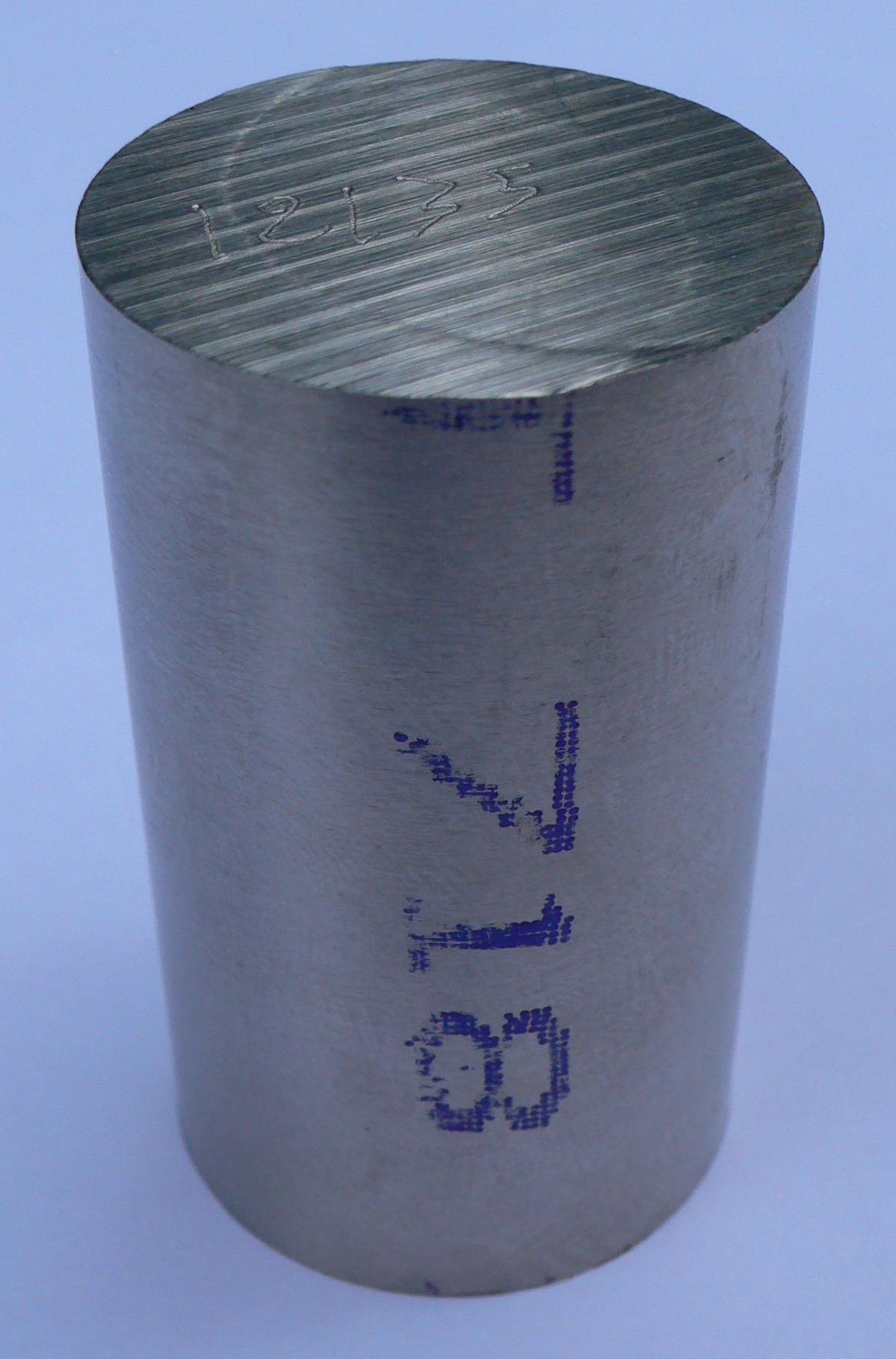

Inconel gate valve--The-Alloy-Valve-Stockist.JPG on:

[Wikipedia]

[Google]

[Amazon]

Inconel is a registered trademark of

Inconel is a registered trademark of

Special Metals Corporation Inconel alloys are typically used in high temperature applications. Common trade names for * Inconel Alloy 625 include: Inconel 625, Chronin 625, Altemp 625, Haynes 625, Nickelvac 625 and Nicrofer 6020. * Inconel Alloy 600 include: NA14, N06600, BS3076, 2.4816, NiCr15Fe (FR), NiCr15Fe (EU) and NiCr15Fe8 (DE). * Inconel 718 include: Nicrofer 5219, Superimphy 718, Haynes 718, Pyromet 718, Supermet 718, and Udimet 718.

Inconel is often encountered in extreme environments. It is common in gas turbine blades, seals, and combustors, as well as turbocharger rotors and seals, electric submersible well pump motor shafts, high temperature fasteners, chemical processing and

Inconel is often encountered in extreme environments. It is common in gas turbine blades, seals, and combustors, as well as turbocharger rotors and seals, electric submersible well pump motor shafts, high temperature fasteners, chemical processing and

/ref>

Vishal Kumar Jaiswal "Experimental Investigation of Process Parameters on Inconel 925 for EDM Process by using Taguchi Method." International Journal for Scientific Research and Development 6.5 (2018): 277-282.

IJSRD

In age hardening or precipitation strengthening varieties, alloying additions of aluminum and titanium combine with nickel to form the intermetallic compound or gamma prime (γ′). Gamma prime forms small cubic crystals that inhibit slip and creep effectively at elevated temperatures.

Special Metals Corporation

Special Metals Corporation (SMC) is an American supplier of special refractory alloys and is headquartered in New Hartford, New York, United States. The company has operations in Huntington, West Virginia; Dunkirk, New York; Burnaugh, Kentucky; ...

for a family of austenitic nickel-chromium

Chromium is a chemical element with the symbol Cr and atomic number 24. It is the first element in group 6. It is a steely-grey, lustrous, hard, and brittle transition metal.

Chromium metal is valued for its high corrosion resistance and hardne ...

-based superalloy

A superalloy, or high-performance alloy, is an alloy with the ability to operate at a high fraction of its melting point. Several key characteristics of a superalloy are excellent mechanical strength, resistance to thermal creep deformation, g ...

s.

Inconel alloys are oxidation- corrosion-resistant materials well suited for service in extreme environments subjected to pressure and heat. When heated, Inconel forms a thick, stable, passivating oxide layer protecting the surface from further attack. Inconel retains strength over a wide temperature range, attractive for high-temperature applications where aluminium and steel would succumb to creep

Creep, Creeps or CREEP may refer to:

People

* Creep, a creepy person

Politics

* Committee for the Re-Election of the President (CRP), mockingly abbreviated as CREEP, an fundraising organization for Richard Nixon's 1972 re-election campaign

Art ...

as a result of thermally-induced crystal vacancies. Inconel's high-temperature strength is developed by solid solution strengthening or precipitation hardening, depending on the alloy.INCONEL alloy 718Special Metals Corporation Inconel alloys are typically used in high temperature applications. Common trade names for * Inconel Alloy 625 include: Inconel 625, Chronin 625, Altemp 625, Haynes 625, Nickelvac 625 and Nicrofer 6020. * Inconel Alloy 600 include: NA14, N06600, BS3076, 2.4816, NiCr15Fe (FR), NiCr15Fe (EU) and NiCr15Fe8 (DE). * Inconel 718 include: Nicrofer 5219, Superimphy 718, Haynes 718, Pyromet 718, Supermet 718, and Udimet 718.

History

The Inconel family of alloys was first developed before December 1932, when its trademark was registered by the International Nickel Company of Delaware and New York. A significant early use was found in support of the development of theWhittle

Whittle may refer to:

Crafts

*Whittling, the carving of wood with a knife

People

* Whittle (name), a surname, and a list of people with the name

Places

* Whittle, Kentucky

* Whittle, Derbyshire, a hamlet near Glossop, Derbyshire, United Kingdom ...

jet engine, during the 1940s by research teams at Henry Wiggin & Co of Hereford, England a subsidiary of the Mond Nickel Company, which merged with Inco in 1928. The Hereford Works and its properties including the Inconel trademark were acquired in 1998 by Special Metals Corporation

Special Metals Corporation (SMC) is an American supplier of special refractory alloys and is headquartered in New Hartford, New York, United States. The company has operations in Huntington, West Virginia; Dunkirk, New York; Burnaugh, Kentucky; ...

.

Specific data

Composition

Inconel alloys vary widely in their compositions, but all are predominantly nickel, with chromium as the second element.Properties

Inconel alloys are oxidation- and corrosion-resistant materials well suited for service in extreme environments subjected to high mechanical loads. When heated, Inconel forms a thick and stable passivating oxide layer protecting the surface from further attack. Inconel retains strength over a wide temperature range, attractive for high-temperature applications where aluminium andsteel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant ty ...

would succumb to creep

Creep, Creeps or CREEP may refer to:

People

* Creep, a creepy person

Politics

* Committee for the Re-Election of the President (CRP), mockingly abbreviated as CREEP, an fundraising organization for Richard Nixon's 1972 re-election campaign

Art ...

as a result of thermally induced crystal vacancies (see Arrhenius equation). Inconel's high temperature strength is developed by solid solution strengthening or precipitation strengthening

Precipitation hardening, also called age hardening or particle hardening, is a heat treatment technique used to increase the yield strength of malleable materials, including most structural alloys of aluminium, magnesium, nickel, titanium, and so ...

