...

.

This process (developed circa 1902) did not use oil, but relied upon flotation by the generation of gas formed by the introduction of acid into the pulp. In 1902, Froment combined oil and gaseous flotation using a modification of the Potter-Delprat process. During the first decade of the twentieth century, Broken Hill became the center of innovation leading to the perfection of the froth flotation process by many technologists there borrowing from each other and building on these first successes.

Yet another process was developed in 1902 by Arthur C. Cattermole, who emulsified the pulp with a small quantity of oil, subjected it to violent agitation, then slow stirring which coagulated the target minerals into nodules which were separated from the pulp by gravity. The Minerals Separation Ltd., formed in Britain in 1903 to acquire the Cattermole patent, found that it proved unsuccessful. Metallurgists on the staff continued to test and combine other discoveries to patent in 1905 their process, called the Sulman-Picard-Ballot process after company officers and patentees. The process proved successful at their Central Block plant, Broken Hill that year. Significant in their "agitation froth flotation" process was the use of less than 1% oil and an agitation step that created small bubbles, which provided more surface to capture the metal and float into a froth at the surface. Useful work was done by Leslie Bradford at Port Pirie and by William Piper, Sir Herbert Gepp

Sir Herbert William Gepp (pron. "Jepp") (28 September 1877 – 14 April 1954) was an Australian industrial chemist, businessman and public servant.

History

Gepp was born in Adelaide, a son of William John Gepp (1843 – 27 March 1915) and his wif ...

and Auguste de Bavay

Auguste Joseph François de Bavay (9 June 1856 – 16 November 1944) was a brewer and industrial chemist in Australia.

History

De Bavay was born in Vilvoorde, Belgium, second son of R. de Bavay, Knight of the Order of Leopold / a son of Xavier de ...

.

Mineral Separation also bought other patents to consolidate ownership of any potential conflicting rights to the flotation process - except for the Elmore patents. In 1910, when the Zinc Corporation replaced its Elmore process with the Minerals Separation (Sulman-Picard-Ballot) froth flotation process at its Broken Hill plant, the primacy of the Minerals Separation over other process contenders was assured. Henry Livingston Sulman was later recognized by his peers in his election as President of the (British) Institution of Mining and Metallurgy The Institution of Mining and Metallurgy (IMM) was a British research institution, founded in 1892. Members of the Institution used the post-nominals MIMM.

In 2002, it merged with The Institute of Materials (IOM) to form the Institute of Materials, ...

, which also awarded him its gold medal.

20th century

Developments in the United States had been less than spectacular. Butters's failures, as well as others, was followed after 1904, with Scotsman Stanley MacQuisten's process (a surface tension based method), which was developed with a modicum of success in Nevada and Idaho, but this would not work when slimes were present, a major fault. Henry E. Wood of Denver had developed his flotation process along the same lines in 1907, patented 1911, with some success on molybdenum ores. For the most part, however, these were isolated attempts without fanfare for what can only be called marginal successes. In 1911, James M. Hyde, a former employee of Minerals Separation, Ltd., modified the Minerals Separation process and installed a test plant in the Butte and Superior Mill in Basin, Montana, the first such installation in the USA. In 1912, he designed the Butte & Superior zinc works, Butte, Montana, the first great flotation plant in America. Minerals Separation, Ltd., which had set up an office in San Francisco, sued Hyde for infringement as well as the Butte & Superior company, both cases were eventually won by the firm in the U. S. Supreme Court.Daniel Cowan Jackling

Daniel Cowan Jackling (August 14, 1869 – March 13, 1956), was an American mining and metallurgical engineer who pioneered the exploitation of low-grade porphyry copper ores at the Bingham Canyon Mine, Utah.

Biography Early life

Born near ...

and partners, who controlled Butte & Superior, also refuted the Minerals Separation patent and funded the ensuing legal battles that lasted over a decade. They - Utah Copper (Kennecott), Nevada Consolidated, Chino Copper, Ray Con and other Jackling firms - eventually settled, in 1922, paying a substantial fee for licenses to use the Minerals Separation process. One unfortunate result of the dispute was professional divisiveness among the mining engineering community for a generation.

