Tribometer on:

[Wikipedia]

[Google]

[Amazon]

A tribometer is an instrument that measures

A tribometer is an instrument that measures

A tribometer is an instrument that measures

A tribometer is an instrument that measures tribological

Tribology is the science and engineering of interacting surfaces in relative motion. It includes the study and application of the principles of friction, lubrication and wear. Tribology is highly interdisciplinary, drawing on many academic field ...

quantities, such as coefficient of friction

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding against each other. There are several types of friction:

*Dry friction is a force that opposes the relative lateral motion of t ...

, friction force, and wear

Wear is the damaging, gradual removal or deformation of material at solid surfaces. Causes of wear can be mechanical (e.g., erosion) or chemical (e.g., corrosion). The study of wear and related processes is referred to as tribology.

Wear in ...

volume, between two surfaces in contact. It was invented by the 18th century Dutch

Dutch commonly refers to:

* Something of, from, or related to the Netherlands

* Dutch people ()

* Dutch language ()

Dutch may also refer to:

Places

* Dutch, West Virginia, a community in the United States

* Pennsylvania Dutch Country

People E ...

scientist Musschenbroek

A tribotester is the general name given to a machine or device used to perform tests and simulations of wear, friction and lubrication

Lubrication is the process or technique of using a lubricant to reduce friction and wear and tear in a contact between two surfaces. The study of lubrication is a discipline in the field of tribology.

Lubrication mechanisms such as fluid-lubric ...

which are the subject of the study of tribology. Often tribotesters are extremely specific in their function and are fabricated by manufacturers who desire to test and analyze the long-term performance of their products. An example is that of orthopedic implant An orthopedic implant is a medical device manufactured to replace a missing joint or bone or to support a damaged bone. The medical implant is mainly fabricated using stainless steel and titanium alloys for strength and the plastic coating that is ...

manufacturers who have spent considerable sums of money to develop tribotesters that accurately reproduce the motions and forces that occur in human hip joint

In vertebrate anatomy, hip (or "coxa"Latin ''coxa'' was used by Celsus in the sense "hip", but by Pliny the Elder in the sense "hip bone" (Diab, p 77) in medical terminology) refers to either an anatomical region or a joint.

The hip region is ...

s so that they can perform accelerated wear tests of their products.

Theory

A simple tribometer is described by a hanging mass and a mass resting on a horizontal surface, connected to each other via a string and pulley. Thecoefficient of friction

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding against each other. There are several types of friction:

*Dry friction is a force that opposes the relative lateral motion of t ...

, ''µ'', when the system is stationary, is determined by increasing the hanging mass until the moment that the resting mass begins to slide. Then using the general equation for friction force:

:

Where ''N'', the normal force, is equal to the weight (mass x gravity) of the sitting mass (''m''T) and ''F'', the loading force, is equal to the weight (mass x gravity) of the hanging mass (''m''H).

To determine the kinetic coefficient of friction the hanging mass is increased or decreased until the mass system moves at a constant speed.

In both cases, the coefficient of friction is simplified to the ratio of the two masses:

:

In most test applications using tribometers, wear is measured by comparing the mass or surfaces of test specimens before and after testing. Equipment and methods used to examine the worn surfaces include optical microscope

The optical microscope, also referred to as a light microscope, is a type of microscope that commonly uses visible light and a system of lenses to generate magnified images of small objects. Optical microscopes are the oldest design of micro ...

s, scanning electron microscopes, optical interferometry

Interferometry is a technique which uses the '' interference'' of superimposed waves to extract information. Interferometry typically uses electromagnetic waves and is an important investigative technique in the fields of astronomy, fiber opt ...

and mechanical roughness testers.

Types

Tribometers are often referred to by the specific contact arrangement they simulate or by the original equipment developer. Several arrangements are: * Four ball * Pin on disc * Ball on disc * Ring on ring * Ball on three plates * Reciprocating pin (usually referred to as ''SRV or HFRR'') * Block on ring * Bouncing ball * Fretting test machine * Twin discBouncing ball

A ''bouncing ball

The physics of a bouncing ball concerns the physical behaviour of bouncing balls, particularly its motion before, during, and after impact against the surface of another body. Several aspects of a bouncing ball's behaviour serve as an intro ...

tribometer'' consists of a ball which is impacted at an angle against a surface. During a typical test, a ball is slid on an angle along a track until it impacts a surface and then bounces off of the surface. The friction produced in the contact between the ball and the surface results in a horizontal force on the surface and a rotational force on the ball. Frictional force is determined by finding the rotational speed of the ball using high speed photography or by measuring the force on the horizontal surface. Pressure in the contact is very high due to the large instantaneous force caused by the impact with the ball.

''Bouncing ball'' tribometers have been used to determine the shear characteristics of lubricants under high pressures such as is found in ball bearings

A ball bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races.

The purpose of a ball bearing is to reduce rotational friction and support radial and axial loads. It achieves this ...

or gears

A gear is a rotating circular machine part having cut teeth or, in the case of a cogwheel or gearwheel, inserted teeth (called ''cogs''), which mesh with another (compatible) toothed part to transmit (convert) torque and speed. The basic p ...

.

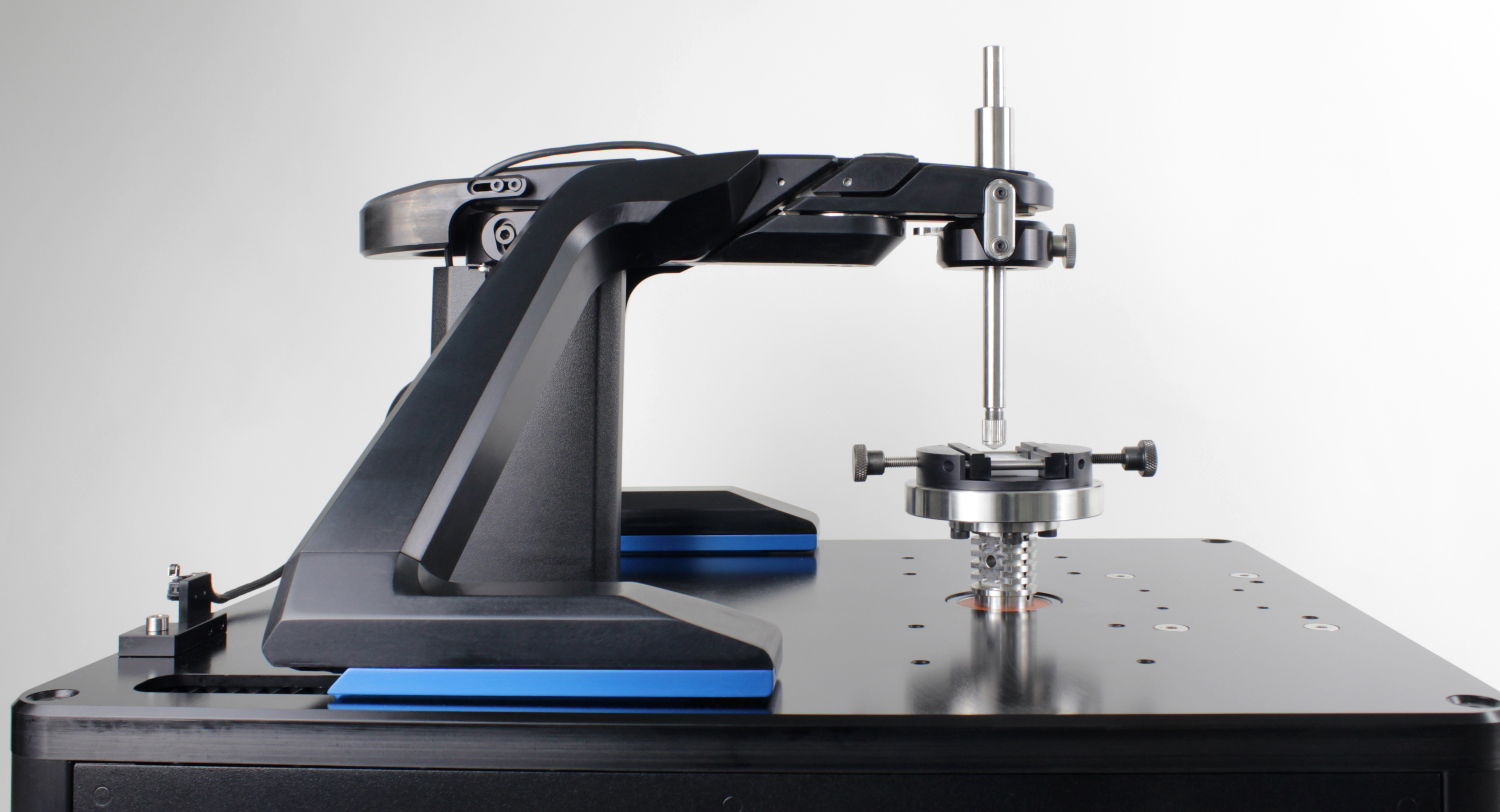

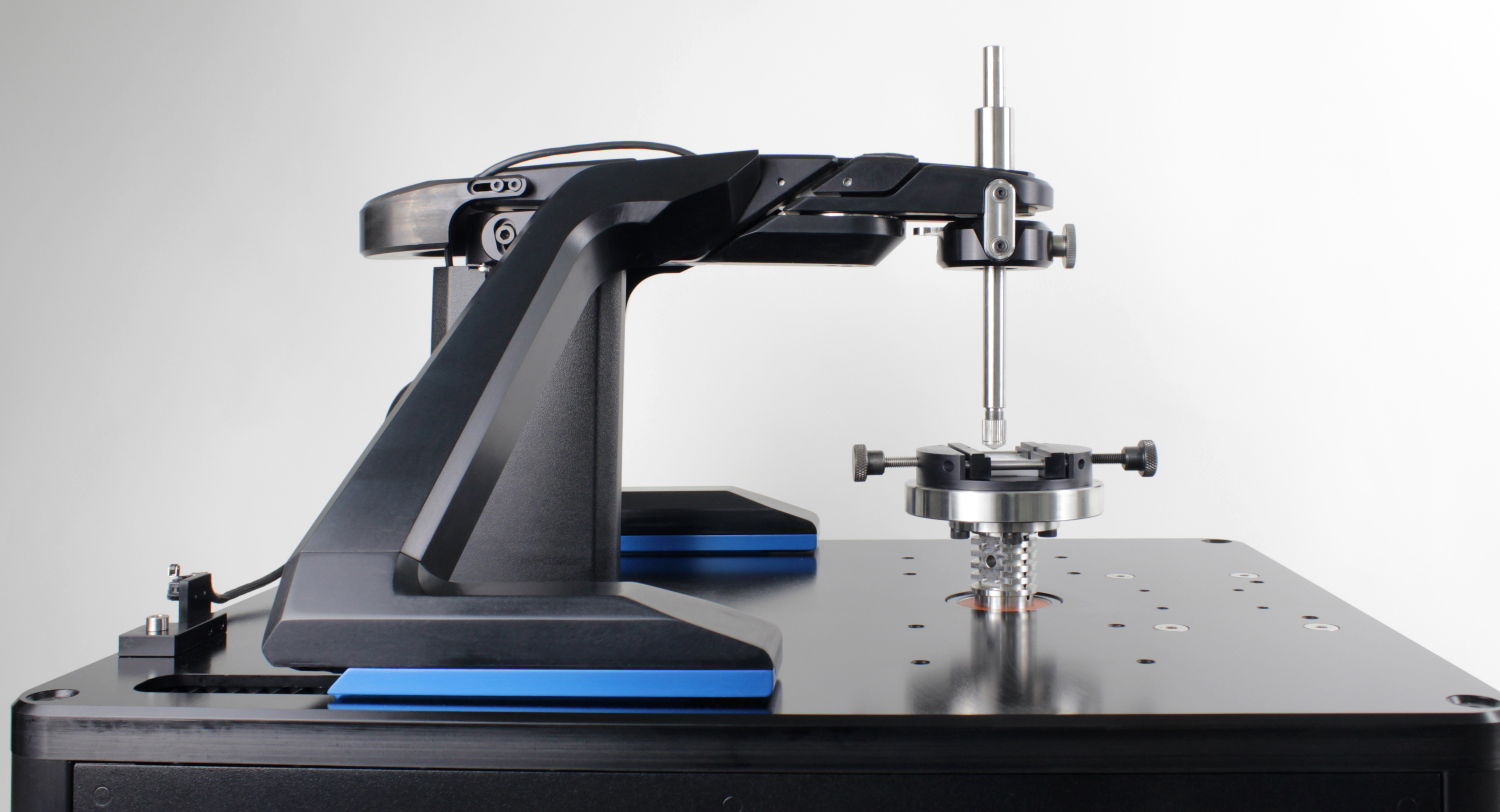

Pin on disc

A ''pin on disc tribometer'' consists of a stationary pin that is normally loaded against a rotating disc. The pin can have any shape to simulate a specific contact, but cylindrical tips are often used to simplify the contact geometry. The coefficient of friction is determined by the ratio of the frictional force to the loading force on the pin. The pin on disc test has proved useful in providing a simple wear and friction test for low frictioncoatings

A coating is a covering that is applied to the surface of an object, usually referred to as the substrate. The purpose of applying the coating may be decorative, functional, or both. Coatings may be applied as liquids, gases or solids e.g. Powd ...

such as diamond-like carbon

Diamond-like carbon (DLC) is a class of amorphous carbon material that displays some of the typical properties of diamond. DLC is usually applied as coatings to other materials that could benefit from such properties.

DLC exists in seven diff ...

coatings on valve train

A valvetrain or valve train is a mechanical system that controls the operation of the intake and exhaust valves in an internal combustion engine. The intake valves control the flow of air/fuel mixture (or air alone for direct-injected engines) ...

components in internal combustion engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal co ...

s.

See also

* Abrasion *Twist compression tester

The Twist Compression Tester ("TCT") is a hydraulically operated bench-top apparatus used to evaluate the level of friction and/or wear between two materials under lubricated or non-lubricated conditions.

Under controlled conditions, a rotating a ...

* Tribology

Tribology is the science and engineering of interacting surfaces in relative motion. It includes the study and application of the principles of friction, lubrication and wear. Tribology is highly interdisciplinary, drawing on many academic fi ...

References

{{Reflist Tribology Measuring instruments Materials science