polybenzimidazoles on:

[Wikipedia]

[Google]

[Amazon]

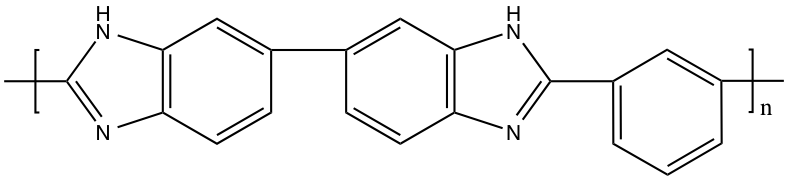

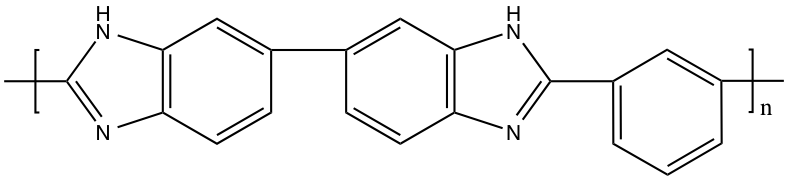

Polybenzimidazole (PBI, short for poly ,2’-(''m''-phenylen)-5,5’-bisbenzimidazole'') fiber is a synthetic fiber with a very high decomposition temperature. It does not exhibit a

aromatic derivatives

can withstand temperatures in excess of about 500 °C without softening and degrading. The polymer synthesized from

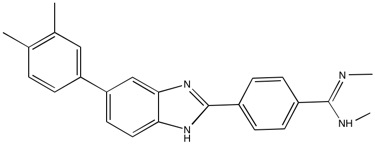

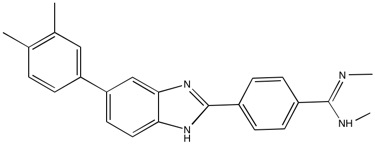

While changing the tetramine and acid, a number of different aromatic poly benzimidazoles have been synthesized. The following table (Table 1) lists some of the combination possibilities that have been synthesized in the literature. Some of the combinations have actually been translated into fibers on a small scale. However, the only significant progress that has been made to date is with PBI.