In 1913, the Minerals Separation paid for a test plant for the Inspiration Copper Company at Miami, Arizona. Built under the San Francisco office director, Edward Nutter, it proved a success. Inspiration engineer L. D. Ricketts ripped out a gravity concentration mill and replaced it with the Minerals Separation process, the first major use of the process at an American copper mine. A major holder of Inspiration stock were men who controlled the great Anaconda mine of Butte. They immediately followed the Inspiration success to build a Minerals Separation licensed plant at Butte, in 1915–1916, a major statement about the final acceptance of the Minerals Separation patented process.

John M. Callow, of General Engineering of Salt Lake City

Salt Lake City (often shortened to Salt Lake and abbreviated as SLC) is the capital and most populous city of Utah, United States. It is the seat of Salt Lake County, the most populous county in Utah. With a population of 200,133 in 2020, th ...

, had followed flotation from technical papers and the introduction in both the Butte and Superior Mill, and at Inspiration Copper in Arizona and determined that mechanical agitation was a drawback to the existing technology. Introducing a porous brick with compressed air, and a mechanical stirring mechanism, Callow applied for a patent in 1914 (some say that Callow, a Jackling partisan, invented his cell as a means to avoid paying royalties to Minerals Separation, which firms using his cell eventually were forced to do by the courts). This method, known as Pneumatic Flotation, was recognized as an alternative to the Minerals Separation process of flotation concentration. The American Institute of Mining Engineers presented Callow the James Douglas Gold Medal in 1926 for his contributions to the field of flotation. By that time, flotation technology was changing, especially with the discovery of the use of xanthates and other reagents, which made the Callow cell and his process obsolete.

Montana Tech professor Antoine Marc Gaudin defined the early period of flotation as the mechanical phase while by the late 1910s it entered the chemical phase. Discoveries in reagents, especially the use of xanthates patented by Minerals Separations chemist Cornelius H. Keller, not so much increased the capture of minerals through the process as making it far more manageable in day-to-day operations. Minerals Separation's initial flotation patents ended 1923, and new ones for chemical processes gave it a significant position into the 1930s. During this period the company also developed and patented flotation processes for iron out of its Hibbing lab and of phosphate in its Florida lab. Another rapid phase of flotation process innovation did not occur until after 1960.

In the 1960s the froth flotation technique was adapted for deinking recycled paper.

The success of the process is evinced by the number of claimants as "discoverers" of flotation. In 1961, American engineers celebrated "50 years of flotation" and enshrined James Hyde and his Butte & Superior mill. In 1977, German engineers celebrated the "hundredth anniversary of flotation" based on the brothers Bessel patent of 1877. The historic Glasdir copper mine site advertises its tours in Wales as site of the "discovery of flotation" based upon the Elmore brothers work. Recent writers, because of the interest in celebrating women in science, champion Carrie Everson of Denver as mother of the process based on her 1885 patent. Omitted from this list are the engineers, metallurgists and chemists of Minerals Separation, Ltd., which, at least in the American and Australian courts, won control of froth flotation patents as well as right of claimant as discoverers of froth flotation. But, as historian Martin Lynch writes, "Mineral Separation would eventually prevail after taking the case to the US Supreme Court nd the House of Lords and in so doing earned for itself the cordial detestation of many in the mining world."

Theory

Froth flotation efficiency is determined by a series of probabilities: those of particle–bubble contact, particle–bubble attachment, transport between the pulp and the froth, and froth collection into the product launder.B W Atkinson, C J Conway and G J Jameson"Fundamentals of Jameson Cell operation including size–yield response,"

in: ''Sixth Australian Coal Preparation Conference, Mackay, Queensland, 6–9 September 1993'' (The Australasian Institute of Mining and Metallurgy: Melbourne, 1993). In a conventional mechanically-agitated cell, the void fraction (i.e. volume occupied by air bubbles) is low (5 to 10 percent) and the bubble size is usually greater than 1 mm. This results in a relatively low interfacial area and a low probability of particle–bubble contact.B W Atkinson, C J Conway and G J Jameson, "High-efficiency flotation of coarse and fine coal," in: ''High-efficiency Coal Preparation: An International Symposium,'' (Society of Mining, Metallurgy and Exploration: Littleton, Colorado, 1995). Consequently, several cells in series are required to increase the particle residence time, thus increasing the probability of particle–bubble contact.

Selective adhesion

Froth flotation depends on the selective adhesion of air bubbles to mineral surfaces in a mineral/water slurry. The air bubbles attach to morehydrophobic

In chemistry, hydrophobicity is the physical property of a molecule that is seemingly repelled from a mass of water (known as a hydrophobe). In contrast, hydrophiles are attracted to water.

Hydrophobic molecules tend to be nonpolar and, ...

particles, as determined by the interfacial energies between the solid, liquid, and gas phases. This energy is determined by the Young–Dupré equation:

:

where:

* γlv is the surface energy of the liquid/vapor interface

* γsv is the surface energy of the solid/vapor interface

* γsl is the surface energy of the solid/liquid interface,

* θ is the contact angle, the angle formed at the junction between vapor, solid, and liquid phases.

Minerals targeted for separation may be chemically surface-modified with collectors so that they are more hydrophobic. Collectors are a type of surfactant

Surfactants are chemical compounds that decrease the surface tension between two liquids, between a gas and a liquid, or interfacial tension between a liquid and a solid. Surfactants may act as detergents, wetting agents, emulsion#Emulsifiers , ...

that increase the natural hydrophobicity of the surface, increasing the separability of the hydrophobic and hydrophilic particles. Collectors either chemically bond via chemisorption

Chemisorption is a kind of adsorption which involves a chemical reaction between the surface and the adsorbate. New chemical bonds are generated at the adsorbent surface. Examples include macroscopic phenomena that can be very obvious, like cor ...

to the mineral or adsorb onto the surface via physisorption

Physisorption, also called physical adsorption, is a process in which the electronic structure of the atom or molecule is barely perturbed upon adsorption.

Overview

The fundamental interacting force of physisorption is Van der Waals force. Even ...

.

IMFs and surface forces in bubble-particle interactions

=Collision

= The collision rates for fine particles (50 - 80 μm) can be accurately modeled, but there is no current theory that accurately models bubble-particle collision for particles as large as 300 μm, which are commonly used in flotation processes. For fine particles,Stokes law

In 1851, George Gabriel Stokes derived an expression, now known as Stokes' law, for the frictional force – also called drag force – exerted on spherical objects with very small Reynolds numbers in a viscous fluid. Stokes' law is derived by ...

underestimates collision probability while the potential equation based on surface charge overestimates collision probability so an intermediate equation is used.

It is important to know the collision rates in the system since this step precedes the adsorption where a three phase system is formed.

=Adsorption (attachment)

= The effectiveness of a medium to adsorb to a particle is influenced by the relationship between the surfaces of both materials. There are multiple factors that affect the efficiency of adsorption in chemical, thermodynamic, and physical domains. These factors can range from surface energy and polarity to the shape, size, and roughness of the particle. In froth flotation, adsorption is a strong consequence of surface energy, since the small particles have a high surface area to size ratio, resulting in higher energy surfaces to form attractions with adsorbates. The air bubbles must selectively adhere to the desired minerals to elevate them to the surface of the slurry while wetting the other minerals and leaving them in the aqueous slurry medium. Particles that can be easily wetted by water are called hydrophilic, while particles that are not easily wetted by water are called hydrophobic. Hydrophobic particles have a tendency to form a separate phase in aqueous media. In froth flotation the effectiveness of an air bubble to adhere to a particle is based on how hydrophobic the particle is. Hydrophobic particles have an affinity to air bubbles, leading to adsorption. The bubble-particle combinations are elevated to the froth zone driven by buoyancy forces. The attachment of the bubbles to the particles is determined by the interfacial energies of between the solid, liquid, and vapor phases, as modeled by the Young/Dupre Equation. The interfacial energies can be based on the natural structure of the materials, or the addition of chemical treatments can improve energy compatibility. Collectors are the main additives used to improve particle surfaces. They function as surfactants to selectively isolate and aid adsorption between the particles of interest and bubbles rising through the slurry. Common collectors used in flotation are anionic sulfur ligands, which have a bifunctional structure with an ionic portion which shares attraction with metals, and a hydrophobic portion such as a long hydrocarbon tail. These collectors coat a particle's surface with a monolayer of non-polar substance to aid separation from the aqueous phase by decreasing the adsorbed particle solubility in water. The adsorbed ligands can form micelles around the particles and form small-particle colloids improving stability and phase separation further.=Desorption (detachment)

= The adsorption of particles to bubbles is essential to separating the minerals from the slurry, but the minerals must be purified from the additives used in separation, such as the collectors, frothers, and modifiers. The product of the cleaning, or desorption process, is known as the cleaner concentrate. The detachment of a particle and bubble requires adsorption bond cleavage driven by shear forces. Depending on the flotation cell type, shear forces are applied by a variety of mechanical systems. Among the most common are impellers and mixers. Some systems combine the functionalities of these components by placing them at key locations where they can take part in multiple froth flotation mechanisms. Cleaning cells also take advantage of gravitational forces to improve separation efficiency. Desorption itself is a chemical phenomenon where compounds are just physically attached to each other without having any chemical bond.Performance calculations

=Relevant equations

= A common quantity used to describe the collection efficiency of a froth flotation process is ''flotation recovery'' (). This quantity incorporates the probabilities of collision and attachment of particles to gas flotation bubbles. : where: * , which is the product of the probability of the particle being collected () and the number of possible particle collisions () * is particle diameter * is bubble diameter * is a specified height within the flotation which the recovery was calculated * is the particle concentration The following are several additional mathematical methods often used to evaluate the effectiveness of froth flotation processes. These equations are more simple than the calculation for ''flotation recovery'', as they are based solely on the amounts of inputs and outputs of the processes.Kawatra, S. K. "Froth Flotation – Fundamental Principles." (n.d.): n. pag. Web. For the following equations: * is the weight percent of feed * is the weight percent concentrate * is the weight percent of tailings * , , and are the metallurgical assays of the concentrate, tailings, and feed, respectively Ratio of feed weight to concentrate weight (unitless) : Percent of metal recovered () in wt''%'' : Percent of metal lost () in wt''%'' : Percent of weight recovered in wt''%'' :See also

* Deinking * Dissolved air flotation (DAF) *Flocculation

Flocculation, in the field of chemistry, is a process by which colloidal particles come out of suspension to sediment under the form of floc or flake, either spontaneously or due to the addition of a clarifying agent. The action differs from ...

* List of waste-water treatment technologies

This page consists of a list of wastewater treatment technologies:

See also

*Agricultural wastewater treatment

* Industrial wastewater treatment

*List of solid waste treatment technologies

* Waste treatment technologies

* Water purification

*S ...

Further reading

*D N Nihill, C M Stewart and P Bowen, "The McArthur River mine—the first years of operation," in: ''AusIMM ’98 – The Mining Cycle, Mount Isa, 19–23 April 1998'' (The Australasian Institute of Mining and Metallurgy: Melbourne, 1998), 73–82. *E V Manlapig, C Green, J W Parkinson and A S Murphy, "The technology and economic incentives for recovering coal from tailings impoundments," ''SME Annual Meeting, Denver, Colorado, 26–28 February 2001, Preprint 01-70'' (Society of Mining, Metallurgy and Exploration: Littleton, Colorado, 2001).References

Further reading

*''Froth Flotation: A Century of Innovation,'' by Maurice C. Fuerstenau et al. 2007, SME, 891 pp.Google Books preview

{{DEFAULTSORT:Froth Flotation Industrial processes Water treatment Metallurgical processes Australian inventions