|

Countersink

A countersink (symbol: ⌵) is a conical hole cut into a manufactured object, or the cutter used to cut such a hole. A common use is to allow the head of a countersunk bolt, screw or rivet, when placed in the hole, to sit flush with or below the surface of the surrounding material (by comparison, a counterbore makes a flat-bottomed hole that might be used with a socket-head capscrew). A countersink may also be used to remove the burr left from a drilling or tapping operation thereby improving the finish of the product and removing any hazardous sharp edges. The basic geometry of a countersink (cutter) inherently can be applied to the plunging applications described above (axial feed only) and also to other milling applications (sideways traversal). Therefore, countersinks overlap in form, function, and sometimes name with chamfering endmills (endmills with angled tips). Regardless of the name given to the cutter, the surface being generated may be a conical chamfer (plunging a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Form Countersinking

A countersink (symbol: ⌵) is a conical hole cut into a manufactured object, or the cutter used to cut such a hole. A common use is to allow the head of a countersunk bolt, screw or rivet, when placed in the hole, to sit flush with or below the surface of the surrounding material (by comparison, a counterbore makes a flat-bottomed hole that might be used with a socket-head capscrew). A countersink may also be used to remove the burr left from a drilling or tapping operation thereby improving the finish of the product and removing any hazardous sharp edges. The basic geometry of a countersink (cutter) inherently can be applied to the plunging applications described above (axial feed only) and also to other milling applications (sideways traversal). Therefore, countersinks overlap in form, function, and sometimes name with chamfering endmills (endmills with angled tips). Regardless of the name given to the cutter, the surface being generated may be a conical chamfer (plunging app ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Counterbore

A counterbore (symbol: ⌴) is a cylindrical flat-bottomed hole that enlarges another coaxial hole, or the tool used to create that feature. A counterbore hole is typically used when a fastener, such as a socket head cap screw or fillister head screw, is required to sit flush with or below the level of a workpiece's surface. Whereas a counterbore is a ''flat-bottomed'' enlargement of a smaller coaxial hole, a countersink is a ''conical'' enlargement of such. A spotface often takes the form of a very shallow counterbore. As mentioned above, the cutters that produce counterbores are often also called counterbores; sometimes, to avoid ambiguity, the term counterbore cutter is used instead. The symbol is Unicode character . Description A counterbore hole is usually used when the head of a fastener, such as a hex head or socket head capscrew, is required to be flush with or below the level of a workpiece's surface. For a spotface, material is removed from a surface to make ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tap And Die

Taps and dies are tools used to create screw threads, which is called threading. Many are cutting tools; others are forming tools. A tap is used to cut or form the female portion of the mating pair (e.g. a nut). A die is used to cut or form the male portion of the mating pair (e.g. a bolt). The process of cutting or forming threads using a tap is called ''tapping'', whereas the process using a die is called ''threading''. Both tools can be used to clean up a thread, which is called ''chasing''. However, using an ordinary tap or die to clean threads generally removes some material, which results in looser, weaker threads. Because of this, machinists generally clean threads with special taps and dies—called ''chasers''—made for that purpose. Chasers are made of softer materials and don't cut new threads. However they still fit tighter than actual fasteners, and are fluted like regular taps and dies so debris can escape. Car mechanics, for example, use chasers on spark plug th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Taps And Dies

Taps and dies are tools used to create screw threads, which is called threading. Many are cutting tools; others are forming tools. A tap is used to cut or form the female portion of the mating pair (e.g. a nut). A die is used to cut or form the male portion of the mating pair (e.g. a bolt). The process of cutting or forming threads using a tap is called ''tapping'', whereas the process using a die is called ''threading''. Both tools can be used to clean up a thread, which is called ''chasing''. However, using an ordinary tap or die to clean threads generally removes some material, which results in looser, weaker threads. Because of this, machinists generally clean threads with special taps and dies—called ''chasers''—made for that purpose. Chasers are made of softer materials and don't cut new threads. However they still fit tighter than actual fasteners, and are fluted like regular taps and dies so debris can escape. Car mechanics, for example, use chasers on spark plug th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Taps And Dies

Taps and dies are tools used to create screw threads, which is called threading. Many are cutting tools; others are forming tools. A tap is used to cut or form the female portion of the mating pair (e.g. a nut). A die is used to cut or form the male portion of the mating pair (e.g. a bolt). The process of cutting or forming threads using a tap is called ''tapping'', whereas the process using a die is called ''threading''. Both tools can be used to clean up a thread, which is called ''chasing''. However, using an ordinary tap or die to clean threads generally removes some material, which results in looser, weaker threads. Because of this, machinists generally clean threads with special taps and dies—called ''chasers''—made for that purpose. Chasers are made of softer materials and don't cut new threads. However they still fit tighter than actual fasteners, and are fluted like regular taps and dies so debris can escape. Car mechanics, for example, use chasers on spark plug th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Screw

A screw and a bolt (see '' Differentiation between bolt and screw'' below) are similar types of fastener typically made of metal and characterized by a helical ridge, called a ''male thread'' (external thread). Screws and bolts are used to fasten materials by the engagement of the screw thread with a similar ''female thread'' (internal thread) in a matching part. Screws are often self-threading (also known as self-tapping) where the thread cuts into the material when the screw is turned, creating an internal thread that helps pull fastened materials together and prevents pull-out. There are many screws for a variety of materials; materials commonly fastened by screws include wood, sheet metal, and plastic. Explanation A screw is a combination of simple machines: it is, in essence, an inclined plane wrapped around a central shaft, but the inclined plane (thread) also comes to a sharp edge around the outside, which acts as a wedge as it pushes into the fastened material, and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flute (cutting Tool)

In the context of machining, a cutting tool or cutter is typically a hardened metal tool that is used to cut, shape, and remove material from a workpiece by means of machining tools as well as abrasive tools by way of shear deformation. The majority of these tools are designed exclusively for metals. There are several different types of single edge cutting tools that are made from a variety of hardened metal alloys that are ground to a specific shape in order to perform a specific part of the turning process resulting in a finished machined part. Single edge cutting tools are used mainly in the turning operations performed by a lathe in which they vary in size as well as alloy composition depending on the size and the type of material being turned. These cutting tools are held stationary by what is known as a tool post which is what manipulates the tools to cut the material into the desired shape. Single edge cutting tools are also the means of cutting material performed by metal sh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

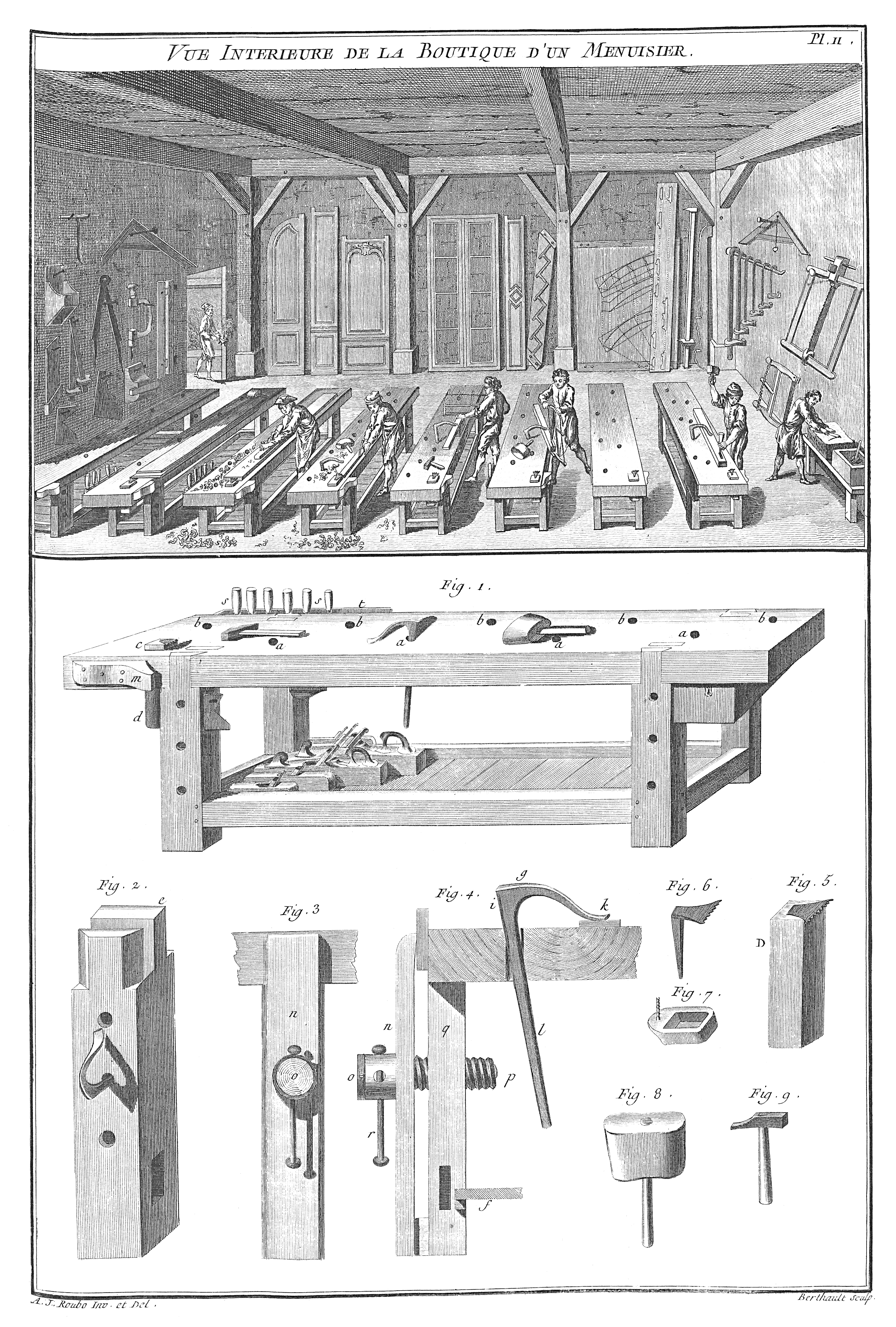

Workbench (woodworking)

A workbench is a specialized table used by woodworkers. Features include a flat, solid work surface and one or more means of holding the material being worked on. There are many styles of woodworking bench, depending on the type of work it's used for or the user’s preferred way of working. Most benches are heavy and rigid enough to keep still while being used. Holding the work Vise A woodworking vise holds work in its jaws, or compressed against a bench dog or holdfast. Holes to receive these stops or clamps are typically drilled in line with a vise in 3-4" intervals, with others added to the benchtop to serve various purposes. There are two main locations for a vise (''vice'' in UK English sp.) or vises on a workbench: on the front, a workbench's long face, known as a " front" ("face", or "shoulder") vise, and on the end, known as a “tail" vise. Either or both may be mounted on the right side of their face to allow a workpiece extending from them to be more ea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sheet Metal

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Sheet metal is one of the fundamental forms used in metalworking, and it can be cut and bent into a variety of shapes. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel. Sheet metal is available in flat pieces or coiled strips. The coils are formed by running a continuous sheet of metal through a roll slitter. In most of the world, sheet metal thickness is consistently specified in millimeters. In the U.S., the thickness of sheet metal is commonly specified by a traditional, non-linear measure known as its gauge. The larger the gauge number, the thinner the metal. Commonly used steel sheet metal ranges from 30 gauge to about 7 gauge. Gauge differs between ferrous ( iron-based) metals and nonferrous metals such as aluminum or copper. Cop ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dimpling

A dimple, also called a gelasin (, ) is a small natural indentation in the flesh on a part of the human body, most notably in the cheek. Numerous cultures believe that cheek dimples are a good luck charm that entices people who perceive them as physically attractive, but they are also associated with heroism and innocence, which has been included in literature for many centuries. Medical research debates whether cheek dimples can be inherited or which type of allele they are, but it is certain that humans with cheek dimples are more likely to have them in both cheeks. Depth and length appearances are affected by the shape of the skull and dimples can appear and disappear due to age. There are four types of facial dimples, including cheek, and the cleft chin (sometimes nicknamed a "chin dimple"). Overview Cheek dimples when present, show up when a person makes a facial expression, such as smiling, whereas a chin dimple is a small line on the chin that stays on the chin without m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |