A3 problem solving on:

[Wikipedia]

[Google]

[Amazon]

A3 problem solving is a structured problem-solving and continuous-improvement approach, first employed at

A3 problem solving is a structured problem-solving and continuous-improvement approach, first employed at

A3 problem solving is a structured problem-solving and continuous-improvement approach, first employed at

A3 problem solving is a structured problem-solving and continuous-improvement approach, first employed at Toyota

is a Japanese multinational automotive manufacturer headquartered in Toyota City, Aichi, Japan. It was founded by Kiichiro Toyoda and incorporated on . Toyota is one of the largest automobile manufacturers in the world, producing about 10 ...

and typically used by lean manufacturing

Lean manufacturing is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. It is closely related to another concept called just-in-time manufacturing ( ...

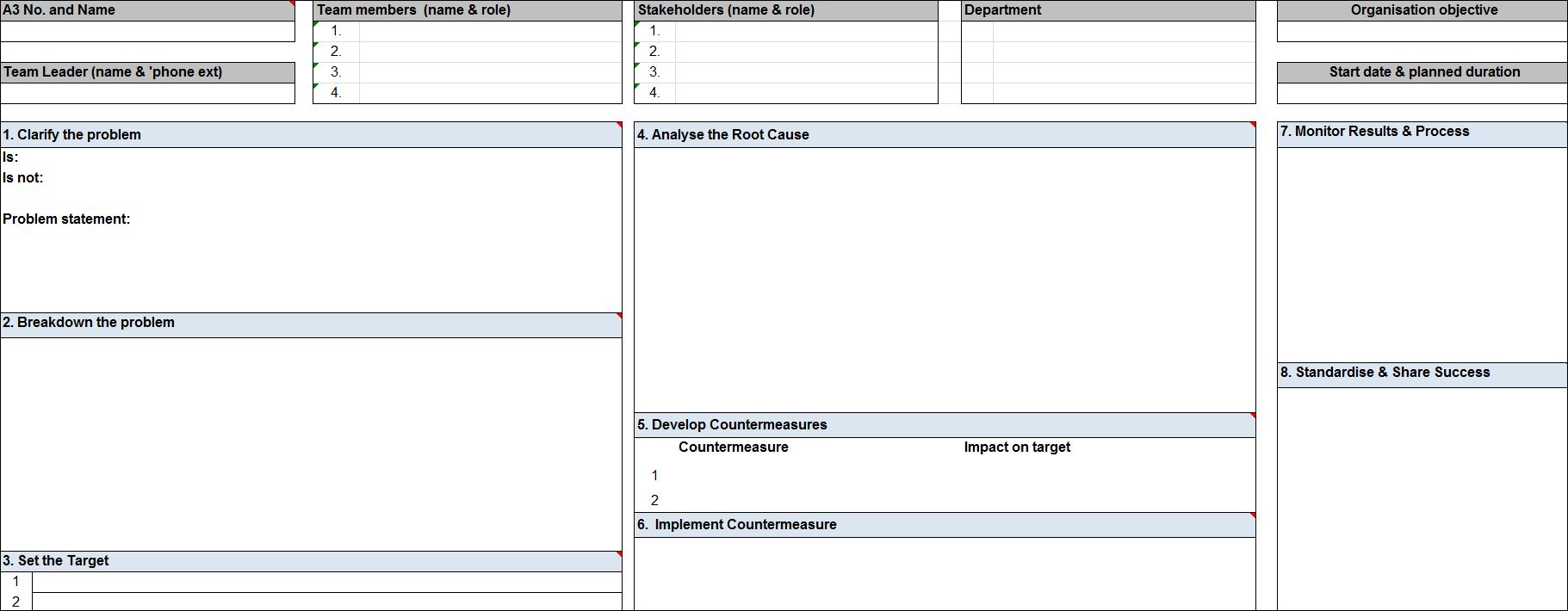

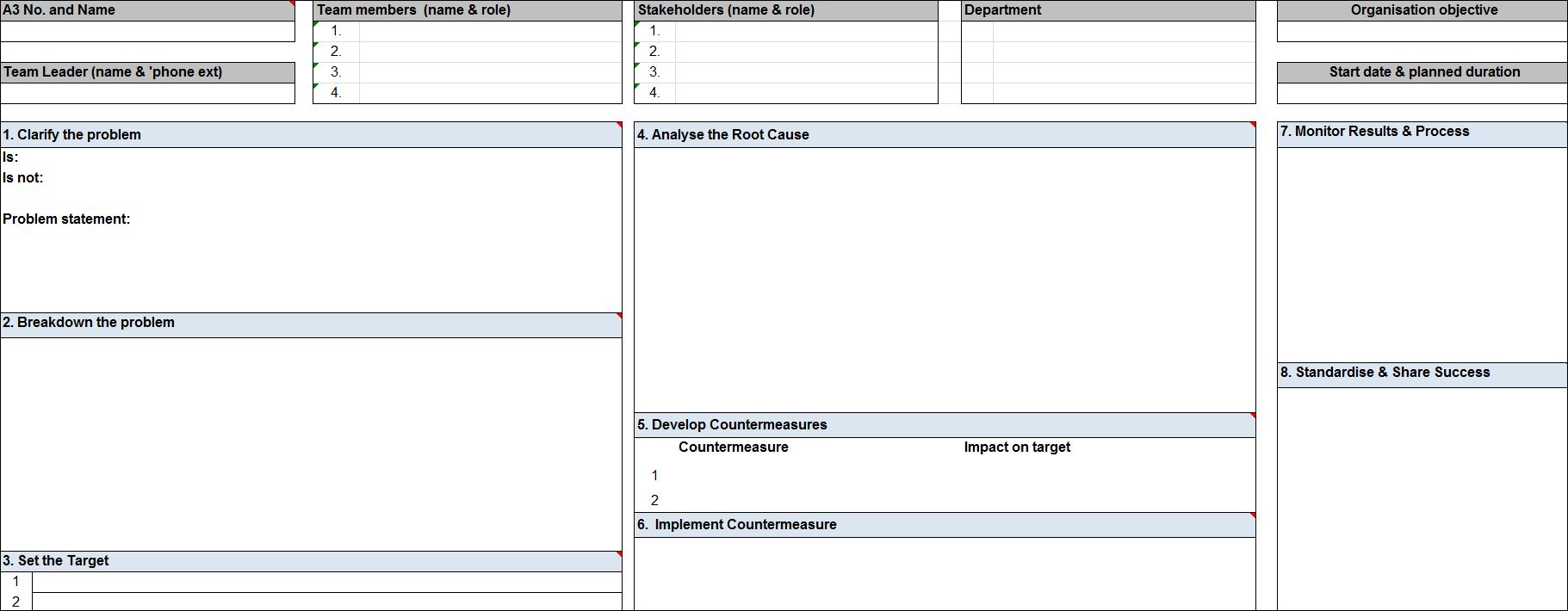

practitioners.; ; It provides a simple and strict procedure that guides problem solving by workers. The approach typically uses a single sheet of ISO A3-size paper, which is the source of its name.

See also

*Analytical quality control Analytical quality control, commonly shortened to AQC, refers to all those processes and procedures designed to ensure that the results of laboratory analysis are consistent, comparable, accurate and within specified limits of precision

Precision, ...

* Corrective and preventative action

Corrective and preventive action (CAPA or simply corrective action) consists of improvements to an organization's processes taken to eliminate causes of non-conformities or other undesirable situations. It is usually a set of actions, laws or regu ...

(CAPA)

* Eight Disciplines Problem Solving

* First article inspection

A First Article Inspection (FAI) is a design verification process for verifying that a new or modified production process produces conforming parts that meet the manufacturing specification detailed in technical or engineering drawings. Typically, ...

(FAI)

* Ishikawa diagram

* Plan–do–check–act

PDCA (plan–do–check–act or plan–do–check–adjust) is an iterative design and management method used in business for the control and continual improvement of processes and products. It is also known as the Shewhart cycle, or the control ...

*

* Root cause analysis

In science

Science is a systematic endeavor that builds and organizes knowledge in the form of testable explanations and predictions about the universe.

Science may be as old as the human species, and some of the earliest archeologic ...

* Quality assurance

Quality assurance (QA) is the term used in both manufacturing and service industries to describe the systematic efforts taken to ensure that the product(s) delivered to customer(s) meet with the contractual and other agreed upon performance, design ...

* Quality management framework

Quality management ensures that an organization, product or service consistently functions well. It has four main components: quality planning, quality assurance, quality control and quality improvement. Quality management is focused not only ...

* Value stream mapping

Notes

References

* * * Quality control tools {{engineering-stub