, depending on the alloy. In age-hardening or precipitation-strengthening varieties, small amounts of niobium

Niobium is a chemical element with chemical symbol Nb (formerly columbium, Cb) and atomic number 41. It is a light grey, crystalline, and ductile transition metal. Pure niobium has a Mohs hardness rating similar to pure titanium, and it has sim ...

combine with nickel to form the intermetallic compound Ni3Nb or gamma double prime (γ″). Gamma prime forms small cubic crystals that inhibit slip and creep effectively at elevated temperatures. The formation of gamma-prime crystals increases over time, especially after three hours of a heat exposure of , and continues to grow after 72 hours of exposure.

Machining

Inconel is a difficult metal to shape and to machine using traditional cold forming techniques due to rapid work hardening. After the first machining pass, work hardening tends to plastically deform either the workpiece or the tool on subsequent passes. For this reason, age-hardened Inconels such as 718 are typically machined using an aggressive but slow cut with a hard tool, minimizing the number of passes required. Alternatively, the majority of the machining can be performed with the workpiece in a "solutionized" form, with only the final steps being performed after age hardening. However some claim that Inconel can be machined extremely quickly with very fast spindle speeds using a multifluted ceramic tool with small depth of cut at high feed rates as this causes localised heating and softening in front of the flute. Externalthreads

Thread may refer to:

Objects

* Thread (yarn), a kind of thin yarn used for sewing

** Thread (unit of measurement), a cotton yarn measure

* Screw thread, a helical ridge on a cylindrical fastener

Arts and entertainment

* ''Thread'' (film), 2016 ...

are machined using a lathe

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to c ...

to "single-point" the threads or by rolling the threads in the solution treated condition (for hardenable alloys) using a screw machine. Inconel 718 can also be roll-threaded after full aging by using induction heat to without increasing the grain size. Holes with internal threads are made by threadmilling. Internal threads can also be formed using a sinker electrical discharge machining (EDM).

More often than machining, water-jet or laser grinding is a preferred and economical method for forming nickel alloy components to shape and finish. Due to the hardness of the abrasives used, the grinding wheels are not as affected by the material work hardening and remain sharp and durable.

Joining

Welding of some Inconel alloys (especially the gamma prime precipitation hardened family; e.g., Waspalloy and X-750) can be difficult due to cracking and microstructural segregation of alloying elements in theheat-affected zone

In fusion welding, the heat-affected zone (HAZ) is the area of base material, either a metal or a thermoplastic, which is not melted but has had its microstructure and properties altered by welding or heat intensive cutting operations. The heat ...

. However, several alloys such as 625 and 718 have been designed to overcome these problems. The most common welding methods are gas tungsten arc welding and electron-beam welding

Electron-beam welding (EBW) is a fusion welding process in which a beam of high-velocity electrons is applied to two materials to be joined. The workpieces melt and flow together as the kinetic energy of the electrons is transformed into heat u ...

.

Uses

Inconel is often encountered in extreme environments. It is common in gas turbine blades, seals, and combustors, as well as turbocharger rotors and seals, electric submersible well pump motor shafts, high temperature fasteners, chemical processing and

Inconel is often encountered in extreme environments. It is common in gas turbine blades, seals, and combustors, as well as turbocharger rotors and seals, electric submersible well pump motor shafts, high temperature fasteners, chemical processing and pressure vessel

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure.

Construction methods and materials may be chosen to suit the pressure application, and will depend on the size o ...

s, heat exchanger tubing, steam generators and core components in nuclear pressurized water reactors, natural gas processing

Natural-gas processing is a range of industrial processes designed to purify raw natural gas by removing impurities, contaminants and higher molecular mass hydrocarbons to produce what is known as ''pipeline quality'' dry natural gas. Natural gas ...

with contaminants such as H2S and CO2, firearm

A firearm is any type of gun designed to be readily carried and used by an individual. The term is legally defined further in different countries (see Legal definitions).

The first firearms originated in 10th-century China, when bamboo tubes ...

sound suppressor blast baffles, and Formula One, NASCAR, NHRA, and APR, LLC exhaust systems. It is also used in the turbo system of the 3rd generation Mazda RX7

The Mazda RX-7 is a front-engine, rear-wheel-drive, rotary engine-powered sports car that was manufactured and marketed by Mazda from 1978 until 2002 across three generations, all of which made use of a compact, lightweight Wankel rotary engine.

...

, and the exhaust systems of high powered Wankel engined Norton motorcycles where exhaust temperatures reach more than . Inconel is increasingly used in the boilers of waste incinerators

Incineration is a list of solid waste treatment technologies, waste treatment process that involves the combustion of substances contained in waste materials. Industrial plants for waste incineration are commonly referred to as waste-to-ene ...

. The Joint European Torus and DIII-D

DIII-D is a tokamak that has been operated since the late 1980s by General Atomics (GA) in San Diego, USA, for the U.S. Department of Energy. The DIII-D National Fusion Facility is part of the ongoing effort to achieve magnetically confined fusio ...

tokamaks' vacuum vessels are made of Inconel. Inconel 718 is commonly used for cryogenic

In physics, cryogenics is the production and behaviour of materials at very low temperatures.

The 13th IIR International Congress of Refrigeration (held in Washington DC in 1971) endorsed a universal definition of “cryogenics” and “cr ...

storage tanks, downhole shafts, wellhead parts, and in the aerospace industry -- where it has become a prime candidate material for constructing heat resistant turbines.

Aerospace

*The Space Shuttle used four Inconel studs to secure the solid rocket boosters to the launch platform, eight total studs supported the entire weight of the ready to fly Shuttle system. Eightfrangible nut

The frangible nut is a component used in many industries, but most commonly by NASA, to sever mechanical connections. It is, by definition, an explosively-splittable nut. The bolt remains intact while the nut itself is split into two or more par ...

s are encased on the outside of the solid rocket boosters, at launch explosives separated the nuts releasing the Shuttle from its launch platform.

*North American Aviation

North American Aviation (NAA) was a major American aerospace manufacturer that designed and built several notable aircraft and spacecraft. Its products included: the T-6 Texan trainer, the P-51 Mustang fighter, the B-25 Mitchell bomber, the F ...

constructed the skin of the North American X-15

The North American X-15 is a hypersonic rocket-powered aircraft. It was operated by the United States Air Force and the National Aeronautics and Space Administration as part of the X-plane series of experimental aircraft. The X-15 set speed an ...

Rocket-powered aircraft out of Inconel X/750 alloy.

* Rocketdyne used Inconel X-750 for the thrust chamber of the F-1 rocket engine

The F-1, commonly known as Rocketdyne F1, was a rocket engine developed by Rocketdyne. This engine uses a gas-generator cycle developed in the United States in the late 1950s and was used in the Saturn V rocket in the 1960s and early 1970s. Five ...

used in the first stage of the Saturn V booster.

*SpaceX

Space Exploration Technologies Corp. (SpaceX) is an American spacecraft manufacturer, launcher, and a satellite communications corporation headquartered in Hawthorne, California. It was founded in 2002 by Elon Musk with the stated goal of ...

uses inconel (Inconel 718) in the engine manifold of their Merlin

Merlin ( cy, Myrddin, kw, Marzhin, br, Merzhin) is a mythical figure prominently featured in the legend of King Arthur and best known as a mage, with several other main roles. His usual depiction, based on an amalgamation of historic and le ...

engine which powers the Falcon 9 launch vehicle.>

*In a first for 3D printing

3D printing or additive manufacturing is the Manufacturing, construction of a three-dimensional object from a computer-aided design, CAD model or a digital 3D modeling, 3D model. It can be done in a variety of processes in which material is ...

, the SpaceX SuperDraco rocket engine that provides launch escape system for the Dragon V2 crew-carrying space capsule is fully printed. In particular, the engine combustion chamber is printed of Inconel using a process of direct metal laser sintering, and operates at very high temperature and a chamber pressure

Within firearms, chamber pressure is the pressure exerted by a cartridge case's outside walls on the inside of a firearm's chamber when the cartridge is fired. The SI unit for chamber pressure is the megapascal (MPa), while the American SAAMI uses ...

of .

* SpaceX cast the Raptor

Raptor or RAPTOR may refer to:

Animals

The word "raptor" refers to several groups of bird-like dinosaurs which primarily capture and subdue/kill prey with their talons.

* Raptor (bird) or bird of prey, a bird that primarily hunts and feeds on v ...

rocket engine manifolds from SX300, later SX500, which are monocrystal nickel alloy (improvement over older Inconel alloys).''SpaceX Casting Raptor Engine Parts from Supersteel Alloys'' Feb 2019/ref>

Automotive

* Tesla is now claiming to use Inconel in place of steel in the main battery pack contactor of its Model S so that it remains springy under the heat of heavy current. Tesla claims that this allows these upgraded vehicles to safely increase the maximum pack output from 1300 to 1500ampere

The ampere (, ; symbol: A), often shortened to amp,SI supports only the use of symbols and deprecates the use of abbreviations for units. is the unit of electric current in the International System of Units (SI). One ampere is equal to elect ...

s, allowing for an increase in power output (acceleration) Tesla refers to as "Ludicrous Mode

The Tesla Model S is a battery-powered liftback car serving as the flagship model of Tesla, Inc. The Model S features a dual-motor, all-wheel drive layout, although earlier versions of the Model S featured a rear-motor and rear-wheel drive la ...

".

* Ford Motor Company is using Inconel to make the turbine wheel in the turbocharger of its EcoBlue diesel engines introduced in 2016.

*The exhaust valves on NHRA Top Fuel and Funny Car drag racing engines are often made of Inconel. Inconel is also used in the manufacture of exhaust valves in high performance aftermarket turbo and Supercharged Mazda Miata engine builds (see Flyin' Miata).

* Ford Australia used Inconel valves in their turbocharged Barra engines. These valves have been proven very reliable, holding in excess of 1900 horsepower.

* BMW has since used Inconel in the exhaust manifold of its high performance luxury car, the BMW M5 E34 with the S38 engine, withstanding higher temperatures and reducing backpressure.

*Jaguar Cars

Jaguar (, ) is the luxury vehicle brand of Jaguar Land Rover, a British multinational car manufacturer with its headquarters in Whitley, Coventry, England. Jaguar Cars was the company that was responsible for the production of Jaguar cars ...

has fit, in their Jaguar F-Type SVR high performance sports car, a new lightweight Inconel titanium exhaust system as standard which withstands higher peak temperatures, reduces backpressure and eliminates of mass from the vehicle.

* DeLorean Motor Company offers Inconel replacements for failure prone OE trailing arm bolts on the DMC-12. Failure of these bolts can result in loss of the vehicle.

Rolled Inconel was frequently used as the recording medium by engraving in black box recorders on aircraft.

Alternatives to the use of Inconel in chemical applications such as scrubbers, columns, reactors, and pipes are Hastelloy, perfluoroalkoxy (PFA) lined carbon steel or fiber reinforced plastic

Fibre-reinforced plastic (FRP; also called fibre-reinforced polymer, or in American English ''fiber'') is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass (in fibreglass), carbon (in carbon-fib ...

.

Inconel alloys

Alloys of inconel include: * Inconel 188: Readily fabricated for commercial gas turbine and aerospace applications. * Inconel 230: Alloy 230 Plate & Sheet mainly used by the power, aerospace, chemical processing and industrial heating industries. * Inconel 600: Solid solution strengthened * Inconel 601: * Inconel 617: Solid solution strengthened (nickel-chromium-cobalt-molybdenum), high-temperature strength, corrosion and oxidation resistant, high workability and weldability. Incorporated in ASME Boiler and Pressure Vessel Code for high temperature nuclear applications such as molten salt reactors April, 2020. * Inconel 625: Acid resistant, good weldability. The LCF version is typically used in bellows. * Inconel 690: Low cobalt content for nuclear applications, and low resistivity * Inconel 713C: Precipitation hardenable nickel-chromium base cast alloy * Inconel 718: Gamma double prime strengthened with good weldability * Inconel X-750: Commonly used for gas turbine components, including blades, seals and rotors. * Inconel 751: Increased aluminium content for improved rupture strength in the 1600 °F range * Inconel 792: Increased aluminium content for improved high temperature corrosion resistant properties, used especially in gas turbines * Inconel 907 * Inconel 909 * Inconel 706 * Inconel 939: Gamma prime strengthened to increase weldability. * Inconel 925: Inconel 925 is a nonstabilized austenitic stainless steel with low carbon content.IJSRD

See also

* Hastelloy * Incoloy * Monel * Nimonic *Stellite

Stellite is a range of cobalt-chromium alloys designed for wear resistance. The alloys may also contain tungsten or molybdenum and a small, but important, amount of carbon.

History

Stellite is a trademarked name of Kennametal Inc. Prior to tha ...

References

{{reflist, 35em Metals Nickel–chromium alloys Refractory metals Superalloys Aerospace materials Nickel alloys Chromium alloys