Brushless motor on:

[Wikipedia]

[Google]

[Amazon]

A brushless DC electric motor (BLDC motor or BL motor), also known as an electronically commutated motor (ECM or EC motor) or synchronous DC motor, is a

A brushless DC electric motor (BLDC motor or BL motor), also known as an electronically commutated motor (ECM or EC motor) or synchronous DC motor, is a

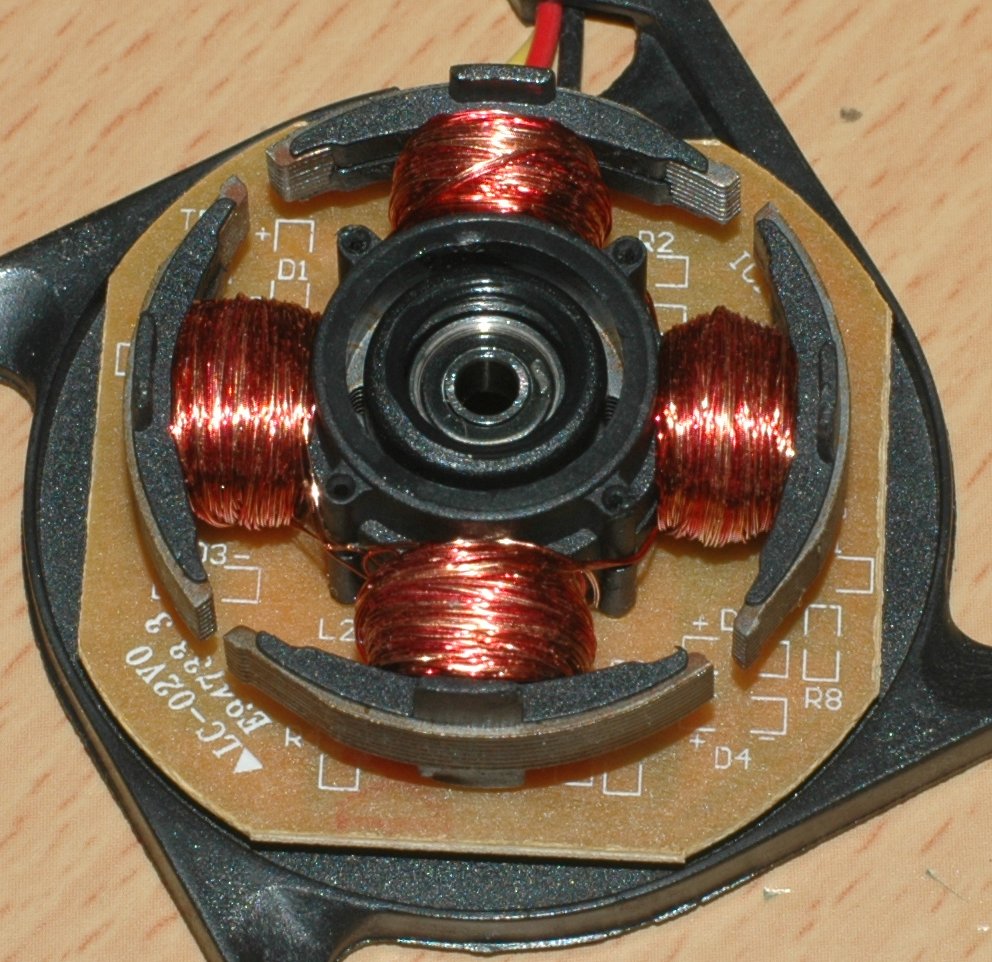

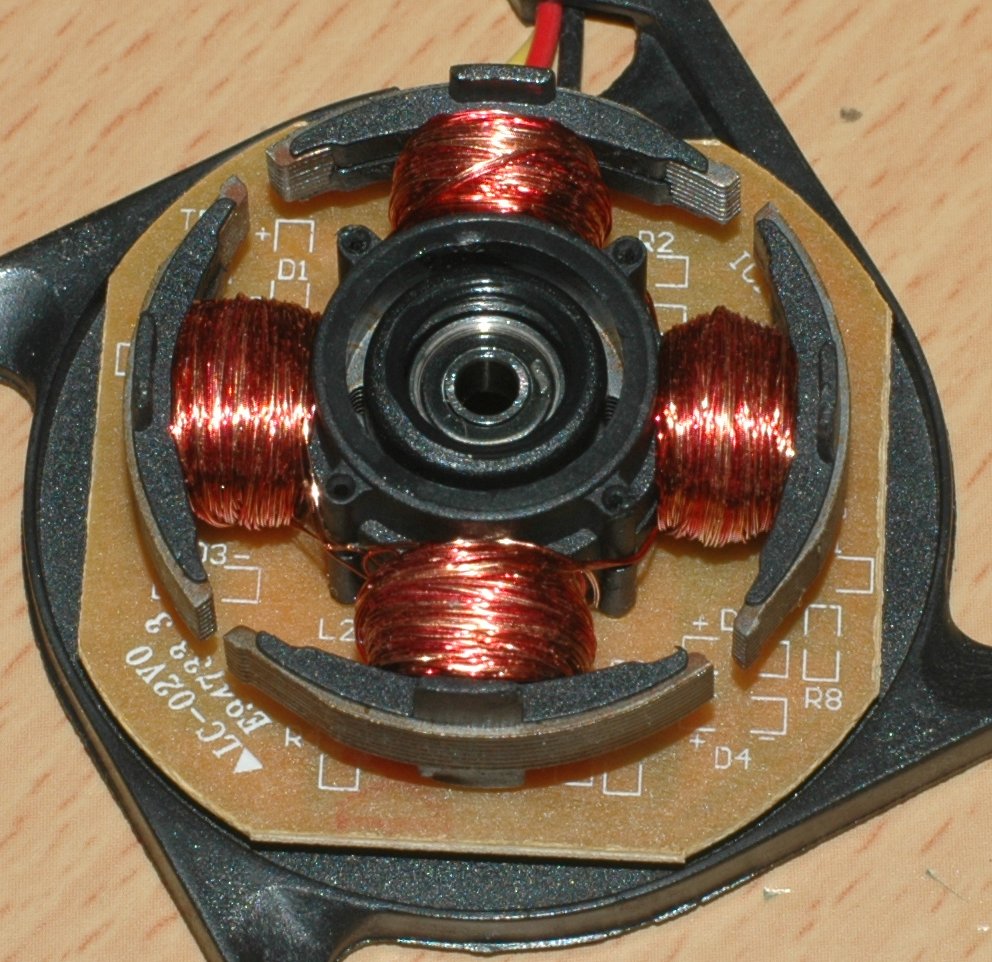

Brushless motors can be constructed in several different physical configurations. In the conventional

Brushless motors can be constructed in several different physical configurations. In the conventional

Brushless motors fulfill many functions originally performed by brushed DC motors, but cost and control complexity prevents brushless motors from replacing brushed motors completely in the lowest-cost areas. Nevertheless, brushless motors have come to dominate many applications, particularly devices such as computer hard drives and CD/DVD players. Small cooling fans in electronic equipment are powered exclusively by brushless motors. They can be found in cordless power tools where the increased efficiency of the motor leads to longer periods of use before the battery needs to be charged. Low speed, low power brushless motors are used in

Brushless motors fulfill many functions originally performed by brushed DC motors, but cost and control complexity prevents brushless motors from replacing brushed motors completely in the lowest-cost areas. Nevertheless, brushless motors have come to dominate many applications, particularly devices such as computer hard drives and CD/DVD players. Small cooling fans in electronic equipment are powered exclusively by brushless motors. They can be found in cordless power tools where the increased efficiency of the motor leads to longer periods of use before the battery needs to be charged. Low speed, low power brushless motors are used in

Brushless motors have become a popular motor choice for

Brushless motors have become a popular motor choice for

"Traxxas Big Block brushless motor"

' Brushless motors are capable of producing more torque and have a faster peak rotational speed compared to nitro- or gasoline-powered engines.

Electric Drives – Brushless DC / AC and Reluctance Motors

with useful diagrams

How Brushless Motor and ESC Work

– Video explanation how Brushless DC Motor works, plus how to control one with an Arduino micro-controller. {{Authority control DC motors Electric motors 20th-century inventions

A brushless DC electric motor (BLDC motor or BL motor), also known as an electronically commutated motor (ECM or EC motor) or synchronous DC motor, is a

A brushless DC electric motor (BLDC motor or BL motor), also known as an electronically commutated motor (ECM or EC motor) or synchronous DC motor, is a synchronous motor

A synchronous electric motor is an AC electric motor in which, at steady state,

the rotation of the shaft is synchronized with the frequency of the supply current; the rotation period is exactly equal to an integral number of AC cycles. Syn ...

using a direct current

Direct current (DC) is one-directional flow of electric charge. An electrochemical cell is a prime example of DC power. Direct current may flow through a conductor such as a wire, but can also flow through semiconductors, insulators, or eve ...

(DC) electric

Electricity is the set of physical phenomena associated with the presence and motion of matter that has a property of electric charge. Electricity is related to magnetism, both being part of the phenomenon of electromagnetism, as described by ...

power supply. It uses an electronic controller to switch DC currents to the motor windings

An electromagnetic coil is an electrical conductor such as a wire in the shape of a coil (spiral or helix). Electromagnetic coils are used in electrical engineering, in applications where electric currents interact with magnetic fields, in de ...

producing magnetic fields which effectively rotate in space and which the permanent magnet rotor follows. The controller adjusts the phase and amplitude of the DC current pulses to control the speed

In everyday use and in kinematics, the speed (commonly referred to as ''v'') of an object is the magnitude

Magnitude may refer to:

Mathematics

*Euclidean vector, a quantity defined by both its magnitude and its direction

*Magnitude (ma ...

and torque

In physics and mechanics, torque is the rotational equivalent of linear force. It is also referred to as the moment of force (also abbreviated to moment). It represents the capability of a force to produce change in the rotational motion of th ...

of the motor. This control system is an alternative to the mechanical commutator (brushes) used in many conventional electric motors.

The construction of a brushless motor system is typically similar to a permanent magnet synchronous motor

A synchronous electric motor is an AC electric motor in which, at steady state,

the rotation of the shaft is synchronized with the frequency of the supply current; the rotation period is exactly equal to an integral number of AC cycles. Sync ...

(PMSM), but can also be a switched reluctance motor, or an induction (asynchronous) motor. They may also use neodymium magnets

A hard_disk_drive.html"_;"title="Nickel-plated_neodymium_magnet_on_a_bracket_from_a_hard_disk_drive">Nickel-plated_neodymium_magnet_on_a_bracket_from_a_hard_disk_drive_

file:Nd-magnet.jpg.html" ;"title="hard_disk_drive_.html" ;"title="hard_disk_d ...

and be outrunner

An outrunner is an electric motor having the rotor outside the stator, as though the motor were turned inside out. They are often used in radio-controlled model aircraft.

This type of motor spins its outer shell around its windings, much like ...

s (the stator is surrounded by the rotor), inrunner

The term inrunner refers to an electric motor where the rotor (runner) is inside the stator. The term is in particular used for brushless motors to differentiate them from outrunners that have their rotor outside the stator. The vast majority of ...

s (the rotor is surrounded by the stator), or axial (the rotor and stator are flat and parallel).

The advantages of a brushless motor over brushed motors are high power-to-weight ratio, high speed, nearly instantaneous control of speed (rpm) and torque, high efficiency, and low maintenance. Brushless motors find applications in such places as computer peripherals (disk drives, printers), hand-held power tools, and vehicles ranging from model aircraft to automobiles. In modern washing machines, brushless DC motors have allowed replacement of rubber belts and gearboxes by a direct-drive design.

Background

Brushed DC motors were invented in the 19th century and are still common. Brushless DC motors were made possible by the development ofsolid state electronics

Solid-state electronics means semiconductor electronics: electronic equipment using semiconductor devices such as transistors, diodes and integrated circuits (ICs). The term is also used as an adjective for devices in which semiconductor electr ...

in the 1960s.

An electric motor develops torque

In physics and mechanics, torque is the rotational equivalent of linear force. It is also referred to as the moment of force (also abbreviated to moment). It represents the capability of a force to produce change in the rotational motion of th ...

by keeping the magnetic fields of the rotor

Rotor may refer to:

Science and technology

Engineering

* Rotor (electric), the non-stationary part of an alternator or electric motor, operating with a stationary element so called the stator

*Helicopter rotor, the rotary wing(s) of a rotorcraft ...

(the rotating part of the machine) and the stator (the fixed part of the machine) misaligned. One or both sets of magnets are electromagnet

An electromagnet is a type of magnet in which the magnetic field is produced by an electric current. Electromagnets usually consist of wire wound into a coil. A current through the wire creates a magnetic field which is concentrated in ...

s, made of a coil of wire wound around an iron core. DC running through the wire winding creates the magnetic field, providing the power which runs the motor. The misalignment generates a torque that tries to realign the fields. As the rotor moves, and the fields come into alignment, it is necessary to move either the rotor's or stator's field to maintain the misalignment and continue to generate torque and movement. The device that moves the fields based on the position of the rotor is called a commutator.

Brush commutator

In brushed motors this is done with a rotary switch on the motor's shaft called a commutator. It consists of a rotating cylinder or disc divided into multiple metal contact segments on the rotor. The segments are connected to conductor windings on the rotor. Two or more stationary contacts called '' brushes'', made of a soft conductor such asgraphite

Graphite () is a crystalline form of the element carbon. It consists of stacked layers of graphene. Graphite occurs naturally and is the most stable form of carbon under standard conditions. Synthetic and natural graphite are consumed on lar ...

, press against the commutator, making sliding electrical contact with successive segments as the rotor turns. The brushes selectively provide electric current to the windings. As the rotor rotates, the commutator selects different windings and the directional current is applied to a given winding such that the rotor's magnetic field remains misaligned with the stator and creates a torque in one direction.

Disadvantages of commutator

The commutator has disadvantages that has led to a decline in use of brushed motors. These disadvantages are: *Thefriction

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding against each other. There are several types of friction:

*Dry friction is a force that opposes the relative lateral motion of ...

of the brushes sliding along the rotating commutator segments causes power losses that can be significant in a low power motor.

*The soft brush material wears down due to friction, creating dust, and eventually the brushes must be replaced. This makes commutated motors unsuitable for low particulate or sealed applications like hard disk motors, and for applications that require maintenance-free operation.

*The electrical resistance of the sliding brush contact causes a voltage drop in the motor circuit called which consumes energy.

*The repeated abrupt switching of the current through the inductance of the windings causes sparks at the commutator contacts, which is a fire hazard in explosive atmospheres and a source of electronic noise, which can cause electromagnetic interference in nearby microelectronic circuits.

During the last hundred years, high-power DC brushed motors, once the mainstay of industry, were replaced by alternating current

Alternating current (AC) is an electric current which periodically reverses direction and changes its magnitude continuously with time in contrast to direct current (DC) which flows only in one direction. Alternating current is the form in whic ...

(AC) synchronous motor

A synchronous electric motor is an AC electric motor in which, at steady state,

the rotation of the shaft is synchronized with the frequency of the supply current; the rotation period is exactly equal to an integral number of AC cycles. Syn ...

s. Today, brushed motors are used only in low power applications or where only DC is available, but the above drawbacks limit their use even in these applications.

Brushless solution

In brushless DC motors, an electronic servo system replaces the mechanical commutator contacts. An electronic sensor detects the angle of the rotor and controlssemiconductor

A semiconductor is a material which has an electrical conductivity value falling between that of a conductor, such as copper, and an insulator, such as glass. Its resistivity falls as its temperature rises; metals behave in the opposite way. ...

switches such as transistor

upright=1.4, gate (G), body (B), source (S) and drain (D) terminals. The gate is separated from the body by an insulating layer (pink).

A transistor is a semiconductor device used to Electronic amplifier, amplify or electronic switch, switch ...

s which switch current through the windings, either reversing the direction of the current or, in some motors turning it off, at the correct angle so the electromagnets create torque in one direction. The elimination of the sliding contact allows brushless motors to have less friction and longer life; their working life is only limited by the lifetime of their bearings.

Brushed DC motors develop a maximum torque

In physics and mechanics, torque is the rotational equivalent of linear force. It is also referred to as the moment of force (also abbreviated to moment). It represents the capability of a force to produce change in the rotational motion of th ...

when stationary, linearly decreasing as velocity increases. Some limitations of brushed motors can be overcome by brushless motors; they include higher efficiency and lower susceptibility to mechanical wear. These benefits come at the cost of potentially less rugged, more complex, and more expensive control electronics.

