Sputter deposition on:

[Wikipedia]

[Google]

[Amazon]

Sputter deposition is a physical vapor deposition (PVD) method of

Sputter deposition is a physical vapor deposition (PVD) method of

Sputter coating in scanning electron microscopy is a sputter deposition process to cover a specimen with a thin layer of conducting material, typically a metal, such as a

Sputter coating in scanning electron microscopy is a sputter deposition process to cover a specimen with a thin layer of conducting material, typically a metal, such as a

An important advantage of sputter deposition is that even materials with very high melting points are easily sputtered while evaporation of these materials in a resistance evaporator or Knudsen cell is problematic or impossible. Sputter deposited films have a composition close to that of the source material. The difference is due to different elements spreading differently because of their different mass (light elements are deflected more easily by the gas) but this difference is constant. Sputtered films typically have a better adhesion on the substrate than evaporated films. A target contains a large amount of material and is maintenance free making the technique suited for ultrahigh vacuum applications. Sputtering sources contain no hot parts (to avoid heating they are typically water cooled) and are compatible with reactive gases such as oxygen. Sputtering can be performed top-down while evaporation must be performed bottom-up. Advanced processes such as epitaxial growth are possible.

Some disadvantages of the sputtering process are that the process is more difficult to combine with a

An important advantage of sputter deposition is that even materials with very high melting points are easily sputtered while evaporation of these materials in a resistance evaporator or Knudsen cell is problematic or impossible. Sputter deposited films have a composition close to that of the source material. The difference is due to different elements spreading differently because of their different mass (light elements are deflected more easily by the gas) but this difference is constant. Sputtered films typically have a better adhesion on the substrate than evaporated films. A target contains a large amount of material and is maintenance free making the technique suited for ultrahigh vacuum applications. Sputtering sources contain no hot parts (to avoid heating they are typically water cooled) and are compatible with reactive gases such as oxygen. Sputtering can be performed top-down while evaporation must be performed bottom-up. Advanced processes such as epitaxial growth are possible.

Some disadvantages of the sputtering process are that the process is more difficult to combine with a

Sputtering sources often employ magnetrons that utilize strong electric and magnetic fields to confine charged plasma particles close to the surface of the sputter target. In a magnetic field, electrons follow helical paths around magnetic field lines, undergoing more ionizing collisions with gaseous neutrals near the target surface than would otherwise occur. (As the target material is depleted, a "racetrack" erosion profile may appear on the surface of the target.) The sputter gas is typically an inert gas such as argon. The extra argon ions created as a result of these collisions lead to a higher deposition rate. The plasma can also be sustained at a lower pressure this way. The sputtered atoms are neutrally charged and so are unaffected by the magnetic trap. Charge build-up on insulating targets can be avoided with the use of RF sputtering where the sign of the anode-cathode bias is varied at a high rate (commonly 13.56 MHz). RF sputtering works well to produce highly insulating oxide films but with the added expense of RF power supplies and impedance matching networks. Stray magnetic fields leaking from ferromagnetic targets also disturb the sputtering process. Specially designed sputter guns with unusually strong permanent magnets must often be used in compensation.

Sputtering sources often employ magnetrons that utilize strong electric and magnetic fields to confine charged plasma particles close to the surface of the sputter target. In a magnetic field, electrons follow helical paths around magnetic field lines, undergoing more ionizing collisions with gaseous neutrals near the target surface than would otherwise occur. (As the target material is depleted, a "racetrack" erosion profile may appear on the surface of the target.) The sputter gas is typically an inert gas such as argon. The extra argon ions created as a result of these collisions lead to a higher deposition rate. The plasma can also be sustained at a lower pressure this way. The sputtered atoms are neutrally charged and so are unaffected by the magnetic trap. Charge build-up on insulating targets can be avoided with the use of RF sputtering where the sign of the anode-cathode bias is varied at a high rate (commonly 13.56 MHz). RF sputtering works well to produce highly insulating oxide films but with the added expense of RF power supplies and impedance matching networks. Stray magnetic fields leaking from ferromagnetic targets also disturb the sputtering process. Specially designed sputter guns with unusually strong permanent magnets must often be used in compensation.

Ion-beam sputtering (IBS) is a method in which the target is external to the ion source. A source can work without any magnetic field like in a

Ion-beam sputtering (IBS) is a method in which the target is external to the ion source. A source can work without any magnetic field like in a

The Foundations of Vacuum Coating Technology by D. Mattox

* *

Thin Film Evaporation GuideSputter Animation

{{DEFAULTSORT:Sputter Deposition Semiconductor device fabrication Plasma processing Thin film deposition

Sputter deposition is a physical vapor deposition (PVD) method of

Sputter deposition is a physical vapor deposition (PVD) method of thin film

A thin film is a layer of material ranging from fractions of a nanometer ( monolayer) to several micrometers in thickness. The controlled synthesis of materials as thin films (a process referred to as deposition) is a fundamental step in many ...

deposition by the phenomenon of sputtering. This involves ejecting material from a "target" that is a source onto a "substrate" such as a silicon

Silicon is a chemical element with the symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic luster, and is a tetravalent metalloid and semiconductor. It is a member of group 14 in the periodic ...

wafer. Resputtering is re-emission of the deposited material during the deposition process by ion or atom bombardment.

Sputtered atoms ejected from the target have a wide energy distribution, typically up to tens of eV (100,000 K). The sputtered ions (typically only a small fraction of the ejected particles are ionized — on the order of 1 percent) can ballistically fly from the target in straight lines and impact energetically on the substrates or vacuum chamber (causing resputtering). Alternatively, at higher gas pressures, the ions collide with the gas atoms that act as a moderator and move diffusively, reaching the substrates or vacuum chamber wall and condensing after undergoing a random walk

In mathematics, a random walk is a random process that describes a path that consists of a succession of random steps on some mathematical space.

An elementary example of a random walk is the random walk on the integer number line \mathbb Z ...

. The entire range from high-energy ballistic impact to low-energy thermalized motion is accessible by changing the background gas pressure. The sputtering gas is often an inert gas

An inert gas is a gas that does not readily undergo chemical reactions with other chemical substances and therefore does not readily form chemical compounds. The noble gases often do not react with many substances and were historically referred to ...

such as argon

Argon is a chemical element with the symbol Ar and atomic number 18. It is in group 18 of the periodic table and is a noble gas. Argon is the third-most abundant gas in Earth's atmosphere, at 0.934% (9340 ppmv). It is more than twice a ...

. For efficient momentum transfer, the atomic weight of the sputtering gas should be close to the atomic weight of the target, so for sputtering light elements neon

Neon is a chemical element with the symbol Ne and atomic number 10. It is a noble gas. Neon is a colorless, odorless, inert monatomic gas under standard conditions, with about two-thirds the density of air. It was discovered (along with krypt ...

is preferable, while for heavy elements krypton

Krypton (from grc, κρυπτός, translit=kryptos 'the hidden one') is a chemical element with the symbol Kr and atomic number 36. It is a colorless, odorless, tasteless noble gas that occurs in trace amounts in the atmosphere and is of ...

or xenon

Xenon is a chemical element with the symbol Xe and atomic number 54. It is a dense, colorless, odorless noble gas found in Earth's atmosphere in trace amounts. Although generally unreactive, it can undergo a few chemical reactions such as the ...

are used. Reactive gases can also be used to sputter compounds. The compound can be formed on the target surface, in-flight or on the substrate depending on the process parameters. The availability of many parameters that control sputter deposition make it a complex process, but also allow experts a large degree of control over the growth and microstructure of the film.

Uses

One of the earliest widespread commercial applications of sputter deposition, which is still one of its most important applications, is in the production of computer hard disks. Sputtering is used extensively in thesemiconductor

A semiconductor is a material which has an electrical conductivity value falling between that of a conductor, such as copper, and an insulator, such as glass. Its resistivity falls as its temperature rises; metals behave in the opposite way ...

industry to deposit thin films of various materials in integrated circuit

An integrated circuit or monolithic integrated circuit (also referred to as an IC, a chip, or a microchip) is a set of electronic circuits on one small flat piece (or "chip") of semiconductor material, usually silicon. Large numbers of tiny ...

processing. Thin antireflection coatings on glass for optical applications are also deposited by sputtering. Because of the low substrate temperatures used, sputtering is an ideal method to deposit contact metals for thin-film transistors. Another familiar application of sputtering is low- emissivity coatings on glass

Glass is a non- crystalline, often transparent, amorphous solid that has widespread practical, technological, and decorative use in, for example, window panes, tableware, and optics. Glass is most often formed by rapid cooling (quenchin ...

, used in double-pane window assemblies. The coating is a multilayer containing silver

Silver is a chemical element with the symbol Ag (from the Latin ', derived from the Proto-Indo-European ''h₂erǵ'': "shiny" or "white") and atomic number 47. A soft, white, lustrous transition metal, it exhibits the highest electrical ...

and metal oxide

An oxide () is a chemical compound that contains at least one oxygen atom and one other element in its chemical formula. "Oxide" itself is the dianion of oxygen, an O2– (molecular) ion. with oxygen in the oxidation state of −2. Most of the E ...

s such as zinc oxide, tin oxide, or titanium dioxide

Titanium dioxide, also known as titanium(IV) oxide or titania , is the inorganic compound with the chemical formula . When used as a pigment, it is called titanium white, Pigment White 6 (PW6), or CI 77891. It is a white solid that is insolu ...

. A large industry has developed around tool bit coating using sputtered nitrides, such as titanium nitride

Titanium nitride (TiN; sometimes known as Tinite) is an extremely hard ceramic material, often used as a physical vapor deposition (PVD) coating on titanium alloys, steel, carbide, and aluminium components to improve the substrate's surface prop ...

, creating the familiar gold colored hard coat. Sputtering is also used as the process to deposit the metal (e.g. aluminium) layer during the fabrication of CDs and DVDs.

Hard disk surfaces use sputtered CrOx and other sputtered materials. Sputtering is one of the main processes of manufacturing optical waveguides and is another way for making efficient photovoltaic

Photovoltaics (PV) is the conversion of light into electricity using semiconducting materials that exhibit the photovoltaic effect, a phenomenon studied in physics, photochemistry, and electrochemistry. The photovoltaic effect is commercially ...

solar cells.

In 2022, researchers at IMEC built up lab superconducting qubits with coherence times exceeding 100 µs and an average

In ordinary language, an average is a single number taken as representative of a list of numbers, usually the sum of the numbers divided by how many numbers are in the list (the arithmetic mean). For example, the average of the numbers 2, 3, 4, 7 ...

single-qubit gate fidelity of 99.94%, using CMOS

Complementary metal–oxide–semiconductor (CMOS, pronounced "sea-moss", ) is a type of metal–oxide–semiconductor field-effect transistor (MOSFET) fabrication process that uses complementary and symmetrical pairs of p-type and n-type MOSF ...

-compatible fabrication techniques such ad sputtering deposition and subtractive etch.

Sputter coating

Sputter coating in scanning electron microscopy is a sputter deposition process to cover a specimen with a thin layer of conducting material, typically a metal, such as a

Sputter coating in scanning electron microscopy is a sputter deposition process to cover a specimen with a thin layer of conducting material, typically a metal, such as a gold

Gold is a chemical element with the symbol Au (from la, aurum) and atomic number 79. This makes it one of the higher atomic number elements that occur naturally. It is a bright, slightly orange-yellow, dense, soft, malleable, and ductile ...

/palladium

Palladium is a chemical element with the symbol Pd and atomic number 46. It is a rare and lustrous silvery-white metal discovered in 1803 by the English chemist William Hyde Wollaston. He named it after the asteroid Pallas, which was itself ...

(Au/Pd) alloy. A conductive coating is needed to prevent charging of a specimen with an electron beam in conventional SEM mode (high vacuum, high voltage). While metal coatings are also useful for increasing signal to noise ratio (heavy metals are good secondary electron emitters), they are of inferior quality when X-ray spectroscopy is employed. For this reason when using X-ray spectroscopy a carbon coating is preferred.

Comparison with other deposition methods

An important advantage of sputter deposition is that even materials with very high melting points are easily sputtered while evaporation of these materials in a resistance evaporator or Knudsen cell is problematic or impossible. Sputter deposited films have a composition close to that of the source material. The difference is due to different elements spreading differently because of their different mass (light elements are deflected more easily by the gas) but this difference is constant. Sputtered films typically have a better adhesion on the substrate than evaporated films. A target contains a large amount of material and is maintenance free making the technique suited for ultrahigh vacuum applications. Sputtering sources contain no hot parts (to avoid heating they are typically water cooled) and are compatible with reactive gases such as oxygen. Sputtering can be performed top-down while evaporation must be performed bottom-up. Advanced processes such as epitaxial growth are possible.

Some disadvantages of the sputtering process are that the process is more difficult to combine with a

An important advantage of sputter deposition is that even materials with very high melting points are easily sputtered while evaporation of these materials in a resistance evaporator or Knudsen cell is problematic or impossible. Sputter deposited films have a composition close to that of the source material. The difference is due to different elements spreading differently because of their different mass (light elements are deflected more easily by the gas) but this difference is constant. Sputtered films typically have a better adhesion on the substrate than evaporated films. A target contains a large amount of material and is maintenance free making the technique suited for ultrahigh vacuum applications. Sputtering sources contain no hot parts (to avoid heating they are typically water cooled) and are compatible with reactive gases such as oxygen. Sputtering can be performed top-down while evaporation must be performed bottom-up. Advanced processes such as epitaxial growth are possible.

Some disadvantages of the sputtering process are that the process is more difficult to combine with a lift-off

Liftoff, lift-off, or lift off may refer to:

Technology

* Lift-off (microtechnology), a fabrication technique

* Flame lift-off, a separation of flame from burner device

* Takeoff, the first moment of flight of an aerospace vehicle

* Reduction ...

for structuring the film. This is because the diffuse transport, characteristic of sputtering, makes a full shadow impossible. Thus, one cannot fully restrict where the atoms go, which can lead to contamination problems. Also, active control for layer-by-layer growth is difficult compared to pulsed laser deposition and inert sputtering gases are built into the growing film as impurities. Pulsed laser deposition is a variant of the sputtering deposition technique in which a laser

A laser is a device that emits light through a process of optical amplification based on the stimulated emission of electromagnetic radiation. The word "laser" is an acronym for "light amplification by stimulated emission of radiation". The ...

beam is used for sputtering. Role of the sputtered and resputtered ions and the background gas is fully investigated during the pulsed laser deposition process.

Types of sputter deposition

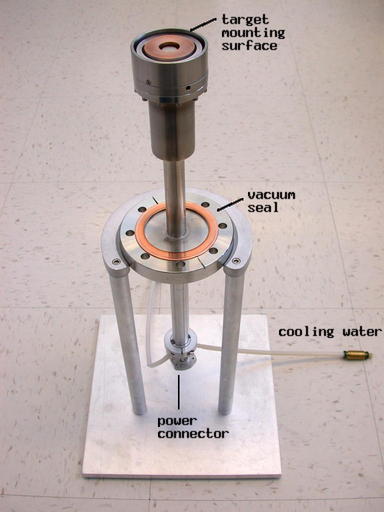

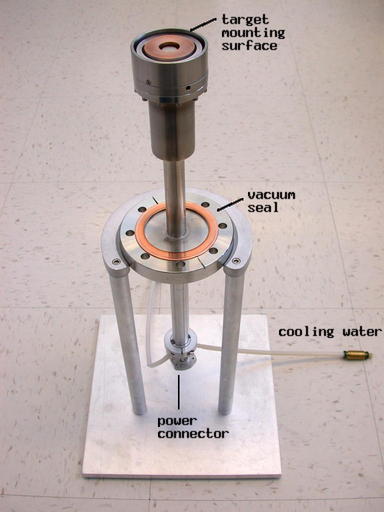

Sputtering sources often employ magnetrons that utilize strong electric and magnetic fields to confine charged plasma particles close to the surface of the sputter target. In a magnetic field, electrons follow helical paths around magnetic field lines, undergoing more ionizing collisions with gaseous neutrals near the target surface than would otherwise occur. (As the target material is depleted, a "racetrack" erosion profile may appear on the surface of the target.) The sputter gas is typically an inert gas such as argon. The extra argon ions created as a result of these collisions lead to a higher deposition rate. The plasma can also be sustained at a lower pressure this way. The sputtered atoms are neutrally charged and so are unaffected by the magnetic trap. Charge build-up on insulating targets can be avoided with the use of RF sputtering where the sign of the anode-cathode bias is varied at a high rate (commonly 13.56 MHz). RF sputtering works well to produce highly insulating oxide films but with the added expense of RF power supplies and impedance matching networks. Stray magnetic fields leaking from ferromagnetic targets also disturb the sputtering process. Specially designed sputter guns with unusually strong permanent magnets must often be used in compensation.

Sputtering sources often employ magnetrons that utilize strong electric and magnetic fields to confine charged plasma particles close to the surface of the sputter target. In a magnetic field, electrons follow helical paths around magnetic field lines, undergoing more ionizing collisions with gaseous neutrals near the target surface than would otherwise occur. (As the target material is depleted, a "racetrack" erosion profile may appear on the surface of the target.) The sputter gas is typically an inert gas such as argon. The extra argon ions created as a result of these collisions lead to a higher deposition rate. The plasma can also be sustained at a lower pressure this way. The sputtered atoms are neutrally charged and so are unaffected by the magnetic trap. Charge build-up on insulating targets can be avoided with the use of RF sputtering where the sign of the anode-cathode bias is varied at a high rate (commonly 13.56 MHz). RF sputtering works well to produce highly insulating oxide films but with the added expense of RF power supplies and impedance matching networks. Stray magnetic fields leaking from ferromagnetic targets also disturb the sputtering process. Specially designed sputter guns with unusually strong permanent magnets must often be used in compensation.

Ion-beam sputtering

Ion-beam sputtering (IBS) is a method in which the target is external to the ion source. A source can work without any magnetic field like in a

Ion-beam sputtering (IBS) is a method in which the target is external to the ion source. A source can work without any magnetic field like in a hot filament ionization gauge

The hot-filament ionization gauge, sometimes called a hot-filament gauge or hot-cathode gauge, is the most widely used low-pressure (vacuum) measuring device for the region from 10−3 to 10−10 Torr. It is a triode, with the filament being th ...

. In a Kaufman

Kaufman or Kauffman may refer to:

People

*Kaufmann (surname) ''Includes Kaufman, Kauffman, Kauffmann''

Places

* Kaufman, Illinois, an unincorporated community in Madison Count

* Kaufman, Texas, a city in Kaufman County

* Kaufman County, Texas, ...

source ions are generated by collisions with electrons that are confined by a magnetic field as in a magnetron. They are then accelerated by the electric field emanating from a grid toward a target. As the ions leave the source they are neutralized by electrons from a second external filament. IBS has an advantage in that the energy and flux of ions can be controlled independently. Since the flux that strikes the target is composed of neutral atoms, either insulating or conducting targets can be sputtered. IBS has found application in the manufacture of thin-film heads for disk drives. A pressure gradient between the ion source and the sample chamber is generated by placing the gas inlet at the source and shooting through a tube into the sample chamber. This saves gas and reduces contamination in UHV applications. The principal drawback of IBS is the large amount of maintenance required to keep the ion source operating.

Reactive sputtering

In reactive sputtering, the sputtered particles from a target material undergo a chemical reaction aiming to deposit a film with different composition on a certain substrate. The chemical reaction that the particles undergo is with a reactive gas introduced into the sputtering chamber such as oxygen or nitrogen, enabling the production of oxide and nitride films, respectively. The introduction of an additional element to the process, i.e. the reactive gas, has a significant influence in the desired depositions, making it more difficult to find ideal working points. Like so, the wide majority of reactive-based sputtering processes are characterized by an hysteresis-like behavior, thus needing proper control of the involved parameters, e.g. the partial pressure of working (or inert) and reactive gases, to undermine it. Berg et al. proposed a significant model, i.e. Berg Model, to estimate the impact upon addition of the reactive gas in sputtering processes. Generally, the influence of the reactive gas' relative pressure and flow were estimated in accordance to the target's erosion and film's deposition rate on the desired substrate. The composition of the film can be controlled by varying the relative pressures of the inert and reactive gases. Film stoichiometry is an important parameter for optimizing functional properties like the stress in SiNx and the index of refraction of SiOx.Ion-assisted deposition

In ion-assisted deposition (IAD), the substrate is exposed to a secondary ion beam operating at a lower power than the sputter gun. Usually a Kaufman source, like that used in IBS, supplies the secondary beam. IAD can be used to depositcarbon

Carbon () is a chemical element with the symbol C and atomic number 6. It is nonmetallic and tetravalent—its atom making four electrons available to form covalent chemical bonds. It belongs to group 14 of the periodic table. Carbon ma ...

in diamond-like form on a substrate. Any carbon atoms landing on the substrate which fail to bond properly in the diamond crystal lattice will be knocked off by the secondary beam. NASA

The National Aeronautics and Space Administration (NASA ) is an independent agency of the US federal government responsible for the civil space program, aeronautics research, and space research.

NASA was established in 1958, succeedin ...

used this technique to experiment with depositing diamond films on turbine

A turbine ( or ) (from the Greek , ''tyrbē'', or Latin ''turbo'', meaning vortex) is a rotary mechanical device that extracts energy from a fluid flow and converts it into useful work. The work produced by a turbine can be used for generating ...

blades in the 1980s. IAD is used in other important industrial applications such as creating tetrahedral amorphous carbon surface coatings on hard disk

A hard disk drive (HDD), hard disk, hard drive, or fixed disk is an electro-mechanical data storage device that stores and retrieves digital data using magnetic storage with one or more rigid rapidly rotating platters coated with magn ...

platters and hard transition metal nitride coatings on medical implants.

High-target-utilization sputtering (HiTUS)

Sputtering may also be performed by remote generation of a high density plasma. The plasma is generated in a side chamber opening into the main process chamber, containing the target and the substrate to be coated. As the plasma is generated remotely, and not from the target itself (as in conventional magnetron sputtering), the ion current to the target is independent of the voltage applied to the target.High-power impulse magnetron sputtering (HiPIMS)

HiPIMS is a method for physical vapor deposition of thin films which is based on magnetron sputter deposition. HiPIMS utilizes extremely high power densities of the order of kW/cm2 in short pulses (impulses) of tens of microseconds at low duty cycle of < 10%.Gas flow sputtering

Gas flow sputtering makes use of the hollow cathode effect, the same effect by whichhollow cathode lamps

A hollow-cathode lamp (HCL) is type of cold cathode lamp used in physics and chemistry as a spectral line source (e.g. for atomic absorption spectrometers) and as a frequency tuner for light sources such as lasers. An HCL takes advantage of ...

operate. In gas flow sputtering a working gas like argon

Argon is a chemical element with the symbol Ar and atomic number 18. It is in group 18 of the periodic table and is a noble gas. Argon is the third-most abundant gas in Earth's atmosphere, at 0.934% (9340 ppmv). It is more than twice a ...

is led through an opening in a metal subjected to a negative electrical potential. Enhanced plasma densities occur in the hollow cathode, if the pressure in the chamber ''p'' and a characteristic dimension ''L'' of the hollow cathode obey the Paschen's law 0.5 Pa·m < ''p''·''L'' < 5 Pa·m. This causes a high flux of ions on the surrounding surfaces and a large sputter effect. The hollow-cathode based gas flow sputtering may thus be associated with large deposition rates up to values of a few µm/min.

Structure and morphology

In 1974 J. A. Thornton applied the structure zone model for the description ofthin film

A thin film is a layer of material ranging from fractions of a nanometer ( monolayer) to several micrometers in thickness. The controlled synthesis of materials as thin films (a process referred to as deposition) is a fundamental step in many ...

morphologies to sputter deposition. In a study on metallic layers prepared by DC sputtering, he extended the structure zone concept initially introduced by Movchan and Demchishin for evaporated films. Thornton introduced a further structure zone T, which was observed at low argon pressures and characterized by densely packed fibrous grains. The most important point of this extension was to emphasize the pressure ''p'' as a decisive process parameter. In particular, if hyperthermal techniques like sputtering etc. are used for the sublimation of source atoms, the pressure governs via the mean free path

In physics, mean free path is the average distance over which a moving particle (such as an atom, a molecule, or a photon) travels before substantially changing its direction or energy (or, in a specific context, other properties), typically as ...

the energy distribution with which they impinge on the surface of the growing film. Next to the deposition temperature ''Td'' the chamber pressure or mean free path should thus always be specified when considering a deposition process.

Since sputter deposition belongs to the group of plasma-assisted processes, next to neutral atoms also charged species (like argon ions) hit the surface of the growing film, and this component may exert a large effect. Denoting the fluxes of the arriving ions and atoms by ''Ji'' and ''Ja'', it turned out that the magnitude of the ''Ji/Ja'' ratio plays a decisive role on the microstructure and morphology obtained in the film. The effect of ion bombardment may quantitatively be derived from structural parameters like preferred orientation of crystallites or texture and from the state of residual stress. It has been shown recently that textures and residual stresses may arise in gas-flow sputtered Ti layers that compare to those obtained in macroscopic Ti work pieces subjected to a severe plastic deformation

In engineering, deformation refers to the change in size or shape of an object. ''Displacements'' are the ''absolute'' change in position of a point on the object. Deflection is the relative change in external displacements on an object. Strain ...

by shot peening

Shot peening is a cold working process used to produce a compressive residual stress layer and modify the mechanical properties of metals and composites. It entails striking a surface with shot (round metallic, glass, or ceramic particles) with ...

.

See also

*Coating

A coating is a covering that is applied to the surface of an object, usually referred to as the substrate. The purpose of applying the coating may be decorative, functional, or both. Coatings may be applied as liquids, gases or solids e.g. Pow ...

References

Further reading

The Foundations of Vacuum Coating Technology by D. Mattox

* *

External links

Thin Film Evaporation Guide

{{DEFAULTSORT:Sputter Deposition Semiconductor device fabrication Plasma processing Thin film deposition