Flong on:

[Wikipedia]

[Google]

[Amazon]

In relief printing, a flong is a temporary negative mould made of a

In relief printing, a flong is a temporary negative mould made of a

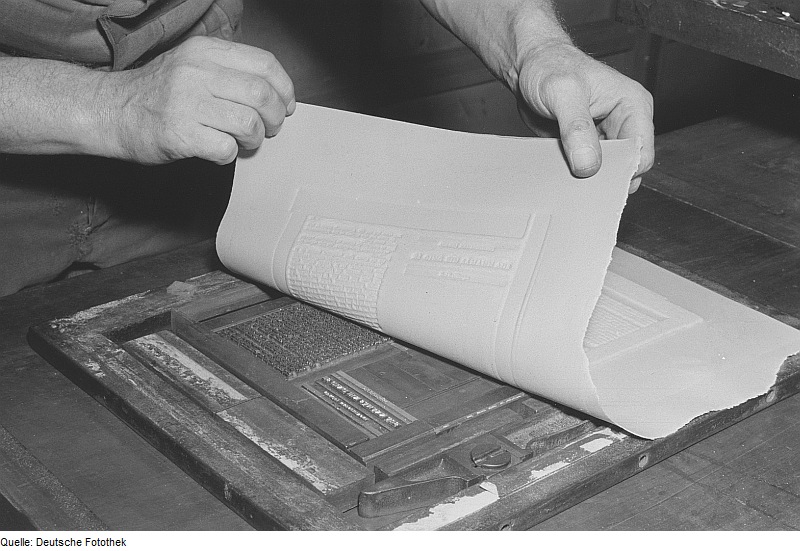

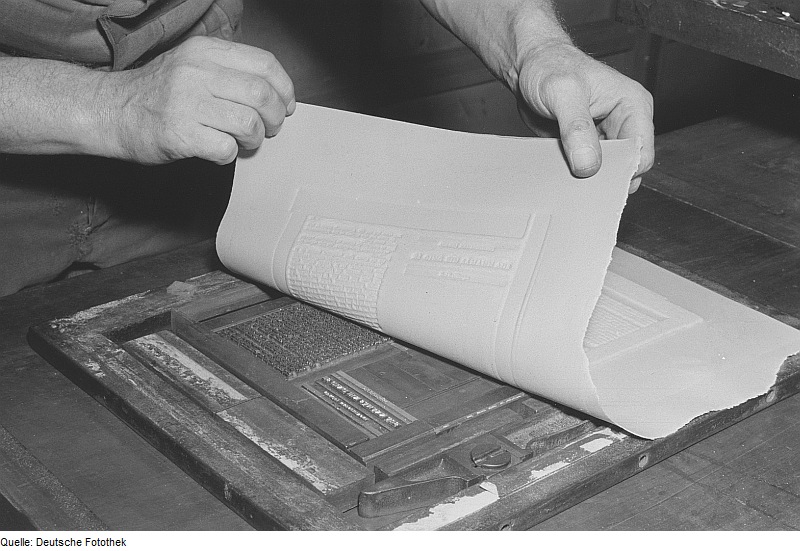

File:Illustration from Stereotyping and Electrotyping 1880 by Wilson- 1 Beating the flong into a forme.jpg, Beating a papier-mâché flong into a forme.

File:Illustration from Stereotyping and Electrotyping 1880 by Wilson- 2 Steam heated drying table.jpg, A steam drying table for the flong and forme.

File:Illustration from Stereotyping and Electrotyping 1880 by Wilson- 3 The dry flong placed in the casting box.jpg, Placing the dry flong in the casting box.

File:Illustration from Stereotyping and Electrotyping 1880 by Wilson- 4 Closing up a gas heated casting box.jpg, Closing up the casting box.

File:Illustration from Stereotyping and Electrotyping 1880 by Wilson- 5 Pouring Molten Type Metal into a gas-heated casting box.jpg, Pouring molten type metal into the casting box.

In relief printing, a flong is a temporary negative mould made of a

In relief printing, a flong is a temporary negative mould made of a forme

Forme may refer to the following:

* Forme (printing), a chase with type locked up ready for printing

* Forme, Škofja Loka, a settlement in Slovenia

* Forme Tour, a professional golf tour

See also

* FORM (disambiguation)

* Form (disambiguation)

...

of set type, in order to cast a metal stereotype

In social psychology, a stereotype is a generalized belief about a particular category of people. It is an expectation that people might have about every person of a particular group. The type of expectation can vary; it can be, for exampl ...

(or "stereo") which can be used in a rotary press

A rotary printing press is a printing press in which the images to be printed are curved around a cylinder. Printing can be done on various substrates, including paper, cardboard, and plastic. Substrates can be sheet feed or unwound on a continuo ...

, or in letterpress printing

Letterpress printing is a technique of relief printing. Using a printing press, the process allows many copies to be produced by repeated direct impression of an inked, raised surface against sheets or a continuous roll of paper. A worker com ...

after the type has been broken down for re-use. The process is called ''stereotyping''.

Types of flong

Strictly speaking only moulds of the so-called papier-mâché wet process are flongs, but the term was applied more widely to moulds for stereos. The following have been used for moulding type to create stereos: *Clay. Invented by a French printer, Gabriel Valleyre in 1730. He pressed the set-up forme in clay or another earthy substance to make a reverse image, and then poured molten copper into the mould. His copies were not very good, due either to the clay he was using, or the softness of the copper. However, the method was later revived, improved, and used by Government Printing Office in Washington. Hoe & Company included for use with the process in their 1881 catalogue. *Plaster of Paris. Gress was already describing this as an old method that had been displaced by the papier-mâché or paper process in 1909.. The plaster process can reproduce finer lines than the paper process, but has the disadvantage that the mould is broken to remove the stereo. This was the process developed by Gad in 1725, where a plaster mould is made of the set-up type. The process was perfected in 1802, but because there were relatively few books that needed repeated print-runs other than bibles or schoolbooks, the process did not come into widespread use for another two decades. The Bank of England printed its notes using stereos from plaster moulds in 1816.Charles Stanhope, 3rd Earl Stanhope

Charles Stanhope, 3rd Earl Stanhope, aka Charles Mahon, 3rd Earl Stanhope, FRS (3 August 175315 December 1816), was a British statesman, inventor, and scientist. He was the father of Lady Hester Stanhope and brother-in-law of William Pitt t ...

had invested a considerable sum of money in developing the process, and he then established and funded a stereotyping plant in London.. However it was not a commercial success and faced considerable opposition from the printing trade.. David noted that it was only with the introduction of the flexible and robust papier-mâché flong in the 1850s that led to the extensive use of stereotyping for novel production.

*Papier-mâché or hot process (also called the wet mat process to distinguish it from the dry mat process). The French printer Claude Genoux is frequently credited with inventing the papier-mâché process and he was granted a French patent for it in 1828. However, the process was described in a 1696 book in the University of Marburg. In the wet process, a number of layers of paper fastened together by a paste made from a range of ingredients, including glue or gum. The paste could be to the stereotyper's own recipe or a proprietary paste.

*Dry mat, or dry matrix process. Here there is no need to beat the matrix into the page of type, as simple pressure is enough. The pressures needed are quite high and effectively require a hydraulic press. It appears to have been first invented in 1893 by George Eastwood in England, but versions were also produced in Germany in 1894 and in the United States in 1900. Use of the dry mat process was limited as the wet process could provide better quality, but improvements in the dry mats led to their replacing the wet process. By 1946, the dry mat process had completely taken over in newspaper publishing in the United States.

The process for making moulds for electrotype

Electrotyping (also galvanoplasty) is a chemical method for forming metal parts that exactly reproduce a model. The method was invented by Moritz von Jacobi in Russia in 1838, and was immediately adopted for applications in printing and several o ...

s was similar, except that these were made with soft materials such as beeswax

Beeswax (''cera alba'') is a natural wax produced by honey bees of the genus ''Apis''. The wax is formed into scales by eight wax-producing glands in the abdominal segments of worker bees, which discard it in or at the hive. The hive work ...

or the naturally occurring mineral wax ozokerite

Ozokerite or ozocerite, archaically referred to as earthwax or earth wax, is a naturally occurring odoriferous mineral wax or paraffin found in many localities. Lacking a definite composition and crystalline structure, it is not considered a min ...

. The thin electrotype shells had to be backed with type metal to a depth of 8mm make them robust enough for use.

The papier-mâché flong

Partridge describes the papier-mâché process thus: "A few sheets of thin paper are soaked in water until soft and then pasted together to form a flong. This flong is beaten into a page of type and dried, thus forming a matrix to receive the molten metal, which, when cooled, becomes an exact duplicate of the type page. A large number of duplicate casts may be made from the same matrix, either in flat form as required for flat-bed presses, or curved to fit the cylinders of rotary presses." The flong was constructed by pasting together two sheets of wetted soft but tough matrix paper and four sheets of strong tissue paper. A rice-straw based tissue paper was used for the side of the flong facing the type. After making up the flong matrix, it can be kept for several days if kept suitably moist by wrapping in a wet blanket for example. The flong slightly larger than the forme was laid over it and then carefully beaten into the forme of type using a brush with stiff bristles. Many gentle blows were better to fewer strong ones. Any hollows in the back of the flong after it was beaten in were filled, either with strawboard or pieces of flong or with a packing compound. The flong was then covered with a sheet of backing paper and moved, still sitting on the forme, to a steam drying table. Here it was covered with four to eight pieces of soft blanket and pressed down to ensure that the flong stayed in contact with the forme while it dried. Drying took six to seven minutes typically, but this depended on the steam pressure. The golden rule for stereotyping was to have cool metal and a hot box to avoid problems with shrinkage cavities on the face of the plate or sinks, where the face of the plate shrank away from the front. Sometimes a casting board was used to slow the cooling at the back of the casting, as this could help to avoid problems due to the flong being a poor conductor. Before casting, the casting box was heated. This could be done by ladling hot type metal into it as many as three times and removing the resulting plate. Alternatively, the mould could be gas-heated. The dry flong was then trimmed, leaving just enough of a margin to go under the gauges in the casting box. These gauges were the pieces of metal, typically an L-shaped piece and a straight piece to border the sides and bottom of the flong in the casting box. The flong was then place in the casting box and the gauges placed at its sides. The box was closed up, with scrap paper used to form an apron to help funnel the molten type metal into the box. The type metal mixture used for stereotype plates had from five to ten percent of tin and fifteen percent of antimony, with the balance in lead. The percentage of tin varies with the type of mould as tin makes the cast sharper. Five percent was fine for textletterpress

Letterpress printing is a technique of relief printing. Using a printing press, the process allows many copies to be produced by repeated direct impression of an inked, raised surface against sheets or a continuous roll of paper. A worker com ...

, but ten percent was needed for half-tone

Halftone is the reprographic technique that simulates continuous-tone imagery through the use of dots, varying either in size or in spacing, thus generating a gradient-like effect.Campbell, Alastair. The Designer's Lexicon. ©2000 Chronicle, ...

blocks.

Illustrations of the papier-mâché process

The following illustrations from ''Stereotyping and Electrotyping'' (1880) by Frederick J. Wilson show some of the steps in the process of making and using a flong.Multiple casts

Wheedon stated that a limited number of duplicate casts could be made from one flong. However, Partridge states that a large number of duplicate casts may be made from the same matrix. Dalgin states that to his knowledge as many as thirty, and maybe more, plates have been cast from a single flong. Fleishman states that while flongs could make multiple casts, they typically could not be removed and reused. However, flongs might be made and then stored without being cast for future use, potentially for decades in the right conditions. Kubler noted that in 1941, theUnited States Government Publishing Office

The United States Government Publishing Office (USGPO or GPO; formerly the United States Government Printing Office) is an agency of the legislative branch of the United States Federal government. The office produces and distributes informatio ...

in Washington had over a quarter of a million flongs in "Mat Only" storage, "the mats being stored for future use and the type destroyed."

Etymology of the word flong

Wilson notes that the word ''flong'' is an English phonetic form of the French word ''flan'', which is pronounced in almost exactly the same way. The word is attributed both to Claude Genoux who used the word ''flan'' in his original patent to describe the papier-mâché matrix, and to James Dellagana, a Swiss stereotyper in London. Apparently, when living in Paris, Dellagana frequently visited a café where he would eat a pastry called a ''flan'', which was built up of different layers. This is a fairly good description of the way in which the flong is built up, with layers of paper interspersed with paste. Kubler states that the outside of France and England the general term for a papier-mâché mat was not a flong but a ''wet mat''. However, several technical manuals from the United States use the terms including Kubler himself and Partridge, as well as the United StatesBureau of Labor Statistics

The Bureau of Labor Statistics (BLS) is a unit of the United States Department of Labor. It is the principal fact-finding agency for the U.S. government in the broad field of labor economics and statistics and serves as a principal agency of ...

1929 study of productivity in Newspaper Printing.

Further reading

Fleishman provides a thorough and well-illustrated explanation of the process in his blog. Dalgin provides a good overview of the mechanics of newspaper production in the middle of the 20th century, including different methods of reproduction. There are also books on the whole stereotype process such as those by Wilson, Partridge, Hatch and Stewart, and Salade.In popular culture

On 1 April 1977 ''The Guardian

''The Guardian'' is a British daily newspaper. It was founded in 1821 as ''The Manchester Guardian'', and changed its name in 1959. Along with its sister papers '' The Observer'' and '' The Guardian Weekly'', ''The Guardian'' is part of the ...

'', a UK newspaper, published a seven-page special report on '' San Serriffe'', an imaginary island to the north-east of the Seychelles

Seychelles (, ; ), officially the Republic of Seychelles (french: link=no, République des Seychelles; Creole: ''La Repiblik Sesel''), is an archipelagic state consisting of 115 islands in the Indian Ocean. Its capital and largest city, ...

. The hoax was full of typographical and printing puns, with towns named after different fonts. The indigenous inhabitants were said to be the ''Flong'' and their language was ki-flong. The hoax is well described, along with images of the pages in the seven page special report which perpetrated the hoax on the Museum of Hoaxes website. The Guardian followed up in 1978 with parodies of twelve UK and Irish newspapers across ten pages: The SS Guardian, The SS Financial Times, The SS Times, The SS Morning Star, The SS Mirror (half page), The SSun (half page), The SS Daily Express (half page), The SS Daily Mail (half page), The SS Irish Times, The SS Telegraph, The SS Sunday Times, and the News of the SS World. However, this was considered to be less successful than the original. Most of the parody newspapers make some reference to the flong. The San Serriffe hoax is ranked fifth in the top one hundred April Fool's Hoaxes by the Museum of Hoaxes.

Notes

References

{{Letterpress Printing terminology