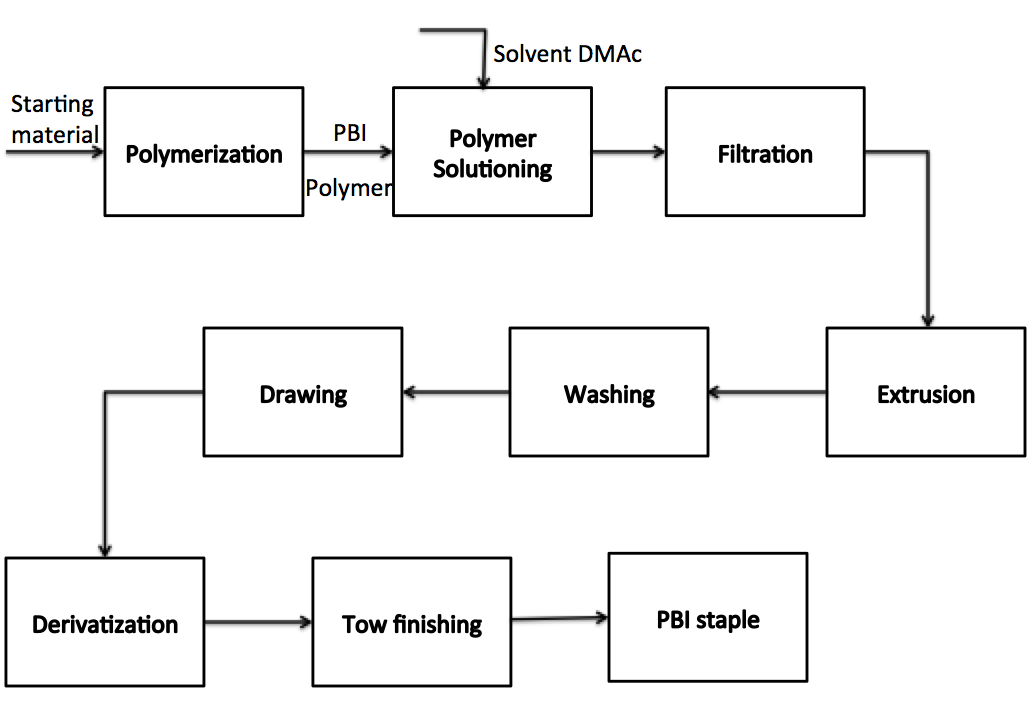

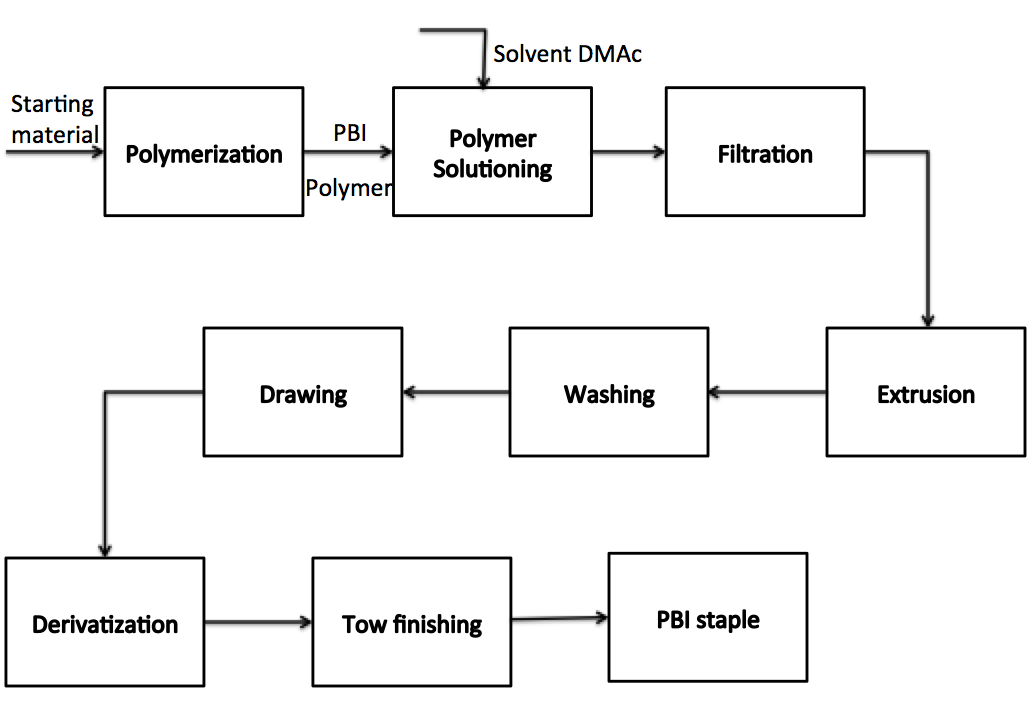

The most common form of PBI used in industry is the fiber form. The fiber process following polymerization is shown in the figure. The polymer is made into solution using dimethylacetamide as solvent. The solution is filtered and converted into fiber using a high temperature dry-spinning process. The fiber is subsequently drawn at elevated temperature to get desired mechanical properties. It is then sulfonated and made into staple using conventional crimping and cutting techniques.

The most common form of PBI used in industry is the fiber form. The fiber process following polymerization is shown in the figure. The polymer is made into solution using dimethylacetamide as solvent. The solution is filtered and converted into fiber using a high temperature dry-spinning process. The fiber is subsequently drawn at elevated temperature to get desired mechanical properties. It is then sulfonated and made into staple using conventional crimping and cutting techniques.

PBI fiber is an excellent candidate for applications in severe environments due to its combination of thermal, chemical and textile properties. Flame and thermal resistance are the critical properties of protective apparel. This kind of apparel applications includes firefighter's protective apparel, astronaut's suits, aluminized crash rescue gear, industrial worker's apparel, and suits for racing car drivers.

PBI fiber is an excellent candidate for applications in severe environments due to its combination of thermal, chemical and textile properties. Flame and thermal resistance are the critical properties of protective apparel. This kind of apparel applications includes firefighter's protective apparel, astronaut's suits, aluminized crash rescue gear, industrial worker's apparel, and suits for racing car drivers.

PBI-blended fabrics have been the preferred choice of active fire departments across the Americas and around the world for over 30 years. From New York, San Diego, San Francisco, Philadelphia, Seattle, Nashville to São Paulo, Belin, Hong Kong and many more. The high decomposition temperature at which PBI starts to degrade is 1300 °F, exceeding Nomex/Kevlar blends (Nomex being at 700 °F and Kevlar at 1100 °F), thus offering superior break-open and thermal protection.

PBI-blended fabrics have been the preferred choice of active fire departments across the Americas and around the world for over 30 years. From New York, San Diego, San Francisco, Philadelphia, Seattle, Nashville to São Paulo, Belin, Hong Kong and many more. The high decomposition temperature at which PBI starts to degrade is 1300 °F, exceeding Nomex/Kevlar blends (Nomex being at 700 °F and Kevlar at 1100 °F), thus offering superior break-open and thermal protection.

According to the Composite Materials Research Group at the

Polybenzimidazole (PBI) - Material InformationPBI Polymer Performance Study

{{DEFAULTSORT:Polybenzimidazole Fiber Flame retardant fabrics Organic polymers Synthetic fibers

melting point

The melting point (or, rarely, liquefaction point) of a substance is the temperature at which it changes state from solid to liquid. At the melting point the solid and liquid phase exist in equilibrium. The melting point of a substance depen ...

, it has exceptional thermal and chemical stability, and it does not readily ignite. It was first discovered by American polymer chemist Carl Shipp Marvel

Carl Shipp "Speed" Marvel (September 11, 1894 – January 4, 1988) was an American chemist who specialized in polymer chemistry. He made important contributions to U.S. synthetic rubber program during World War II, and later worked at developing ...

in the pursuit of new materials with superior stability, retention of stiffness, toughness at elevated temperature. Due to its high stability, polybenzimidazole is used to fabricate high-performance protective apparel such as firefighter's gear, astronaut space suits, high temperature protective gloves, welders’ apparel and aircraft wall fabrics. Polybenzimidazole has been applied as a membrane in fuel cells.

History

Discovery

Brinker and Robinson first reported aliphatic polybenzimidazoles in 1949. However the discovery of aromatic polybenzimidazole, which shows excellent physical and chemical properties, was generally credited toCarl Shipp Marvel

Carl Shipp "Speed" Marvel (September 11, 1894 – January 4, 1988) was an American chemist who specialized in polymer chemistry. He made important contributions to U.S. synthetic rubber program during World War II, and later worked at developing ...

in the 1950s. The Material Laboratory of Wright Patterson Air Force Base

Wright-Patterson Air Force Base (WPAFB) is a United States Air Force base and census-designated place just east of Dayton, Ohio, in Greene County, Ohio, Greene and Montgomery County, Ohio, Montgomery counties. It includes both Wright and Patte ...

approached Marvel. They were looking for materials suitable for drogue parachute

A drogue parachute is a parachute designed for deployment from a rapidly-moving object. It can be used for various purposes, such as to decrease speed, to provide control and stability, or as a pilot parachute to deploy a larger parachute. V ...

s which could tolerate short-time mechanical stress. However, the thermal resistance of all known filaments at that time was inadequate. The original search concentrated on aromatic condensation polymers but the amide linkage proved to be weak link for the aim of maximal thermal stability

In thermodynamics, thermal stability describes the stability of a water body and its resistance to mixing.Schmidt, W. 1928. Über Temperatur und Stabilitätsverhältnisse von Seen. Geogr. Ann 10: 145 - 177. It is the amount of work needed to t ...

