|

Standardization

Standardization or standardisation is the process of implementing and developing technical standards based on the consensus of different parties that include firms, users, interest groups, standards organizations and governments. Standardization can help maximize compatibility, interoperability, safety, repeatability, or quality. It can also facilitate a normalization of formerly custom processes. In social sciences, including economics, the idea of ''standardization'' is close to the solution for a coordination problem, a situation in which all parties can realize mutual gains, but only by making mutually consistent decisions. History Early examples Standard weights and measures were developed by the Indus Valley civilization.Iwata, Shigeo (2008), "Weights and Measures in the Indus Valley", ''Encyclopaedia of the History of Science, Technology, and Medicine in Non-Western Cultures (2nd edition)'' edited by Helaine Selin, pp. 2254–2255, Springer, . The centraliz ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Technical Standard

A technical standard is an established norm or requirement for a repeatable technical task which is applied to a common and repeated use of rules, conditions, guidelines or characteristics for products or related processes and production methods, and related management systems practices. A technical standard includes definition of terms; classification of components; delineation of procedures; specification of dimensions, materials, performance, designs, or operations; measurement of quality and quantity in describing materials, processes, products, systems, services, or practices; test methods and sampling procedures; or descriptions of fit and measurements of size or strength. It is usually a formal document that establishes uniform engineering or technical criteria, methods, processes, and practices. In contrast, a custom, convention, company product, corporate standard, and so forth that becomes generally accepted and dominant is often called a ''de facto'' standard. A techni ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Technical Standard

A technical standard is an established norm or requirement for a repeatable technical task which is applied to a common and repeated use of rules, conditions, guidelines or characteristics for products or related processes and production methods, and related management systems practices. A technical standard includes definition of terms; classification of components; delineation of procedures; specification of dimensions, materials, performance, designs, or operations; measurement of quality and quantity in describing materials, processes, products, systems, services, or practices; test methods and sampling procedures; or descriptions of fit and measurements of size or strength. It is usually a formal document that establishes uniform engineering or technical criteria, methods, processes, and practices. In contrast, a custom, convention, company product, corporate standard, and so forth that becomes generally accepted and dominant is often called a ''de facto'' standard. A techni ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Safety

Safety is the state of being "safe", the condition of being protected from harm or other danger. Safety can also refer to the control of recognized hazards in order to achieve an acceptable level of risk. Meanings There are two slightly different meanings of ''safety''. For example, ''home safety'' may indicate a building's ability to protect against external harm events (such as weather, home invasion, etc.), or may indicate that its internal installations (such as appliances, stairs, etc.) are safe (not dangerous or harmful) for its inhabitants. Discussions of safety often include mention of related terms. Security is such a term. With time the definitions between these two have often become interchanged, equated, and frequently appear juxtaposed in the same sentence. Readers unfortunately are left to conclude whether they comprise a redundancy. This confuses the uniqueness that should be reserved for each by itself. When seen as unique, as we intend here, each term will a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Quality (business)

In business, engineering, and manufacturing, quality – or high quality – has a pragmatic interpretation as the non-inferiority or superiority of something (goods or services); it is also defined as being suitable for the intended purpose (fitness for purpose) while satisfying customer expectations. Quality is a perceptual, conditional, and somewhat subjective attribute and may be understood differently by different people. Consumers may focus on the specification quality of a product/service, or how it compares to competitors in the marketplace. Producers might measure the conformance quality, or degree to which the product/service was produced correctly. Support personnel may measure quality in the degree that a product is reliable, maintainable, or sustainable. In such ways, the subjectivity of quality is rendered objective via operational definitions and measured with metrics such as proxy measures. Description There are many aspects of quality in a business conte ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Screw-cutting Lathe

A screw-cutting lathe is a machine (specifically, a lathe) capable of cutting very accurate screw threads via single-point screw-cutting, which is the process of guiding the linear motion of the tool bit in a precisely known ratio to the rotating motion of the workpiece. This is accomplished by gearing the leadscrew (which drives the tool bit's movement) to the spindle with a certain gear ratio for each thread pitch. Every degree of spindle rotation is matched by a certain distance of linear tool travel, depending on the desired thread pitch (English or metric, fine or coarse, etc.). The name "screw-cutting lathe" carries a taxonomic qualification on its use—it is a term of historical classification rather than one of current commercial machine tool terminology. Early lathes, many centuries ago, were not adapted to screw-cutting. Later, from the Late Middle Ages until the early nineteenth century, some lathes were distinguishable as "screw-cutting lathes" because of the scre ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Repeatability

