|

Slurry

A slurry is a mixture of denser solids suspended in liquid, usually water. The most common use of slurry is as a means of transporting solids or separating minerals, the liquid being a carrier that is pumped on a device such as a centrifugal pump. The size of solid particles may vary from 1 micrometre up to hundreds of millimetres. The particles may settle below a certain transport velocity and the mixture can behave like a Newtonian or non-Newtonian fluid. Depending on the mixture, the slurry may be abrasive and/or corrosive. Examples Examples of slurries include: *Cement slurry, a mixture of cement, water, and assorted dry and liquid additives used in the petroleum and other industries *Soil/cement slurry, also called Controlled Low-Strength Material (CLSM), flowable fill, controlled density fill, flowable mortar, plastic soil-cement, K-Krete, and other names *A mixture of thickening agent, oxidizers, and water used to form a gel explosive *A mixture of pyroclastic materi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Slurry Wall

A slurry wall is a civil engineering technique used to build reinforced concrete walls in areas of soft earth close to open water, or with a high groundwater table. This technique is typically used to build diaphragm (water-blocking) walls surrounding tunnels and open cuts, and to lay foundations. Construction While a trench is being excavated to create a form for a wall, it is simultaneously filled with slurry (usually a mixture of bentonite and water). The dense but liquid slurry prevents the trench from collapsing by providing outward pressure, which balances the inward hydraulic forces and also retards water flow into the trench. The density of the slurry mix must be carefully monitored and adjusted to produce the correct outward pressure to prevent the trench walls from collapsing. Slurry walls are typically constructed by starting with a set of concrete guide walls, typically deep and thick. The guide walls are constructed near the ground surface to outline the desir ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coal Slurry

Coal slurry is a mixture of solids (mined coal or coal waste) and liquids (water or organic) produced by a coal preparation plant. Preparation To transform the coal ash into a slurry, coal is separated from non-combustible components and can be fractionated by particle size as well. Coal slurry can be transferred by pipeline or with specialized pumps such as a progressive cavity pump to pump the highly abrasive, corrosive and viscous coal slurry. More than 7 billion tons of coal are mined per year (2010), using approximately 200 litres of water per ton. However, the amount of water required hinges on the surface characteristics of the coal being used. Most coal slurries require the addition of a surfactant to reduce the viscosity, ergo reduce the stress on pipelines and pumps. Recent studies have employed new methods of slurry preparation, like using ultrasonic irradiation and a mixture of natural and synthetic surfactants to improve the stability and rheological properties of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Slurry Pit

A slurry pit, also known as a farm slurry pit, slurry tank, slurry lagoon or slurry store, is a hole, dam, or circular concrete structure where farmers gather all their animal waste together with other unusable organic matter, such as hay and water run off from washing down dairies, stables, and barns, in order to convert it over a lengthy period of time into fertilizer that can eventually be reused on their lands to fertilize crops. The decomposition of this waste material produces deadly gases, making slurry pits potentially lethal without precautions such as the use of a breathing apparatus with air supply. Nutrient value The liquid manure blend, or slurry, can be a rich source of nitrogen, phosphorus, and potassium. Risks Slurry pits present risks of drowning, as well as of suffocation. Decomposition generates gases such as ammonia, methane, carbon dioxide, and hydrogen sulphide Hydrogen sulfide is a chemical compound with the formula . It is a colorless chalcogen-hyd ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Slurry Oil

A slurry is a mixture of denser solids suspended in liquid, usually water. The most common use of slurry is as a means of transporting solids or separating minerals, the liquid being a carrier that is pumped on a device such as a centrifugal pump. The size of solid particles may vary from 1 micrometre up to hundreds of millimetres. The particles may settle below a certain transport velocity and the mixture can behave like a Newtonian or non-Newtonian fluid. Depending on the mixture, the slurry may be abrasive and/or corrosive. Examples Examples of slurries include: *Cement slurry, a mixture of cement, water, and assorted dry and liquid additives used in the petroleum and other industries *Soil/cement slurry, also called Controlled Low-Strength Material (CLSM), flowable fill, controlled density fill, flowable mortar, plastic soil-cement, K-Krete, and other names *A mixture of thickening agent, oxidizers, and water used to form a gel explosive *A mixture of pyroclastic material ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rawmill

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker (cement), clinker, which is then ground to make cement in the cement mill. The raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a large effect upon the efficiency of the whole manufacturing process. History The history of the development of the technology of raw material grinding defines the early history of cement technology. Other stages of cement manufacture used existing technology in the early days. Early hydraulic materials such as hydraulic limes, cement, natural cements and James Parker (cement maker), Parker's Roman cement were all based on "natural" raw materials, burned "as-dug". Because these natural blends of minerals occur only rarely, manufacturers were interested in making a fine-grained artificial mixture ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bentonite

Bentonite () is an absorbent swelling clay consisting mostly of montmorillonite (a type of smectite) which can either be Na-montmorillonite or Ca-montmorillonite. Na-montmorillonite has a considerably greater swelling capacity than Ca-montmorillonite. Bentonite usually forms from the weathering of volcanic ash in seawater, or by hydrothermal circulation through the porosity of volcanic ash beds, which converts (devitrification) the volcanic glass ( obsidian, rhyolite, dacite) present in the ash into clay minerals. In the mineral alteration process, a large fraction (up to 40-50 wt.%) of amorphous silica is dissolved and leached away, leaving the bentonite deposit in place. Bentonite beds are white or pale blue or green (traces of reduced ) in fresh exposures, turning to a cream color and then yellow, red, or brown (traces of oxidized ) as the exposure is weathered further. As a swelling clay, bentonite has the ability to absorb large quantities of water, which i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Slurry Ice

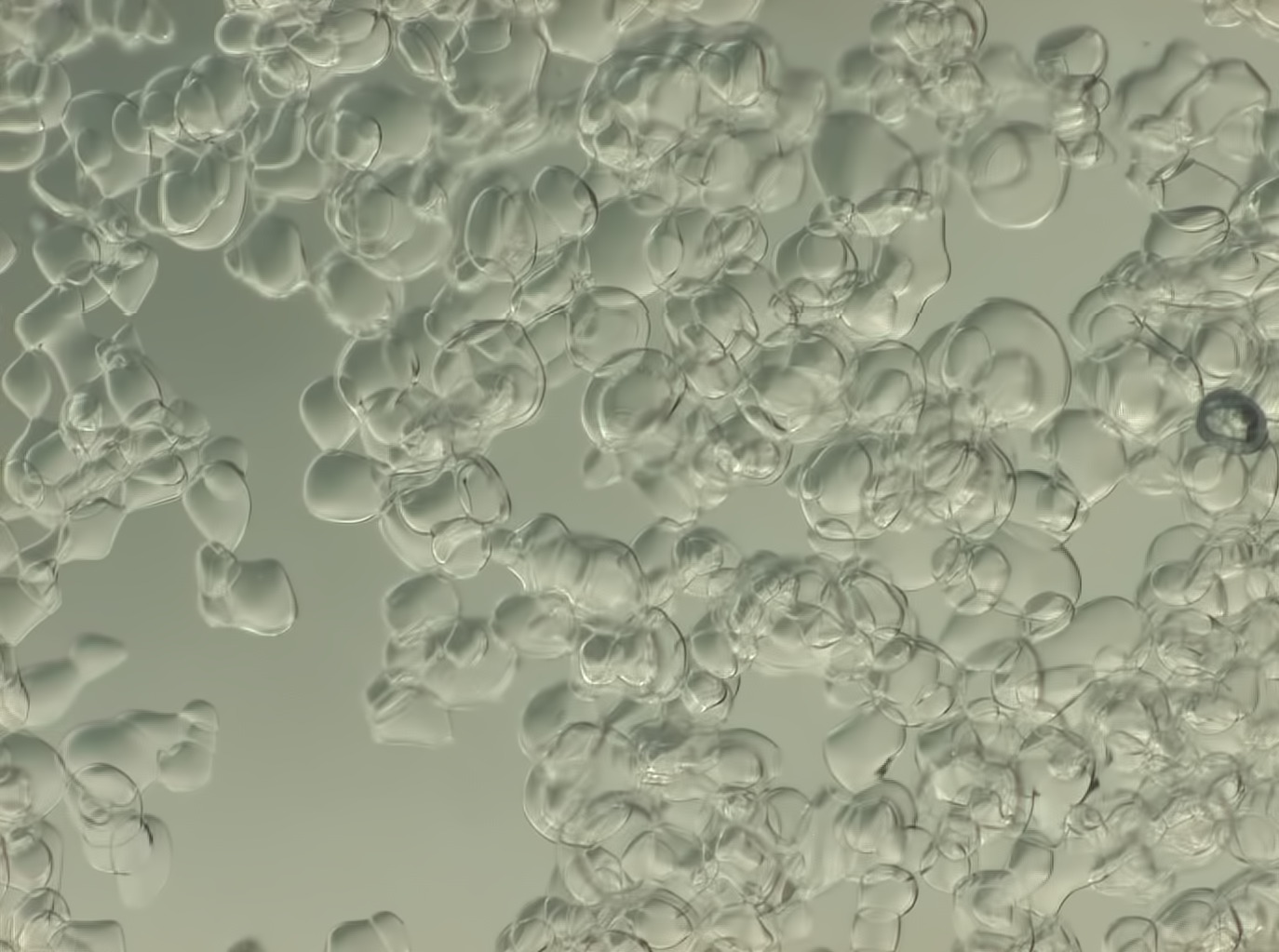

Slurry ice is a phase changing refrigerant made up of millions of ice "micro-crystals" (typically 0.1 to 1 mm in diameter) formed and suspended within a solution of water and a freezing point depressant. Some compounds used in the field are salt, ethylene glycol, propylene glycol, alcohols like isobutyl and ethanol, and sugars like sucrose and glucose. Slurry ice has greater heat absorption compared to single phase refrigerants like brine, because the melting enthalpy (latent heat) of the ice is also used. __TOC__ Characteristics The small ice particle size results in greater heat transfer area than other types of ice for a given weight. It can be packed inside a container as dense as 700 kg/m3, the highest ice-packing factor among all usable industrial ice. The spherical crystals have good flow properties, making them easy to distribute through conventional pumps and piping and over product in direct contact chilling applications, allowing them to flow into crevices and pr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chemical-mechanical Polishing

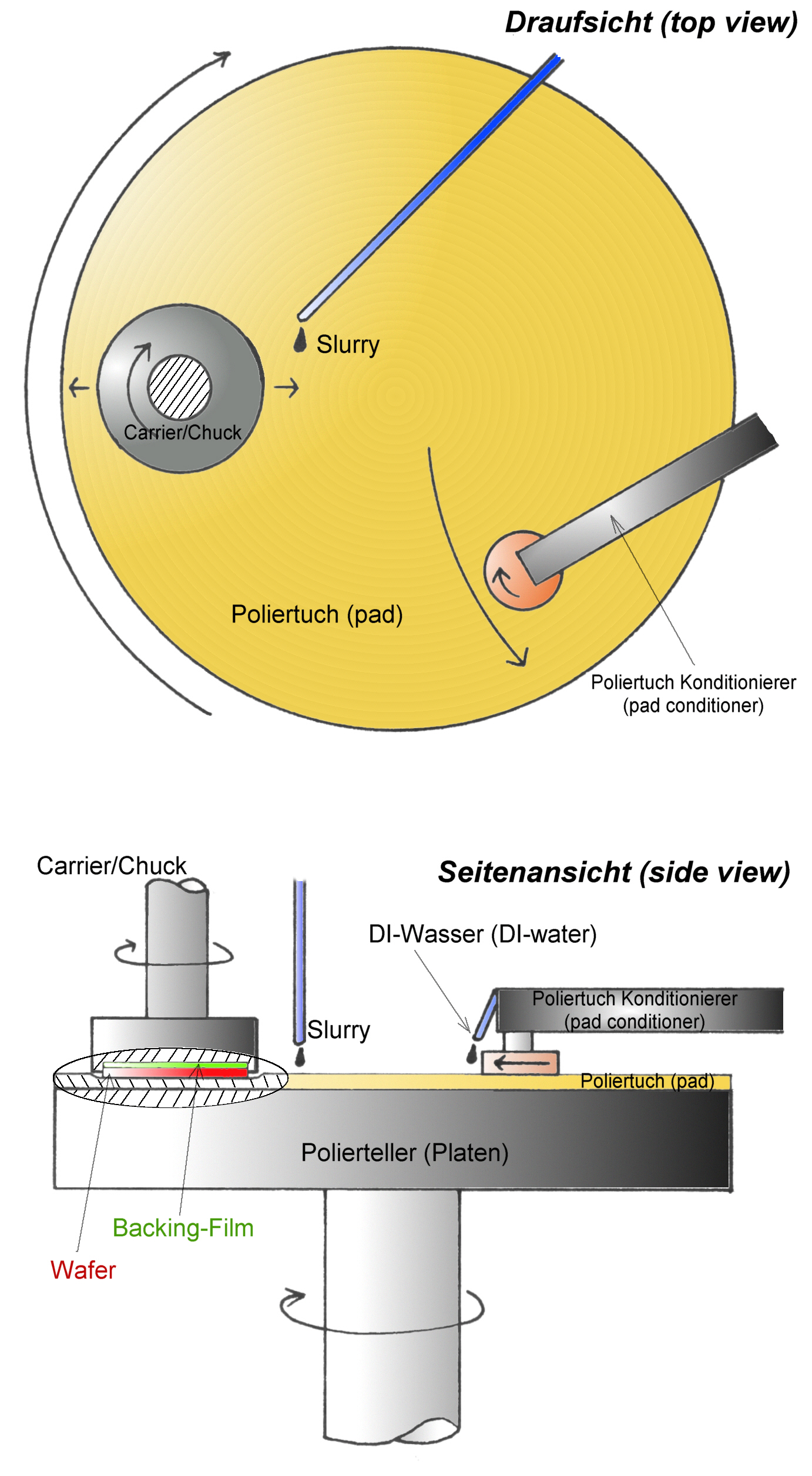

Chemical mechanical polishing (CMP) or planarization is a process of smoothing surfaces with the combination of chemical and mechanical forces. It can be thought of as a hybrid of chemical etching and free abrasive polishing. Description The process uses an abrasive and corrosive chemical slurry (commonly a colloid) in conjunction with a polishing pad and retaining ring, typically of a greater diameter than the wafer. The pad and wafer are pressed together by a dynamic polishing head and held in place by a plastic retaining ring. The dynamic polishing head is rotated with different axes of rotation (i.e., not concentric). This removes material and tends to even out any irregular topography, making the wafer flat or planar. This may be necessary to set up the wafer for the formation of additional circuit elements. For example, CMP can bring the entire surface within the depth of field of a photolithography system, or selectively remove material based on its position. Typical depth- ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Meat Slurry

A reconstituted meat, meat slurry, or emulsified meat is a liquefied meat product that contains fewer fats, pigments and less myoglobin than unprocessed dark meats. Meat slurry is more malleable than dark meats and eases the process of meat distribution as pipelines may be used. Meat slurry is not designed to sell for general consumption; rather, it is used as a meat supplement in food products for humans, such as chicken nuggets, and food for domestic animals. Poultry is a common meat slurry. Beef and pork are also used. Properties and production The characteristics of dark meat from poultry; such as its color, low plasticity, and high fat content; are caused by myoglobin, a pigmented chemical compound found in muscle tissue that undergoes frequent use. Because domestic poultry rarely fly, the flight muscles in the breast contain little myoglobin and appear white. Dark meat which is high in myoglobin is less useful in industry, especially fast food, because it is difficult to mo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Water Gel Explosive

A water-gel explosive is a fuel sensitized explosive mixture consisting of an aqueous ammonium nitrate solution that acts as the oxidizer. Water gels that are cap-insensitive are referred to under United States safety regulations as blasting agents. Water gel explosives have a jelly-like consistency and come in sausage-like packing stapled shut on both sides. Water-gel explosives have almost completely displaced dynamite, becoming the most-used civil blasting agents. Composition Water gels usually have many different ingredients. They contain a gelatinizing agent, also known as a thickener, that modifies their consistency, ranging from easily pourable gels to hard solids. Polyvinyl alcohol, guar gum, dextran gums, and urea-formaldehyde resins are the typical gelling agents. Guar, specifically, is a gelling agent used for the aqueous portion of the water gel explosives. The primary component of water gels is methylamine nitrate. Methylamine nitrate is the salt formed by the neu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Slip (ceramics)

A slip is a clay slurry used to produce pottery and other ceramic wares. Liquified clay, in which there is no fixed ratio of water and clay, is called slip or clay slurry which is used either for joining leather-hard (semi-hardened) clay body (pieces of pottery) together by slipcasting with mould, glazing or decorating the pottery by painting or dipping the pottery with slip.What is slip in pottery thepotterywheel.com, accessed 10 July 2021. Pottery on which slip has been applied either for glazing or decoration is called the . Engobe, from the French word for slip, is an |

Thickening Agent

A thickening agent or thickener is a substance which can increase the viscosity of a liquid without substantially changing its other properties. Edible thickeners are commonly used to thicken sauces, soups, and puddings without altering their taste; thickeners are also used in paints, inks, explosives, and cosmetics. Thickeners may also improve the suspension of other ingredients or emulsions which increases the stability of the product. Thickening agents are often regulated as food additives and as cosmetics and personal hygiene product ingredients. Some thickening agents are gelling agents (gellants), forming a gel, dissolving in the liquid phase as a colloid mixture that forms a weakly cohesive internal structure. Others act as mechanical thixotropic additives with discrete particles adhering or interlocking to resist strain. Thickening agents can also be used when a medical condition such as dysphagia causes difficulty in swallowing. Thickened liquids play a v ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |