Cylinder (locomotive) on:

[Wikipedia]

[Google]

[Amazon]

The cylinder is the power-producing element of the

The cylinder is the power-producing element of the

The next stage, for example '' Stephenson's Rocket'', was to drive the wheels directly from steeply inclined cylinders placed at the back of the locomotive. Direct drive became the standard arrangement, but the cylinders were moved to the front and placed either horizontal or nearly horizontal.

The next stage, for example '' Stephenson's Rocket'', was to drive the wheels directly from steeply inclined cylinders placed at the back of the locomotive. Direct drive became the standard arrangement, but the cylinders were moved to the front and placed either horizontal or nearly horizontal.

* Inside valve gear driving inside valves, e.g.

* Inside valve gear driving inside valves, e.g.

There are many other variations, e.g. geared steam locomotives which may have only one cylinder.

The only conventional steam locomotive with one cylinder that is known is the Nielson One-Cylinder Locomotive.

There are many other variations, e.g. geared steam locomotives which may have only one cylinder.

The only conventional steam locomotive with one cylinder that is known is the Nielson One-Cylinder Locomotive.

The cylinder is the power-producing element of the

The cylinder is the power-producing element of the steam engine

A steam engine is a heat engine that performs mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a cylinder. This pushing force can be trans ...

powering a steam locomotive

A steam locomotive is a locomotive that provides the force to move itself and other vehicles by means of the expansion of steam. It is fuelled by burning combustible material (usually coal, oil or, rarely, wood) to heat water in the locomot ...

. The cylinder

A cylinder (from ) has traditionally been a three-dimensional solid, one of the most basic of curvilinear geometric shapes. In elementary geometry, it is considered a prism with a circle as its base.

A cylinder may also be defined as an infin ...

is made pressure-tight with end covers and a piston; a valve distributes the steam to the ends of the cylinder. Cylinders were cast in iron and later made of steel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant ty ...

. The cylinder casting includes other features such as (in the case of the early Rocket locomotive

Stephenson's ''Rocket'' is an early steam locomotive of 0-2-2 wheel arrangement. It was built for and won the Rainhill Trials of the Liverpool and Manchester Railway (L&MR), held in October 1829 to show that improved locomotives would be mor ...

) valve ports and mounting feet. The last big American locomotives incorporated the cylinders as part of huge one-piece steel castings that were the main frame of the locomotive. Renewable wearing surfaces were needed inside the cylinders and provided by cast-iron bushings.

The way the valve controlled the steam entering and leaving the cylinder was known as steam distribution and shown by the shape of the indicator diagram

An indicator diagram is a chart used to measure the thermal, or cylinder, performance of reciprocating steam and internal combustion engines and compressors. An indicator chart records the pressure in the cylinder versus the volume swept by the ...

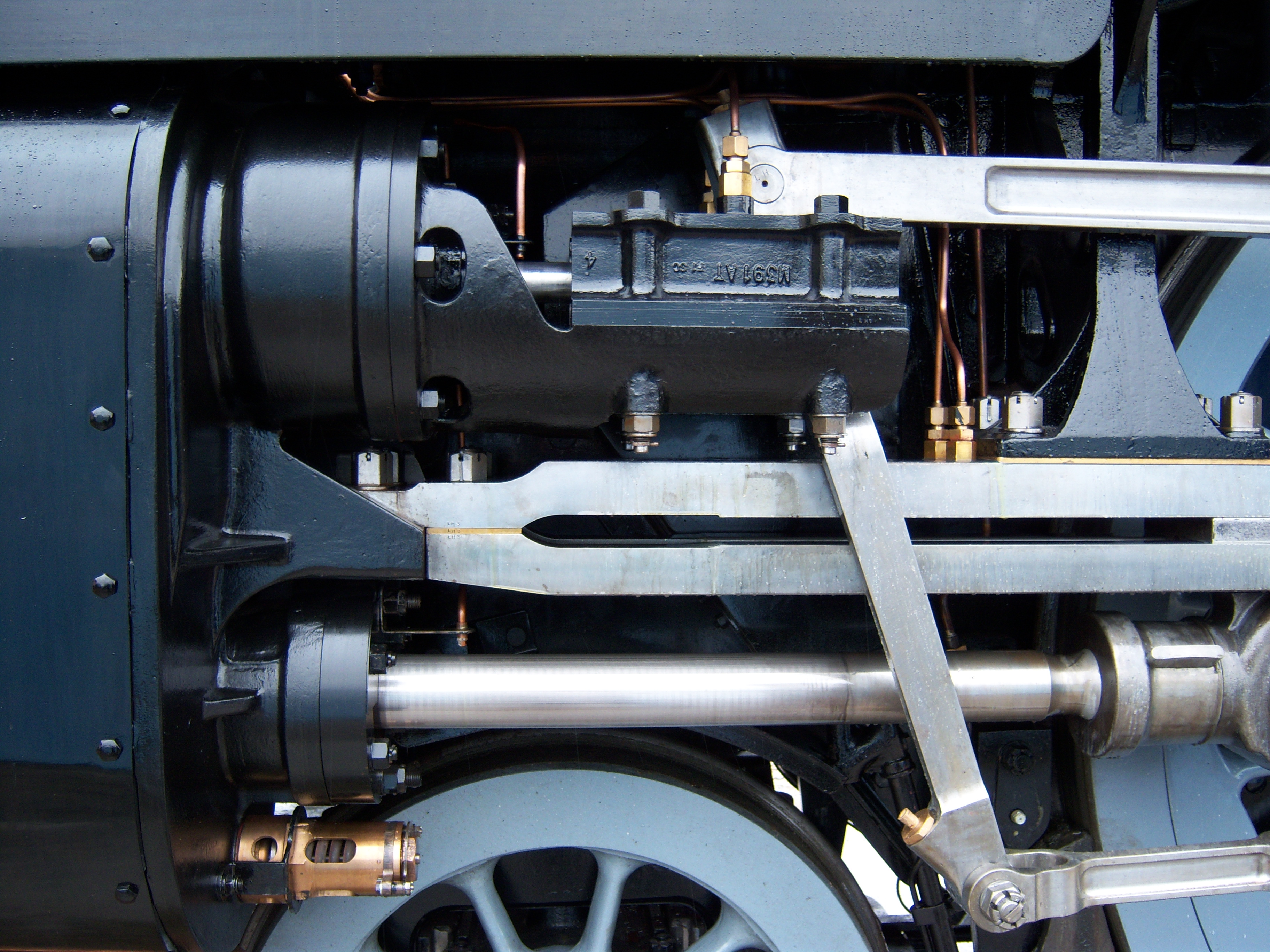

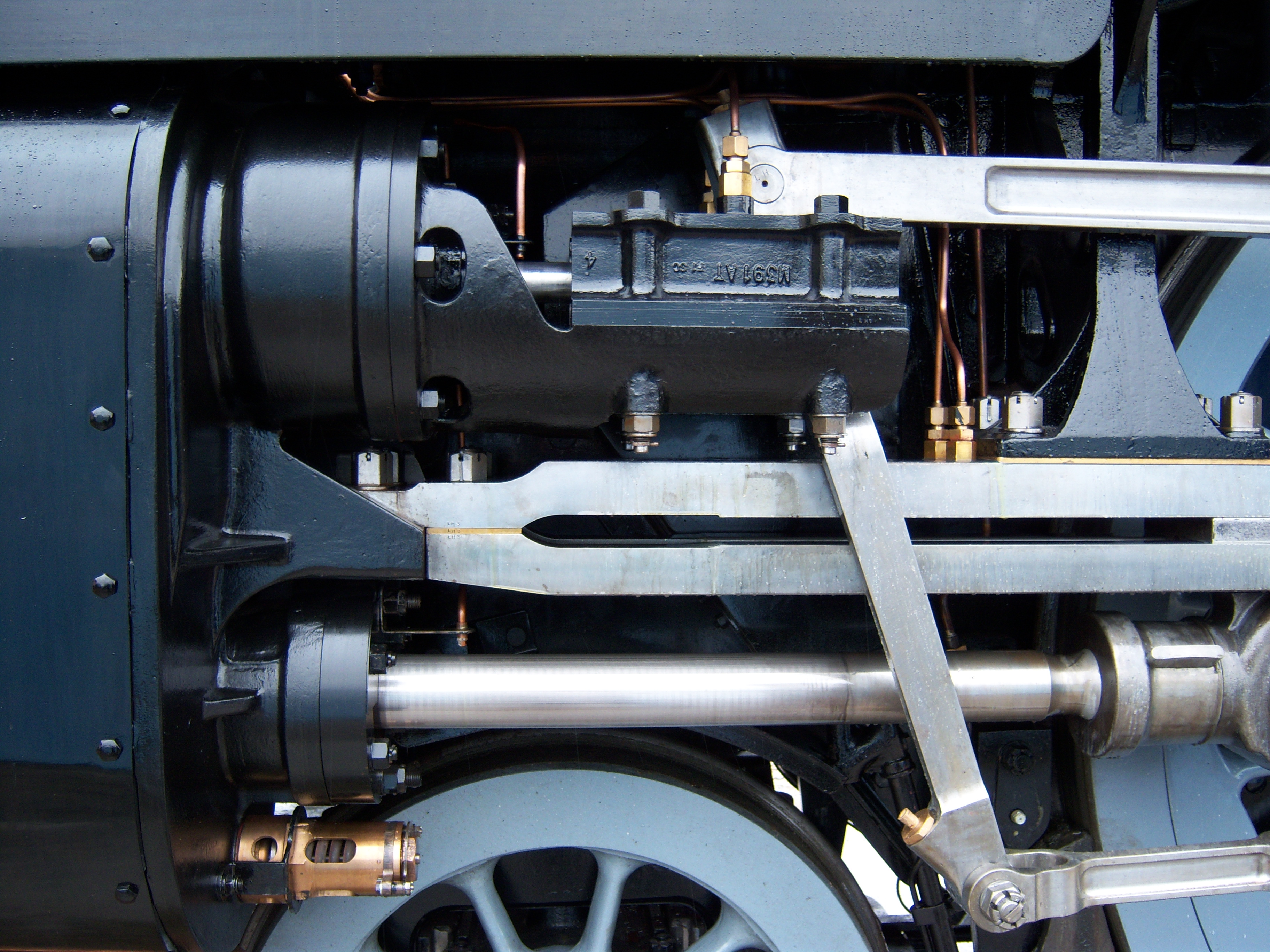

. What happened to the steam inside the cylinder was assessed separately from what happened in the boiler and how much friction the moving machinery had to cope with. This assessment was known as "engine performance" or "cylinder performance". The cylinder performance, together with the boiler and machinery performance, established the efficiency of the complete locomotive. The pressure of the steam in the cylinder was measured as the piston moved and the power moving the piston was calculated and known as cylinder power. The forces produced in the cylinder moved the train but were also damaging to the structure which held the cylinders in place. Bolted joints came loose, cylinder castings and frames cracked and reduced the availability of the locomotive.

Cylinders may be arranged in several different ways.

Early locomotives

On early locomotives, such as '' Puffing Billy'', the cylinders were often set vertically and the motion was transmitted through beams, as in a beam engine.Direct drive

The next stage, for example '' Stephenson's Rocket'', was to drive the wheels directly from steeply inclined cylinders placed at the back of the locomotive. Direct drive became the standard arrangement, but the cylinders were moved to the front and placed either horizontal or nearly horizontal.

The next stage, for example '' Stephenson's Rocket'', was to drive the wheels directly from steeply inclined cylinders placed at the back of the locomotive. Direct drive became the standard arrangement, but the cylinders were moved to the front and placed either horizontal or nearly horizontal.

Inside or outside cylinders

The front-mounted cylinders could be placed either inside (between the frames) or outside. Examples of each are: * Inside cylinders, on the ''Planet

A planet is a large, rounded astronomical body that is neither a star nor its remnant. The best available theory of planet formation is the nebular hypothesis, which posits that an interstellar cloud collapses out of a nebula to create a you ...

'' locomotive

* Outside cylinders, on Stephenson's Rocket

In the 19th and early 20th centuries, inside cylinders were widely used in the United Kingdom, but outside cylinders were more common in Continental Europe

Continental Europe or mainland Europe is the contiguous continent of Europe, excluding its surrounding islands. It can also be referred to ambiguously as the European continent, – which can conversely mean the whole of Europe – and, by ...

and the United States. The reason for this difference is unclear. From about 1920, outside cylinders became more common in the UK but many inside-cylinder engines continued to be built. Inside cylinders give a more stable ride with less yaw or "nosing" but access for maintenance is more difficult. Some designers used inside cylinders for aesthetic reasons.

Three or four cylinders

The demand for more power led to the development of engines with three cylinders (two outside and one inside) or four cylinders (two outside and two inside). Examples: * Three cylinders,SR Class V

The SR V class, more commonly known as the ''Schools'' class, is a class of steam locomotive designed by Richard Maunsell for the Southern Railway. The class was a cut down version of his ''Lord Nelson'' class but also incorporated component ...

, LNER Class A4, Merchant Navy class

* Four Cylinders, LMS Princess Royal Class

The London, Midland and Scottish Railway (LMS) Princess Royal Class is a class of express passenger 4-6-2 steam locomotive designed by William Stanier. Twelve examples were built at Crewe Works, between 1933 and 1935, for use on the West Coast ...

, LMS Coronation Class

The London, Midland and Scottish Railway (LMS) Coronation Class is a class of express passenger steam locomotives designed by William Stanier. They were an enlarged and improved version of his previous design, the LMS Princess Royal Class, an ...

, GWR Castle Class

The 4073 or Castle Class are 4-6-0 steam locomotives of the Great Western Railway, built between 1923 and 1950. They were designed by the railway's Chief Mechanical Engineer, Charles Collett, for working the company's express passenger trains. ...

Crank angles

On a two-cylinder engine the cranks, whether inside or outside, are set at 90 degrees. As the cylinders are double-acting (i.e. fed with steam alternately at each end) this gives four impulses per revolution and ensures that there are no dead centres. On a three-cylinder engine, two arrangements are possible: * cranks set to give six equally spaced impulses per revolution – the usual arrangement. If the three cylinder axes are parallel, the cranks will be 120 degrees apart, but if the centre cylinder does not drive the leading driving axle, it will probably be inclined (as on most US three-cylinder locomotives and on some of Gresley's three-cylinder locomotives in Great Britain), and the inside crank will be correspondingly shifted from 120 degrees. For a given tractive effort and adhesion factor, a three-cylinder locomotive of this design will be less prone to wheelslip when starting than a 2-cylinder locomotive. * outside cranks set at 90 degrees, inside crank set at 135 degrees, giving six unequally spaced impulses per revolution. This arrangement was sometimes used on three-cylindercompound locomotive

A compound locomotive is a steam locomotive which is powered by a compound engine, a type of steam engine where steam is expanded in two or more stages. The locomotive was only one application of compounding. Two and three stages were used in shi ...

s which used the outside (low pressure) cylinders for starting. This will give evenly spaced exhausts when the engine is working compound.

Two arrangements are also possible on a four-cylinder engine:

* all four cranks set at 90 degrees. With this arrangement the cylinders act in pairs, so there are four impulses per revolution, as with a two-cylinder engine. Most four-cylinder engines are of this type. It is cheaper and simpler to use only one set of valve gear on each side of the locomotive and to operate the second cylinder on that side by means of a rocking shaft from the first cylinder's valve spindle since the required valve events at the second cylinder are a mirror image of the first cylinder.

* pairs of cranks set at 90 degrees with the inside pair set at 45 degrees to the outside pair. This gives eight impulses per revolution. It increases weight and complexity, by requiring four sets of valve gear

The valve gear of a steam engine is the mechanism that operates the inlet and exhaust valves to admit steam into the cylinder and allow exhaust steam to escape, respectively, at the correct points in the cycle. It can also serve as a reversing ...

, but gives smoother torque

In physics and mechanics, torque is the rotational equivalent of linear force. It is also referred to as the moment of force (also abbreviated to moment). It represents the capability of a force to produce change in the rotational motion of th ...

and reduces the risk of slipping

Slipping is a technique used in boxing that is similar to bobbing. It is considered one of the four basic defensive strategies, along with blocking, holding, and clinching. It is performed by moving the head to either side so that the opponent ...

. This was relatively unusual in British practice but was used on the SR Lord Nelson class

The SR class LN or ''Lord Nelson'' class is a type of 4-cylinder 4-6-0 steam locomotive designed for the Southern Railway by Richard Maunsell in 1926. They were intended for Continental boat trains between London (Victoria) and Dover harbour ...

. Such locomotives are easily distinguished by their exhaust beats, which occur at twice the frequency of a normal 2- or 4-cylinder engine.

Valves

The valve chests or steam chests which contain the slide valves orpiston valve

A "piston valve" is a device used to control the motion of a fluid along a tube or pipe by means of the linear motion of a piston within a chamber or cylinder.

Examples of piston valves are:

* The valves used in many brass instruments

* The va ...

s may be located in various positions.

Inside cylinders

If the cylinders are small, the valve chests may be located between the cylinders. For larger cylinders the valve chests are usually on top of the cylinders but, in early locomotives, they were sometimes underneath the cylinders.Outside cylinders

The valve chests are usually on top of the cylinders but, in older locomotives, the valve chests were sometimes located alongside the cylinders and inserted through slots in the frames. This meant that, while the cylinders were outside, the valves were inside and could be driven by inside valve gear.Valve gear

There are many variations in the location of thevalve gear

The valve gear of a steam engine is the mechanism that operates the inlet and exhaust valves to admit steam into the cylinder and allow exhaust steam to escape, respectively, at the correct points in the cycle. It can also serve as a reversing ...

. In British practice, inside valve gear is usually of the Stephenson type while outside valve gear is usually of the Walschaerts

The Walschaerts valve gear is a type of valve gear used to regulate the flow of steam to the pistons in steam locomotives, invented by Belgian railway engineer Egide Walschaerts in 1844.

The gear is sometimes named without the final "s", since ...

type. However, this is not a rigid rule and most types of valve gear are capable of being used either inside or outside. Joy valve gear was once popular, e.g. on the LNWR G Class

The London and North Western Railway (LNWR) Class G were several related classes of 0-8-0 steam locomotives. These 0-8-0s were the principal work-horses for freight traffic on the latter-day London & North Western.

History

32 of this class ...

.

Inside cylinders

On inside-cylinder engines the valve gear is nearly always inside (between the frames), e.g.LMS Fowler Class 3F

The London Midland and Scottish Railway (LMS) Fowler 3F is a class of steam locomotive, often known as Jinty. They represent the ultimate development of the Midland Railway's six-coupled tank engines. They could reach speeds of up to 60 ...

.

On some locomotives the valve gear is located outside the frames, e.g. Italian State Railways Class 640.

Outside cylinders

On engines with outside cylinders there are three possible variations: * Inside valve gear driving inside valves, e.g.

* Inside valve gear driving inside valves, e.g. NER Class T2

The North Eastern Railway Class T2, classified as Class Q6 by the LNER, is a class of 0-8-0 steam locomotive designed for heavy freight, especially for hauling long coal trains to various collieries in the North Eastern region of the UK, with ...

* Inside valve gear driving outside valves through rocking shafts, e.g. GWR 4900 Class

The Great Western Railway 4900 Class or Hall Class is a class of 4-6-0 mixed-traffic steam locomotives designed by Charles Collett for the Great Western Railway. A total of 259 were built at Swindon Works, numbered 4900–4999, 5900–5999 ...

* Outside valve gear driving outside valves, e.g. LSWR N15 Class

The LSWR N15 class was a British 2–cylinder 4-6-0 express passenger steam locomotive designed by Robert W. Urie. The class has a complex build history spanning three sub-classes and eight years of construction from 1918 to 1927. The first b ...

Three cylinders

There are three common variations: * Three sets of valve gear (two outside, one inside), e.g.LNER Peppercorn Class A2

The London and North Eastern Railway (LNER) Peppercorn Class A2 is a class of steam locomotive designed for express passenger work by Arthur Peppercorn, the chief designer of the LNER after Edward Thompson. All save the first of the 15 bu ...

* Outside valve gear driving the outside valves. Inside valve driven by Gresley conjugated valve gear, e.g. LNER Class A1/A3

The London and North Eastern Railway LNER Gresley Classes A1 and A3 locomotives represented two distinct stages in the history of the British "Pacific" steam locomotives designed by Nigel Gresley. They were designed for main line passenger se ...

* Three sets of inside valve gear (all valves inside), e.g. NER Class T3

North Eastern Railway Class T3, classified Q7 by the LNER is a class of 0-8-0 steam locomotive designed for heavy freight. Five were built by the NER in 1919 and a further 10 by the London and North Eastern Railway (LNER) in 1924.

Perform ...

Four cylinders

There are three common variations: * Four sets of valve gear (two outside, two inside), e.g.SR Lord Nelson class

The SR class LN or ''Lord Nelson'' class is a type of 4-cylinder 4-6-0 steam locomotive designed for the Southern Railway by Richard Maunsell in 1926. They were intended for Continental boat trains between London (Victoria) and Dover harbour ...

* Inside valve gear driving the inside valves directly and the outside valves via rocking shafts, e.g. GWR 4073 Class

The 4073 or Castle Class are 4-6-0 steam locomotives of the Great Western Railway, built between 1923 and 1950. They were designed by the railway's Chief Mechanical Engineer, Charles Collett, for working the company's express passenger trains. ...

* Outside valve gear driving the outside valves directly and the inside valves via rocking shafts, e.g. LMS Princess Coronation Class

The London, Midland and Scottish Railway (LMS) Coronation Class is a class of express passenger steam locomotives designed by William Stanier. They were an enlarged and improved version of his previous design, the LMS Princess Royal Class, a ...

Other variations

See also

*Cylinder bore

In a piston engine, the bore (or cylinder bore) is the diameter of each cylinder.

Engine displacement is calculated based on bore, stroke length and the number of cylinders:

displacement =

The stroke ratio, determined by dividing the bore by ...

* Cylinder (engine)

In a reciprocating engine, the cylinder is the space in which a piston travels.

The inner surface of the cylinder is formed from either a thin metallic liner (also called "sleeve") or a surface coating applied to the engine block. A piston is s ...

* Cylinder stroke

* Hydrolock

Hydrolock (a shorthand notation for hydrostatic lock or hydraulic lock) is an abnormal condition of any device which is designed to compress a gas by mechanically restraining it; most commonly the reciprocating internal combustion engine, the ...

* Steam locomotive components

References

{{Steam engine configurations Locomotive parts Steam locomotive technologies