A typical brushless motor has permanent magnets that rotate around a fixed armature, eliminating problems associated with connecting current to the moving armature. An electronic controller replaces the commutator assembly of the brushed DC motor, which continually switches the phase to the windings to keep the motor turning. The controller performs similar timed power distribution by using a solid-state circuit rather than the commutator system.

Brushless motors offer several advantages over brushed DC motors, including high torque to weight ratio, increased efficiency producing more torque per watt

The watt (symbol: W) is the unit of power or radiant flux in the International System of Units (SI), equal to 1 joule per second or 1 kg⋅m2⋅s−3. It is used to quantify the rate of energy transfer. The watt is named after James ...

, increased reliability, reduced noise, longer lifetime by eliminating brush and commutator erosion, elimination of ionizing sparks from the commutator, and an overall reduction of electromagnetic interference (EMI). With no windings on the rotor, they are not subjected to centrifugal forces, and because the windings are supported by the housing, they can be cooled by conduction, requiring no airflow inside the motor for cooling. This in turn means that the motor's internals can be entirely enclosed and protected from dirt or other foreign matter.

Brushless motor commutation can be implemented in software using a microcontroller, or may alternatively be implemented using analog or digital circuits. Commutation with electronics instead of brushes allows for greater flexibility and capabilities not available with brushed DC motors, including speed limiting, microstepping operation for slow and fine motion control, and a holding torque when stationary. Controller software can be customized to the specific motor being used in the application, resulting in greater commutation efficiency.

The maximum power that can be applied to a brushless motor is limited almost exclusively by heat; too much heat weakens the magnets and will damage the windings' insulation.

When converting electricity into mechanical power, brushless motors are more efficient than brushed motors primarily due to the absence of brushes, which reduces mechanical energy loss due to friction. The enhanced efficiency is greatest in the no-load and low-load regions of the motor's performance curve.

Environments and requirements in which manufacturers use brushless-type DC motors include maintenance-free operation, high speeds, and operation where sparking is hazardous (i.e. explosive environments) or could affect electronically sensitive equipment.

The construction of a brushless motor resembles a stepper motor, but the motors have important differences due to differences in implementation and operation. While stepper motors are frequently stopped with the rotor in a defined angular position, a brushless motor is usually intended to produce continuous rotation. Both motor types may have a rotor position sensor for internal feedback. Both a stepper motor and a well-designed brushless motor can hold finite torque at zero RPM.

Controller implementations

Because the controller implements the traditional brushes' functionality it needs to know the rotor's orientation relative to the stator coils. This is automatic in a brushed motor due to the fixed geometry of the rotor shaft and brushes. Some designs use Hall effect sensors or a rotary encoder to directly measure the rotor's position. Others measure the back-EMF in the undriven coils to infer the rotor position, eliminating the need for separate Hall effect sensors. These are therefore often called ''sensorless'' controllers. Controllers that sense rotor position based on back-EMF have extra challenges in initiating motion because no back-EMF is produced when the rotor is stationary. This is usually accomplished by beginning rotation from an arbitrary phase, and then skipping to the correct phase if it is found to be wrong. This can cause the motor to run backwards briefly, adding even more complexity to the startup sequence. Other sensorless controllers are capable of measuring winding saturation caused by the position of the magnets to infer the rotor position. A typical controller contains three polarity-reversible outputs controlled by a logic circuit. Simple controllers employcomparator

In electronics, a comparator is a device that compares two voltages or currents and outputs a digital signal indicating which is larger. It has two analog input terminals V_+ and V_- and one binary digital output V_\text. The output is ideally

: ...

s working from the orientation sensors to determine when the output phase should be advanced. More advanced controllers employ a microcontroller to manage acceleration, control motor speed and fine-tune efficiency.

Two key performance parameters of brushless DC motors are the motor constants (torque constant) and ( back-EMF constant, also known as speed constant ).

Variations in construction

inrunner

The term inrunner refers to an electric motor where the rotor (runner) is inside the stator. The term is in particular used for brushless motors to differentiate them from outrunners that have their rotor outside the stator. The vast majority of ...

configuration, the permanent magnets are part of the rotor. Three stator windings surround the rotor. In the external-rotor outrunner

An outrunner is an electric motor having the rotor outside the stator, as though the motor were turned inside out. They are often used in radio-controlled model aircraft.

This type of motor spins its outer shell around its windings, much like ...

configuration, the radial relationship between the coils and magnets is reversed; the stator coils form the center (core) of the motor, while the permanent magnets spin within an overhanging rotor that surrounds the core. Outrunners typically have more poles, set up in triplets to maintain the three groups of windings, and have a higher torque at low RPMs. In the flat axial flux type, used where there are space or shape constraints, stator and rotor plates are mounted face to face. In all brushless motors, the coils are stationary.

There are two common electrical winding configurations; the delta configuration connects three windings to each other in a triangle-like circuit, and power is applied at each of the connections. The wye (''Y''-shaped) configuration, sometimes called a star winding, connects all of the windings to a central point, and power is applied to the remaining end of each winding. A motor with windings in delta configuration gives low torque at low speed but can give higher top speed. Wye configuration gives high torque at low speed, but not as high top speed. The wye winding is normally more efficient. Delta-connected windings can allow high-frequency parasitic electrical currents to circulate entirely within the motor. A Wye-connected winding does not contain a closed loop in which parasitic currents can flow, preventing such losses. Aside from the higher impedance of the wye configuration, from a controller standpoint, the two winding configurations can be treated exactly the same.

Applications

Brushless motors fulfill many functions originally performed by brushed DC motors, but cost and control complexity prevents brushless motors from replacing brushed motors completely in the lowest-cost areas. Nevertheless, brushless motors have come to dominate many applications, particularly devices such as computer hard drives and CD/DVD players. Small cooling fans in electronic equipment are powered exclusively by brushless motors. They can be found in cordless power tools where the increased efficiency of the motor leads to longer periods of use before the battery needs to be charged. Low speed, low power brushless motors are used in

Brushless motors fulfill many functions originally performed by brushed DC motors, but cost and control complexity prevents brushless motors from replacing brushed motors completely in the lowest-cost areas. Nevertheless, brushless motors have come to dominate many applications, particularly devices such as computer hard drives and CD/DVD players. Small cooling fans in electronic equipment are powered exclusively by brushless motors. They can be found in cordless power tools where the increased efficiency of the motor leads to longer periods of use before the battery needs to be charged. Low speed, low power brushless motors are used in direct-drive turntable

A direct-drive turntable is one of the three main phonograph designs currently being produced. The other styles are the belt-drive turntable and the idler-wheel type. Each name is based upon the type of coupling used between the platter of the ...

s for gramophone record

A phonograph record (also known as a gramophone record, especially in British English), or simply a record, is an analog sound storage medium in the form of a flat disc with an inscribed, modulated spiral groove. The groove usually starts ne ...

s.

Transport

Brushless motors are found in electric vehicles, hybrid vehicles,personal transporter

A personal transporter (also powered transporter, electric rideable, personal light electric vehicle, personal mobility device, etc.) is any of a class of compact, mostly recent (21st century), motorised micromobility vehicle for transporting an ...

s, and electric aircraft. Most electric bicycles use brushless motors that are sometimes built into the wheel hub itself, with the stator fixed solidly to the axle and the magnets attached to and rotating with the wheel. The same principle is applied in self-balancing scooter

A self-balancing scooter (also hoverboard, self-balancing board, segway or electric scooter board) is a self-balancing personal transporter consisting of two motorized wheels connected to a pair of articulated pads on which the rider places thei ...

wheels. Most electrically powered radio-controlled models use brushless motors because of their high efficiency.

Cordless tools

Brushless motors are found in many modern cordless tools, including somestring trimmer

A string trimmer, also known by the portmanteau strimmer and the trademarks Weedwacker, Weed eater and Whipper Snipper. is a garden tool for cutting grass, small weeds, and groundcover. It uses a whirling monofilament line instead of a blad ...

s, leaf blowers, saws (circular

Circular may refer to:

* The shape of a circle

* ''Circular'' (album), a 2006 album by Spanish singer Vega

* Circular letter (disambiguation)

** Flyer (pamphlet), a form of advertisement

* Circular reasoning, a type of logical fallacy

* Circular ...

and reciprocating), and drills/ drivers. The weight and efficiency advantages of brushless over brushed motors are more important to handheld, battery-powered tools than to large, stationary tools plugged into an AC outlet.

Heating and ventilation

There is a trend in the heating, ventilation, and air conditioning (HVAC) andrefrigeration

The term refrigeration refers to the process of removing heat from an enclosed space or substance for the purpose of lowering the temperature.International Dictionary of Refrigeration, http://dictionary.iifiir.org/search.phpASHRAE Terminology, ht ...

industries to use brushless motors instead of various types of AC motor

An AC motor is an electric motor driven by an alternating current (AC). The AC motor commonly consists of two basic parts, an outside stator having coils supplied with alternating current to produce a rotating magnetic field, and an inside rotor ...

s. The most significant reason to switch to a brushless motor is a reduction in power required to operate them versus a typical AC motor. In addition to the brushless motor's higher efficiency, HVAC systems, especially those featuring variable-speed or load modulation, use brushless motors to give the built-in microprocessor continuous control over cooling and airflow.

Industrial engineering

The application of brushless DC motors within industrial engineering primarily focuses onmanufacturing engineering

Manufacturing engineering or production engineering is a branch of professional engineering that shares many common concepts and ideas with other fields of engineering such as mechanical, chemical, electrical, and industrial engineering.

Manufa ...

or industrial automation

Automation describes a wide range of technologies that reduce human intervention in processes, namely by predetermining decision criteria, subprocess relationships, and related actions, as well as embodying those predeterminations in machines ...

design. Brushless motors are ideally suited for manufacturing applications because of their high power density, good speed-torque characteristics, high efficiency, wide speed ranges and low maintenance. The most common uses of brushless DC motors in industrial engineering are motion control

Motion control is a sub-field of automation, encompassing the systems or sub-systems involved in moving parts of machines in a controlled manner. Motion control systems are extensively used in a variety of fields for automation purposes, includi ...

, linear actuator

A linear actuator is an actuator that creates motion in a straight line, in contrast to the circular motion of a conventional electric motor. Linear actuators are used in machine tools and industrial machinery, in computer peripherals such as ...

s, servomotor

A servomotor (or servo motor) is a rotary actuator or linear actuator that allows for precise control of angular or linear position, velocity and acceleration. It consists of a suitable motor coupled to a sensor for position feedback. It also ...

s, actuators

An actuator is a component of a machine that is responsible for moving and controlling a mechanism or system, for example by opening a valve. In simple terms, it is a "mover".

An actuator requires a control device (controlled by control signal) an ...

for industrial robots, extruder drive motors and feed drives for CNC machine

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer. A CNC machine processes a pie ...

tools.

Brushless motors are commonly used as pump, fan and spindle drives in adjustable or variable speed applications as they are capable of developing high torque with good speed response. In addition, they can be easily automated for remote control. Due to their construction, they have good thermal characteristics and high energy efficiency. To obtain a variable speed response, brushless motors operate in an electromechanical system that includes an electronic motor controller

A motor controller is a device or group of devices that can coordinate in a predetermined manner the performance of an electric motor. A motor controller might include a manual or automatic means for starting and stopping the motor, selecting forw ...

and a rotor position feedback sensor. Brushless DC motors are widely used as servomotors for machine tool servo drives. Servomotors are used for mechanical displacement, positioning or precision motion control. DC stepper motor

A stepper motor, also known as step motor or stepping motor, is a brushless DC electric motor that divides a full rotation into a number of equal steps. The motor's position can be commanded to move and hold at one of these steps without any posi ...

s can also be used as servomotors; however, since they are operated with open loop control, they typically exhibit torque pulsations.

Brushless motors are used in industrial positioning and actuation applications. For assembly robots, Brushless technogy may be used to build linear motors. The advantage of linear motors is that they can produce linear motion without the need of a transmission system, such as ballscrews, leadscrew, rack-and-pinion, cam

Calmodulin (CaM) (an abbreviation for calcium-modulated protein) is a multifunctional intermediate calcium-binding messenger protein expressed in all eukaryotic cells. It is an intracellular target of the secondary messenger Ca2+, and the bin ...

, gear

A gear is a rotating circular machine part having cut teeth or, in the case of a cogwheel or gearwheel, inserted teeth (called ''cogs''), which mesh with another (compatible) toothed part to transmit (convert) torque and speed. The basic ...

s or belts, that would be necessary for rotary motors. Transmission systems are known to introduce less responsiveness and reduced accuracy. Direct drive, brushless DC linear motors consist of a slotted stator with magnetic teeth and a moving actuator, which has permanent magnets and coil windings. To obtain linear motion, a motor controller excites the coil windings in the actuator causing an interaction of the magnetic fields resulting in linear motion. Tubular linear motors are another form of linear motor design operated in a similar way.

Aeromodelling

Brushless motors have become a popular motor choice for

Brushless motors have become a popular motor choice for model aircraft

A model aircraft is a small unmanned aircraft. Many are replicas of real aircraft. Model aircraft are divided into two basic groups: flying and non-flying. Non-flying models are also termed static, display, or shelf models.

Aircraft manufactur ...

including helicopters

A helicopter is a type of rotorcraft in which lift and thrust are supplied by horizontally spinning rotors. This allows the helicopter to take off and land vertically, to hover, and to fly forward, backward and laterally. These attributes ...

and drones. Their favorable power-to-weight ratios and wide range of available sizes have revolutionized the market for electric-powered model flight, displacing virtually all brushed electric motors, except for low powered inexpensive often toy grade aircraft. They have also encouraged growth of simple, lightweight electric model aircraft, rather than the previous internal combustion engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal c ...

s powering larger and heavier models. The increased power-to-weight ratio of modern batteries and brushless motors allows models to ascend vertically, rather than climb gradually. The low noise and lack of mass compared to small glow fuel internal combustion engines is another reason for their popularity.

Legal restrictions for the use of combustion engine driven model aircraft in some countries, most often due to potential for noise pollution

Noise pollution, also known as environmental noise or sound pollution, is the propagation of noise with ranging impacts on the activity of human or animal life, most of them are harmful to a degree. The source of outdoor noise worldwide is ma ...

—even with purpose-designed muffler

A muffler (North American and Australian English) or silencer (British English) is a device for reducing the noise emitted by the exhaust of an internal combustion engine—especially a noise-deadening device forming part of the exhaust sys ...

s for almost all model engines being available over the most recent decades—have also supported the shift to high-power electric systems.

Radio-controlled cars

Their popularity has also risen in the radio-controlled (RC) car area. Brushless motors have been legal in North American RC car racing in accordance with Radio Operated Auto Racing (ROAR) since 2006. These motors provide a great amount of power to RC racers and, if paired with appropriate gearing and high-discharge lithium polymer (Li-Po) orlithium iron phosphate

Lithium iron phosphate or lithium ferro-phosphate (LFP) is an inorganic compound with the formula . It is a gray, red-grey, brown or black solid that is insoluble in water. The material has attracted attention as a component of lithium iron phosp ...

(LiFePO4) batteries, these cars can achieve speeds over . The maker's product specifications indicate the usage of a "Traxxas Big Block brushless motor"

' Brushless motors are capable of producing more torque and have a faster peak rotational speed compared to nitro- or gasoline-powered engines.

Nitro engine

A nitro engine generally refers to an engine powered with a fuel that contains some portion (usually between 10% and 40%) of nitromethane mixed with methanol. Nitromethane is a highly combustible substance that is generally only used in very spec ...

s peak at around 46,800 r/min and , while a smaller brushless motor can reach 50,000 r/min and . Larger brushless RC motors can reach upwards of and 28,000 r/min to power one-fifth-scale models.

See also

* Piezoelectric motor *Squirrel-cage rotor

A squirrel-cage rotor is the rotating part of the common squirrel-cage induction motor. It consists of a cylinder of steel laminations, with aluminum or copper conductors embedded in its surface. In operation, the non-rotating stator winding i ...

References

Further reading

* * * * *External links

* * * FlashElectric Drives – Brushless DC / AC and Reluctance Motors

with useful diagrams

How Brushless Motor and ESC Work

– Video explanation how Brushless DC Motor works, plus how to control one with an Arduino micro-controller. {{Authority control DC motors Electric motors 20th-century inventions