Crankshaft jap grayscale.jpg on:

[Wikipedia]

[Google]

[Amazon]

A crankshaft is a mechanical component used in a piston engine to convert the

The crankshaft located within the

The crankshaft located within the

In some engines, the crankshaft contains direct links between adjacent crank pins, without the usual intermediate main bearing. These links are called ''flying arms''. This arrangement is sometimes used in V6 and

In some engines, the crankshaft contains direct links between adjacent crank pins, without the usual intermediate main bearing. These links are called ''flying arms''. This arrangement is sometimes used in V6 and

Crankshafts can be created from a steel bar using roll forging. Today, manufacturers tend to favour the use of forged crankshafts due to their lighter weight, more compact dimensions and better inherent damping. With forged crankshafts, vanadium micro-alloyed steels are mainly used as these steels can be air-cooled after reaching high strengths without additional heat treatment, except for the surface hardening of the bearing surfaces. The low alloy content also makes the material cheaper than high alloy steels. Carbon steels also require additional heat treatment to reach the desired properties.

Crankshafts can be created from a steel bar using roll forging. Today, manufacturers tend to favour the use of forged crankshafts due to their lighter weight, more compact dimensions and better inherent damping. With forged crankshafts, vanadium micro-alloyed steels are mainly used as these steels can be air-cooled after reaching high strengths without additional heat treatment, except for the surface hardening of the bearing surfaces. The low alloy content also makes the material cheaper than high alloy steels. Carbon steels also require additional heat treatment to reach the desired properties.

The earliest hand-operated cranks appeared in China during the

The earliest hand-operated cranks appeared in China during the

A crank in the form of an eccentrically-mounted handle of the rotary Quern-stone, handmill appeared in 5th century BC Celtiberians, Celtiberian Spain and ultimately spread across the Roman Empire. A Roman iron crank dating to the 2nd century AD was excavated in Augusta Raurica, Switzerland. The crank-operated Roman Empire, Roman mill is dated to the late 2nd century.

A crank in the form of an eccentrically-mounted handle of the rotary Quern-stone, handmill appeared in 5th century BC Celtiberians, Celtiberian Spain and ultimately spread across the Roman Empire. A Roman iron crank dating to the 2nd century AD was excavated in Augusta Raurica, Switzerland. The crank-operated Roman Empire, Roman mill is dated to the late 2nd century.

Evidence for the crank combined with a connecting rod appears in the Hierapolis mill, dating to the 3rd century; they are also found in stone sawmills in Roman Syria and Ephesus dating to the 6th century.: Because of the findings at Ephesus and Gerasa the invention of the crank and connecting rod system has had to be redated from the 13th to the 6th c; now the Hierapolis relief takes it back another three centuries, which confirms that water-powered stone saw mills were indeed in use when Ausonius wrote his Mosella. The pediment of the Hierapolis mill shows a waterwheel fed by a mill race powering via a gear train two frame saws which cut blocks by the way of some kind of connecting rods and cranks. The crank and connecting rod mechanisms of the other two archaeologically-attested sawmills worked without a gear train. Water-powered marble saws in Germany were mentioned by the late 4th century poet Ausonius; about the same time, these mill types seem also to be indicated by Gregory of Nyssa from Anatolia.

A rotary Grindstone (tool), grindstone operated by a crank handle is shown in the Carolingian dynasty, Carolingian manuscript ''Utrecht Psalter''; the pen drawing of around 830 goes back to a late antique original. Cranks used to turn wheels are also depicted or described in various works dating from the tenth to thirteenth centuries.

The first depictions of the compound crank in the carpenter's Brace (tool), brace appear between 1420 and 1430 in northern European artwork. The rapid adoption of the compound crank can be traced in the works of an unknown German engineer writing on the state of military technology during the Hussite Wars: first, the connecting-rod, applied to cranks, reappeared; second, double-compound cranks also began to be equipped with connecting-rods; and third, the flywheel was employed for these cranks to get them over the 'dead-spot'. The concept was much improved by the Italian engineer and writer Roberto Valturio in 1463, who devised a boat with five sets, where the parallel cranks are all joined to a single power source by one connecting-rod, an idea also taken up by his compatriot Italian painter Francesco di Giorgio.

The crank had become common in Europe by the early 15th century, as seen in the works of the military engineer Konrad Kyeser (1366–after 1405).. Devices depicted in Kyeser's ''Bellifortis'' include cranked windlasses for spanning siege crossbows, cranked chain of buckets for water-lifting and cranks fitted to a wheel of bells. Kyeser also equipped the Archimedes' screws for water-raising with a crank handle, an innovation which subsequently replaced the ancient practice of working the pipe by treading.

Pisanello painted a piston-pump driven by a water-wheel and operated by two simple cranks and two connecting-rods.

The 15th also century saw the introduction of cranked rack-and-pinion devices, called cranequins, which were fitted to the crossbow's stock as a means of exerting even more force while spanning the missile weapon. In the textile industry, cranked reels for winding skeins of yarn were introduced.

The Italian physician Guido da Vigevano (c. 1280−1349), planning for a new crusade, made illustrations for a Paddle steamer#History, paddle boat and war carriages that were propelled by manually turned compound cranks and gear wheels, identified as an early crankshaft prototype by Lynn Townsend White. The ''Luttrell Psalter'', dating to around 1340, describes a grindstone which was rotated by two cranks, one at each end of its axle; the geared hand-mill, operated either with one or two cranks, appeared later in the 15th century.

Evidence for the crank combined with a connecting rod appears in the Hierapolis mill, dating to the 3rd century; they are also found in stone sawmills in Roman Syria and Ephesus dating to the 6th century.: Because of the findings at Ephesus and Gerasa the invention of the crank and connecting rod system has had to be redated from the 13th to the 6th c; now the Hierapolis relief takes it back another three centuries, which confirms that water-powered stone saw mills were indeed in use when Ausonius wrote his Mosella. The pediment of the Hierapolis mill shows a waterwheel fed by a mill race powering via a gear train two frame saws which cut blocks by the way of some kind of connecting rods and cranks. The crank and connecting rod mechanisms of the other two archaeologically-attested sawmills worked without a gear train. Water-powered marble saws in Germany were mentioned by the late 4th century poet Ausonius; about the same time, these mill types seem also to be indicated by Gregory of Nyssa from Anatolia.

A rotary Grindstone (tool), grindstone operated by a crank handle is shown in the Carolingian dynasty, Carolingian manuscript ''Utrecht Psalter''; the pen drawing of around 830 goes back to a late antique original. Cranks used to turn wheels are also depicted or described in various works dating from the tenth to thirteenth centuries.

The first depictions of the compound crank in the carpenter's Brace (tool), brace appear between 1420 and 1430 in northern European artwork. The rapid adoption of the compound crank can be traced in the works of an unknown German engineer writing on the state of military technology during the Hussite Wars: first, the connecting-rod, applied to cranks, reappeared; second, double-compound cranks also began to be equipped with connecting-rods; and third, the flywheel was employed for these cranks to get them over the 'dead-spot'. The concept was much improved by the Italian engineer and writer Roberto Valturio in 1463, who devised a boat with five sets, where the parallel cranks are all joined to a single power source by one connecting-rod, an idea also taken up by his compatriot Italian painter Francesco di Giorgio.

The crank had become common in Europe by the early 15th century, as seen in the works of the military engineer Konrad Kyeser (1366–after 1405).. Devices depicted in Kyeser's ''Bellifortis'' include cranked windlasses for spanning siege crossbows, cranked chain of buckets for water-lifting and cranks fitted to a wheel of bells. Kyeser also equipped the Archimedes' screws for water-raising with a crank handle, an innovation which subsequently replaced the ancient practice of working the pipe by treading.

Pisanello painted a piston-pump driven by a water-wheel and operated by two simple cranks and two connecting-rods.

The 15th also century saw the introduction of cranked rack-and-pinion devices, called cranequins, which were fitted to the crossbow's stock as a means of exerting even more force while spanning the missile weapon. In the textile industry, cranked reels for winding skeins of yarn were introduced.

The Italian physician Guido da Vigevano (c. 1280−1349), planning for a new crusade, made illustrations for a Paddle steamer#History, paddle boat and war carriages that were propelled by manually turned compound cranks and gear wheels, identified as an early crankshaft prototype by Lynn Townsend White. The ''Luttrell Psalter'', dating to around 1340, describes a grindstone which was rotated by two cranks, one at each end of its axle; the geared hand-mill, operated either with one or two cranks, appeared later in the 15th century.

Around 1480, the early medieval rotary grindstone was improved with a treadle and crank mechanism. Cranks mounted on push-carts first appear in a German engraving of 1589. Crankshafts were also described by Leonardo da Vinci (1452–1519) and a Dutch farmer and windmill owner by the name Cornelis Corneliszoon van Uitgeest in 1592. His wind-powered sawmill used a crankshaft to convert a windmill's circular motion into a back-and-forward motion powering the saw. Corneliszoon was granted a patent for his crankshaft in 1597.

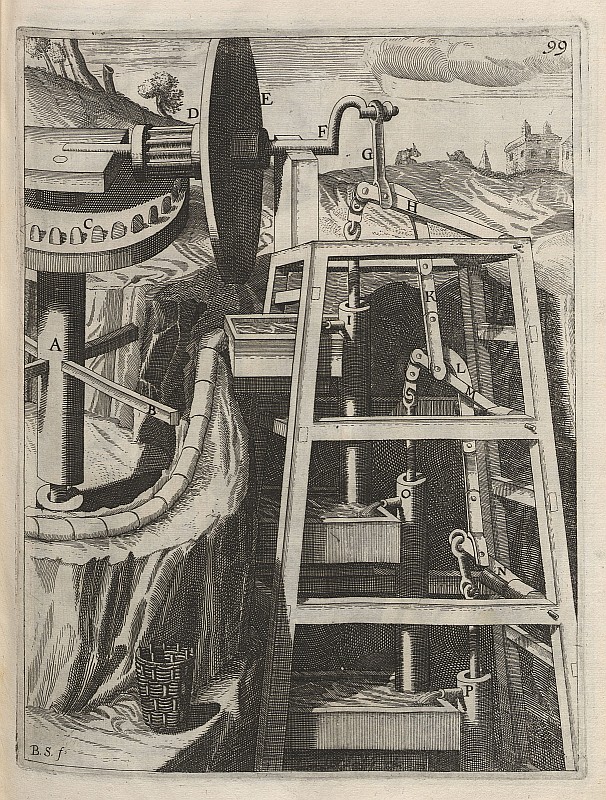

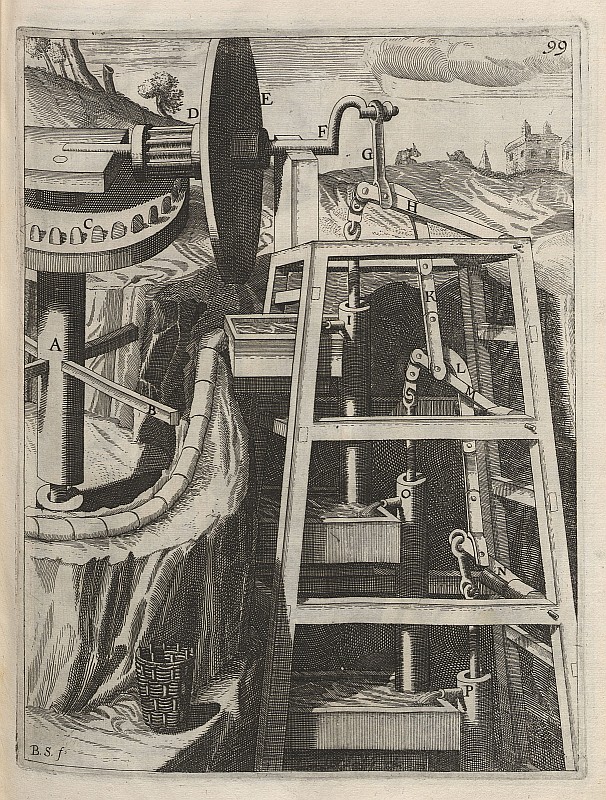

From the 16th century onwards, evidence of cranks and connecting rods integrated into machine design becomes abundant in the technological treatises of the period: Agostino Ramelli's ''The Diverse and Artifactitious Machines'' of 1588 depicts eighteen examples, a number that rises in the ''Theatrum Machinarum Novum'' by Georg Andreas Böckler to 45 different machines. Cranks were formerly common on some machines in the early 20th century; for example almost all phonographs before the 1930s were powered by clockwork motors wound with cranks. Reciprocating piston engines use cranks to convert the linear piston motion into rotational motion. Internal combustion engines of early 20th century automobiles were usually started with hand cranks, before Automobile self starter, electric starters came into general use.

Around 1480, the early medieval rotary grindstone was improved with a treadle and crank mechanism. Cranks mounted on push-carts first appear in a German engraving of 1589. Crankshafts were also described by Leonardo da Vinci (1452–1519) and a Dutch farmer and windmill owner by the name Cornelis Corneliszoon van Uitgeest in 1592. His wind-powered sawmill used a crankshaft to convert a windmill's circular motion into a back-and-forward motion powering the saw. Corneliszoon was granted a patent for his crankshaft in 1597.

From the 16th century onwards, evidence of cranks and connecting rods integrated into machine design becomes abundant in the technological treatises of the period: Agostino Ramelli's ''The Diverse and Artifactitious Machines'' of 1588 depicts eighteen examples, a number that rises in the ''Theatrum Machinarum Novum'' by Georg Andreas Böckler to 45 different machines. Cranks were formerly common on some machines in the early 20th century; for example almost all phonographs before the 1930s were powered by clockwork motors wound with cranks. Reciprocating piston engines use cranks to convert the linear piston motion into rotational motion. Internal combustion engines of early 20th century automobiles were usually started with hand cranks, before Automobile self starter, electric starters came into general use.

The Crank-Connecting Rod System in a Continuously Rotating Machine

The author Sally Ganchy identified a crankshaft in his twin-cylinder pump mechanism, including both the crank and shaft mechanisms.Donald Hill (2012)

''The Book of Knowledge of Ingenious Mechanical Devices'', page 273

Springer Science + Business Media

reciprocating motion

Reciprocating motion, also called reciprocation, is a repetitive up-and-down or back-and-forth linear motion. It is found in a wide range of mechanisms, including reciprocating engines and pumps. The two opposite motions that comprise a single r ...

into rotational motion

Rotation, or spin, is the circular movement of an object around a '' central axis''. A two-dimensional rotating object has only one possible central axis and can rotate in either a clockwise or counterclockwise direction. A three-dimensional ...

. The crankshaft is a rotating shaft containing one or more crankpin

A crankpin or crank pin, also known as a rod bearing journal, is a mechanical device in an engine which connects the crankshaft to the connecting rod for each cylinder. It has a cylindrical surface, to allow the crankpin to rotate relative to the ...

s, that are driven by the pistons via the connecting rods.

The crankpins are also called ''rod bearing journals'', and they rotate within the "big end" of the connecting rods.

Most modern crankshafts are located in the engine block

In an internal combustion engine, the engine block is the structure which contains the cylinders and other components. In an early automotive engine, the engine block consisted of just the cylinder block, to which a separate crankcase was attac ...

. They are made from steel or cast iron

Cast iron is a class of iron– carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impur ...

, using either a forging, casting

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a ''casting'', which is ejected ...

or machining process.

Design

The crankshaft located within the

The crankshaft located within the engine block

In an internal combustion engine, the engine block is the structure which contains the cylinders and other components. In an early automotive engine, the engine block consisted of just the cylinder block, to which a separate crankcase was attac ...

, held in place via main bearing

Main may refer to:

Geography

* Main River (disambiguation)

**Most commonly the Main (river) in Germany

* Main, Iran, a village in Fars Province

*"Spanish Main", the Caribbean coasts of mainland Spanish territories in the 16th and 17th centuries

...

s which allow the crankshaft to rotate within the block. The up-down motion of each piston is transferred to the crankshaft via connecting rods

A connecting rod, also called a 'con rod', is the part of a piston engine which connects the piston to the crankshaft. Together with the crank, the connecting rod converts the reciprocating motion of the piston into the rotation of the cranksha ...

. A flywheel

A flywheel is a mechanical device which uses the conservation of angular momentum to store rotational energy; a form of kinetic energy proportional to the product of its moment of inertia and the square of its rotational speed. In particular, as ...

is often attached to one end of the crankshaft, in order to smoothen the power delivery and reduce vibration.

A crankshaft is subjected to enormous stresses, in some cases more than per cylinder. Crankshafts for single-cylinder engine

A single-cylinder engine, sometimes called a thumper, is a piston engine with one cylinder. This engine is often used for motorcycles, motor scooters, go-karts, all-terrain vehicles, radio-controlled vehicles, portable tools and garden machinery ...

s are usually a simpler design than for engines with multiple cylinders.

Bearings

The crankshaft is able to rotate in the engine block due to the 'main bearings'. Since the crankshaft is subject to large horizontal and torsional forces from each cylinder, these main bearings are located at various points along the crankshaft, rather than just one at each end. The number of main bearings is determined based on the overall load factor and the maximum engine speed. Crankshafts in diesel engines often use a main bearing between every cylinder and at both ends of the crankshaft, due to the high forces of combustion present. Flexing of the crankshaft was a factor inV8 engine

A V8 engine is an eight-cylinder piston engine in which two banks of four cylinders share a common crankshaft and are arranged in a V configuration.

The first V8 engine was produced by the French Antoinette company in 1904, developed and u ...

s replacing straight-eight engines in the 1950s; the long crankshafts of the latter suffered from an unacceptable amount of flex when engine designers began using higher compression ratios and higher engine speeds (RPM).

Piston stroke

The distance between the axis of the crankpins and the axis of the crankshaft determines the stroke length of the engine. Most modern car engines are classified as "over square" or short-stroke, wherein the stroke is less than the diameter of thecylinder bore

In a piston engine, the bore (or cylinder bore) is the diameter of each cylinder.

Engine displacement is calculated based on bore, stroke length and the number of cylinders:

displacement =

The stroke ratio, determined by dividing the bore by ...

. A common way to increase the low-RPM torque of an engine is to increase the stroke, sometimes known as "stroking" the engine. Historically, the trade-off for a long-stroke engine was a lower rev limit and increased vibration at high RPM, due to the increased piston velocity.

Cross-plane and flat-plane configurations

When designing an engine, the crankshaft configuration is closely related to the engine'sfiring order

The firing order of an internal combustion engine is the sequence of ignition for the cylinders.

In a spark ignition (e.g. gasoline/petrol) engine, the firing order corresponds to the order in which the spark plugs are operated. In a diesel engi ...

.

Most production V8 engines (such as the Ford Modular engine

The Ford Modular engine is Ford Motor Company's overhead camshaft (OHC) V8 and V10 gasoline-powered small block engine family. Despite popular belief that the Modular engine family received its moniker from the sharing of engine parts across nu ...

and the General Motors LS engine) use a cross-plane crank whereby the crank throws are spaced 90° apart. However, some high-performance V8 engines (such as the Ferrari 488

The Ferrari 488 (Type F142M) is a mid-engine sports car produced by the Italian automobile manufacturer Ferrari. The car replaced the 458, being the first mid-engine Ferrari to use a turbocharged V8 since the F40. It was succeeded by the Ferra ...

) instead use a flat-plane crank

The flat-plane crank (sometimes flatplane) is a type of crankshaft for use in internal combustion engines that has a 180 degree angle between crank throws.

Details

Flat-plane cranks are used in V-configuration engines, generally with eight c ...

, whereby the throws are spaced 180° apart, which essentially results in two inline-four engines sharing a common crankcase. Flat-plane engines are usually able to operate at higher RPM, however they have higher second-order vibrations, so they are better suited to racing car engines.

Engine balance

For some engines it is necessary to providecounterweight

A counterweight is a weight that, by applying an opposite force, provides balance and stability of a mechanical system. The purpose of a counterweight is to make lifting the load faster and more efficient, which saves energy and causes less wea ...

s for the reciprocating mass of the piston, conrods and crankshaft, in order to improve the engine balance

Engine balance refers to how the forces (resulting from combustion or rotating/reciprocating components) are balanced within an internal combustion engine or steam engine. The most commonly used terms are ''primary balance'' and ''secondary bala ...

. These counterweights are typically cast as part of the crankshaft but, occasionally, are bolt-on pieces.

Flying arms

In some engines, the crankshaft contains direct links between adjacent crank pins, without the usual intermediate main bearing. These links are called ''flying arms''. This arrangement is sometimes used in V6 and

In some engines, the crankshaft contains direct links between adjacent crank pins, without the usual intermediate main bearing. These links are called ''flying arms''. This arrangement is sometimes used in V6 and V8 engine

A V8 engine is an eight-cylinder piston engine in which two banks of four cylinders share a common crankshaft and are arranged in a V configuration.

The first V8 engine was produced by the French Antoinette company in 1904, developed and u ...

s, in order to maintain an even firing interval while using different V angles, and to reduce the number of main bearings required. The downside of flying arms is that the rigidity of the crankshaft is reduced, which can cause problems at high RPM or high power outputs.

Counter-rotating crankshafts

In most engines, each connecting rod is attached a single crankshaft, which results in the angle of the connecting rod varying as the piston moves through its stroke. This variation in angle pushes the pistons against the cylinder wall, which causes friction between the piston and cylinder wall. To prevent this, some early engines - such as the 1900-1904 Lanchester Engine Company flat-twin engines - connected each piston to two crankshafts that are rotating in opposite directions. This arrangement cancels out the lateral forces and reduces the requirement for counterweights. This design is rarely used, however a similar principle applies to balance shafts, which are occasionally used.Construction

Forged crankshafts

Crankshafts can be created from a steel bar using roll forging. Today, manufacturers tend to favour the use of forged crankshafts due to their lighter weight, more compact dimensions and better inherent damping. With forged crankshafts, vanadium micro-alloyed steels are mainly used as these steels can be air-cooled after reaching high strengths without additional heat treatment, except for the surface hardening of the bearing surfaces. The low alloy content also makes the material cheaper than high alloy steels. Carbon steels also require additional heat treatment to reach the desired properties.

Crankshafts can be created from a steel bar using roll forging. Today, manufacturers tend to favour the use of forged crankshafts due to their lighter weight, more compact dimensions and better inherent damping. With forged crankshafts, vanadium micro-alloyed steels are mainly used as these steels can be air-cooled after reaching high strengths without additional heat treatment, except for the surface hardening of the bearing surfaces. The low alloy content also makes the material cheaper than high alloy steels. Carbon steels also require additional heat treatment to reach the desired properties.

Cast crankshafts

Another construction method is tocast

Cast may refer to:

Music

* Cast (band), an English alternative rock band

* Cast (Mexican band), a progressive Mexican rock band

* The Cast, a Scottish musical duo: Mairi Campbell and Dave Francis

* ''Cast'', a 2012 album by Trespassers William

...

the crankshaft from ductile. Cast iron crankshafts are today mostly found in cheaper production engines where the loads are lower.

Machined crankshafts

Crankshafts can also bemachined

Machining is a process in which a material (often metal) is cut to a desired final shape and size by a controlled material-removal process. The processes that have this common theme are collectively called subtractive manufacturing, which utilizes ...

from billet

A billet is a living-quarters to which a soldier is assigned to sleep. Historically, a billet was a private dwelling that was required to accept the soldier.

Soldiers are generally billeted in barracks or garrisons when not on combat duty, alth ...

, often a bar of high quality vacuum remelted steel. Though the fiber flow (local inhomogeneities of the material's chemical composition generated during casting) does not follow the shape of the crankshaft (which is undesirable), this is usually not a problem since higher quality steels, which normally are difficult to forge, can be used. Per unit, these crankshafts tend to be very expensive due to the large amount of material that must be removed with lathes and milling machines, the high material cost, and the additional heat treatment required. However, since no expensive tooling is needed, this production method allows small production runs without high up-front costs.

History

China

The earliest hand-operated cranks appeared in China during the

The earliest hand-operated cranks appeared in China during the Han Dynasty

The Han dynasty (, ; ) was an imperial dynasty of China (202 BC – 9 AD, 25–220 AD), established by Liu Bang (Emperor Gao) and ruled by the House of Liu. The dynasty was preceded by the short-lived Qin dynasty (221–207 BC) and a warr ...

(202 BC-220 AD). They were used for silk-reeling, hemp-spinning, for the agricultural winnowing

Winnowing is a process by which chaff is separated from grain. It can also be used to remove pests from stored grain. Winnowing usually follows threshing in grain preparation. In its simplest form, it involves throwing the mixture into the ...

fan, in the water-powered flour-sifter, for hydraulic-powered metallurgic bellows

A bellows or pair of bellows is a device constructed to furnish a strong blast of air. The simplest type consists of a flexible bag comprising a pair of rigid boards with handles joined by flexible leather sides enclosing an approximately airtig ...

, and in the well windlass. The rotary winnowing fan greatly increased the efficiency of separating grain from husks and stalks. However, the potential of the crank of converting circular motion into reciprocal motion never seems to have been fully realized in China, and the crank was typically absent from such machines until the turn of the 20th century.

Europe

A crank in the form of an eccentrically-mounted handle of the rotary Quern-stone, handmill appeared in 5th century BC Celtiberians, Celtiberian Spain and ultimately spread across the Roman Empire. A Roman iron crank dating to the 2nd century AD was excavated in Augusta Raurica, Switzerland. The crank-operated Roman Empire, Roman mill is dated to the late 2nd century.

A crank in the form of an eccentrically-mounted handle of the rotary Quern-stone, handmill appeared in 5th century BC Celtiberians, Celtiberian Spain and ultimately spread across the Roman Empire. A Roman iron crank dating to the 2nd century AD was excavated in Augusta Raurica, Switzerland. The crank-operated Roman Empire, Roman mill is dated to the late 2nd century.

Around 1480, the early medieval rotary grindstone was improved with a treadle and crank mechanism. Cranks mounted on push-carts first appear in a German engraving of 1589. Crankshafts were also described by Leonardo da Vinci (1452–1519) and a Dutch farmer and windmill owner by the name Cornelis Corneliszoon van Uitgeest in 1592. His wind-powered sawmill used a crankshaft to convert a windmill's circular motion into a back-and-forward motion powering the saw. Corneliszoon was granted a patent for his crankshaft in 1597.

From the 16th century onwards, evidence of cranks and connecting rods integrated into machine design becomes abundant in the technological treatises of the period: Agostino Ramelli's ''The Diverse and Artifactitious Machines'' of 1588 depicts eighteen examples, a number that rises in the ''Theatrum Machinarum Novum'' by Georg Andreas Böckler to 45 different machines. Cranks were formerly common on some machines in the early 20th century; for example almost all phonographs before the 1930s were powered by clockwork motors wound with cranks. Reciprocating piston engines use cranks to convert the linear piston motion into rotational motion. Internal combustion engines of early 20th century automobiles were usually started with hand cranks, before Automobile self starter, electric starters came into general use.

Around 1480, the early medieval rotary grindstone was improved with a treadle and crank mechanism. Cranks mounted on push-carts first appear in a German engraving of 1589. Crankshafts were also described by Leonardo da Vinci (1452–1519) and a Dutch farmer and windmill owner by the name Cornelis Corneliszoon van Uitgeest in 1592. His wind-powered sawmill used a crankshaft to convert a windmill's circular motion into a back-and-forward motion powering the saw. Corneliszoon was granted a patent for his crankshaft in 1597.

From the 16th century onwards, evidence of cranks and connecting rods integrated into machine design becomes abundant in the technological treatises of the period: Agostino Ramelli's ''The Diverse and Artifactitious Machines'' of 1588 depicts eighteen examples, a number that rises in the ''Theatrum Machinarum Novum'' by Georg Andreas Böckler to 45 different machines. Cranks were formerly common on some machines in the early 20th century; for example almost all phonographs before the 1930s were powered by clockwork motors wound with cranks. Reciprocating piston engines use cranks to convert the linear piston motion into rotational motion. Internal combustion engines of early 20th century automobiles were usually started with hand cranks, before Automobile self starter, electric starters came into general use.

Western Asia

The non-manual crank appears in several of the hydraulic devices described by the Banū Mūsā brothers in their 9th-century ''Book of Ingenious Devices''. These automatically operated cranks appear in several devices, two of which contain an action which approximates to that of a crankshaft, anticipating Ismail al-Jazari's invention by several centuries and its first appearance in Europe by over five centuries. The automatic crank described by the Banū Mūsā would not have allowed a full rotation, however, but only a small modification was required to convert it to a crankshaft. Arab engineer Ismail al-Jazari (1136–1206), in the Artuqids, Artuqid Sultanate, described a crank and connecting rod system in a rotating machine in two of his water-raising machines.Ahmad Y HassanThe Crank-Connecting Rod System in a Continuously Rotating Machine

The author Sally Ganchy identified a crankshaft in his twin-cylinder pump mechanism, including both the crank and shaft mechanisms.Donald Hill (2012)

''The Book of Knowledge of Ingenious Mechanical Devices'', page 273

Springer Science + Business Media

See also

*Crankset, Bicycle crankset *Brace (tool) *Cam *Cam engine *Camshaft *Crank (mechanism) *Crankcase *Torsional vibration#Crankshaft torsional vibration, Crankshaft torsional vibration *Piston motion equations *Tunnel crankshaft *Scotch yoke *SwashplateReferences

Sources

* * * * * * * * * * * * *External links

*Interactive crank animation https://www.desmos.com/calculator/8l2kvyivqo *D & T Mechanisms - Interactive Tools for Teachers (applets) https://web.archive.org/web/20140714155346/http://www.content.networcs.net/tft/mechanisms.htm * {{Authority control Crankshafts, Engine components Engine technology Linkages (mechanical) Piston engines