Enhanced Oil Recovery on:

[Wikipedia]

[Google]

[Amazon]

Enhanced oil recovery (abbreviated EOR), also called tertiary recovery, is the extraction of

Enhanced oil recovery (abbreviated EOR), also called tertiary recovery, is the extraction of

In this approach, various methods are used to heat the crude oil in the formation to reduce its viscosity and/or vaporize part of the oil and thus decrease the mobility ratio. The increased heat reduces the surface tension and increases the permeability of the oil. The heated oil may also vaporize and then condense forming improved oil. Methods include cyclic steam injection, steam flooding and combustion. These methods improve the sweep efficiency and the displacement efficiency. Steam injection has been used commercially since the 1960s in California fields. In 2011 solar thermal enhanced oil recovery projects were started in California and

In this approach, various methods are used to heat the crude oil in the formation to reduce its viscosity and/or vaporize part of the oil and thus decrease the mobility ratio. The increased heat reduces the surface tension and increases the permeability of the oil. The heated oil may also vaporize and then condense forming improved oil. Methods include cyclic steam injection, steam flooding and combustion. These methods improve the sweep efficiency and the displacement efficiency. Steam injection has been used commercially since the 1960s in California fields. In 2011 solar thermal enhanced oil recovery projects were started in California and

In 2000,

In 2000,

"CO2-Enhanced Oil Recovery."

Excerpt from a WRI Policy Note, "Weighing U.S. Energy Options: The WRI Bubble Chart." World Resources Institute, Washington, DC. The Department of Energy (DOE) has estimated that full use of 'next generation' CO2-EOR in United States could generate an additional of recoverable oil resources. Developing this potential would depend on the availability of commercial CO2 in large volumes, which could be made possible by widespread use of carbon capture and storage. For comparison, the total undeveloped US domestic oil resources still in the ground total more than , most of it remaining unrecoverable. The DOE estimates that if the EOR potential were to be fully realized, state and local treasuries would gain $280 billion in revenues from future royalties, severance taxes, and state income taxes on oil production, aside from other economic benefits. The main barrier to taking further advantage of CO2 EOR in the United States has been an insufficient supply of affordable CO2. Currently, there is a cost gap between what an oilfield operation could afford to pay for CO2 under normal market conditions and the cost to capture and transport CO2 from power plants and industrial sources, so most CO2 comes from natural sources. However, using CO2 from power plants or industrial sources could reduce the carbon footprint (if the CO2 is stored underground). For some industrial sources, such as natural gas processing or fertilizer and ethanol production, the cost gap is small (potentially $10–20/tonne CO2). For other man-made sources of CO2, including power generation and a variety of industrial processes, capture costs are greater, and the cost gap becomes much larger (potentially $30–50/tonne CO2). The Enhanced Oil Recovery Initiative has brought together leaders from industry, the environmental community, labor, and state governments to advance CO2 EOR in the United States and close the price gap. In the US, regulations can both assist and slow down the development of EOR for use in carbon capture & utilization, as well as general oil production. One of the primary regulations governing EOR is the Safe Drinking Water Act of 1974 (SDWA), which gives most of the regulatory power over EOR and similar oil recovery operations to the

IPCC Special Report on Carbon dioxide Capture and Storage

Chapter 5, Underground geological storage. Intergovernmental Panel on Climate Change (IPCC), 2005.

ttps://web.archive.org/web/20090425063318/http://www.fossil.energy.gov/programs/oilgas/publications/eor_co2/Undeveloped_Oil_Document.pdf pdf// US Department of Energy, analysis of EOR potential. Game Changer Improvements Could Dramatically Increase Domestic Oil Resource Recovery. An analysis by Advanced Resources International, Arlington, VA, for the U.S. Department of Energy's Office of Fossil Energy. Advanced Resources International, February 2006. See als

press release

Enhanced Oil Recovery Institute

– University of Wyoming

Licensable Technology: Particle Stabilized Emulsions of Carbon Dioxide & Water for Enhanced Oil Recovery & Extraction Processes

– Massachusetts Technology Portal

Oilfield Glossary: Enhanced Oil Recovery

– Schlumberger, Ltd.

Center for Petroleum and Geosystems Engineering

– University of Texas at Austin

Polymer Flooding, Reservoir Sweep Improvement, New Mexico Tech {{DEFAULTSORT:Enhanced Oil Recovery Petroleum production

Enhanced oil recovery (abbreviated EOR), also called tertiary recovery, is the extraction of

Enhanced oil recovery (abbreviated EOR), also called tertiary recovery, is the extraction of crude oil

Petroleum, also known as crude oil, or simply oil, is a naturally occurring yellowish-black liquid mixture of mainly hydrocarbons, and is found in geological formations. The name ''petroleum'' covers both naturally occurring unprocessed crude ...

from an oil field that cannot be extracted otherwise. EOR can extract 30% to 60% or more of a reservoir's oil, compared to 20% to 40% using primary and secondary recovery

Petroleum is a fossil fuel that can be drawn from beneath the earth's surface. Reservoirs of petroleum was formed through the mixture of plants, algae, and sediments in shallow seas under high pressure. Petroleum is mostly recovered from oil dri ...

. According to the US Department of Energy, carbon dioxide

Carbon dioxide ( chemical formula ) is a chemical compound made up of molecules that each have one carbon atom covalently double bonded to two oxygen atoms. It is found in the gas state at room temperature. In the air, carbon dioxide is t ...

and water

Water (chemical formula ) is an inorganic, transparent, tasteless, odorless, and nearly colorless chemical substance, which is the main constituent of Earth's hydrosphere and the fluids of all known living organisms (in which it acts as ...

are injected along with one of three EOR techniques: thermal injection, gas injection, and chemical injection. More advanced, speculative EOR techniques are sometimes called quaternary recovery.

Methods

There are three primary techniques of EOR: gas injection, thermal injection, and chemical injection. Gas injection, which uses gases such asnatural gas

Natural gas (also called fossil gas or simply gas) is a naturally occurring mixture of gaseous hydrocarbons consisting primarily of methane in addition to various smaller amounts of other higher alkanes. Low levels of trace gases like carbon d ...

, nitrogen

Nitrogen is the chemical element with the symbol N and atomic number 7. Nitrogen is a nonmetal and the lightest member of group 15 of the periodic table, often called the pnictogens. It is a common element in the universe, estimated at se ...

, or carbon dioxide

Carbon dioxide ( chemical formula ) is a chemical compound made up of molecules that each have one carbon atom covalently double bonded to two oxygen atoms. It is found in the gas state at room temperature. In the air, carbon dioxide is t ...

(CO2), accounts for nearly 60 percent of EOR production in the United States. Thermal injection, which involves the introduction of heat

In thermodynamics, heat is defined as the form of energy crossing the boundary of a thermodynamic system by virtue of a temperature difference across the boundary. A thermodynamic system does not ''contain'' heat. Nevertheless, the term is ...

, accounts for 40 percent of EOR production in the United States, with most of it occurring in California. Chemical injection, which can involve the use of long-chained molecules called polymer

A polymer (; Greek '' poly-'', "many" + '' -mer'', "part")

is a substance or material consisting of very large molecules called macromolecules, composed of many repeating subunits. Due to their broad spectrum of properties, both synthetic a ...

s to increase the effectiveness of waterfloods, accounts for about one percent of EOR production in the United States. In 2013, a technique called Plasma-Pulse technology was introduced into the United States from Russia. This technique can result in another 50 percent of improvement in existing well production.

Gas injection

Gas injection or miscible flooding is presently the most-commonly used approach in enhanced oil recovery. Miscible flooding is a general term for injection processes that introduce miscible gases into the reservoir. A miscible displacement process maintains reservoir pressure and improves oil displacement because the interfacial tension between oil and gas is reduced. This refers to removing the interface between the two interacting fluids. This allows for total displacement efficiency. Gases used include CO2, natural gas or nitrogen. The fluid most commonly used for miscible displacement is carbon dioxide because it reduces the oilviscosity

The viscosity of a fluid is a measure of its resistance to deformation at a given rate. For liquids, it corresponds to the informal concept of "thickness": for example, syrup has a higher viscosity than water.

Viscosity quantifies the int ...

and is less expensive than liquefied petroleum gas

Liquefied petroleum gas (LPG or LP gas) is a fuel gas which contains a flammable mixture of hydrocarbon gases, specifically propane, propylene, butylene, isobutane and n-butane.

LPG is used as a fuel gas in heating appliances, cookin ...

. Oil displacement by carbon dioxide injection relies on the phase behavior of the mixtures of that gas and the crude, which are strongly dependent on reservoir temperature, pressure and crude oil composition.

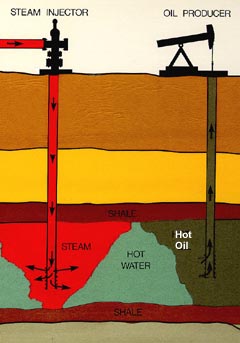

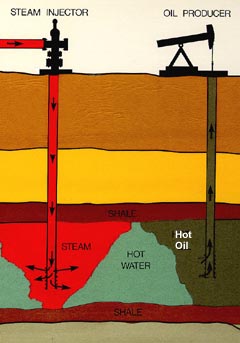

Thermal injection

In this approach, various methods are used to heat the crude oil in the formation to reduce its viscosity and/or vaporize part of the oil and thus decrease the mobility ratio. The increased heat reduces the surface tension and increases the permeability of the oil. The heated oil may also vaporize and then condense forming improved oil. Methods include cyclic steam injection, steam flooding and combustion. These methods improve the sweep efficiency and the displacement efficiency. Steam injection has been used commercially since the 1960s in California fields. In 2011 solar thermal enhanced oil recovery projects were started in California and

In this approach, various methods are used to heat the crude oil in the formation to reduce its viscosity and/or vaporize part of the oil and thus decrease the mobility ratio. The increased heat reduces the surface tension and increases the permeability of the oil. The heated oil may also vaporize and then condense forming improved oil. Methods include cyclic steam injection, steam flooding and combustion. These methods improve the sweep efficiency and the displacement efficiency. Steam injection has been used commercially since the 1960s in California fields. In 2011 solar thermal enhanced oil recovery projects were started in California and Oman

Oman ( ; ar, عُمَان ' ), officially the Sultanate of Oman ( ar, سلْطنةُ عُمان ), is an Arabian country located in southwestern Asia. It is situated on the southeastern coast of the Arabian Peninsula, and spans the mouth of ...

, this method is similar to thermal EOR but uses a solar array to produce the steam.

In July 2015, Petroleum Development Oman

Petroleum Development Oman (PDO) is the leading exploration and production company in the Sultanate of Oman. The Company delivers the majority of the country's crude oil production and natural gas supply. The company is owned by the Government of ...

and GlassPoint Solar

GlassPoint is a private company founded in 2009 that designs and manufactures solar steam generators which use solar thermal technology to generate steam for industrial processes.

Overview

GlassPoint's enclosed trough technology enclos ...

announced that they signed a $600 million agreement to build a 1 GWth solar field on the Amal oilfield. The project, named Miraah

Miraah is a solar thermal energy plant that is under construction in Oman for the production of steam for solar thermal enhanced oil recovery. In July 2015, Petroleum Development Oman and GlassPoint Solar announced that they signed a $600 mill ...

, will be the world's largest solar field measured by peak thermal capacity.

In November 2017, GlassPoint and Petroleum Development Oman (PDO) completed construction on the first block of the Miraah solar plant safely on schedule and on budget, and successfully delivered steam to the Amal West oilfield.

Also in November 2017, GlassPoint and Aera Energy

Aera Energy LLC (or simply Aera) is a natural gas, oil exploration and production company started as a joint venture between Shell plc (through Shell USA) and Mobil (which later merged to form ExxonMobil). Headquartered in Bakersfield, Californ ...

announced a joint project to create California's largest solar EOR field at the South Belridge Oil Field

The South Belridge Oil Field is a large oil field in northwestern Kern County, San Joaquin Valley, California, about forty miles west of Bakersfield. Discovered in 1911, and having a cumulative production of over of oil at the end of 2008, i ...

, near Bakersfield, California

Bakersfield is a city in Kern County, California, United States. It is the county seat and largest city of Kern County. The city covers about near the southern end of the San Joaquin Valley and the Central Valley region. Bakersfield's populat ...

. The facility is projected to produce approximately 12 million barrels of steam per year through a 850MW thermal solar steam generator. It will also cut carbon emissions from the facility by 376,000 metric tons per year.

Steam flooding

Steam flooding (see sketch) is one means of introducing heat to the reservoir by pumping steam into the well with a pattern similar to that of water injection. Eventually the steam condenses to hot water; in the steam zone the oil evaporates, and in the hot water zone the oil expands. As a result, the oil expands, the viscosity drops, and the permeability increases. To ensure success the process has to be cyclical. This is the principal enhanced oil recovery program in use today. * '' Solar EOR'' is a form of steam flooding that uses solar arrays to concentrate the sun's energy to heat water and generate steam. Solar EOR is proving to be a viable alternative to gas-fired steam production for theoil industry

The petroleum industry, also known as the oil industry or the oil patch, includes the global processes of exploration, extraction, refining, transportation (often by oil tankers and pipelines), and marketing of petroleum products. The larges ...

.

Fire flooding

Fire flooding works best when the oil saturation and porosity are high. Combustion generates the heat within the reservoir itself. Continuous injection of air or other gas mixture with high oxygen content will maintain the flame front. As the fire burns, it moves through the reservoir toward production wells. Heat from the fire reduces oil viscosity and helps vaporize reservoir water to steam. The steam, hot water, combustion gas and a bank of distilled solvent all act to drive oil in front of the fire toward production wells. There are three methods of combustion: Dry forward, reverse and wet combustion. Dry forward uses an igniter to set fire to the oil. As the fire progresses the oil is pushed away from the fire toward the producing well. In reverse the air injection and the ignition occur from opposite directions. In wet combustion water is injected just behind the front and turned into steam by the hot rock. This quenches the fire and spreads the heat more evenly.Chemical injection

The injection of various chemicals, usually as dilute solutions, have been used to aid mobility and the reduction insurface tension

Surface tension is the tendency of liquid surfaces at rest to shrink into the minimum surface area possible. Surface tension is what allows objects with a higher density than water such as razor blades and insects (e.g. water striders) t ...

. Injection of alkaline or caustic

Caustic most commonly refers to:

* Causticity, a property of various corrosive substances

** Sodium hydroxide, sometimes called ''caustic soda''

** Potassium hydroxide, sometimes called ''caustic potash''

** Calcium oxide, sometimes called ''caust ...

solutions into reservoirs with oil that have organic acid

An organic acid is an organic compound with acidic properties. The most common organic acids are the carboxylic acids, whose acidity is associated with their carboxyl group –COOH. Sulfonic acids, containing the group –SO2OH, are ...

s naturally occurring in the oil will result in the production of soap

Soap is a salt of a fatty acid used in a variety of cleansing and lubricating products. In a domestic setting, soaps are surfactants usually used for washing, bathing, and other types of housekeeping. In industrial settings, soaps are us ...

that may lower the interfacial tension

Surface tension is the tendency of liquid surfaces at rest to shrink into the minimum surface area possible. Surface tension is what allows objects with a higher density than water such as razor blades and insects (e.g. water striders) t ...

enough to increase production. Injection of a dilute solution of a water-soluble

In chemistry, solubility is the ability of a substance, the solute, to form a solution with another substance, the solvent. Insolubility is the opposite property, the inability of the solute to form such a solution.

The extent of the solub ...

polymer to increase the viscosity of the injected water can increase the amount of oil recovered in some formations. Dilute solutions of surfactant

Surfactants are chemical compounds that decrease the surface tension between two liquids, between a gas and a liquid, or interfacial tension between a liquid and a solid. Surfactants may act as detergents, wetting agents, emulsion#Emulsifiers , ...

s such as petroleum sulfonates or biosurfactants such as rhamnolipid

Rhamnolipids are a class of glycolipid produced by ''Pseudomonas aeruginosa'', amongst other organisms, frequently cited as bacterial surfactants. They have a glycosyl head group, in this case a rhamnose moiety, and a 3-(hydroxyalkanoyloxy)alkanoic ...

s may be injected to lower the interfacial tension

Surface tension is the tendency of liquid surfaces at rest to shrink into the minimum surface area possible. Surface tension is what allows objects with a higher density than water such as razor blades and insects (e.g. water striders) t ...

or capillary pressure In fluid statics, capillary pressure () is the pressure between two immiscible fluids in a thin tube (see capillary action), resulting from the interactions of forces between the fluids and solid walls of the tube. Capillary pressure can serve as bo ...

that impedes oil droplets from moving through a reservoir, this is analyzed in terms of the bond number, relating capillary forces to gravitational ones. Special formulations of oil, water and surfactant, microemulsions, can be particularly effective in reducing interfacial tension. Application of these methods is usually limited by the cost of the chemicals and their adsorption and loss onto the rock of the oil containing formation. In all of these methods the chemicals are injected into several wells and the production occurs in other nearby wells.

Polymer flooding

Polymer flooding consists in mixing long chain polymer molecules with the injected water in order to increase the water viscosity. This method improves the vertical and areal sweep efficiency as a consequence of improving the water/oil mobility ratio. Surfactants may be used in conjunction with polymers and hyperbranched polyglycerols; they decrease the interfacial tension between the oil and water. This reduces the residual oil saturation and improves the macroscopic efficiency of the process. Primary surfactants usually have co-surfactants, activity boosters, and co-solvents added to them to improve stability of the formulation. Caustic flooding is the addition of sodium hydroxide to injection water. It does this by lowering the surface tension, reversing the rock wettability, emulsification of the oil, mobilization of the oil and helps in drawing the oil out of the rock.Low salinity nanofluids

EOR processes can be enhanced with nanoparticles in three ways: nanocatalysts, nanofluids, and nanoemulsions. Nanofluids are base fluids that contain nanoparticles in colloidal suspensions. Nanofluids perform many functions in EOR of oil fields, including pore disjoining pressure, channel plugging, interfacial tension reduction, mobility ratio, wettability alteration, and asphaltene precipitation prevention. Nanofluids facilitates disjoining pressure to remove sediment entrapped oil via aggregation at the interface. Alternatively, wettability alteration and interfacial surface tension reduction are other alternative mechanism of EOR.Microbial injection

Microbial injection is part of microbial enhanced oil recovery and is rarely used because of its higher cost and because the development is not widely accepted. Thesemicrobe

A microorganism, or microbe,, ''mikros'', "small") and ''organism'' from the el, ὀργανισμός, ''organismós'', "organism"). It is usually written as a single word but is sometimes hyphenated (''micro-organism''), especially in olde ...

s function either by partially digesting long hydrocarbon

In organic chemistry, a hydrocarbon is an organic compound consisting entirely of hydrogen and carbon. Hydrocarbons are examples of group 14 hydrides. Hydrocarbons are generally colourless and hydrophobic, and their odors are usually weak or ...

molecules, by generating biosurfactants, or by emitting carbon dioxide (which then functions as described in Gas injection above).