Repeatability or test–retest reliability is the closeness of the agreement between the results of successive measurements of the same measure, when carried out under the same conditions of measurement. In other words, the measurements are taken by a single person or instrument on the same item, under the same conditions, and in a short period of time. A less-than-perfect test–retest reliability causes test–retest variability. Such variability can be caused by, for example, intra-individual variability and inter-observer variability. A measurement may be said to be ''repeatable'' when this variation is smaller than a pre-determined acceptance criterion. Test–retest variability is practically used, for example, in medical monitoring of conditions. In these situations, there is often a predetermined "critical difference", and for differences in monitored values that are smaller than this critical difference, the possibility of variability as a sole cause of the differen ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mohenjo-daro

Mohenjo-daro (; sd, موئن جو دڙو'', ''meaning 'Mound of the Dead Men';Mohenjo-Daro (archaeological site, Pakistan) on Encyclopedia Britannica website Retrieved 25 November 2019 ur, ) is an archaeological site in the province of , . Built around 2500 BCE, it was the largest settlement of the ancient , and one of the world's earliest major |

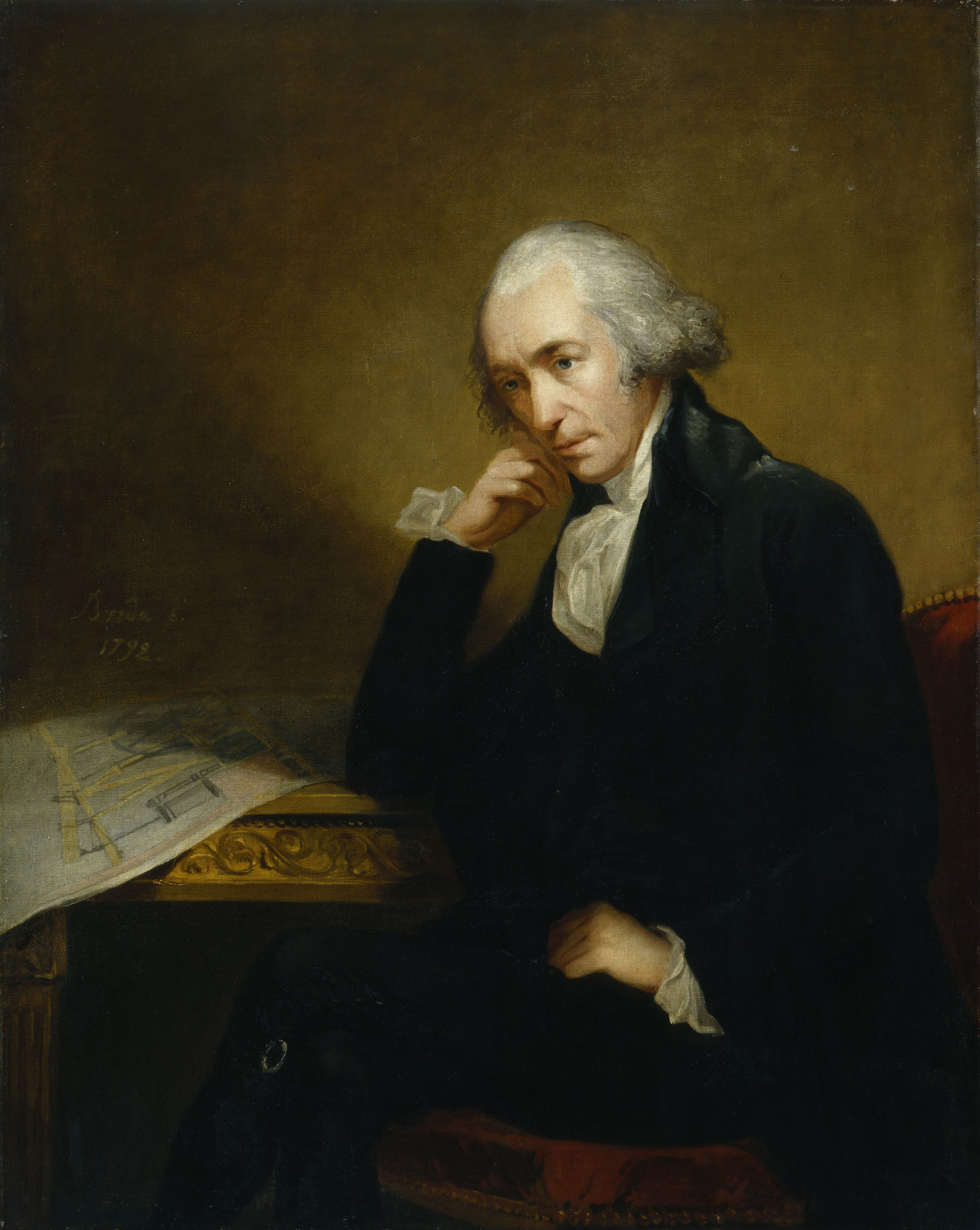

Henry Maudslay

Henry Maudslay ( pronunciation and spelling) (22 August 1771 – 14 February 1831) was an English machine tool innovator, tool and die maker, and inventor. He is considered a founding father of machine tool technology. His inventions were an important foundation for the Industrial Revolution. Maudslay's invention of a metal lathe to cut metal, circa 1800, enabled the manufacture of standard screw thread sizes. Standard screw thread sizes allowed interchangeable parts and the development of mass production. Early life Maudslay was the fifth of seven children of Henry Maudslay, a wheelwright in the Royal Engineers, and Margaret (''nee'' Whitaker), the young widow of Joseph Laundy. His father was wounded in action and so in 1756 became an 'artificer' at the Royal Arsenal, Woolwich (then in Kent), where he remained until 1776 and died in 1780. The family lived in an alley that no longer exists, off Beresford Square, between Powis Street and Beresford Street. Career ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Interchangeable Parts

Interchangeable parts are parts (components) that are identical for practical purposes. They are made to specifications that ensure that they are so nearly identical that they will fit into any assembly of the same type. One such part can freely replace another, without any custom fitting, such as filing. This interchangeability allows easy assembly of new devices, and easier repair of existing devices, while minimizing both the time and skill required of the person doing the assembly or repair. The concept of interchangeability was crucial to the introduction of the assembly line at the beginning of the 20th century, and has become an important element of some modern manufacturing but is missing from other important industries. Interchangeability of parts was achieved by combining a number of innovations and improvements in machining operations and the invention of several machine tools, such as the slide rest lathe, screw-cutting lathe, turret lathe, milling machine and m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine Tool

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All machine tools have some means of constraining the work piece and provide a guided movement of the parts of the machine. Thus, the relative movement between the workpiece and the cutting tool (which is called the toolpath) is controlled or constrained by the machine to at least some extent, rather than being entirely "offhand" or " freehand". It is a power-driven metal cutting machine which assists in managing the needed relative motion between cutting tool and the job that changes the size and shape of the job material. The precise definition of the term ''machine tool'' varies among users, as discussed below. While all machine tools are "machines that help people to make things", not all factory machines are machine tools. Today machi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Revolution

The Industrial Revolution was the transition to new manufacturing processes in Great Britain, continental Europe, and the United States, that occurred during the period from around 1760 to about 1820–1840. This transition included going from hand production methods to machines, new chemical manufacturing and iron production processes, the increasing use of steam power and water power, the development of machine tools and the rise of the mechanized factory system. Output greatly increased, and a result was an unprecedented rise in population and in the rate of population growth. Textiles were the dominant industry of the Industrial Revolution in terms of employment, value of output and capital invested. The textile industry was also the first to use modern production methods. The Industrial Revolution began in Great Britain, and many of the technological and architectural innovations were of British origin. By the mid-18th century, Britain was the world's leadi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Maudslay Screw-cutting Lathes Of Circa 1797 And 1800

Henry Maudslay ( pronunciation and spelling) (22 August 1771 – 14 February 1831) was an English machine tool innovator, tool and die maker, and inventor. He is considered a founding father of machine tool technology. His inventions were an important foundation for the Industrial Revolution. Maudslay's invention of a metal lathe to cut metal, circa 1800, enabled the manufacture of standard screw thread sizes. Standard screw thread sizes allowed interchangeable parts and the development of mass production. Early life Maudslay was the fifth of seven children of Henry Maudslay, a wheelwright in the Royal Engineers, and Margaret (''nee'' Whitaker), the young widow of Joseph Laundy. His father was wounded in action and so in 1756 became an 'artificer' at the Royal Arsenal, Woolwich (then in Kent), where he remained until 1776 and died in 1780. The family lived in an alley that no longer exists, off Beresford Square, between Powis Street and Beresford Street. Career Maud ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |