|

Dremel

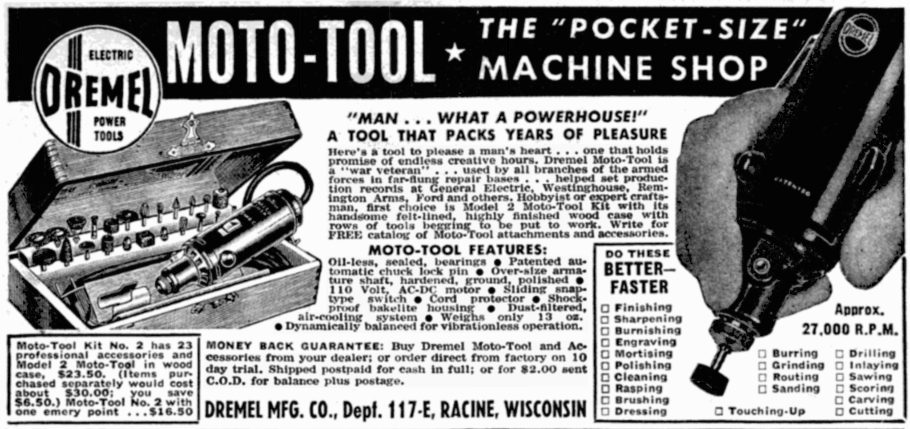

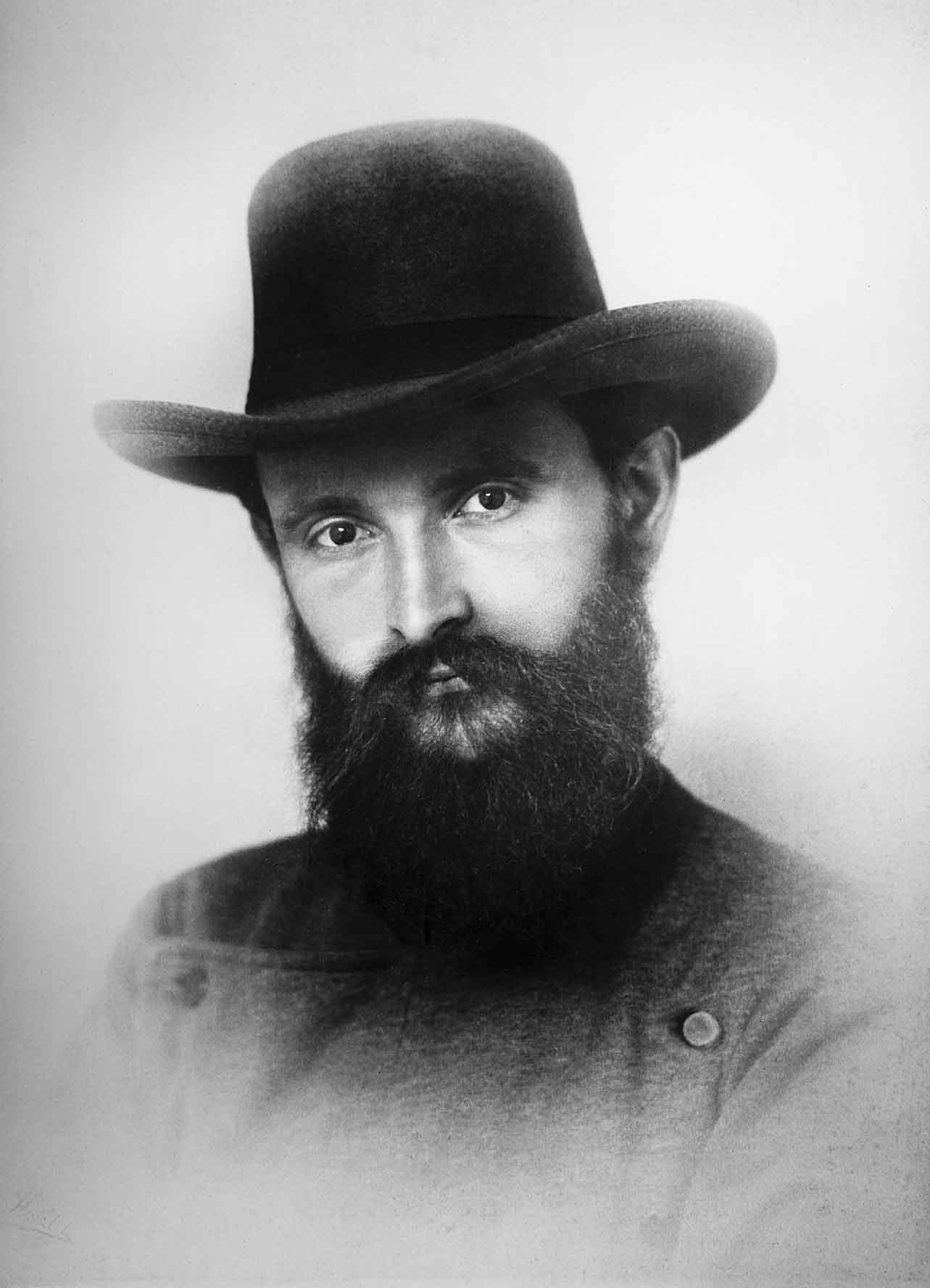

Dremel ( ) is a multinational brand of power tools, focusing on home improvement and hobby applications. Dremel is known primarily for its rotary tools such as the Dremel 3000, 4000 and 8200 series which are similar to the pneumatic die grinders used in the metalworking industry by tool or moldmakers. Dremel later expanded its product range and now produces butane tools, benchtop and hand-held saws and oscillating tools. The Dremel die grinder tools were originally developed by Albert J. Dremel, an Austrian immigrant who founded the Dremel Company in 1932 in Racine, Wisconsin. The company was purchased by Robert Bosch GmbH in 1993, and today it is a division of the Robert Bosch Tool Corporation located in Mount Prospect, Illinois. History Founded by the Austrian inventor Albert J. Dremel in 1932, the company is located in Racine, Wisconsin, US. Albert J. Dremel held 55 patents across a wide range of inventions, including an electric eraser, electric fish scaler, electric ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dremel

Dremel ( ) is a multinational brand of power tools, focusing on home improvement and hobby applications. Dremel is known primarily for its rotary tools such as the Dremel 3000, 4000 and 8200 series which are similar to the pneumatic die grinders used in the metalworking industry by tool or moldmakers. Dremel later expanded its product range and now produces butane tools, benchtop and hand-held saws and oscillating tools. The Dremel die grinder tools were originally developed by Albert J. Dremel, an Austrian immigrant who founded the Dremel Company in 1932 in Racine, Wisconsin. The company was purchased by Robert Bosch GmbH in 1993, and today it is a division of the Robert Bosch Tool Corporation located in Mount Prospect, Illinois. History Founded by the Austrian inventor Albert J. Dremel in 1932, the company is located in Racine, Wisconsin, US. Albert J. Dremel held 55 patents across a wide range of inventions, including an electric eraser, electric fish scaler, electric ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electric Eraser

An eraser (also known as a rubber in some Commonwealth countries, including South Africa from the material first used) is an article of stationery that is used for removing marks from paper or skin (e.g. parchment or vellum). Erasers have a rubbery consistency and come in a variety of shapes, sizes and colors. Some pencils have an eraser on one end. Less expensive erasers are made from synthetic rubber and synthetic soy-based gum, but more expensive or specialized erasers are made from vinyl, plastic, or gum-like materials. At first, erasers were invented to erase mistakes made with a pencil; later, more abrasive ink erasers were introduced. The term is also used for things that remove marks from chalkboards and whiteboards. History Before rubber erasers used today, tablets of wax were used to erase lead or charcoal marks from paper. Bits of rough stone such as sandstone or pumice were used to remove small errors from parchment or papyrus documents written in ink. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Racine, Wisconsin

Racine ( ) is a city in and the county seat of Racine County, Wisconsin, United States. It is located on the shore of Lake Michigan at the mouth of the Root River. Racine is situated 22 miles (35 km) south of Milwaukee and approximately 60 miles (100 km) north of Chicago. It is the principal city of the US Census Bureau's Racine metropolitan area (consisting only of Racine County). The Racine metropolitan area is, in turn, counted as part of the Milwaukee combined statistical area. As of the 2020 U.S. Census, the city had a population of 77,816, making it the 5th largest city in Wisconsin. In January 2017, it was rated "the most affordable place to live in the world" by the Demographia International Housing Affordability survey. Racine is the headquarters of a number of industries, including J. I. Case heavy equipment, S. C. Johnson & Son cleaning and chemical products, Dremel Corporation, Reliance Controls Corporation time controls and transfer switches, Twin Disc, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scroll Saw

A scroll saw is a small electric or pedal-operated saw used to cut intricate curves in wood, metal, or other materials. The fineness of its blade allows it to cut more delicately than a power jigsaw, and more easily than a hand coping saw or fretsaw. Like those tools, it is capable of creating curves with edges, by pivoting its table. The scroll saw's name derives from its traditional use in making scrollwork, sculptural ornaments which prominently featured scroll-head designs. Advantages While somewhat similar to a band saw, a scroll saw uses a reciprocating blade rather than a continuous loop. Like a hand coping saw, the scroll saw's blade can be removed and placed through a pre-drilled starting hole, allowing interior cutouts to be made without an entry slot. Also, the fineness in both width and tooth count of a scroll's blade permits significantly more intricate curves than even the narrowest gauge band-saw blade. The majority of scroll saws offer a small light on a flexi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Robert Bosch Tool Corporation

Robert Bosch GmbH (; ), commonly known as Bosch and stylized as BOSCH, is a German multinational engineering and technology company headquartered in Gerlingen, Germany. The company was founded by Robert Bosch in Stuttgart in 1886. Bosch is 92% owned by Robert Bosch Stiftung, a charitable institution. Although the charity is funded by owning the vast majority of shares, it has no voting rights and is involved in health and social causes unrelated to Bosch’s business. Bosch's core operating areas are spread across four business sectors: mobility (hardware and software), consumer goods (including household appliances and power tools), industrial technology (including drive and control) and energy and building technology. History 1886–1920 The company started in a backyard in Stuttgart-West as the ''Werkstätte für Feinmechanik und Elektrotechnik'' (''Workshop for Precision Mechanics and Electrical Engineering'') on 15 November 1886. The next year Bosch presented a low ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Robert Bosch GmbH

Robert Bosch GmbH (; ), commonly known as Bosch and stylized as BOSCH, is a German multinational engineering and technology company headquartered in Gerlingen, Germany. The company was founded by Robert Bosch in Stuttgart in 1886. Bosch is 92% owned by Robert Bosch Stiftung, a charitable institution. Although the charity is funded by owning the vast majority of shares, it has no voting rights and is involved in health and social causes unrelated to Bosch’s business. Bosch's core operating areas are spread across four business sectors: mobility (hardware and software), consumer goods (including household appliances and power tools), industrial technology (including drive and control) and energy and building technology. History 1886–1920 The company started in a backyard in Stuttgart-West as the ''Werkstätte für Feinmechanik und Elektrotechnik'' (''Workshop for Precision Mechanics and Electrical Engineering'') on 15 November 1886. The next year Bosch presented a low v ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Table Saw

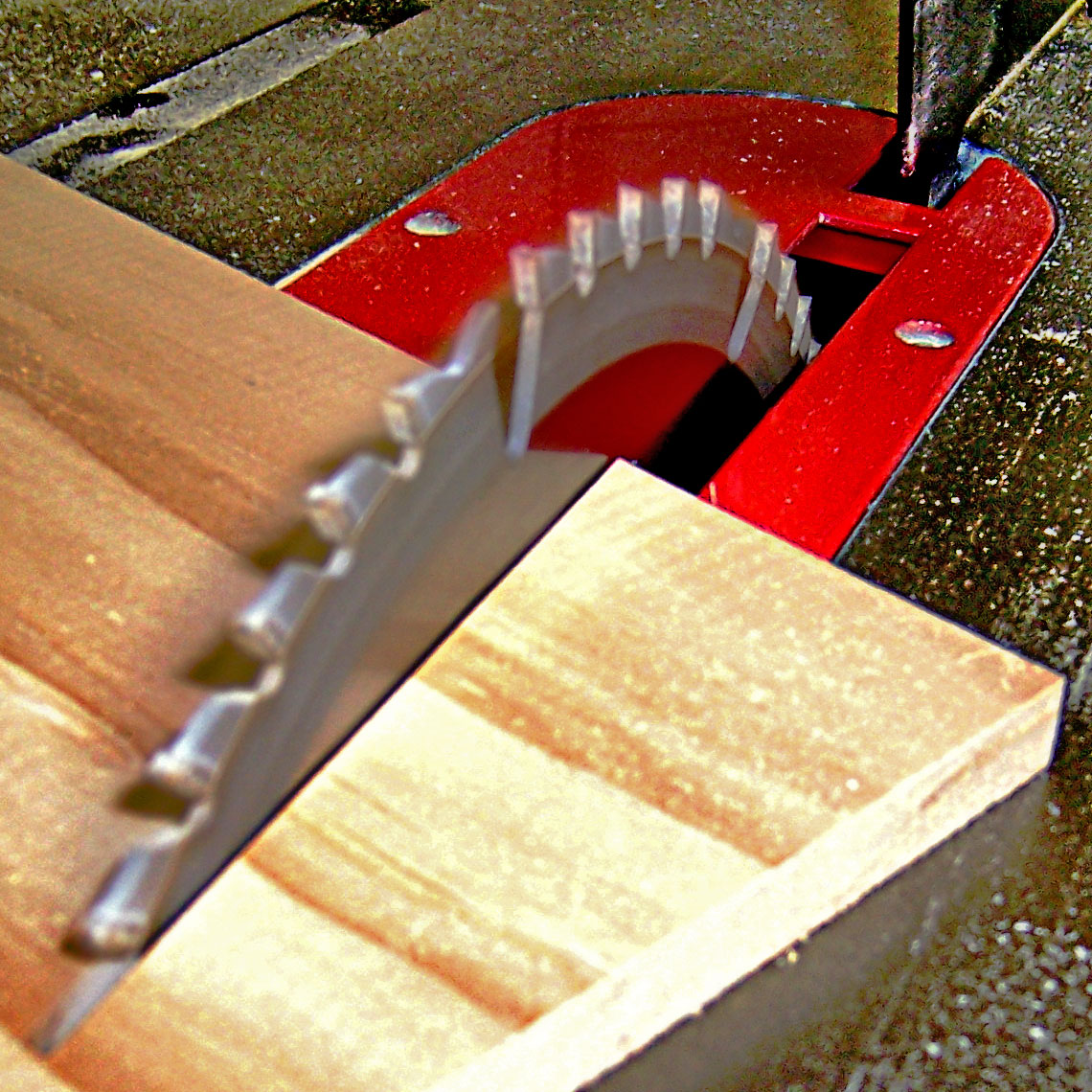

A table saw (also known as a sawbench or bench saw in England) is a woodworking tool, consisting of a circular saw blade, mounted on an arbor, that is driven by an electric motor (either directly, by belt, or by gears). The blade protrudes through the top of a table, which provides support for the material, usually wood, being cut. In most modern table saws, the depth of the cut is varied by moving the blade up and down: the higher the blade protrudes above the table, the deeper the cut that is made in the material. In some early table saws, the blade and arbor were fixed, and the table was moved up and down to expose more or less of the blade. The angle of cut is controlled by adjusting the angle of blade. Some earlier saws angled the table to control the cut angle. Types The general types of table saws are compact, benchtop, jobsite, contractor, hybrid, cabinet, and sliding table saws. Benchtop Benchtop table saws are lightweight and are designed to be placed on a table o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Butane Torch

A butane torch is a tool which creates an intensely hot flame using a fuel mixture of LPGs typically including some percentage of butane, a flammable gas. Consumer air butane torches are often claimed to develop flame temperatures up to approximately . This temperature is high enough to melt many common metals, such as aluminum and copper, and hot enough to vaporize many organic compounds as well. Applications Brazing, soldering, plumbing Often used as daily task tools, butane torches work very well for home improvement and work to solve problems with plumbing, soldering and brazing. Most of the times copper, silver and other metals are used for home repairs of tubes and other house things. Culinary Butane torches are frequently employed as kitchen gadgets to caramelize sugar in cooking, such as when making crème brûlée. They may be marketed as kitchen torches, cooking torches, or culinary torches. Use of the butane torch in the kitchen is not limited to caramelizing ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Belt Sander

A belt sander or strip sander is a sander used in shaping and finishing wood and other materials. It consists of an electric motor that turns a pair of drums on which a continuous loop of sandpaper is mounted. Belt sanders may be handheld and moved over the material, or stationary (fixed), where the material is moved to the sanding belt. Stationary belt sanders are sometimes mounted on a work bench, in which case they are called bench sanders. Stationary belt sanders are often combined with a disc sander. Belt sanders can have a very aggressive action on wood and are normally used only for the beginning stages of the sanding process, or used to rapidly remove material. Sometimes they are also used for removing paints or finishes from wood. Fitted with fine grit sand paper, a belt sander can be used to achieve a completely smooth surface. Stationary belt sanders are used for removing non-ferrous metals, such as aluminum. Non-ferrous metals tend to clog grinding wheels, quickly ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Profit Sharing

Profit sharing is various incentive plans introduced by businesses that provide direct or indirect payments to employees that depend on company's profitability in addition to employees' regular salary and bonuses. In publicly traded companies these plans typically amount to allocation of shares to employees. The profit sharing plans are based on predetermined economic sharing rules that define the split of gains between the company as a principal and the employee as an agent.Moffatt, Mike. (2008) About.com Sharing Rule' Economics Glossary; Terms Beginning with S. Accessed June 19, 2008. For example, suppose the profits are x, which might be a random variable. Before knowing the profits, the principal and agent might agree on a sharing rule s(x). Here, the agent will receive s(x) and the principal will receive the residual gain x-s(x). Profit-sharing tends to lead to less conflict and more cooperation between labor and their employers. History Profit sharing has been common amon ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Razor

A razor is a bladed tool primarily used in the removal of body hair through the act of shaving. Kinds of razors include straight razors, safety razors, disposable razors, and electric razors. While the razor has been in existence since before the Bronze Age (the oldest razor-like object has been dated to 18,000 BC), the most common types of razors currently used are the safety razor and the electric razor. History Razors have been identified from many Bronze Age cultures. These were made of bronze or obsidian and were generally oval-shaped, with a small tang protruding from one of the short ends.Warwickshire County Council: New Prehistoric Archaeology Objects "Even further away in time ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |