A cathode-ray tube (CRT) is a

vacuum tube

A vacuum tube, electron tube, valve (British usage), or tube (North America), is a device that controls electric current flow in a high vacuum between electrodes to which an electric potential difference has been applied.

The type known as ...

containing one or more

electron gun

An electron gun (also called electron emitter) is an electrical component in some vacuum tubes that produces a narrow, collimated electron beam that has a precise kinetic energy. The largest use is in cathode-ray tubes (CRTs), used in nearly ...

s, which emit

electron

The electron ( or ) is a subatomic particle with a negative one elementary electric charge. Electrons belong to the first generation of the lepton particle family,

and are generally thought to be elementary particles because they have n ...

beams that are manipulated to display images on a

phosphorescent screen.

The images may represent electrical

waveform

In electronics, acoustics, and related fields, the waveform of a signal is the shape of its graph as a function of time, independent of its time and magnitude scales and of any displacement in time.David Crecraft, David Gorham, ''Electro ...

s (

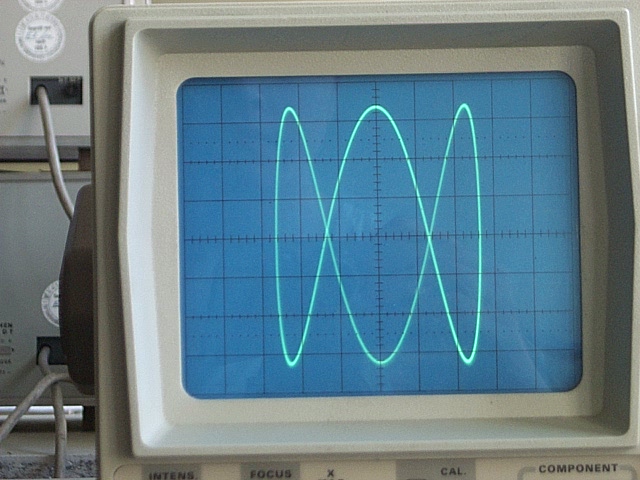

oscilloscope

An oscilloscope (informally a scope) is a type of electronic test instrument that graphically displays varying electrical voltages as a two-dimensional plot of one or more signals as a function of time. The main purposes are to display repetiti ...

), pictures (

television set

A television set or television receiver, more commonly called the television, TV, TV set, telly, tele, or tube, is a device that combines a tuner, display, and loudspeakers, for the purpose of viewing and hearing television broadcasts, or using ...

,

computer monitor

A computer monitor is an output device that displays information in pictorial or textual form. A discrete monitor comprises a visual display, support electronics, power supply, housing, electrical connectors, and external user controls.

The ...

),

radar

Radar is a detection system that uses radio waves to determine the distance (''ranging''), angle, and radial velocity of objects relative to the site. It can be used to detect aircraft, Marine radar, ships, spacecraft, guided missiles, motor v ...

targets, or other phenomena. A CRT on a television set is commonly called a picture tube. CRTs have also been

used as memory devices, in which case the screen is not intended to be visible to an observer. The term ''

cathode ray

Cathode rays or electron beam (e-beam) are streams of electrons observed in discharge tubes. If an evacuated glass tube is equipped with two electrodes and a voltage is applied, glass behind the positive electrode is observed to glow, due to el ...

'' was used to describe electron beams when they were first discovered, before it was understood that what was emitted from the cathode was a beam of electrons.

In CRT television sets and computer monitors, the entire front area of the tube is scanned repeatedly and systematically in a fixed pattern called a

raster. In color devices, an image is produced by controlling the intensity of each of three

electron beams, one for each additive primary color (red, green, and blue) with a

video signal

Video is an electronic medium for the recording, copying, playback, broadcasting, and display of moving visual media. Video was first developed for mechanical television systems, which were quickly replaced by cathode-ray tube (CRT) sy ...

as a reference.

In modern CRT monitors and televisions the beams are bent by

magnetic deflection, using a

deflection yoke

A deflection yoke is a kind of magnetic lens, used in cathode ray tubes to scan the electron beam both vertically and horizontally over the whole screen.

In a CRT television, the electron beam is moved in a raster scan on the screen. By adjusti ...

.

Electrostatic deflection

Electrostatic deflection refers to a way for modifying the path of a beam of charged particles by the use of an electric field applied transverse to the path of the particles. The technique is called electro''static'' because the strength and di ...

is commonly used in

oscilloscope

An oscilloscope (informally a scope) is a type of electronic test instrument that graphically displays varying electrical voltages as a two-dimensional plot of one or more signals as a function of time. The main purposes are to display repetiti ...

s.

[

]

A CRT is a glass envelope which is deep (i.e., long from front screen face to rear end), heavy, and fragile. The interior is evacuated to to or less, to facilitate the free flight of electrons from the gun(s) to the tube's face without scattering due to collisions with air molecules. As such, handling a CRT carries the risk of violent implosion that can hurl glass at great velocity. The face is typically made of thick

A CRT is a glass envelope which is deep (i.e., long from front screen face to rear end), heavy, and fragile. The interior is evacuated to to or less, to facilitate the free flight of electrons from the gun(s) to the tube's face without scattering due to collisions with air molecules. As such, handling a CRT carries the risk of violent implosion that can hurl glass at great velocity. The face is typically made of thick lead glass

Lead glass, commonly called crystal, is a variety of glass in which lead replaces the calcium content of a typical potash glass. Lead glass contains typically 18–40% (by weight) lead(II) oxide (PbO), while modern lead crystal, historically a ...

or special barium-strontium glass to be shatter-resistant and to block most X-ray

An X-ray, or, much less commonly, X-radiation, is a penetrating form of high-energy electromagnetic radiation. Most X-rays have a wavelength ranging from 10 picometers to 10 nanometers, corresponding to frequencies in the range 30&nb ...

emissions. CRTs make up most of the weight of CRT TVs and computer monitors.flat-panel display

A flat-panel display (FPD) is an electronic display used to display visual content such as text or images. It is present in consumer, medical, transportation, and industrial equipment.

Flat-panel displays are thin, lightweight, provide better l ...

technologies such as LCD, plasma display

A plasma display panel (PDP) is a type of flat panel display that uses small cells containing plasma: ionized gas that responds to electric fields. Plasma televisions were the first large (over 32 inches diagonal) flat panel displays to be rele ...

, and OLED

An organic light-emitting diode (OLED or organic LED), also known as organic electroluminescent (organic EL) diode, is a light-emitting diode (LED) in which the emissive electroluminescent layer is a film of organic compound that emits light i ...

displays which are cheaper to manufacture and run, as well as significantly lighter and less bulky. Flat-panel displays can also be made in very large sizes whereas to was about the largest size of a CRT.

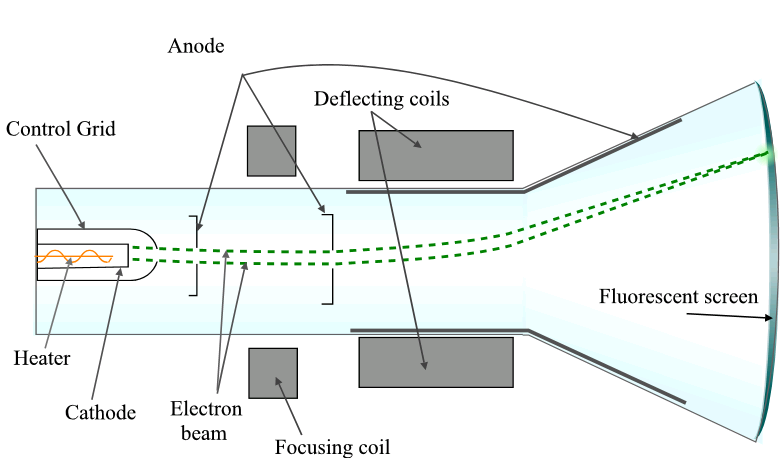

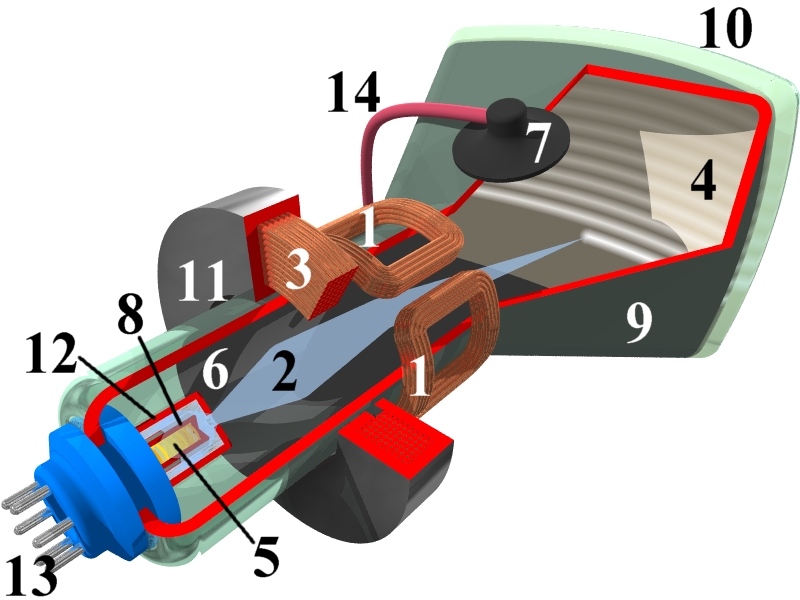

A CRT works by electrically heating a tungsten coil which in turn heats a cathode in the rear of the CRT, causing it to emit electrons which are modulated and focused by electrodes. The electrons are steered by deflection coils or plates, and an anode accelerates them towards the phosphor

A phosphor is a substance that exhibits the phenomenon of luminescence; it emits light when exposed to some type of radiant energy. The term is used both for fluorescent or phosphorescent substances which glow on exposure to ultraviolet or v ...

-coated screen, which generates light when hit by the electrons.

History

Discoveries

Cathode rays were discovered by

Cathode rays were discovered by Julius Plücker

Julius Plücker (16 June 1801 – 22 May 1868) was a German mathematician and physicist. He made fundamental contributions to the field of analytical geometry and was a pioneer in the investigations of cathode rays that led eventually to the dis ...

and Johann Wilhelm Hittorf. Hittorf observed that some unknown rays were emitted from the cathode

A cathode is the electrode from which a conventional current leaves a polarized electrical device. This definition can be recalled by using the mnemonic ''CCD'' for ''Cathode Current Departs''. A conventional current describes the direction in whi ...

(negative electrode) which could cast shadows on the glowing wall of the tube, indicating the rays were traveling in straight lines. In 1890, Arthur Schuster

Sir Franz Arthur Friedrich Schuster (12 September 1851 – 14 October 1934) was a German-born British physicist known for his work in spectroscopy, electrochemistry, optics, X-radiography and the application of harmonic analysis to physics. ...

demonstrated cathode rays could be deflected by electric field

An electric field (sometimes E-field) is the physical field that surrounds electrically charged particles and exerts force on all other charged particles in the field, either attracting or repelling them. It also refers to the physical field ...

s, and William Crookes

Sir William Crookes (; 17 June 1832 – 4 April 1919) was a British chemist and physicist who attended the Royal College of Chemistry, now part of Imperial College London, and worked on spectroscopy. He was a pioneer of vacuum tubes, inventing t ...

showed they could be deflected by magnetic fields. In 1897, J. J. Thomson succeeded in measuring the charge-mass-ratio of cathode rays, showing that they consisted of negatively charged particles smaller than atoms, the first "subatomic particle

In physical sciences, a subatomic particle is a particle that composes an atom. According to the Standard Model of particle physics, a subatomic particle can be either a composite particle, which is composed of other particles (for example, a p ...

s", which had already been named ''electron

The electron ( or ) is a subatomic particle with a negative one elementary electric charge. Electrons belong to the first generation of the lepton particle family,

and are generally thought to be elementary particles because they have n ...

s'' by Irish physicist George Johnstone Stoney

George Johnstone Stoney FRS (15 February 1826 – 5 July 1911) was an Irish physicist. He is most famous for introducing the term ''electron'' as the "fundamental unit quantity of electricity".

He had introduced the concept, though not the wor ...

in 1891. The earliest version of the CRT was known as the "Braun tube", invented by the German physicist Ferdinand Braun in 1897.

It was a cold-cathode diode

A diode is a two-terminal electronic component that conducts current primarily in one direction (asymmetric conductance); it has low (ideally zero) resistance in one direction, and high (ideally infinite) resistance in the other.

A diod ...

, a modification of the Crookes tube

A Crookes tube (also Crookes–Hittorf tube) is an early experimental electrical discharge tube, with partial vacuum, invented by English physicist William Crookes and others around 1869-1875, in which cathode rays, streams of electrons, were ...

with a phosphor

A phosphor is a substance that exhibits the phenomenon of luminescence; it emits light when exposed to some type of radiant energy. The term is used both for fluorescent or phosphorescent substances which glow on exposure to ultraviolet or v ...

-coated screen. Braun was the first to conceive the use of a CRT as a display device.

In 1908, Alan Archibald Campbell-Swinton, fellow of the Royal Society

The Royal Society, formally The Royal Society of London for Improving Natural Knowledge, is a learned society and the United Kingdom's national academy of sciences. The society fulfils a number of roles: promoting science and its benefits, re ...

(UK), published a letter in the scientific journal ''Nature

Nature, in the broadest sense, is the physical world or universe. "Nature" can refer to the phenomena of the physical world, and also to life in general. The study of nature is a large, if not the only, part of science. Although humans are ...

'', in which he described how "distant electric vision" could be achieved by using a cathode-ray tube (or "Braun" tube) as both a transmitting and receiving device.[

]

He expanded on his vision in a speech given in London in 1911 and reported in ''The Times

''The Times'' is a British daily national newspaper based in London. It began in 1785 under the title ''The Daily Universal Register'', adopting its current name on 1 January 1788. ''The Times'' and its sister paper '' The Sunday Times'' ( ...

'' and the ''Journal of the Röntgen Society''.[

][

]

The first cathode-ray tube to use a hot cathode

In vacuum tubes and gas-filled tubes, a hot cathode or thermionic cathode is a cathode electrode which is heated to make it emit electrons due to thermionic emission. This is in contrast to a cold cathode, which does not have a heating elemen ...

was developed by John Bertrand Johnson (who gave his name to the term Johnson noise

Johnson is a surname of Anglo-Norman origin meaning "Son of John". It is the second most common in the United States and 154th most common in the world. As a common family name in Scotland, Johnson is occasionally a variation of ''Johnston'', a ...

) and Harry Weiner Weinhart of Western Electric

The Western Electric Company was an American electrical engineering and manufacturing company officially founded in 1869. A wholly owned subsidiary of American Telephone & Telegraph for most of its lifespan, it served as the primary equipment ma ...

, and became a commercial product in 1922. The introduction of hot cathodes allowed for lower acceleration anode voltages and higher electron beam currents, since the anode now only accelerated the electrons emitted by the hot cathode, and no longer had to have a very high voltage to induce electron emission from the cold cathode.

Development

In 1926, Kenjiro Takayanagi demonstrated a CRT television receiver with a mechanical video camera that received images with a 40-line resolution.[

]

In 1927, Philo Farnsworth created a television prototype.

The CRT was named in 1929 by inventor Vladimir K. Zworykin.RCA

The RCA Corporation was a major American electronics company, which was founded as the Radio Corporation of America in 1919. It was initially a patent trust owned by General Electric (GE), Westinghouse, AT&T Corporation and United Fruit Comp ...

was granted a trademark for the term (for its cathode-ray tube) in 1932; it voluntarily released the term to the public domain in 1950.

In the 1930s, Allen B. DuMont made the first CRTs to last 1,000 hours of use, which was one of the factors that led to the widespread adoption of television.

The first commercially made electronic television sets with cathode-ray tubes were manufactured by Telefunken

Telefunken was a German radio and television apparatus company, founded in Berlin in 1903, as a joint venture of Siemens & Halske and the ''Allgemeine Elektrizitäts-Gesellschaft'' (AEG) ('General electricity company').

The name "Telefunken" ap ...

in Germany in 1934.

In 1947, the cathode-ray tube amusement device

The cathode-ray tube amusement device is the earliest known interactive electronic game as well as the first game to incorporate an electronic display. The device simulates an artillery shell arcing towards targets on a cathode-ray tube (CRT) scre ...

, the earliest known interactive

Across the many fields concerned with interactivity, including information science, computer science, human-computer interaction, communication, and industrial design, there is little agreement over the meaning of the term "interactivity", but mo ...

electronic game

An electronic game is a game that uses electronics to create an interactive system with which a player can play. Video games are the most common form today, and for this reason the two terms are often used interchangeably. There are other common ...

as well as the first to incorporate a cathode-ray tube screen, was created.

From 1949 to the early 1960s, there was a shift from circular CRTs to rectangular CRTs, although the first rectangular CRTs were made in 1938 by Telefunken.[

][

] While circular CRTs were the norm, European TV sets often blocked portions of the screen to make it appear somewhat rectangular while American sets often left the entire front of the CRT exposed or only blocked the upper and lower portions of the CRT.

In 1954, RCA produced some of the first color CRTs, the 15GP22 CRTs used in the CT-100,[

]Aiken tube Aiken may refer to:

Places

* Aiken, Illinois

* Aiken County, South Carolina

* Aiken, South Carolina, Aiken County's county seat

* The University of South Carolina Aiken

* Aiken, Texas (disambiguation)

** Aiken, Bell County, Texas

** Aiken, Floyd ...

was invented. It was a CRT in a flat-panel display format with a single electron gun. Deflection was electrostatic and magnetic, but due to patent problems, it was never put into production. It was also envisioned as a head-up display

A head-up display, or heads-up display, also known as a HUD (), is any transparent display that presents data without requiring users to look away from their usual viewpoints. The origin of the name stems from a pilot being able to view informa ...

in aircraft. By the time patent issues were solved, RCA had already invested heavily in conventional CRTs.

1968 marks the release of Sony

, commonly stylized as SONY, is a Japanese multinational conglomerate corporation headquartered in Minato, Tokyo, Japan. As a major technology company, it operates as one of the world's largest manufacturers of consumer and professional ...

Trinitron

Trinitron was Sony's brand name for its line of aperture-grille-based CRTs used in television sets and computer monitors. One of the first truly innovative television systems to enter the market since the 1950s, the Trinitron was announced in ...

brand with the model KV-1310, which was based on Aperture Grille technology. It was acclaimed to have improved the output brightness. The Trinitron screen was identical with its upright cylindrical shape due to its unique triple cathode single gun construction.

In 1987, flat-screen CRTs were developed by Zenith

The zenith (, ) is an imaginary point directly "above" a particular location, on the celestial sphere. "Above" means in the vertical direction ( plumb line) opposite to the gravity direction at that location ( nadir). The zenith is the "high ...

for computer monitors, reducing reflections and helping increase image contrast and brightness.[

][

] Such CRTs were expensive, which limited their use to computer monitors.float glass

Float glass is a sheet of glass made by floating molten glass on a bed of molten metal, typically tin, although lead and other various low- melting-point alloys were used in the past. This method gives the sheet uniform thickness and very flat su ...

.surface-conduction electron-emitter display

A surface-conduction electron-emitter display (SED) is a display technology for flat panel displays developed by a number of companies. SEDs use nanoscopic-scale electron emitters to energize colored phosphors and produce an image. In a genera ...

and field-emission displays, respectively. They both were flat-panel displays that had one (SED) or several (FED) electron emitters per subpixel in place of electron guns. The electron emitters were placed on a sheet of glass and the electrons were accelerated to a nearby sheet of glass with phosphors using an anode voltage. The electrons were not focused, making each subpixel essentially a flood beam CRT. They were never put into mass production as LCD technology was significantly cheaper, eliminating the market for such displays.

The last large-scale manufacturer of (in this case, recycled) CRTs, Videocon, ceased in 2015.price fixing

Price fixing is an anticompetitive agreement between participants on the same side in a market to buy or sell a product, service, or commodity only at a fixed price, or maintain the market conditions such that the price is maintained at a given ...

. The same occurred in Canada in 2018.

Worldwide sales of CRT computer monitors peaked in 2000, at 90 million units, while those of CRT TVs peaked in 2005 at 130 million units.

Decline

Beginning in the late 90s to the early 2000s, CRTs began to be replaced with LCDs, starting first with computer monitors smaller than 15 inches in size, largely because of their lower bulk. Among the first manufacturers to stop CRT production was Hitachi

() is a Japanese multinational conglomerate corporation headquartered in Chiyoda, Tokyo, Japan. It is the parent company of the Hitachi Group (''Hitachi Gurūpu'') and had formed part of the Nissan ''zaibatsu'' and later DKB Group and Fuyo G ...

in 2001, followed by Sony in Japan in 2004,Flat-panel display

A flat-panel display (FPD) is an electronic display used to display visual content such as text or images. It is present in consumer, medical, transportation, and industrial equipment.

Flat-panel displays are thin, lightweight, provide better l ...

s dropped in price and started significantly displacing cathode-ray tubes in the 2000s. LCD monitor sales began exceeding those of CRTs in 2003–2004 and LCD TV sales started exceeding those of CRTs in some markets in 2005.

Despite being a mainstay of display technology for decades, CRT-based computer monitors and televisions are now virtually a dead technology. Demand for CRT screens dropped in the late 2000s. Despite efforts from Samsung and LG to make CRTs competitive with their LCD and plasma counterparts, offering slimmer and cheaper models to compete with similarly sized and more expensive LCDs,Boeing 747-400

The Boeing 747-400 is a large, long-range wide-body airliner produced by Boeing Commercial Airplanes, an advanced variant of the initial Boeing 747.

The "Advanced Series 300" was announced at the September 1984 Farnborough Airshow, targeti ...

and the Airbus A320

The Airbus A320 family is a series of narrow-body airliners developed and produced by Airbus.

The A320 was launched in March 1984, first flew on 22 February 1987, and was introduced in April 1988 by Air France.

The first member of the fam ...

used CRT instruments in their glass cockpit

A glass cockpit is an aircraft cockpit that features electronic (digital) flight instrument displays, typically large LCD screens, rather than the traditional style of analog dials and gauges. While a traditional cockpit relies on numerous ...

s instead of mechanical instruments. Airlines such as Lufthansa

Deutsche Lufthansa AG (), commonly shortened to Lufthansa, is the flag carrier of Germany. When combined with its subsidiaries, it is the second- largest airline in Europe in terms of passengers carried. Lufthansa is one of the five founding ...

still use CRT technology, which also uses floppy disk

A floppy disk or floppy diskette (casually referred to as a floppy, or a diskette) is an obsolescent type of disk storage composed of a thin and flexible disk of a magnetic storage medium in a square or nearly square plastic enclosure lined ...

s for navigation updates. They are also used in some military equipment for similar reasons.

, at least one company manufactures new CRTs for these markets.

A popular consumer usage of CRTs is for retrogaming

Retrogaming, also known as classic gaming and old school gaming, is the current playing and collection of obsolete personal computers, consoles, and video games. Usually, retrogaming is based upon systems that are outmoded or discontinued, alt ...

. Some games are impossible to play without CRT display hardware, and some games play better. Reasons for this include:

* CRTs refresh faster than LCDs, because they use interlaced lines.

* CRTs are able to correctly display certain oddball resolutions, such as the 256x224 resolution of the Nintendo Entertainment System

The Nintendo Entertainment System (NES) is an 8-bit third-generation home video game console produced by Nintendo. It was first released in Japan in 1983 as the commonly known as the The NES, a redesigned version, was released in America ...

(NES).

* Light gun

A light gun is a pointing device for computers and a control device for arcade and video games, typically shaped to resemble a pistol.

Early history

The first light guns were produced in the 1930s, following the development of light-sensin ...

s only work on CRTs because they depend on the progressive timing properties of CRTs.

Construction

Body

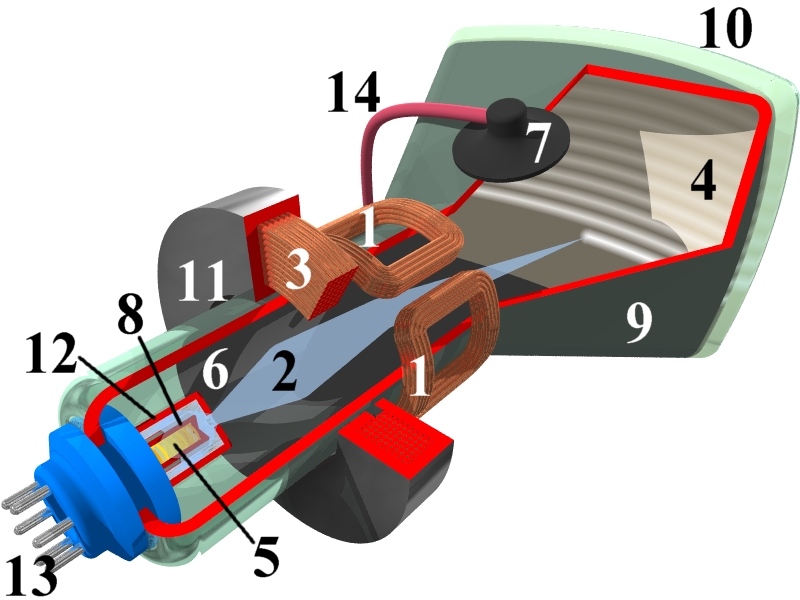

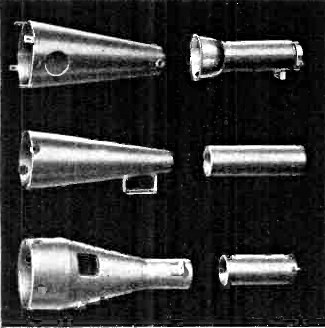

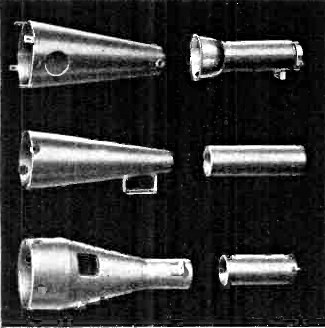

The body of a CRT is usually made up of three parts: A screen/faceplate/panel, a cone/funnel, and a neck.

The body of a CRT is usually made up of three parts: A screen/faceplate/panel, a cone/funnel, and a neck.AGC Inc.

, formerly Asahi Glass Co., Ltd.'(旭硝子株式会社), is a Japanese global glass manufacturing company, headquartered in Tokyo. It is the largest glass company in the world and one of the core Mitsubishi companies.

The company is listed on ...

, O-I Glass, Samsung Corning Precision Materials, Corning Inc.

Corning Incorporated is an American multinational technology company that specializes in specialty glass, ceramics, and related materials and technologies including advanced optics, primarily for industrial and scientific applications. The c ...

, and Nippon Electric Glass

, also known as NEG, is a Japanese glass manufacturer. The company is a manufacturer of glass for flat panel displays (FPD). It has about 20% share in the world's production of glass for liquid crystal displays (LCD).

The company is listed on ...

; others such as Videocon, Sony for the US market and Thomson made their own glass.lead oxide

Lead oxides are a group of inorganic compounds with formulas including lead (Pb) and oxygen (O).

Common lead oxides include:

* Lead(II) oxide, PbO, litharge (red), massicot (yellow)

* Lead(II,IV) oxide

Lead(II,IV) oxide, also called red lead o ...

(PbO),barium oxide

Barium oxide, also known as baria, is a white hygroscopic non-flammable compound with the formula BaO. It has a cubic structure and is used in cathode ray tubes, crown glass, and catalysts. It is harmful to human skin and if swallowed in larg ...

, and 12% of strontium oxide

Strontium oxide or strontia, SrO, is formed when strontium reacts with oxygen. Burning strontium in air results in a mixture of strontium oxide and strontium nitride. It also forms from the decomposition of strontium carbonate SrCO3. It is a stro ...

.

Size and weight

The size of the screen of a CRT is measured in two ways: the size of the screen or the face diagonal, and the viewable image size/area or viewable screen diagonal, which is the part of the screen with phosphor. The size of the screen is the viewable image size plus its black edges which are not coated with phosphor.

Anode

The outer conductive coating is connected to ground while the inner conductive coating is connected using the anode button/cap through a series of capacitors and diodes (a Cockcroft–Walton generator

The Cockcroft–Walton (CW) generator, or multiplier, is an electric circuit that generates a high DC voltage from a low-voltage AC or pulsing DC input. It was named after the British and Irish physicists John Douglas Cockcroft and Ernest ...

) to the high voltage flyback transformer; the inner coating is the anode of the CRT,voltage multiplier 280px, Villard cascade voltage multiplier.

A voltage multiplier is an electrical circuit that converts AC electrical power from a lower voltage to a higher DC voltage, typically using a network of capacitors and diodes.

Voltage multipliers can ...

for the current delivered by the flyback.

For the inner funnel coating, monochrome CRTs use aluminum while color CRTs use aquadag;corona discharge

A corona discharge is an electrical discharge caused by the ionization of a fluid such as air surrounding a conductor carrying a high voltage. It represents a local region where the air (or other fluid) has undergone electrical breakdown ...

.

The anode button must be specially shaped to establish a hermetic seal between the button and funnel. X-rays may leak through the anode button, although that may not be the case in newer CRTs starting from the late 1970s to early 1980s, thanks to a new button and clip design.

Electron gun

The electron gun emits the electrons that ultimately hit the phosphors on the screen of the CRT. The electron gun contains a heater, which heats a cathode, which generates electrons that, using grids, are focused and ultimately accelerated into the screen of the CRT. The acceleration occurs in conjunction with the inner aluminum or aquadag coating of the CRT. The electron gun is positioned so that it aims at the center of the screen.

Construction and method of operation

It has a hot cathode

In vacuum tubes and gas-filled tubes, a hot cathode or thermionic cathode is a cathode electrode which is heated to make it emit electrons due to thermionic emission. This is in contrast to a cold cathode, which does not have a heating elemen ...

that is heated by a tungsten filament heating element; the heater may draw 0.5 to 2 A of current depending on the CRT. The voltage applied to the heater can affect the life of the CRT. Heating the cathode energizes the electrons in it, aiding electron emission,[ Some CRTs may use two grids and lenses to focus the electron beam.]Vertical blanking interval

In a raster scan display, the vertical blanking interval (VBI), also known as the vertical interval or VBLANK, is the time between the end of the final visible line of a frame or field and the beginning of the first visible line of the next fra ...

and Horizontal blanking interval

Horizontal blanking interval refers to a part of the process of displaying images on a computer monitor or television screen via raster scanning. CRT screens display images by moving beams of electrons very quickly across the screen. Once the be ...

.) Incorrect biasing can lead to visible retrace lines on one or more colors, creating retrace lines that are tinted or white (for example, tinted red if the red color is affected, tinted magenta if the red and blue colors are affected, and white if all colors are affected).

Gamma

CRTs have a pronounced triode

A triode is an electronic amplifying vacuum tube (or ''valve'' in British English) consisting of three electrodes inside an evacuated glass envelope: a heated filament or cathode, a grid, and a plate (anode). Developed from Lee De Forest's ...

characteristic, which results in significant gamma

Gamma (uppercase , lowercase ; ''gámma'') is the third letter of the Greek alphabet. In the system of Greek numerals it has a value of 3. In Ancient Greek, the letter gamma represented a voiced velar stop . In Modern Greek, this letter r ...

(a nonlinear relationship in an electron gun between applied video voltage and beam intensity).

Deflection

There are two types of deflection: magnetic and electrostatic. Magnetic is usually used in TVs and monitors as it allows for higher deflection angles (and hence shallower CRTs) and deflection power (which allows for higher electron beam current and hence brighter images) while avoiding the need for high voltages for deflection of up to 2000 volts,

Magnetic deflection

Those that use magnetic deflection may use a yoke that has two pairs of deflection coils; one pair for vertical, and another for horizontal deflection.

Electrostatic deflection

Mostly used in oscilloscopes. Deflection is carried out by applying a voltage across two pairs of plates, one for horizontal, and the other for vertical deflection. The electron beam is steered by varying the voltage difference across plates in a pair; For example, applying a voltage to the upper plate of the vertical deflection pair, while keeping the voltage in the bottom plate at 0 volts, will cause the electron beam to be deflected towards the upper part of the screen; increasing the voltage in the upper plate while keeping the bottom plate at 0 will cause the electron beam to be deflected to a higher point in the screen (will cause the beam to be deflected at a higher deflection angle). The same applies with the horizontal deflection plates. Increasing the length and proximity between plates in a pair can also increase the deflection angle.

Burn-in

Burn-in is when images are physically "burned" into the screen of the CRT; this occurs due to degradation of the phosphors due to prolonged electron bombardment of the phosphors, and happens when a fixed image or logo is left for too long on the screen, causing it to appear as a "ghost" image or, in severe cases, also when the CRT is off. To counter this, screensaver

A screensaver (or screen saver) is a computer program that blanks the display screen or fills it with moving images or patterns when the computer has been idle for a designated time. The original purpose of screensavers was to prevent phosphor ...

s were used in computers to minimize burn-in.

Evacuation

CRTs are evacuated or exhausted (a vacuum is formed) inside an oven at approx. 375–475 °C, in a process called baking or bake-out. The evacuation process also outgasses any materials inside the CRT, while decomposing others such as the polyvinyl alcohol used to apply the phosphors. The heating and cooling are done gradually to avoid inducing stress, stiffening and possibly cracking the glass; the oven heats the gases inside the CRT, increasing the speed of the gas molecules which increases the chances of them getting drawn out by the vacuum pump. The temperature of the CRT is kept to below that of the oven, and the oven starts to cool just after the CRT reaches 400 °C, or, the CRT was kept at a temperature higher than 400 °C for up to 15–55 minutes. The CRT was heated during or after evacuation, and the heat may have been used simultaneously to melt the frit in the CRT, joining the screen and funnel. The pump used is a turbomolecular pump

A turbomolecular pump is a type of vacuum pump, superficially similar to a turbopump, used to obtain and maintain high vacuum. These pumps work on the principle that gas molecules can be given momentum in a desired direction by repeated collisi ...

or a diffusion pump

Diffusion pumps use a high speed jet of vapor to direct gas molecules in the pump throat down into the bottom of the pump and out the exhaust. They were the first type of high vacuum pumps operating in the regime of free molecular flow, where the ...

. Formerly mercury vacuum pumps were also used. After baking, the CRT is disconnected ("sealed or tipped off") from the vacuum pump. The getter is then fired using an RF (induction) coil. The getter is usually in the funnel or in the neck of the CRT.

Rebuilding

CRTs used to be rebuilt; repaired or refurbished. The rebuilding process included the disassembly of the CRT, the disassembly and repair or replacement of the electron gun(s), the removal and redeposition of phosphors and aquadag Aquadag is a trade name for a water-based colloidal graphite coating commonly used in cathode ray tubes (CRTs). It is manufactured by Acheson Industries, a subsidiary of ICI. The name is a shortened form of "Aqueous Deflocculated Acheson Graphite ...

, etc. Rebuilding was popular until the 1960s because CRTs were expensive and wore out quickly, making repair worth it.

Reactivation

Also known as rejuvenation, the goal is to temporarily restore the brightness of a worn CRT. This is often done by carefully increasing the voltage on the cathode heater and the current and voltage on the control grids of the electron gun either manually. Some rejuvenators can also fix heater-to-cathode shorts by running a capacitive discharge through the short.

Phosphors

Phosphor

A phosphor is a substance that exhibits the phenomenon of luminescence; it emits light when exposed to some type of radiant energy. The term is used both for fluorescent or phosphorescent substances which glow on exposure to ultraviolet or v ...

s in CRTs emit secondary electrons due to them being inside the vacuum of the CRT. The secondary electrons are collected by the anode of the CRT.

Phosphor persistence

Various phosphors are available depending upon the needs of the measurement or display application. The brightness, color, and persistence of the illumination depends upon the type of phosphor used on the CRT screen. Phosphors are available with persistences ranging from less than one microsecond

A microsecond is a unit of time in the International System of Units (SI) equal to one millionth (0.000001 or 10−6 or ) of a second. Its symbol is μs, sometimes simplified to us when Unicode is not available.

A microsecond is equal to 1000 ...

to several seconds. For visual observation of brief transient events, a long persistence phosphor may be desirable. For events which are fast and repetitive, or high frequency, a short-persistence phosphor is generally preferable. The phosphor persistence must be low enough to avoid smearing or ghosting artifacts at high refresh rates.

Limitations and workarounds

Blooming

Variations in anode voltage can lead to variations in brightness in parts or all of the image, in addition to blooming, shrinkage or the image getting zoomed in or out. Lower voltages lead to blooming and zooming in, while higher voltages do the opposite. Some blooming is unavoidable, which can be seen as bright areas of an image that expand, distorting or pushing aside surrounding darker areas of the same image. Blooming occurs because bright areas have a higher electron beam current from the electron gun, making the beam wider and harder to focus. Poor voltage regulation causes focus and anode voltage to go down with increasing electron beam current.

Doming

Doming is a phenomenon found on some CRT televisions in which parts of the shadow mask

The shadow mask is one of the two technologies used in the manufacture of cathode-ray tube (CRT) televisions and computer monitors which produce clear, focused color images. The other approach is the aperture grille, better known by its tr ...

become heated. In televisions that exhibit this behavior, it tends to occur in high-contrast scenes in which there is a largely dark scene with one or more localized bright spots. As the electron beam hits the shadow mask in these areas it heats unevenly. The shadow mask warps due to the heat differences, which causes the electron gun to hit the wrong colored phosphors and incorrect colors to be displayed in the affected area. Thermal expansion causes the shadow mask to expand by around 100 microns.

During normal operation, the shadow mask is heated to around 80–90 °C.

High voltage

Image brightness is related to the anode voltage and to the CRTs size, so higher voltages are needed for both larger screens and higher image brightness. Image brightness is also controlled by the current of the electron beam.

Size

Size is limited by anode voltage, as it would require a higher dielectric strength to prevent arcing (corona discharge) and the electrical losses and ozone generation it causes, without sacrificing image brightness. The weight of the CRT, which originates from the thick glass needed to safely sustain a vacuum, imposes a practical limit on the size of a CRT. The 43-inch Sony PVM-4300 CRT monitor weighs . Smaller CRTs weigh significantly less, as an example, 32-inch CRTs weigh up to and 19-inch CRTs weigh up to . For comparison, a 32-inch flat panel TV only weighs approx. and a 19-inch flat panel TV weighs .

Shadow masks become more difficult to make with increasing resolution and size.

Limits imposed by deflection

At high deflection angles, resolutions and refresh rates (since higher resolutions and refresh rates require significantly higher frequencies to be applied to the horizontal deflection coils), the deflection yoke starts to produce large amounts of heat, due to the need to move the electron beam at a higher angle, which in turn requires exponentially larger amounts of power. As an example, to increase the deflection angle from 90 to 120°, power consumption of the yoke must also go up from 40 watts to 80 watts, and to increase it further from 120 to 150°, deflection power must again go up from 80 watts to 160 watts. This normally makes CRTs that go beyond certain deflection angles, resolutions and refresh rates impractical, since the coils would generate too much heat due to resistance caused by the skin effect

Skin effect is the tendency of an alternating electric current (AC) to become distributed within a conductor such that the current density is largest near the surface of the conductor and decreases exponentially with greater depths in the co ...

, surface and eddy current

Eddy currents (also called Foucault's currents) are loops of electrical current induced within conductors by a changing magnetic field in the conductor according to Faraday's law of induction or by the relative motion of a conductor in a magnet ...

losses, and/or possibly causing the glass underneath the coil to become conductive (as the electrical conductivity of glass decreases with increasing temperature). Some deflection yokes are designed to dissipate the heat that comes from their operation.

Comparison with other technologies

* LCD advantages over CRT: Lower bulk, power consumption and heat generation, higher refresh rates (up to 360 Hz), higher contrast ratios

* CRT advantages over LCD: Better color reproduction, no motion blur, multisyncing available in many monitors, no input lag

Types

CRTs were produced in two major categories, picture tubes and display tubes.overscan

Overscan is a behaviour in certain television sets, in which part of the input picture is shown outside of the visible bounds of the screen. It exists because cathode-ray tube (CRT) television sets from the 1930s through to the early 2000s were ...

and were of higher resolution.

Picture tube CRTs have overscan, meaning the actual edges of the image are not shown; this is deliberate to allow for adjustment variations between CRT TVs, preventing the ragged edges (due to blooming) of the image from being shown on screen. The shadow mask may have grooves that reflect away the electrons that do not hit the screen due to overscan.

Monochrome CRTs

If the CRT is a black and white (B&W or monochrome) CRT, there is a single electron gun in the neck and the funnel is coated on the inside with aluminum that has been applied by evaporation; the aluminum is evaporated in a vacuum and allowed to condense on the inside of the CRT.

If the CRT is a black and white (B&W or monochrome) CRT, there is a single electron gun in the neck and the funnel is coated on the inside with aluminum that has been applied by evaporation; the aluminum is evaporated in a vacuum and allowed to condense on the inside of the CRT.ion trap

An ion trap is a combination of electric and/or magnetic fields used to capture charged particles — known as ions — often in a system isolated from an external environment. Atomic and molecular ion traps have a number of applications in phy ...

s, necessary to prevent ion burn on the phosphor, while also reflecting light generated by the phosphor towards the screen, managing heat and absorbing electrons providing a return path for them; previously funnels were coated on the inside with aquadag, used because it can be applied like paint;

Color CRTs

Color CRTs use three different phosphors which emit red, green, and blue light respectively. They are packed together in stripes (as in

Color CRTs use three different phosphors which emit red, green, and blue light respectively. They are packed together in stripes (as in aperture grille

An aperture grille is one of two major technologies used to manufacture color cathode-ray tube (CRT) televisions and computer displays; the other is the shadow mask.

Fine vertical wires behind the front glass of the display screen separate t ...

designs) or clusters called "triads" (as in shadow mask

The shadow mask is one of the two technologies used in the manufacture of cathode-ray tube (CRT) televisions and computer monitors which produce clear, focused color images. The other approach is the aperture grille, better known by its tr ...

CRTs).shadow mask

The shadow mask is one of the two technologies used in the manufacture of cathode-ray tube (CRT) televisions and computer monitors which produce clear, focused color images. The other approach is the aperture grille, better known by its tr ...

tube uses a metal plate with tiny holes, typically in a delta configuration, placed so that the electron beam only illuminates the correct phosphors on the face of the tube;[ blocking all other electrons.]aperture grille

An aperture grille is one of two major technologies used to manufacture color cathode-ray tube (CRT) televisions and computer displays; the other is the shadow mask.

Fine vertical wires behind the front glass of the display screen separate t ...

of tensioned vertical wires to achieve the same result.[ The shadow mask has a single hole for each triad.]

Shadow mask

The shadow mask absorbs or reflects electrons that would otherwise strike the wrong phosphor dots,Cromaclear

Cromaclear is a trademark for CRT technology used by NEC during the mid to late-90s. This adopted the slotted shadow mask and inline electron gun pioneered by the 1966 GE Porta-Color and used by most then-current television tubes to computer moni ...

; Trinitron and Diamondtron use aperture grilles while Cromaclear uses a slot mask. Some shadow mask CRTs have color phosphors that are smaller in diameter than the electron beams used to light them,

Screen manufacture

Early color CRTs did not have a black matrix, which was introduced by Zenith in 1969, and Panasonic in 1970.photolithography

In integrated circuit manufacturing, photolithography or optical lithography is a general term used for techniques that use light to produce minutely patterned thin films of suitable materials over a substrate, such as a silicon wafer, to protec ...

. The inner side of the screen is coated with phosphor particles suspended in PVA photoresist slurry, which is then dried using infrared light, exposed, and developed. The exposure is done using a "lighthouse" that uses an ultraviolet light source with a corrector lens to allow the CRT to achieve color purity. Removable shadow masks with spring-loaded clips are used as photomasks. The process is repeated with all colors. Usually the green phosphor is the first to be applied.amyl acetate

Amyl acetate (pentyl acetate) is an organic compound and an ester with the chemical formula CH3COO H2sub>4CH3 and the molecular weight 130.19g/mol. It is colorless and has a scent similar to bananas and apples. The compound is the condensation p ...

or in a polymer

A polymer (; Greek '' poly-'', "many" + '' -mer'', "part")

is a substance or material consisting of very large molecules called macromolecules, composed of many repeating subunits. Due to their broad spectrum of properties, both synthetic a ...

with an alkyl methacrylate monomer

In chemistry, a monomer ( ; '' mono-'', "one" + '' -mer'', "part") is a molecule that can react together with other monomer molecules to form a larger polymer chain or three-dimensional network in a process called polymerization.

Classification

...

together with an organic solvent to dissolve the polymer and monomer.

Convergence and purity in color CRTs

Due to limitations in the dimensional precision with which CRTs can be manufactured economically, it has not been practically possible to build color CRTs in which three electron beams could be aligned to hit phosphors of respective color in acceptable coordination, solely on the basis of the geometric configuration of the electron gun axes and gun aperture positions, shadow mask apertures, etc. The shadow mask ensures that one beam will only hit spots of certain colors of phosphors, but minute variations in physical alignment of the internal parts among individual CRTs will cause variations in the exact alignment of the beams through the shadow mask, allowing some electrons from, for example, the red beam to hit, say, blue phosphors, unless some individual compensation is made for the variance among individual tubes.

Color convergence and color purity are two aspects of this single problem. Firstly, for correct color rendering it is necessary that regardless of where the beams are deflected on the screen, all three hit the same spot (and nominally pass through the same hole or slot) on the shadow mask. This is called convergence. More specifically, the convergence at the center of the screen (with no deflection field applied by the yoke) is called static convergence, and the convergence over the rest of the screen area (specially at the edges and corners) is called dynamic convergence.magnetic fields

A magnetic field is a vector field that describes the magnetic influence on moving electric charges, electric currents, and magnetic materials. A moving charge in a magnetic field experiences a force perpendicular to its own velocity and to ...

parallel to the planes of the magnets, which are perpendicular to the electron gun axes. Often, one ring has two poles, another has 4, and the remaining ring has 6 poles. Each pair of magnetic rings forms a single effective magnet whose field vector

Vector most often refers to:

*Euclidean vector, a quantity with a magnitude and a direction

*Vector (epidemiology), an agent that carries and transmits an infectious pathogen into another living organism

Vector may also refer to:

Mathematic ...

can be fully and freely adjusted (in both direction and magnitude). By rotating a pair of magnets relative to each other, their relative field alignment can be varied, adjusting the effective field strength of the pair. (As they rotate relative to each other, each magnet's field can be considered to have two opposing components at right angles, and these four components wo each for two magnetsform two pairs, one pair reinforcing each other and the other pair opposing and canceling each other. Rotating away from alignment, the magnets' mutually reinforcing field components decrease as they are traded for increasing opposed, mutually cancelling components.) By rotating a pair of magnets together, preserving the relative angle between them, the direction of their collective magnetic field can be varied. Overall, adjusting all of the convergence/purity magnets allows a finely tuned slight electron beam deflection or lateral offset to be applied, which compensates for minor static convergence and purity errors intrinsic to the uncalibrated tube. Once set, these magnets are usually glued in place, but normally they can be freed and readjusted in the field (e.g. by a TV repair shop) if necessary.

On some CRTs, additional fixed adjustable magnets are added for dynamic convergence or dynamic purity at specific points on the screen, typically near the corners or edges. Further adjustment of dynamic convergence and purity typically cannot be done passively, but requires active compensation circuits, one to correct convergence horizontally and another to correct it vertically. The deflection yoke contains convergence coils, a set of two per color, wound on the same core, to which the convergence signals are applied. That means 6 convergence coils in groups of 3, with 2 coils per group, with one coil for horizontal convergence correction and another for vertical convergence correction, with each group sharing a core. The groups are separated 120° from one another. Dynamic convergence is necessary because the front of the CRT and the shadow mask aren't spherical, compensating for electron beam defocusing and astigmatism. The fact that the CRT screen isn't spherical leads to geometry problems which may be corrected using a circuit. The signals used for convergence are parabolic waveforms derived from three signals coming from a vertical output circuit. The parabolic signal is fed into the convergence coils, while the other two are sawtooth signals that, when mixed with the parabolic signals, create the necessary signal for convergence. A resistor and diode are used to lock the convergence signal to the center of the screen to prevent it from being affected by the static convergence. The horizontal and vertical convergence circuits are similar. Each circuit has two resonators, one usually tuned to 15,625 Hz and the other to 31,250 Hz, which set the frequency of the signal sent to the convergence coils. Dynamic convergence may be accomplished using electrostatic quadrupole fields in the electron gun. Dynamic convergence means that the electron beam does not travel in a perfectly straight line between the deflection coils and the screen, since the convergence coils cause it to become curved to conform to the screen.

The convergence signal may instead be a sawtooth signal with a slight sine wave appearance, the sine wave part is created using a capacitor in series with each deflection coil. In this case, the convergence signal is used to drive the deflection coils. The sine wave part of the signal causes the electron beam to move more slowly near the edges of the screen. The capacitors used to create the convergence signal are known as the s-capacitors. This type of convergence is necessary due to the high deflection angles and flat screens of many CRT computer monitors. The value of the s-capacitors must be chosen based on the scan rate of the CRT, so multi-syncing monitors must have different sets of s-capacitors, one for each refresh rate.

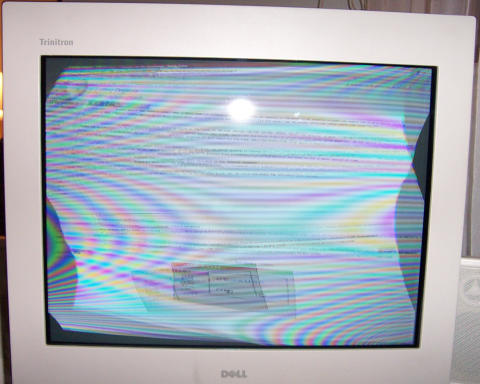

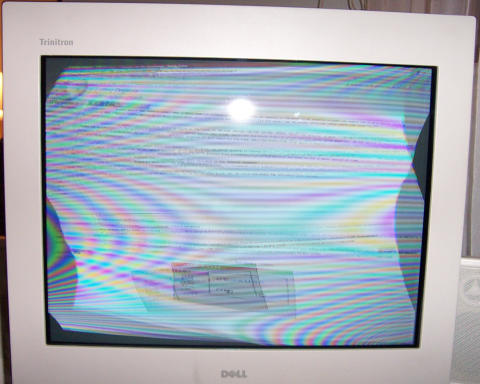

Magnetic shielding and degaussing

If the shadow mask or aperture grille becomes magnetized, its magnetic field alters the paths of the electron beams. This causes errors of "color purity" as the electrons no longer follow only their intended paths, and some will hit some phosphors of colors other than the one intended. For example, some electrons from the red beam may hit blue or green phosphors, imposing a magenta or yellow tint to parts of the image that are supposed to be pure red. (This effect is localized to a specific area of the screen if the magnetization is localized.) Therefore, it is important that the shadow mask or aperture grille not be magnetized. The earth's magnetic field may have an effect on the color purity of the CRT.

If the shadow mask or aperture grille becomes magnetized, its magnetic field alters the paths of the electron beams. This causes errors of "color purity" as the electrons no longer follow only their intended paths, and some will hit some phosphors of colors other than the one intended. For example, some electrons from the red beam may hit blue or green phosphors, imposing a magenta or yellow tint to parts of the image that are supposed to be pure red. (This effect is localized to a specific area of the screen if the magnetization is localized.) Therefore, it is important that the shadow mask or aperture grille not be magnetized. The earth's magnetic field may have an effect on the color purity of the CRT.degaussing

Degaussing is the process of decreasing or eliminating a remnant magnetic field. It is named after the gauss, a unit of magnetism, which in turn was named after Carl Friedrich Gauss. Due to magnetic hysteresis, it is generally not possible to red ...

(demagnetizing) coil mounted around the perimeter of the CRT face. Upon power-up of the CRT display, the degaussing circuit produces a brief, alternating current through the coil which fades to zero over a few seconds, producing a decaying alternating magnetic field from the coil. This degaussing field is strong enough to remove shadow mask magnetization in most cases, maintaining color purity. In unusual cases of strong magnetization where the internal degaussing field is not sufficient, the shadow mask may be degaussed externally with a stronger portable degausser or demagnetizer. However, an excessively strong magnetic field, whether alternating or constant, may mechanically deform (bend) the shadow mask, causing a permanent color distortion on the display which looks very similar to a magnetization effect.

Resolution

Dot pitch defines the maximum resolution of the display, assuming delta-gun CRTs. In these, as the scanned resolution approaches the dot pitch resolution, moiré appears, as the detail being displayed is finer than what the shadow mask can render. Aperture grille monitors do not suffer from vertical moiré, however, because their phosphor stripes have no vertical detail. In smaller CRTs, these strips maintain position by themselves, but larger aperture-grille CRTs require one or two crosswise (horizontal) support strips; one for smaller CRTs, and two for larger ones. The support wires block electrons, causing the wires to be visible. In aperture grille CRTs, dot pitch is replaced by stripe pitch. Hitachi developed the Enhanced Dot Pitch (EDP) shadow mask, which uses oval holes instead of circular ones, with respective oval phosphor dots.

Projection CRTs

Projection CRTs were used in CRT projector

A CRT projector is a video projector that uses a small, high-brightness cathode ray tube (CRT) as the image generating element. The image is then focused and enlarged onto a screen using a lens kept in front of the CRT face. The first color CRT ...

s and CRT rear-projection television

Rear-projection television (RPTV) is a type of large-screen television display technology. Until approximately 2006, most of the relatively affordable consumer large screen TVs up to used rear-projection technology. A variation is a video proje ...

s, and are usually small (being 7 to 9 inches across);

Beam-index tube

Beam-index tubes, also known as Uniray, Apple CRT or Indextron,Philco

Philco (an acronym for Philadelphia Battery Company) is an American electronics industry, electronics manufacturer headquartered in Philadelphia. Philco was a pioneer in battery, radio, and television production. In 1961, the company was purchased ...

to create a color CRT without a shadow mask, eliminating convergence and purity problems, and allowing for shallower CRTs with higher deflection angles. It also required a lower voltage power supply for the final anode since it didn't use a shadow mask, which normally blocks around 80% of the electrons generated by the electron gun. The lack of a shadow mask also made it immune to the earth's magnetic field while also making degaussing unnecessary and increasing image brightness.

Flat CRTs

Flat CRTs are those with a flat screen. Despite having a flat screen, they may not be completely flat, especially on the inside, instead having a greatly increased curvature. A notable exception is the LG Flatron (made by LG.Philips Displays, later LP Displays) which is truly flat on the outside and inside, but has a bonded glass pane on the screen with a tensioned rim band to provide implosion protection. Such completely flat CRTs were first introduced by Zenith in 1986, and used

flat tensioned shadow masks, where the shadow mask is held under tension, providing increased resistance to blooming.

Flat CRTs are those with a flat screen. Despite having a flat screen, they may not be completely flat, especially on the inside, instead having a greatly increased curvature. A notable exception is the LG Flatron (made by LG.Philips Displays, later LP Displays) which is truly flat on the outside and inside, but has a bonded glass pane on the screen with a tensioned rim band to provide implosion protection. Such completely flat CRTs were first introduced by Zenith in 1986, and used

flat tensioned shadow masks, where the shadow mask is held under tension, providing increased resistance to blooming.

Radar CRTs

Radar CRTs such as the 7JP4 had a circular screen and scanned the beam from the center outwards. The screen often had two colors, often a bright short persistence color that only appeared as the beam scanned the display and a long persistence phosphor afterglow. When the beam strikes the phosphor, the phosphor brightly illuminates, and when the beam leaves, the dimmer long persistence afterglow would remain lit where the beam struck the phosphor, alongside the radar targets that were "written" by the beam, until the beam re-struck the phosphor. The deflection yoke rotated, causing the beam to rotate in a circular fashion.

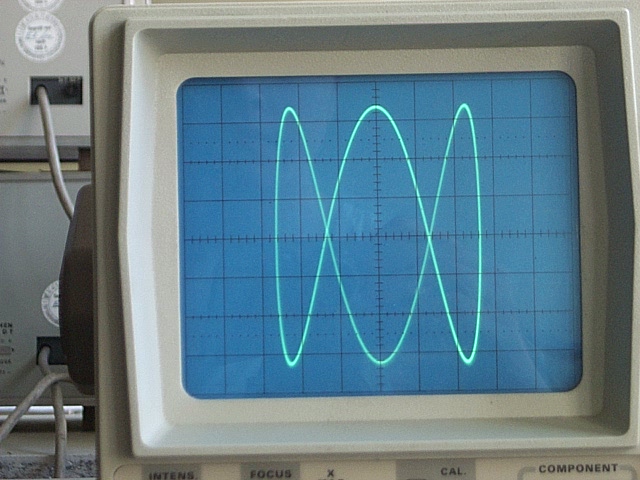

Oscilloscope CRTs

In

In oscilloscope

An oscilloscope (informally a scope) is a type of electronic test instrument that graphically displays varying electrical voltages as a two-dimensional plot of one or more signals as a function of time. The main purposes are to display repetiti ...

CRTs, electrostatic deflection

Electrostatic deflection refers to a way for modifying the path of a beam of charged particles by the use of an electric field applied transverse to the path of the particles. The technique is called electro''static'' because the strength and di ...

is used, rather than the magnetic deflection commonly used with television and other large CRTs. The beam is deflected horizontally by applying an electric field

An electric field (sometimes E-field) is the physical field that surrounds electrically charged particles and exerts force on all other charged particles in the field, either attracting or repelling them. It also refers to the physical field ...

between a pair of plates to its left and right, and vertically by applying an electric field to plates above and below. Televisions use magnetic rather than electrostatic deflection because the deflection plates obstruct the beam when the deflection angle is as large as is required for tubes that are relatively short for their size. Some Oscilloscope CRTs incorporate post deflection anodes (PDAs) that are spiral-shaped to ensure even anode potential across the CRT and operate at up to 15,000 volts. In PDA CRTs the electron beam is deflected before it is accelerated, improving sensitivity and legibility, specially when analyzing voltage pulses with short duty cycles.

Microchannel plate

When displaying fast one-shot events, the electron beam must deflect very quickly, with few electrons impinging on the screen, leading to a faint or invisible image on the display. Oscilloscope CRTs designed for very fast signals can give a brighter display by passing the electron beam through a micro-channel plate just before it reaches the screen. Through the phenomenon of secondary emission

In particle physics, secondary emission is a phenomenon where primary incident particles of sufficient energy, when hitting a surface or passing through some material, induce the emission of secondary particles. The term often refers to the em ...

, this plate multiplies the number of electrons reaching the phosphor screen, giving a significant improvement in writing rate (brightness) and improved sensitivity and spot size as well.

Graticules

Most oscilloscopes have a graticule

Graticule may refer to:

* An oscilloscope graticule scale

* The reticle pattern in an optical instrument

* Graticule (cartography), a grid of lines on a map

See also

* Grid (disambiguation)

Grid, The Grid, or GRID may refer to:

Common us ...

as part of the visual display, to facilitate measurements. The graticule may be permanently marked inside the face of the CRT, or it may be a transparent external plate made of glass or acrylic

Acrylic may refer to:

Chemicals and materials

* Acrylic acid, the simplest acrylic compound

* Acrylate polymer, a group of polymers (plastics) noted for transparency and elasticity

* Acrylic resin, a group of related thermoplastic or thermosett ...

plastic. An internal graticule eliminates parallax error

Parallax is a displacement or difference in the apparent position of an object viewed along two different lines of sight and is measured by the angle or semi-angle of inclination between those two lines. Due to foreshortening, nearby objects ...

, but cannot be changed to accommodate different types of measurements. Oscilloscopes commonly provide a means for the graticule to be illuminated from the side, which improves its visibility.

Image storage tubes

These are found in ''analog phosphor storage oscilloscopes''. These are distinct from ''

These are found in ''analog phosphor storage oscilloscopes''. These are distinct from ''digital storage oscilloscope

A digital storage oscilloscope (DSO) is an oscilloscope which stores and analyses the input signal digitally rather than using analog techniques. It is now the most common type of oscilloscope in use because of the advanced trigger, storage, ...

s'' which rely on solid state digital memory to store the image.

Where a single brief event is monitored by an oscilloscope, such an event will be displayed by a conventional tube only while it actually occurs. The use of a long persistence phosphor may allow the image to be observed after the event, but only for a few seconds at best. This limitation can be overcome by the use of a direct view storage cathode-ray tube (storage tube). A storage tube will continue to display the event after it has occurred until such time as it is erased. A storage tube is similar to a conventional tube except that it is equipped with a metal grid coated with a dielectric

In electromagnetism, a dielectric (or dielectric medium) is an electrical insulator that can be polarised by an applied electric field. When a dielectric material is placed in an electric field, electric charges do not flow through the ma ...

layer located immediately behind the phosphor screen. An externally applied voltage to the mesh initially ensures that the whole mesh is at a constant potential. This mesh is constantly exposed to a low velocity electron beam from a 'flood gun' which operates independently of the main gun. This flood gun is not deflected like the main gun but constantly 'illuminates' the whole of the storage mesh. The initial charge on the storage mesh is such as to repel the electrons from the flood gun which are prevented from striking the phosphor screen.

When the main electron gun writes an image to the screen, the energy in the main beam is sufficient to create a 'potential relief' on the storage mesh. The areas where this relief is created no longer repel the electrons from the flood gun which now pass through the mesh and illuminate the phosphor screen. Consequently, the image that was briefly traced out by the main gun continues to be displayed after it has occurred. The image can be 'erased' by resupplying the external voltage to the mesh restoring its constant potential. The time for which the image can be displayed was limited because, in practice, the flood gun slowly neutralises the charge on the storage mesh. One way of allowing the image to be retained for longer is temporarily to turn off the flood gun. It is then possible for the image to be retained for several days. The majority of storage tubes allow for a lower voltage to be applied to the storage mesh which slowly restores the initial charge state. By varying this voltage a variable persistence is obtained. Turning off the flood gun and the voltage supply to the storage mesh allows such a tube to operate as a conventional oscilloscope tube.

Vector monitors

Vector monitors were used in early computer aided design systems and are in some late-1970s to mid-1980s arcade games such as ''Asteroids

An asteroid is a minor planet of the inner Solar System. Sizes and shapes of asteroids vary significantly, ranging from 1-meter rocks to a dwarf planet almost 1000 km in diameter; they are rocky, metallic or icy bodies with no atmosphere. ...

''.

They draw graphics point-to-point, rather than scanning a raster. Either monochrome or color CRTs can be used in vector displays, and the essential principles of CRT design and operation are the same for either type of display; the main difference is in the beam deflection patterns and circuits.

Data storage tubes

The Williams tube or Williams-Kilburn tube was a cathode-ray tube used to electronically store binary data. It was used in computers of the 1940s as a random-access digital storage device. In contrast to other CRTs in this article, the Williams tube was not a display device, and in fact could not be viewed since a metal plate covered its screen.

Cat's eye

In some vacuum tube

A vacuum tube, electron tube, valve (British usage), or tube (North America), is a device that controls electric current flow in a high vacuum between electrodes to which an electric potential difference has been applied.

The type known as ...

radio sets, a "Magic Eye" or "Tuning Eye" tube was provided to assist in tuning the receiver. Tuning would be adjusted until the width of a radial shadow was minimized. This was used instead of a more expensive electromechanical meter, which later came to be used on higher-end tuners when transistor sets lacked the high voltage required to drive the device. The same type of device was used with tape recorders as a recording level meter, and for various other applications including electrical test equipment.

Charactrons

Some displays for early computers (those that needed to display more text than was practical using vectors, or that required high speed for photographic output) used Charactron CRTs. These incorporate a perforated metal character mask (stencil

Stencilling produces an image or pattern on a surface, by applying pigment to a surface through an intermediate object, with designed holes in the intermediate object, to create a pattern or image on a surface, by allowing the pigment to reach ...

), which shapes a wide electron beam to form a character on the screen. The system selects a character on the mask using one set of deflection circuits, but that causes the extruded beam to be aimed off-axis, so a second set of deflection plates has to re-aim the beam so it is headed toward the center of the screen. A third set of plates places the character wherever required. The beam is unblanked (turned on) briefly to draw the character at that position. Graphics could be drawn by selecting the position on the mask corresponding to the code for a space (in practice, they were simply not drawn), which had a small round hole in the center; this effectively disabled the character mask, and the system reverted to regular vector behavior. Charactrons had exceptionally long necks, because of the need for three deflection systems.

Nimo

Nimo was the trademark of a family of small specialised CRTs manufactured by

Nimo was the trademark of a family of small specialised CRTs manufactured by Industrial Electronic Engineers

Industrial Electronic Engineers, Inc. (IEE; sometimes spelled Industrial Electronics Engineers), is an American electronics company based in Van Nuys, California. Founded by Donald Gumpertz in 1946, the company is best known for its electronic di ...

. These had 10 electron guns which produced electron beams in the form of digits in a manner similar to that of the charactron. The tubes were either simple single-digit displays or more complex 4- or 6- digit displays produced by means of a suitable magnetic deflection system. Having little of the complexities of a standard CRT, the tube required a relatively simple driving circuit, and as the image was projected on the glass face, it provided a much wider viewing angle than competitive types (e.g., nixie tube

A Nixie tube ( ), or cold cathode display, is an electronic device used for displaying numerals or other information using glow discharge.

The glass tube contains a wire-mesh anode and multiple cathodes, shaped like numerals or other symbo ...

s). However, their requirement for several voltages and their high voltage made them uncommon.

Flood-beam CRT

Flood-beam CRTs are small tubes that are arranged as pixels for large video walls like Jumbotrons. The first screen using this technology (called Diamond Vision by Mitsubishi Electric) was introduced by Mitsubishi Electric

, established on 15 January 1921, is a Japanese multinational electronics and electrical equipment manufacturing company headquartered in Tokyo, Japan. It is one of the core companies of Mitsubishi. The products from MELCO include elevators an ...

for the 1980 Major League Baseball All-Star Game

The 1980 Major League Baseball All-Star Game was the 51st midseason exhibition between the all-stars of the American League (AL) and the National League (NL), the two leagues comprising Major League Baseball. The game was played on July 8, 1980 ...

. It differs from a normal CRT in that the electron gun within does not produce a focused controllable beam. Instead, electrons are sprayed in a wide cone across the entire front of the phosphor screen, basically making each unit act as a single light bulb. Each one is coated with a red, green or blue phosphor, to make up the color sub-pixels. This technology has largely been replaced with light-emitting diode

A light-emitting diode (LED) is a semiconductor Electronics, device that Light#Light sources, emits light when Electric current, current flows through it. Electrons in the semiconductor recombine with electron holes, releasing energy i ...

displays. Unfocused and undeflected CRTs were used as grid-controlled stroboscope lamps since 1958. Electron-stimulated luminescence

Electron-stimulated luminescence (ESL) is production of light by cathodoluminescence, i.e. by a beam of electrons made to hit a fluorescent phosphor surface. This is also the method used to produce light in a cathode ray tube (CRT). Experimental li ...

(ESL) lamps, which use the same operating principle, were released in 2011.

Print-head CRT

CRTs with an unphosphored front glass but with fine wires embedded in it were used as electrostatic print heads in the 1960s. The wires would pass the electron beam current through the glass onto a sheet of paper where the desired content was therefore deposited as an electrical charge pattern. The paper was then passed near a pool of liquid ink with the opposite charge. The charged areas of the paper attract the ink and thus form the image.

Zeus – thin CRT display

In the late 1990s and early 2000s Philips Research Laboratories

Koninklijke Philips N.V. (), commonly shortened to Philips, is a Dutch multinational conglomerate corporation that was founded in Eindhoven in 1891. Since 1997, it has been mostly headquartered in Amsterdam, though the Benelux headquarters is ...

experimented with a type of thin CRT known as the ''Zeus'' display, which contained CRT-like functionality in a flat-panel display

A flat-panel display (FPD) is an electronic display used to display visual content such as text or images. It is present in consumer, medical, transportation, and industrial equipment.

Flat-panel displays are thin, lightweight, provide better l ...

. The devices were demonstrated but never marketed.

Slimmer CRT

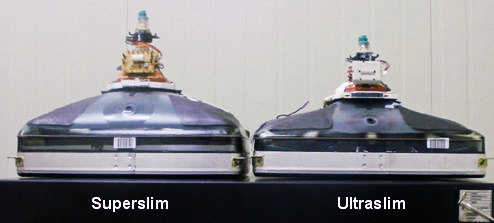

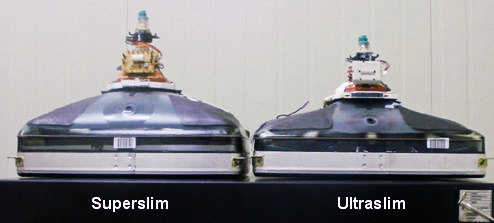

Some CRT manufacturers, both LG.Philips Displays (later LP Displays) and Samsung SDI, innovated CRT technology by creating a slimmer tube. Slimmer CRT had the trade names Superslim, Ultraslim,

Some CRT manufacturers, both LG.Philips Displays (later LP Displays) and Samsung SDI, innovated CRT technology by creating a slimmer tube. Slimmer CRT had the trade names Superslim, Ultraslim,

Health concerns

Ionizing radiation

CRTs can emit a small amount of X-ray

An X-ray, or, much less commonly, X-radiation, is a penetrating form of high-energy electromagnetic radiation. Most X-rays have a wavelength ranging from 10 picometers to 10 nanometers, corresponding to frequencies in the range 30&nb ...

radiation; this is a result of the electron beam's bombardment of the shadow mask/aperture grille and phosphors, which produces bremsstrahlung

''Bremsstrahlung'' (), from "to brake" and "radiation"; i.e., "braking radiation" or "deceleration radiation", is electromagnetic radiation produced by the deceleration of a charged particle when deflected by another charged particle, typical ...

(braking radiation) as the high-energy electrons are decelerated. The amount of radiation escaping the front of the monitor is widely considered not to be harmful. The Food and Drug Administration

The United States Food and Drug Administration (FDA or US FDA) is a federal agency of the Department of Health and Human Services. The FDA is responsible for protecting and promoting public health through the control and supervision of food ...

regulations in are used to strictly limit, for instance, television receivers to 0.5 milliroentgens per hour at a distance of from any external surface; since 2007, most CRTs have emissions that fall well below this limit. Note that the roentgen is an outdated unit and does not account for dose absorption. The conversion rate is about .877 roentgen per rem

Rem or REM may refer to:

Music

* R.E.M., an American rock band

* ''R.E.M.'' (EP), by Green

* "R.E.M." (song), by Ariana Grande

Organizations

* La République En Marche!, a French centrist political party

* Reichserziehungsministerium, in Nazi ...

. Assuming that the viewer absorbed the entire dose (which is unlikely), and that they watched TV for 2 hours a day, a .5 milliroentgen hourly dose would increase the viewers yearly dose by 320 millirem. For comparison, the average background radiation in the United States is 310 millirem a year. Negative effects of chronic radiation are not generally noticeable until doses over 20,000 millirem.