|

Wärtsilä-Sulzer RTA96-C

The Wärtsilä RT-flex96C is a two-stroke turbocharged low-speed diesel engine designed by the Finnish manufacturer Wärtsilä. It is designed for large container ships that run on heavy fuel oil. Its largest 14-cylinder version is 13.5 meters high, 26.59 meters long, weighs over 2,300 tonnes, and produces 80.08 megawatts. The engine is the largest reciprocating engine in the world. The 14-cylinder version first entered commercial service in September 2006 aboard the ''Emma Mærsk''. The design is similar to the older RTA96C engine, but with common rail technology (in place of traditional camshaft, chain gear, fuel pump and hydraulic actuator systems). This provides maximum performance at lower revolutions per minute (rpm), reduces fuel consumption and emits lower levels of harmful emissions. The engine has crosshead bearings so the always-vertical piston rods create a tight seal under the pistons. Consequently, the lubrication of the engine is split: the cylinders an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wärtsilä

Wärtsilä Oyj Abp (), trading internationally as Wärtsilä Corporation, is a Finnish company which manufactures and services power sources and other equipment in the marine and energy markets. The core products of Wärtsilä include technologies for the energy sector, including gas, multi-fuel, liquid fuel and biofuel power plants and energy storage systems; and technologies for the marine sector, including cruise ships, ferries, fishing vessels, merchant ships, navy ships, special vessels, tugs, yachts and offshore vessels. Ship design capabilities include ferries, tugs, and vessels for the fishing, merchant, offshore and special segments. Services offerings include online services, underwater services, turbocharger services, and also services for the marine, energy, and oil and gas markets. At the end of June 2018, the company employed more than 19,000 workers. Wärtsilä has two main businesses; Energy Business focusing on the energy market, and Marine Business focusing on ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydraulic Actuator

A hydraulic cylinder (also called a linear hydraulic motor) is a mechanical actuator that is used to give a unidirectional force through a unidirectional stroke. It has many applications, notably in construction equipment ( engineering vehicles), manufacturing machinery, elevators, and civil engineering. Operation Hydraulic cylinders get their power from pressurized hydraulic fluid, which is incompressible. Typically oil is used as hydraulic fluid. The hydraulic cylinder consists of a cylinder barrel, in which a piston connected to a piston rod moves back and forth. The barrel is closed on one end by the cylinder bottom (also called the cap) and the other end by the cylinder head (also called the gland) where the piston rod comes out of the cylinder. The piston has sliding rings and seals. The piston divides the inside of the cylinder into two chambers, the bottom chamber (cap end) and the piston rod side chamber (rod end/head-end). Flanges, trunnions, clevises, and lugs are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Straight Engine

The straight or inline engine is an internal combustion engine with all cylinders aligned in one row and having no offset. Usually found in four, six and eight cylinder configurations, they have been used in automobiles, locomotives and aircraft, although the term in-line has a broader meaning when applied to aircraft engines, see Inline engine (aviation). Design A straight engine is considerably easier to build than an otherwise equivalent horizontally opposed or V engine, because both the cylinder bank and crankshaft can be milled from a single metal casting, and it requires fewer cylinder heads and camshafts. In-line engines are also smaller in overall physical dimensions than designs such as the radial, and can be mounted in any direction. Straight configurations are simpler than their V-shaped counterparts. Although six-cylinder engines are inherently balanced, the four-cylinder models are inherently off balance and rough, unlike 90-degree V fours and horizontally ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diesel Engine

The diesel engine, named after Rudolf Diesel, is an internal combustion engine in which ignition of the fuel is caused by the elevated temperature of the air in the cylinder due to mechanical compression; thus, the diesel engine is a so-called compression-ignition engine (CI engine). This contrasts with engines using spark plug-ignition of the air-fuel mixture, such as a petrol engine ( gasoline engine) or a gas engine (using a gaseous fuel like natural gas or liquefied petroleum gas). Diesel engines work by compressing only air, or air plus residual combustion gases from the exhaust (known as exhaust gas recirculation (EGR)). Air is inducted into the chamber during the intake stroke, and compressed during the compression stroke. This increases the air temperature inside the cylinder to such a high degree that atomised diesel fuel injected into the combustion chamber ignites. With the fuel being injected into the air just before combustion, the dispersion of the fuel i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbocharger

In an internal combustion engine, a turbocharger (often called a turbo) is a forced induction device that is powered by the flow of exhaust gases. It uses this energy to compress the intake gas, forcing more air into the engine in order to produce more power for a given displacement. The current categorisation is that a turbocharger is powered by the kinetic energy of the exhaust gasses, whereas a is mechanically powered (usually by a belt from the engine's crankshaft). However, up until the mid-20th century, a turbocharger was called a "turbosupercharger" and was considered a type of supercharger. History Prior to the invention of the turbocharger, |

Engine Configuration

The engine configuration describes the fundamental operating principles by which internal combustion engines are categorized. Piston engines are often categorized by their cylinder layout, valves and camshafts. Wankel engines are often categorized by the number of rotors present. Gas turbine engines are often categorized into turbojets, turbofans, turboprops and turboshafts. Piston engines Piston engines are usually designed with the cylinders in lines parallel to the crankshaft. It is called a straight engine (or 'inline engine') when the cylinders arranged in a single line. Where the cylinders are arranged in two or more lines (such as in V engines or flat engines), each line of cylinders is referred to as a 'cylinder bank'. The angle between cylinder banks is called the 'bank angle'. Engines with multiple banks are shorter than straight engines and can be designed to cancel out the unbalanced forces from each bank, in order to reduce the vibration. Most engines with fou ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Uniflow Diesel Engine

A two-stroke (or two-stroke cycle) engine is a type of internal combustion engine that completes a power cycle with two strokes (up and down movements) of the piston during one power cycle, this power cycle being completed in one revolution of the crankshaft. A four-stroke engine requires four strokes of the piston to complete a power cycle during two crankshaft revolutions. In a two-stroke engine, the end of the combustion stroke and the beginning of the compression stroke happen simultaneously, with the intake and exhaust (or scavenging) functions occurring at the same time. Two-stroke engines often have a high power-to-weight ratio, power being available in a narrow range of rotational speeds called the power band. Two-stroke engines have fewer moving parts than four-stroke engines. History The first commercial two-stroke engine involving cylinder compression is attributed to Scottish engineer Dugald Clerk, who patented his design in 1881. However, unlike most later two- ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dead Centre (engineering)

In a reciprocating engine, the dead centre is the position of a piston in which it is either farthest from, or nearest to, the crankshaft. The former is known as Top Dead Centre (TDC) while the latter is known as Bottom Dead Centre (BDC). More generally, the dead centre is any position of a crank where the applied force is straight along its axis, meaning no turning force can be applied. Many sorts of machines are crank driven, including unicycles, bicycles, tricycles, various types of machine presses, gasoline engines, diesel engines, steam locomotives, and other steam engines. Crank-driven machines rely on the energy stored in a flywheel to overcome the dead centre, or are designed, in the case of multi-cylinder engines, so that dead centres can never exist on all cranks at the same time. A steam locomotive is an example of the latter, the connecting rods being arranged such that the dead centre for each cylinder occurs out of phase with the other one (or more) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lubrication

Lubrication is the process or technique of using a lubricant to reduce friction and wear and tear in a contact between two surfaces. The study of lubrication is a discipline in the field of tribology. Lubrication mechanisms such as fluid-lubricated systems are designed so that the applied load is partially or completely carried by hydrodynamic or hydrostatic pressure, which reduces solid body interactions (and consequently friction and wear). Depending on the degree of surface separation, different lubrication regimes can be distinguished. Adequate lubrication allows smooth, continuous operation of machine elements, reduces the rate of wear, and prevents excessive stresses or seizures at bearings. When lubrication breaks down, components can rub destructively against each other, causing heat, local welding, destructive damage and failure. Lubrication mechanisms Fluid-lubricated systems As the load increases on the contacting surfaces, distinct situations can be observed ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Piston

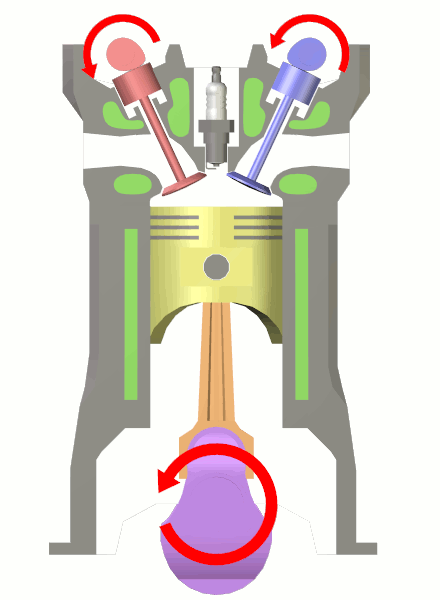

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors, hydraulic cylinders and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tight by piston rings. In an engine, its purpose is to transfer force from expanding gas in the cylinder to the crankshaft via a piston rod and/or connecting rod. In a pump, the function is reversed and force is transferred from the crankshaft to the piston for the purpose of compressing or ejecting the fluid in the cylinder. In some engines, the piston also acts as a valve by covering and uncovering ports in the cylinder. __TOC__ Piston engines Internal combustion engines An internal combustion engine is acted upon by the pressure of the expanding combustion gases in the combustion chamber space at the top of the cylinder. This force then acts downwards through the connecting rod and onto the crankshaft. The connecting rod is a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Piston Rod

In a piston engine, a piston rod joins a piston to the crosshead and thus to the connecting rod that drives the crankshaft or (for steam locomotives) the driving wheels. Internal combustion engines, and in particular all current automobile engines, do not generally have piston rods. Instead they use trunk pistons, where the piston and crosshead are combined and so do not need a rod between them. The term ''piston rod'' has been used as a synonym for 'connecting rod' in the context of these engines. Engines with crossheads have piston rods. These include most steam locomotives and some large marine diesel engines. Steam engines The first single-acting beam engines, such as Newcomen's, had a single power stroke acting downwards. Rather than a piston rod, they used an iron chain. This could transmit a tensile force, but not a compression force pushing upwards. The piston was sealed in the cylinder around its rim but the top of the cylinder was open. Later, a rudimentary pist ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |