Degree of reaction on:

[Wikipedia]

[Google]

[Amazon]

In

it is easy to see that for isentropic process ∆H ≃ ∆P. Hence it can be implied

:

The same can be expressed mathematically as:S.M,Yahya, Turbines, Compressors and Fans, 4th ed. McGraw,2011

:

Where 1 to 3ss in Figure 1 represents the isentropic process beginning from stator inlet at 1 to rotor outlet at 3. And 2 to 3s is the isentropic process from rotor inlet at 2 to rotor outlet at 3. The

it is easy to see that for isentropic process ∆H ≃ ∆P. Hence it can be implied

:

The same can be expressed mathematically as:S.M,Yahya, Turbines, Compressors and Fans, 4th ed. McGraw,2011

:

Where 1 to 3ss in Figure 1 represents the isentropic process beginning from stator inlet at 1 to rotor outlet at 3. And 2 to 3s is the isentropic process from rotor inlet at 2 to rotor outlet at 3. The  Another useful definition used commonly uses stage velocities as:

:

is the

Another useful definition used commonly uses stage velocities as:

:

is the

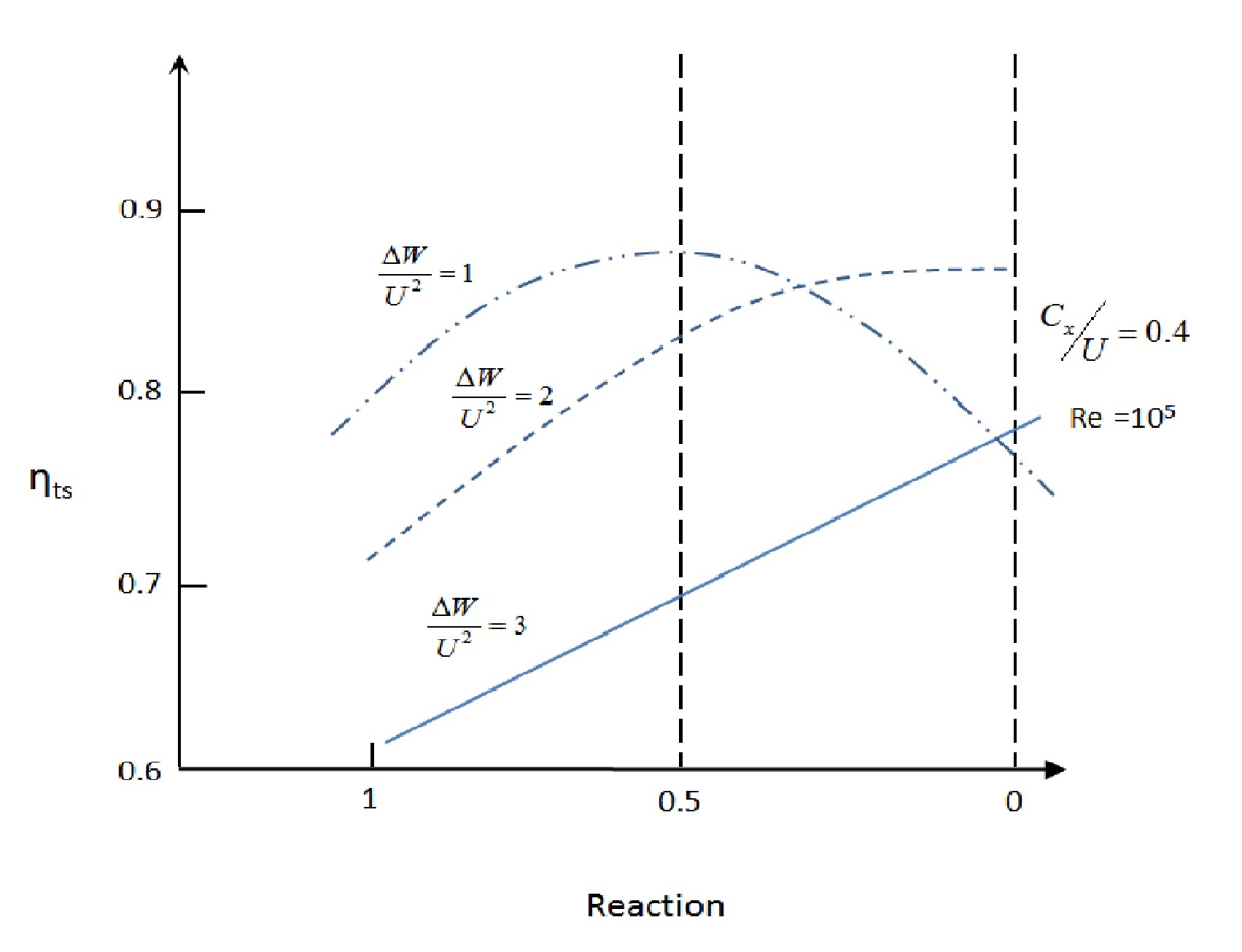

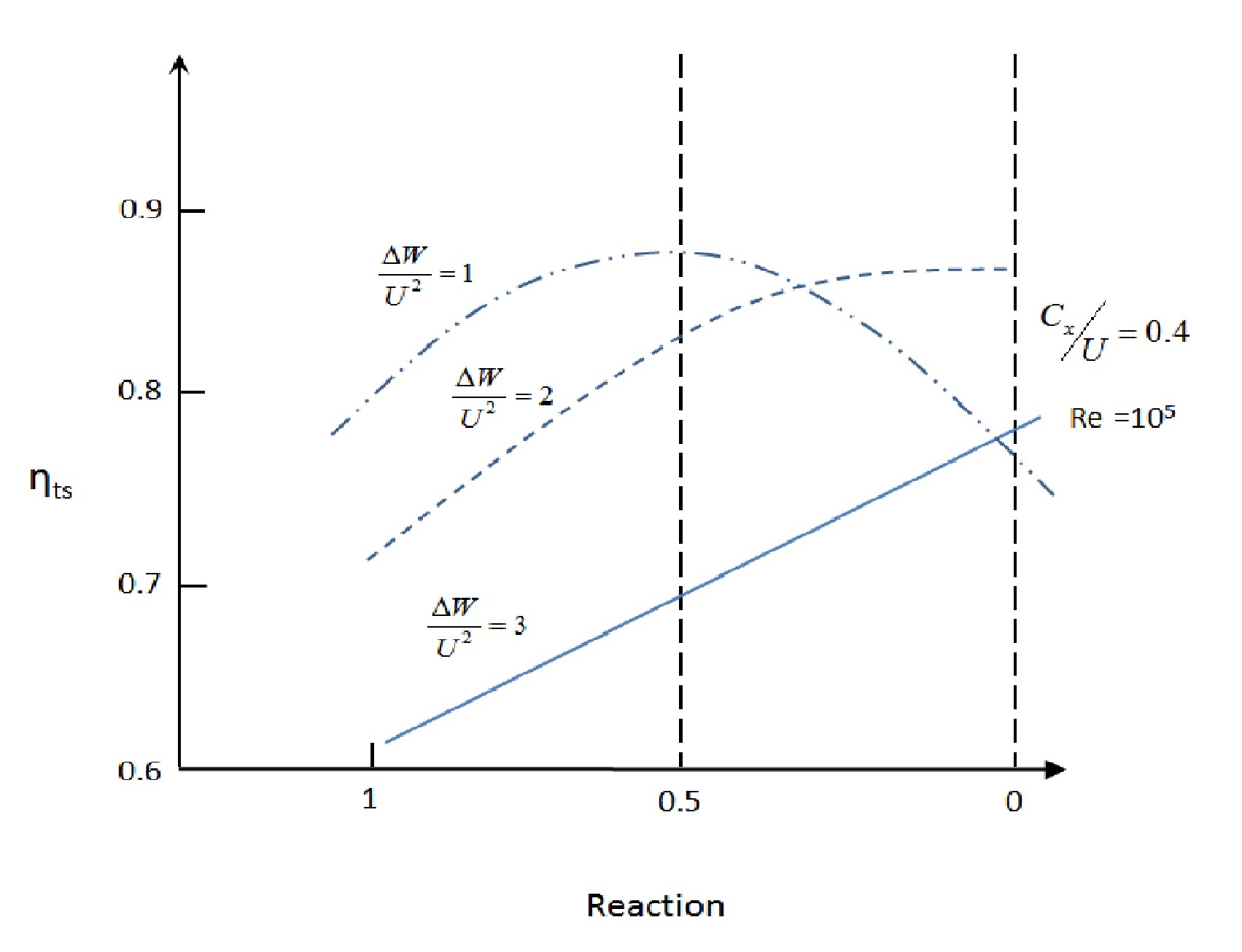

The Figure 3Shapiro, A. H., Soderberg, C. R., Stenning, A. H., Taylor, E. S. and Horlock, J. H. (1957). Notes on Turbomachinery. Department of Mechanical Engineering, Massachusetts Institute of Technology. alongside shows the variation of total-to-static efficiency at different blade loading coefficient with the degree of reaction.

The governing equation is written as

:

where

is the stage loading factor. The diagram shows the optimization of total - to - static efficiency at a given stage loading factor, by a suitable choice of reaction. It is evident from the diagram that for a fixed stage loading factor that there is a relatively small change in total-to-static efficiency for a wide range of designs.

The Figure 3Shapiro, A. H., Soderberg, C. R., Stenning, A. H., Taylor, E. S. and Horlock, J. H. (1957). Notes on Turbomachinery. Department of Mechanical Engineering, Massachusetts Institute of Technology. alongside shows the variation of total-to-static efficiency at different blade loading coefficient with the degree of reaction.

The governing equation is written as

:

where

is the stage loading factor. The diagram shows the optimization of total - to - static efficiency at a given stage loading factor, by a suitable choice of reaction. It is evident from the diagram that for a fixed stage loading factor that there is a relatively small change in total-to-static efficiency for a wide range of designs.

turbomachinery

Turbomachinery, in mechanical engineering, describes machines that transfer energy between a rotor and a fluid, including both turbines and compressors. While a turbine transfers energy from a fluid to a rotor, a compressor transfers energy from ...

, degree of reaction or reaction ratio (R) is defined as the ratio of the static pressure

Pressure (symbol: ''p'' or ''P'') is the force applied perpendicular to the surface of an object per unit area over which that force is distributed. Gauge pressure (also spelled ''gage'' pressure)The preferred spelling varies by country and e ...

rise in the rotating blades of a compressor (or drop in turbine blades) to the static pressure rise in the compressor stage (or drop in a turbine stage). Alternatively it is the ratio of static enthalpy

Enthalpy , a property of a thermodynamic system, is the sum of the system's internal energy and the product of its pressure and volume. It is a state function used in many measurements in chemical, biological, and physical systems at a constant ...

change in the rotor to the static enthalpy change in the stage.

Degree of reaction (R) is an important factor in designing the blades of a turbine

A turbine ( or ) (from the Greek , ''tyrbē'', or Latin ''turbo'', meaning vortex) is a rotary mechanical device that extracts energy from a fluid flow and converts it into useful work. The work produced by a turbine can be used for generating e ...

, compressors

A compressor is a mechanical device that increases the pressure of a gas by reducing its volume. An air compressor is a specific type of gas compressor.

Compressors are similar to pumps: both increase the pressure on a fluid and both can trans ...

, pumps

A pump is a device that moves fluids (liquids or gases), or sometimes slurries, by mechanical action, typically converted from electrical energy into hydraulic energy. Pumps can be classified into three major groups according to the method they ...

and other turbo-machinery

Turbomachinery, in mechanical engineering, describes machines that transfer energy between a rotor and a fluid, including both turbines and compressors. While a turbine transfers energy from a fluid to a rotor, a compressor transfers energy from ...

.

Various definitions exist in terms of enthalpies, pressures or flow geometry

Geometry (; ) is, with arithmetic, one of the oldest branches of mathematics. It is concerned with properties of space such as the distance, shape, size, and relative position of figures. A mathematician who works in the field of geometry is c ...

of the device.

In case of turbines

A turbine ( or ) (from the Greek , ''tyrbē'', or Latin ''turbo'', meaning vortex) is a rotary mechanical device that extracts energy from a fluid flow and converts it into useful Work (physics), work. The work produced by a turbine can be used ...

, both impulse and reaction machines, Degree of reaction (R) is defined as the ratio of energy transfer by the change in static head to the total energy transfer in the rotor

Rotor may refer to:

Science and technology

Engineering

*Rotor (electric), the non-stationary part of an alternator or electric motor, operating with a stationary element so called the stator

* Helicopter rotor, the rotary wing(s) of a rotorcraft ...

i.e.

:.

For a gas turbine

A gas turbine, also called a combustion turbine, is a type of continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part (known as the gas generator or core) and are, in the directi ...

or compressor it is defined as the ratio of isentropic

In thermodynamics, an isentropic process is an idealized thermodynamic process that is both adiabatic and reversible. The work transfers of the system are frictionless, and there is no net transfer of heat or matter. Such an idealized process ...

heat drop in the moving blades (i.e. the rotor) to the sum of the isentropic heat drops in the fixed blades (i.e. the stator) and the moving blades i.e.

:.

In pumps, degree of reaction deals in static and dynamic head. Degree of reaction is defined as the fraction of energy transfer by change in static head to the total energy transfer in the rotor i.e.

:.

Relation

Most turbo machines are efficient to a certain degree and can be approximated to undergo isentropic process in the stage. Hence from , it is easy to see that for isentropic process ∆H ≃ ∆P. Hence it can be implied

:

The same can be expressed mathematically as:S.M,Yahya, Turbines, Compressors and Fans, 4th ed. McGraw,2011

:

Where 1 to 3ss in Figure 1 represents the isentropic process beginning from stator inlet at 1 to rotor outlet at 3. And 2 to 3s is the isentropic process from rotor inlet at 2 to rotor outlet at 3. The

it is easy to see that for isentropic process ∆H ≃ ∆P. Hence it can be implied

:

The same can be expressed mathematically as:S.M,Yahya, Turbines, Compressors and Fans, 4th ed. McGraw,2011

:

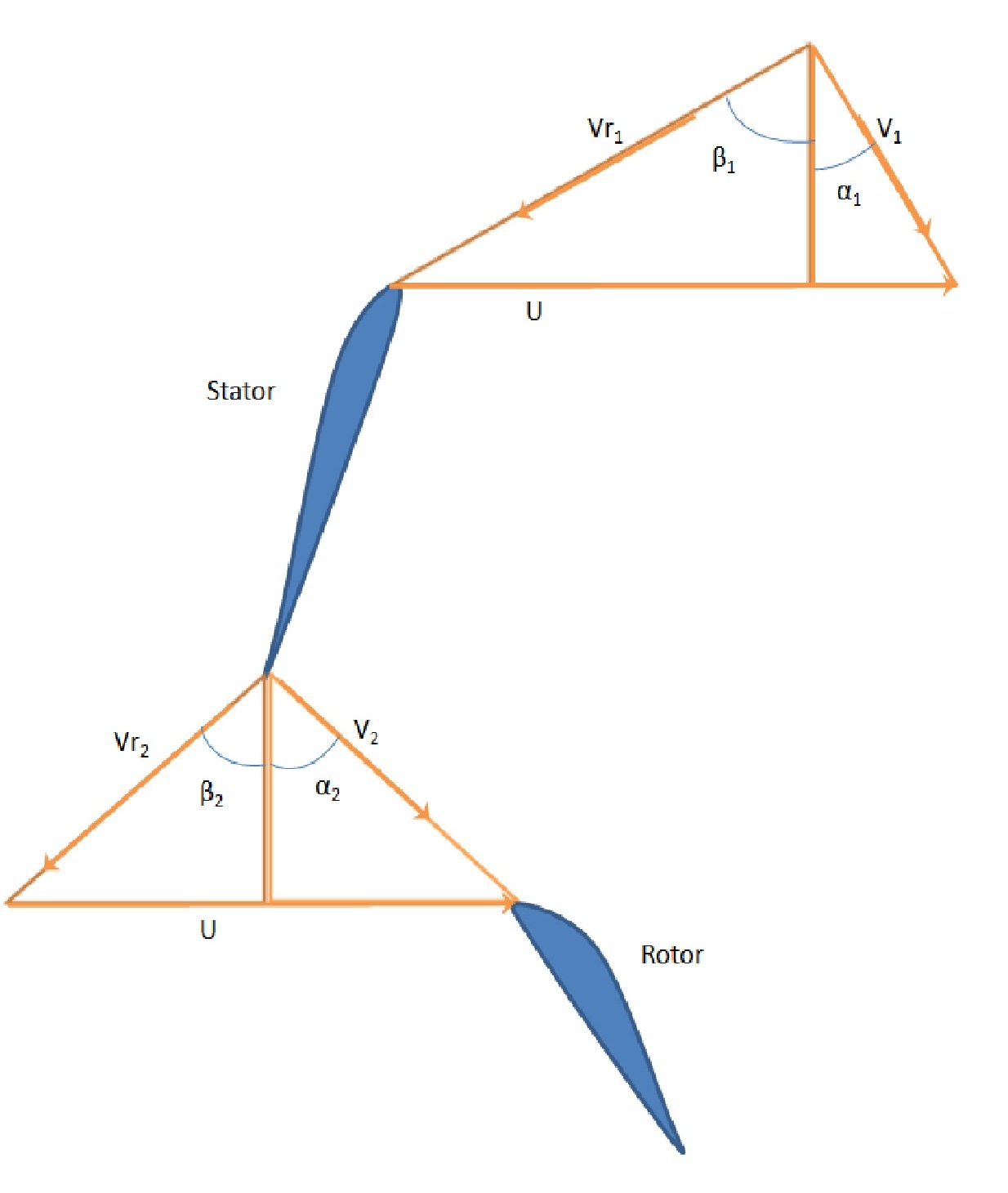

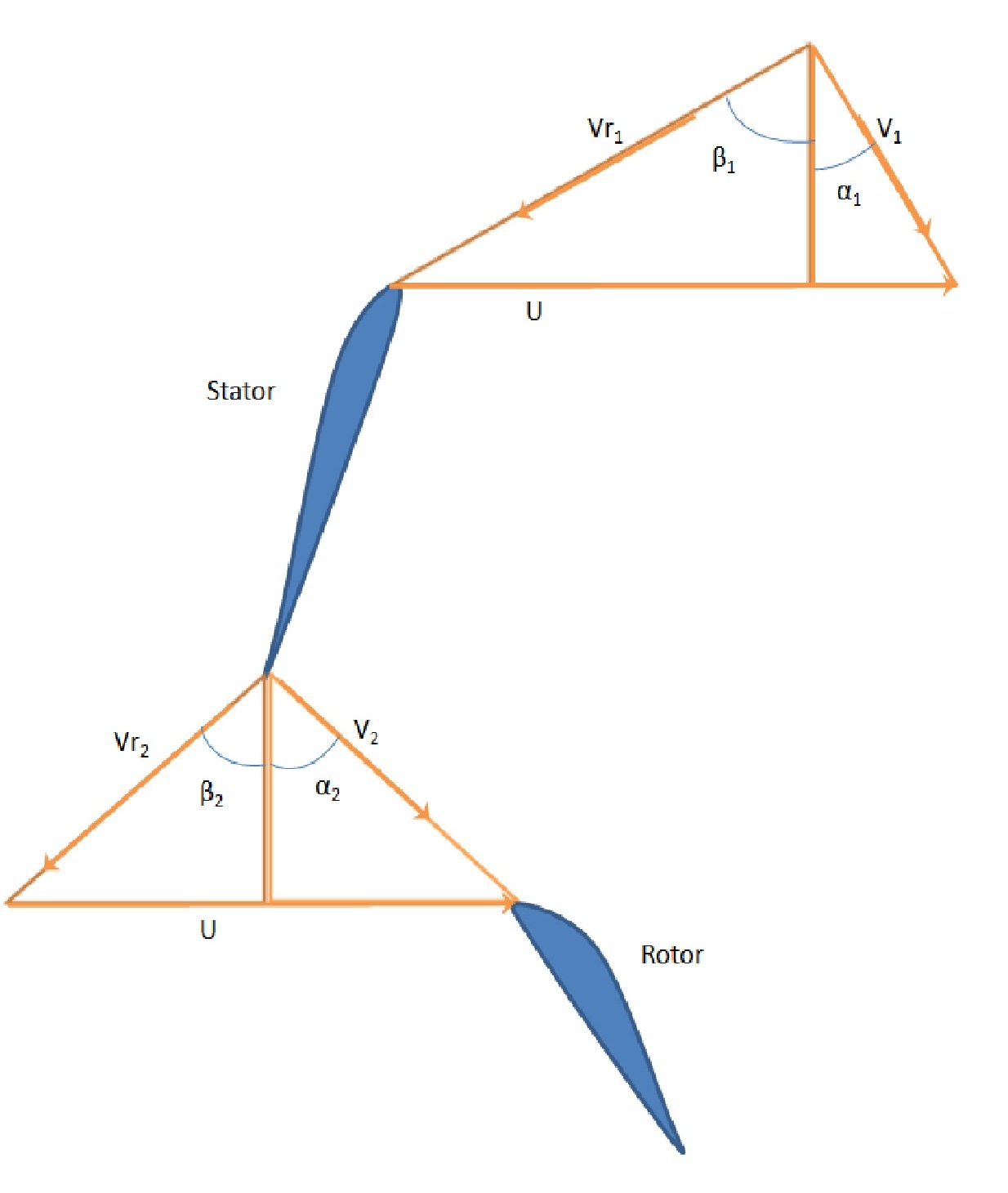

Where 1 to 3ss in Figure 1 represents the isentropic process beginning from stator inlet at 1 to rotor outlet at 3. And 2 to 3s is the isentropic process from rotor inlet at 2 to rotor outlet at 3. The velocity triangle In turbomachinery, a velocity triangle or a velocity diagram is a triangle representing the various components of velocities of the working fluid in a turbomachine. Velocity triangles may be drawn for both the inlet and outlet sections of any turbo ...

(Figure 2.) for the flow process within the stage represents the change in fluid velocity as it flows first in the stator or the fixed blades and then through the rotor or the moving blades. Due to the change in velocities there is a corresponding pressure change.

Another useful definition used commonly uses stage velocities as:

:

is the

Another useful definition used commonly uses stage velocities as:

:

is the enthalpy

Enthalpy , a property of a thermodynamic system, is the sum of the system's internal energy and the product of its pressure and volume. It is a state function used in many measurements in chemical, biological, and physical systems at a constant ...

drop in the rotor and

:

is the total enthalpy

Enthalpy , a property of a thermodynamic system, is the sum of the system's internal energy and the product of its pressure and volume. It is a state function used in many measurements in chemical, biological, and physical systems at a constant ...

drop. The degree of reaction is then expressed asDixon, S. L., Fluid Mechanics and Thermodynamics of Turbo-machinery, 5th ed. Elsevier,2011.

:

For axial machines , then

:

The degree of reaction can also be written in terms of the geometry of the turbomachine as obtained by

:

where is the vane angle of rotor outlet and is the vane angle of stator outlet. In practice is substituted as ϕ and as giving The degree of reaction now depends only on ϕ and which again depend on geometrical parameters β3 and β2 i.e. the vane angles of stator outlet and rotor outlet. Using the velocity triangles degree of reaction can be derived as:

:

This relation is again very useful when the rotor blade angle and rotor vane angle are defined for the given geometry.

Choice of reaction (R) and effect on efficiency

The Figure 3Shapiro, A. H., Soderberg, C. R., Stenning, A. H., Taylor, E. S. and Horlock, J. H. (1957). Notes on Turbomachinery. Department of Mechanical Engineering, Massachusetts Institute of Technology. alongside shows the variation of total-to-static efficiency at different blade loading coefficient with the degree of reaction.

The governing equation is written as

:

where

is the stage loading factor. The diagram shows the optimization of total - to - static efficiency at a given stage loading factor, by a suitable choice of reaction. It is evident from the diagram that for a fixed stage loading factor that there is a relatively small change in total-to-static efficiency for a wide range of designs.

The Figure 3Shapiro, A. H., Soderberg, C. R., Stenning, A. H., Taylor, E. S. and Horlock, J. H. (1957). Notes on Turbomachinery. Department of Mechanical Engineering, Massachusetts Institute of Technology. alongside shows the variation of total-to-static efficiency at different blade loading coefficient with the degree of reaction.

The governing equation is written as

:

where

is the stage loading factor. The diagram shows the optimization of total - to - static efficiency at a given stage loading factor, by a suitable choice of reaction. It is evident from the diagram that for a fixed stage loading factor that there is a relatively small change in total-to-static efficiency for a wide range of designs.

50% reaction

The degree of reaction contributes to the stage efficiency and thus used as a design parameter. Stages having 50% degree of reaction are used where the pressure drop is equally shared by the stator and therotor

Rotor may refer to:

Science and technology

Engineering

*Rotor (electric), the non-stationary part of an alternator or electric motor, operating with a stationary element so called the stator

* Helicopter rotor, the rotary wing(s) of a rotorcraft ...

for a turbine

A turbine ( or ) (from the Greek , ''tyrbē'', or Latin ''turbo'', meaning vortex) is a rotary mechanical device that extracts energy from a fluid flow and converts it into useful work. The work produced by a turbine can be used for generating e ...

.

This reduces the tendency of boundary layer

In physics and fluid mechanics, a boundary layer is the thin layer of fluid in the immediate vicinity of a bounding surface formed by the fluid flowing along the surface. The fluid's interaction with the wall induces a no-slip boundary condi ...

separation from the blade surface avoiding large stagnation pressure

In fluid dynamics, stagnation pressure is the static pressure at a stagnation point in a fluid flow.Clancy, L.J., ''Aerodynamics'', Section 3.5 At a stagnation point the fluid velocity is zero. In an incompressible flow, stagnation pressure is equ ...

losses.

If R= then from the relation of degree of reaction,, , α2 = β3 and the velocity triangle In turbomachinery, a velocity triangle or a velocity diagram is a triangle representing the various components of velocities of the working fluid in a turbomachine. Velocity triangles may be drawn for both the inlet and outlet sections of any turbo ...

(Figure 4.) is symmetric. The stage enthalpy

Enthalpy , a property of a thermodynamic system, is the sum of the system's internal energy and the product of its pressure and volume. It is a state function used in many measurements in chemical, biological, and physical systems at a constant ...

gets equally distributed in the stage (Figure 5.) . In addition the whirl

Whirl may refer to:

Spinning

* Whirling, a dance genre

* Whirl (''Transformers''), a character in the ''Transformers'' franchise

* Tilt-A-Whirl, a type of amusement ride

* Atomic whirl, a symbol of atheism

* ''Whirl'' magazine, a luxury lifesty ...

components are also the same at the inlet of rotor

Rotor may refer to:

Science and technology

Engineering

*Rotor (electric), the non-stationary part of an alternator or electric motor, operating with a stationary element so called the stator

* Helicopter rotor, the rotary wing(s) of a rotorcraft ...

and diffuser

Diffuser may refer to:

Aerodynamics

* Diffuser (automotive), a shaped section of a car's underbody which improves the car's aerodynamic properties

* Part of a jet engine air intake, especially when operated at supersonic speeds

* The channel bet ...

.

Reaction less than 50%

Stage having reaction less than half suggest that pressure drop or enthalpy drop in the rotor is less than the pressure drop in the stator for the turbine. The same follows for a pump or compressor as shown in Figure 6. From the relation for degree of reaction, , , α2 > β3.

Reaction more than 50%

Stage having reaction more than half suggest that pressure drop or enthalpy drop in the rotor is more than the pressure drop in the stator for the turbine. The same follows for a pump or compressor. From the relation for degree of reaction,, , α2 < β3 which is also shown in corresponding Figure 7.Reaction = zero

This is special case used for impulse turbine which suggest that entire pressure drop in the turbine is obtained in the stator. The stator performs a nozzle action converting pressure head to velocity head. It is difficult to achieve adiabatic expansion in the impulse stage, i.e. expansion only in the nozzle, due to irreversibility involved, in actual practice. Figure 8 shows the corresponding enthalpy drop for the reaction = 0 case.

References

Further reading and works referred to

* Gopalakrishnan, G. and Prithvi Raj, D., A Treatise on Turbomachines, Scitech, Chennai, India, 2012 * * Shepherd, D.G., Principles of Turbomachinery, Ninth Printing, Macmillan, 1969 * Wisclicenus,G.F., Fluid Mechanics of Turbomachinery, McGraw-Hill, New York, 1947 * Thomson, W.R., Preliminary Design of Gas Turbines, Emmott and CO. Ltd., London, 1963 * Traupel, W., Thermische Turbomachinen, 3rd Edn, Springer Verlag, Berlin, 1978 * Ainley, D. G. and Mathieson, G. C. R. (1951). A method of performance estimation for axial flow turbines. ARC R. and M. * Dunham, J. and Panton, J. (1973). Experiments on the design of a small axial turbine. Conference Publication 3, Instn. Mech. Engrs. * Horlock, J. H. (1960). Losses and efficiencies in axial-flow turbines. Int. J. Mech. Sci., * Kim, T. H., Takao, M., Setoguchi, T., Kaneko, K. and Inoue, M. (2001). Performance comparison of turbines for wave power conversion. Int. J. Therm. Sci., * http://www.physicsforums.com/archive/index.php/t-243219.html * https://www.scribd.com/doc/55453233/18/Degree-of-reaction {{DEFAULTSORT:Degree of Reaction Turbines Steam turbines Pumps Gas compressors Ventilation fans Hydraulic engineering