Three approaches have been used to achieve microbial injection. In the first approach, bacterial cultures mixed with a food source (a carbohydrate such as molasses

Molasses () is a viscous substance resulting from refining sugarcane or sugar beets into sugar. Molasses varies in the amount of sugar, method of extraction and age of the plant. Sugarcane molasses is primarily used to sweeten and flavour foods ...

is commonly used) are injected into the oil field. In the second approach, used since 1985, nutrients are injected into the ground to nurture existing microbial bodies; these nutrients cause the bacteria to increase production of the natural surfactants they normally use to metabolize crude oil underground. After the injected nutrients are consumed, the microbes go into near-shutdown mode, their exteriors become hydrophilic

A hydrophile is a molecule or other molecular entity that is attracted to water molecules and tends to be dissolved by water.Liddell, H.G. & Scott, R. (1940). ''A Greek-English Lexicon'' Oxford: Clarendon Press.

In contrast, hydrophobes are n ...

, and they migrate to the oil-water interface area, where they cause oil droplets to form from the larger oil mass, making the droplets more likely to migrate to the wellhead. This approach has been used in oilfields near the Four Corners and in the Beverly Hills Oil Field in Beverly Hills, California.

The third approach is used to address the problem of paraffin wax

Paraffin wax (or petroleum wax) is a soft colorless solid derived from petroleum, coal, or oil shale that consists of a mixture of hydrocarbon molecules containing between 20 and 40 carbon atoms. It is solid at room temperature and begins t ...

components of the crude oil, which tend to precipitate as the crude flows to the surface, since the Earth's surface is considerably cooler than the petroleum deposits (a temperature drop of 9–10–14 °C per thousand feet of depth is usual).

Liquid carbon dioxide superfluids

Carbon dioxide (CO2) is particularly effective in reservoirs deeper than 2,000 ft., where CO2 will be in a supercritical state. In high pressure applications with lighter oils, CO2 is miscible with the oil, with resultant swelling of the oil, and reduction in viscosity, and possibly also with a reduction in the surface tension with the reservoir rock. In the case of low pressure reservoirs or heavy oils, CO2 will form an immiscible fluid, or will only partially mix with the oil. Some oil swelling may occur, and oil viscosity can still be significantly reduced. In these applications, between one-half and two-thirds of the injected CO2 returns with the produced oil and is usually re-injected into the reservoir to minimize operating costs. The remainder is trapped in the oil reservoir by various means. Carbon dioxide as a solvent has the benefit of being more economical than other similarly miscible fluids such aspropane

Propane () is a three-carbon alkane with the molecular formula . It is a gas at standard temperature and pressure, but compressible to a transportable liquid. A by-product of natural gas processing and petroleum refining, it is commonly used as ...

and butane

Butane () or ''n''-butane is an alkane with the formula C4H10. Butane is a gas at room temperature and atmospheric pressure. Butane is a highly flammable, colorless, easily liquefied gas that quickly vaporizes at room temperature. The name but ...

.

Water-alternating-gas (WAG)

Water-alternating-gas (WAG) injection is another technique employed in EOR. Water is used in addition to carbon dioxide. A saline solution is used here so that carbonate formations in oil wells are not disturbed. Water and carbon dioxide are injected into the oil well for larger recovery, as they typically have low miscibility with oil. Use of both water and carbon dioxide also lowers the mobility of carbon dioxide, making the gas more effective at displacing the oil in the well. According to a study done by Kovscek, using small slugs of both carbon dioxide and water allows for quick recovery of the oil. Additionally, in a study done by Dang in 2014, using water with a lower salinity allows for greater oil removal, and greater geochemical interactions.Plasma-pulse

Plasma-pulse technology is a technique used in the US as of 2013. The technology originated in the Russian Federation at theSt. Petersburg State Mining University

ST, St, or St. may refer to:

Arts and entertainment

* Stanza, in poetry

* Suicidal Tendencies, an American heavy metal/hardcore punk band

* Star Trek, a science-fiction media franchise

* Summa Theologica, a compendium of Catholic philosoph ...

with funding and assistance from the Skolkovo Innovation Center. The development team in Russia and deployment teams across Russia, Europe and now the USA have tested this technology in vertical wells with nearly 90% of wells showing positive effects.

The Plasma-Pulse Oil Well EOR uses low energy emissions to create the same effect that many other technologies can produce except without negative ecological impact. In nearly every case the volume of water pulled with the oil is actually reduced from pre-EOR treatment instead of increased. Current clients and users of the new technology include ConocoPhillips, ONGC, Gazprom, Rosneft

PJSC Rosneft Oil Company ( stylized as ROSNEFT) is a Russian integrated energy company headquartered in Moscow. Rosneft specializes in the exploration, extraction, production, refining, transport, and sale of petroleum, natural gas, and petro ...

and Lukoil

The PJSC Lukoil Oil Company ( stylized as LUKOIL or ЛУКОЙЛ in Cyrillic script) is a Russian multinational energy corporation headquartered in Moscow, specializing in the business of extraction, production, transport, and sale of petrol ...

.

It is based in the same technology as the Russian pulsed plasma thruster

A pulsed plasma thruster (PPT), also known as a plasma jet engine, is a form of electric spacecraft propulsion. PPTs are generally considered the simplest form of electric spacecraft propulsion and were the first form of electric propulsion to be ...

which was used on two space ships and is currently being advanced for use in horizontal wells.

Economic costs and benefits

Adding oil recovery methods adds to the cost of oil—in the case of CO2 typically between 0.5–8.0 US$ per tonne of CO2. The increased extraction of oil on the other hand, is an economic benefit with the revenue depending on prevailing oil prices. Onshore EOR has paid in the range of a net 10–16 US$ per tonne of CO2 injected for oil prices of 15–20 US$/ barrel. Prevailing prices depend on many factors but can determine the economic suitability of any procedure, with more procedures and more expensive procedures being economically viable at higher prices. Example: With oil prices at around 90 US$/barrel, the economic benefit is about 70 US$ per tonne CO2. The U.S. Department of Energy estimates that 20 billion tons of captured CO2 could produce 67 billion barrels of economically recoverable oil. The oil and gas industry argues that the use of captured, anthropogenic carbon dioxide, derived from the exploitation oflignite

Lignite, often referred to as brown coal, is a soft, brown, combustible, sedimentary rock formed from naturally compressed peat. It has a carbon content around 25–35%, and is considered the lowest rank of coal due to its relatively low heat ...

coal reserves, to drive electric power generation and support EOR from existing and future oil and gas wells offers a multifaceted solution to U.S. energy, environmental, and economic challenges. There is no doubt that coal

Coal is a combustible black or brownish-black sedimentary rock, formed as rock strata called coal seams. Coal is mostly carbon with variable amounts of other elements, chiefly hydrogen, sulfur, oxygen, and nitrogen.

Coal is formed when ...

and oil resources are finite. The U.S. is in a strong position to leverage such traditional energy sources to supply future power needs while other sources are being explored and developed. For the coal industry

Coal is a combustible black or brownish-black sedimentary rock, formed as rock strata called coal seams. Coal is mostly carbon with variable amounts of other elements, chiefly hydrogen, sulfur, oxygen, and nitrogen.

Coal is formed when dead ...

, CO2 EOR creates a market for coal gasification byproducts

A by-product or byproduct is a secondary product derived from a production process, manufacturing process or chemical reaction; it is not the primary product or service being produced.

A by-product can be useful and marketable or it can be consid ...

and reduces the costs associated with carbon sequestration and storage.

From 1986 to 2008, the quote oil production deriving from EOR has increased from 0.3% to 5%, thanks to an increasing oil demand and a reduction of oil supply.

EOR projects with CO2 from carbon capture

Boundary Dam Power Station, Canada

SaskPower

Saskatchewan Power Corporation, operating as SaskPower, is the principal electric utility in Saskatchewan, Canada. Established in 1929 by the provincial government, it serves more than 538,000 customers and manages over $11.8 billion in assets. S ...

's Boundary Dam Power Station project retrofitted its coal-fired power station in 2014 with carbon capture and sequestration (CCS) technology. The plant will capture 1 million tonnes of annually, which it sold to Cenovus Energy

Cenovus Energy Inc. (pronounced se-nō-vus) is an integrated oil and natural gas company headquartered in Calgary, Alberta.

Cenovus was formed in 2009 when Encana Corporation split into two distinct companies, with Cenovus becoming focused on oi ...

for enhanced oil recovery at its Weyburn Oil Field

Weyburn is the eleventh-largest city in Saskatchewan, Canada. The city has a population of 10,870. It is on the Souris River southeast of the provincial capital of Regina and is north from the North Dakota border in the United States. The ...

, prior to the sale of Cenovus's Saskatchewan assets in 2017 to Whitecap Resources. The project is expected to inject a net 18 million ton CO2 and recover an additional of oil, extending the life of the oil field by 25 years. There is a projected 26+ million tonnes (net of production) of to be stored in Weyburn, plus another 8.5 million tonnes (net of production) stored at the Weyburn-Midale Carbon Dioxide Project

The Weyburn-Midale Carbon Dioxide Project (or IEA GHG Weyburn-Midale Monitoring and Storage Project) is, as of 2008, the world's largest carbon capture and storage project.Allan Casey, ''Carbon Cemetery'', Canadian Geographic Magazine, Jan/Feb 2 ...

, resulting in a net reduction in atmospheric CO2 by CO2 storage in the oilfield. That's the equivalent of taking nearly 7 million cars off the road for a year. Since CO2 injection began in late 2000, the EOR project has performed largely as predicted. Currently, some 1600 m3 (10,063 barrels) per day of incremental oil is being produced from the field.

Petra Nova, United States

ThePetra Nova

The Petra Nova project is a coal-energy-sector/clean-energy project designed to reduce carbon emissions from one of the boilers of a coal burning power plant in Thompsons, Texas. It is a multi-million dollar project taken up by NRG Energy and JX ...

project uses post-combustion amine absorption to capture some of the carbon dioxide emissions from one of the boilers at the W.A Parish

The W.A. Parish Generating Station is a 3.65-gigawatt (3,653 MW), dual-fired power plant located near Thompsons, Texas. The station occupies a 4,664-acre site near Smithers Lake southwest of Houston in Fort Bend County and consists of two four ...

power plant in Texas, and transports it by pipeline to the West Ranch oil field for use in enhanced oil recovery.

Kemper Project, United States (canceled)

Mississippi Power

Mississippi Power (NYSEMPJ is an investor-owned electric utility and a wholly owned subsidiary of Atlanta-based Southern Company. Mississippi Power Company (MPC) is headquartered in Gulfport, Mississippi.

Mississippi Power has 1,253 employees an ...

's Kemper County energy facility, or Kemper Project

The Kemper Project, also called the Kemper County energy facility or Plant Ratcliffe, is a natural gas-fired electrical generating station currently under construction in Kemper County, Mississippi. Mississippi Power, a subsidiary of Southern Com ...

, was to have been a first-of-its-kind plant in the U.S. that was expected to be online in 2015. Its coal gasification component has since been canceled, and the plant has been converted to a conventional natural gas combined cycle power plant without carbon capture. The Southern Company

Southern Company is an American gas and electric utility holding company based in the southern United States. It is headquartered in Atlanta, Georgia, with executive offices also located in Birmingham, Alabama. The company is the second larg ...

subsidiary worked with the U.S. Department of Energy and other partners with the intention to develop cleaner, less expensive, more reliable methods for producing electricity with coal that also support EOR production. The gasification technology was designated to fuel the integrated gasification combined cycle power plant. Additionally, the unique location of the Kemper Project, and its proximity to oil reserves, made it an ideal candidate for enhanced oil recovery.

Weyburn-Midale, Canada

In 2000,

In 2000, Saskatchewan

Saskatchewan ( ; ) is a Provinces and territories of Canada, province in Western Canada, western Canada, bordered on the west by Alberta, on the north by the Northwest Territories, on the east by Manitoba, to the northeast by Nunavut, and on t ...

's Weyburn-Midale oil field began to employ EOR as a method of oil extraction. In 2008, the oilfield became the world's largest storage site of carbon dioxide. The Carbon Dioxide comes through 320 km of pipeline from Dakota Gasification facility. It is estimated that the EOR project will store around 20 million tons of Carbon Dioxide, generate about 130 million barrels of oil, and extend the life of the field by over two decades. The site is also notable as it hosted a study on the effects of EOR on nearby seismic activity.

CO2 EOR in the United States

The United States has been using CO2 EOR for several decades. For over 30 years, oil fields in the Permian Basin have implemented EOR using naturally sourced from New Mexico and Colorado.Logan, Jeffrey and Venezia, John (2007"CO2-Enhanced Oil Recovery."

Excerpt from a WRI Policy Note, "Weighing U.S. Energy Options: The WRI Bubble Chart." World Resources Institute, Washington, DC. The Department of Energy (DOE) has estimated that full use of 'next generation' CO2-EOR in United States could generate an additional of recoverable oil resources. Developing this potential would depend on the availability of commercial CO2 in large volumes, which could be made possible by widespread use of carbon capture and storage. For comparison, the total undeveloped US domestic oil resources still in the ground total more than , most of it remaining unrecoverable. The DOE estimates that if the EOR potential were to be fully realized, state and local treasuries would gain $280 billion in revenues from future royalties, severance taxes, and state income taxes on oil production, aside from other economic benefits. The main barrier to taking further advantage of CO2 EOR in the United States has been an insufficient supply of affordable CO2. Currently, there is a cost gap between what an oilfield operation could afford to pay for CO2 under normal market conditions and the cost to capture and transport CO2 from power plants and industrial sources, so most CO2 comes from natural sources. However, using CO2 from power plants or industrial sources could reduce the carbon footprint (if the CO2 is stored underground). For some industrial sources, such as natural gas processing or fertilizer and ethanol production, the cost gap is small (potentially $10–20/tonne CO2). For other man-made sources of CO2, including power generation and a variety of industrial processes, capture costs are greater, and the cost gap becomes much larger (potentially $30–50/tonne CO2). The Enhanced Oil Recovery Initiative has brought together leaders from industry, the environmental community, labor, and state governments to advance CO2 EOR in the United States and close the price gap. In the US, regulations can both assist and slow down the development of EOR for use in carbon capture & utilization, as well as general oil production. One of the primary regulations governing EOR is the Safe Drinking Water Act of 1974 (SDWA), which gives most of the regulatory power over EOR and similar oil recovery operations to the

EPA

The Environmental Protection Agency (EPA) is an independent executive agency of the United States federal government tasked with environmental protection matters. President Richard Nixon proposed the establishment of EPA on July 9, 1970; it be ...

. The agency in turn delegated some of this power to its own Underground Injection Control Program, and much of the rest of this regulatory authority to state and tribal governments, making much of EOR regulation a localized affair under the minimum requirements of the SDWA. The EPA then collects information from these local governments and individual wells to ensure they follow overall federal regulation, such as the Clean Air Act, which dictates reporting guidelines for any Carbon Dioxide sequestration operations. Beyond the atmospheric concerns, most of these federal guidelines are to ensure that the Carbon Dioxide injection causes no major damage to America's waterways. Overall, the locality of EOR regulation can make EOR projects more difficult, as different standards in different regions can slow down construction and force separate approaches to utilize the same technology.

In February 2018, Congress passed and the President signed an expansion of the carbon capture tax credits defined in section 45Q of the IRS' Internal Revenue code. Previously, these credits were limited to $10/ton and capped at a total of 75 million tons. Under the expansion, carbon capture and utilization projects like EOR will be eligible for a tax credit of $35/ton, and sequestration projects will receive a $50/ton credit. The expanded tax credit would be available for 12 years to any plant constructed by 2024, with no volume cap. If successful, these credits "could help sequester between 200 million and 2.2 billion metric tons of carbon dioxide" and bring down carbon capture and sequestration costs from a currently estimated $60/ton at Petra Nova to as low as $10/ton.

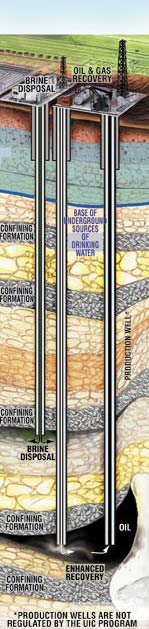

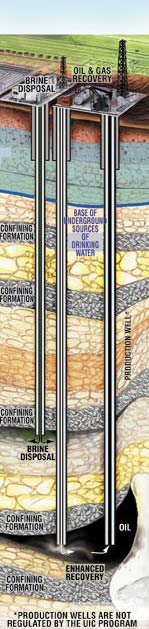

Environmental impacts

Enhanced oil recovery wells typically pump large quantities ofproduced water

Produced water is a term used in the oil industry or geothermal industry to describe water that is produced as a byproduct during the extraction of oil and natural gas, or used as a medium for heat extraction. Produced water is the kind of brackis ...

to the surface. This water contains brine and may also contain toxic

Toxicity is the degree to which a chemical substance or a particular mixture of substances can damage an organism. Toxicity can refer to the effect on a whole organism, such as an animal, bacterium, or plant, as well as the effect on a sub ...

heavy metals and radioactive substances. This can be very damaging to drinking water

Drinking water is water that is used in drink or food preparation; potable water is water that is safe to be used as drinking water. The amount of drinking water required to maintain good health varies, and depends on physical activity level, ...

sources and the environment generally if not properly controlled. Disposal wells are used to prevent surface contamination of soil and water by injecting the produced water deep underground.

In the United States, injection well activity is regulated by the United States Environmental Protection Agency

The Environmental Protection Agency (EPA) is an independent executive agency of the United States federal government tasked with environmental protection matters. President Richard Nixon proposed the establishment of EPA on July 9, 1970; it ...

(EPA) and state governments under the Safe Drinking Water Act. EPA has issued Underground Injection Control (UIC) regulations in order to protect drinking water sources. Enhanced oil recovery wells are regulated as "Class II" wells by the EPA. The regulations require well operators to reinject the brine used for recovery deep underground in Class II disposal wells.

See also

* Gas reinjection * Steam assisted gravity drainage * Water injection (oil production) * Wikiversity:Enhanced oil recoveryReferences

IPCC Special Report on Carbon dioxide Capture and Storage

Chapter 5, Underground geological storage. Intergovernmental Panel on Climate Change (IPCC), 2005.

ttps://web.archive.org/web/20090425063318/http://www.fossil.energy.gov/programs/oilgas/publications/eor_co2/Undeveloped_Oil_Document.pdf pdf// US Department of Energy, analysis of EOR potential. Game Changer Improvements Could Dramatically Increase Domestic Oil Resource Recovery. An analysis by Advanced Resources International, Arlington, VA, for the U.S. Department of Energy's Office of Fossil Energy. Advanced Resources International, February 2006. See als

press release

External links

Enhanced Oil Recovery Institute

– University of Wyoming

Licensable Technology: Particle Stabilized Emulsions of Carbon Dioxide & Water for Enhanced Oil Recovery & Extraction Processes

– Massachusetts Technology Portal

Oilfield Glossary: Enhanced Oil Recovery

– Schlumberger, Ltd.

Center for Petroleum and Geosystems Engineering

– University of Texas at Austin

Polymer Flooding, Reservoir Sweep Improvement, New Mexico Tech {{DEFAULTSORT:Enhanced Oil Recovery Petroleum production