of the polymer, whereas Marvel's research focused on condensation polymers with aromatic and heteroaromatic

In chemistry, aromaticity is a chemical property of cyclic compound, cyclic (ring (chemistry), ring-shaped), ''typically'' plane (geometry), planar (flat) molecular structures with pi bonds in Resonance (chemistry), resonance (those containing ...

repeating unit

In polymer chemistry, a repeat unit or repeating unit (or mer) is a part of a polymer whose repetition would produce the complete polymer chain (except for the end-groups) by linking the repeat units together successively along the chain, like th ...

s. This progressively led to the discovery of polybenzimidazole.

Development

Its development history can be summarized in the following list: * In 1961, polybenzimidazole was developed by H. Vogel and C.S. Marvel with anticipation that the polymers would have exceptional thermal and oxidative stability. * Subsequently, in 1963,NASA

The National Aeronautics and Space Administration (NASA ) is an independent agencies of the United States government, independent agency of the US federal government responsible for the civil List of government space agencies, space program ...

and the Air Force Materials Lab sponsored considerable work with polybenimidazole for aerospace and defense applications as a non-flammable and thermally stable textile fiber.

* In 1969, the United States Air Force selected polybenzimidazole (PBI) for its superior thermal protective performance after a 1967 fire aboard the Apollo 1

Apollo 1, initially designated AS-204, was intended to be the first crewed mission of the Apollo program, the American undertaking to land the first man on the Moon. It was planned to launch on February 21, 1967, as the first low Earth orbita ...

spacecraft killed three astronauts.

* In the early 1970s USAF laboratories experimented with polybenzimidazole fibers for protective clothing

Personal protective equipment (PPE) is protective clothing, helmets, goggles, or other garments or equipment designed to protect the wearer's body from injury or infection. The hazards addressed by protective equipment include physical, elec ...

to reduce aircrew deaths from fires.

* In the 1970s, NASA continued to use PBI as part of the astronauts’ clothing on Apollo, Skylab

Skylab was the first United States space station, launched by NASA, occupied for about 24 weeks between May 1973 and February 1974. It was operated by three separate three-astronaut crews: Skylab 2, Skylab 3, and Skylab 4. Major operations ...

and numerous space shuttle flights.

* When Skylab

Skylab was the first United States space station, launched by NASA, occupied for about 24 weeks between May 1973 and February 1974. It was operated by three separate three-astronaut crews: Skylab 2, Skylab 3, and Skylab 4. Major operations ...

fell to Earth, the part that survived the re-entry was coated in PBI and thus did not burn up.

* 1980s – PBI was introduced to the fire service, and through Project Fires an outer shell for turnout gear was developed. PBI Gold fabric was born, consisting of 40% PBI/60% para-aramid. Previous to this, combinations of Nomex, leather, and Kevlar materials were used in the US.

* 1983 – A unique production plant goes on-line and PBI fibers become commercially available.

* 1990s – Short-cut PBI fibers are introduced for use in automotive braking systems. PBI staple fiber enters the aircraft market for seat fire blocking layers.

* 1992 – Lightweight PBI fabrics are developed for flame-resistant workwear for electric utility and petrochemical applications.

* 1994 – PBI Gold fabric is engineered in black and was specified by the FDNY

The New York City Fire Department, officially the Fire Department of the City of New York (FDNY), is an American department of the government of New York City that provides fire protection services, technical rescue/special operations services, ...

.

* 2001 – After the terrorist attacks on September 11, many of the 343 fire fighters killed were only identifiable by their TenCate PBI Turnout Gear.

* 2003 – PBI Matrix was commercialized and introduced as the next-generation PBI for firefighter turnout gear.

Properties

General physical properties

PBI are usually yellow to brown solid infusible up to 400 °C or higher. Thesolubility

In chemistry, solubility is the ability of a substance, the solute, to form a solution with another substance, the solvent. Insolubility is the opposite property, the inability of the solute to form such a solution.

The extent of the solub ...

of PBI is controversial, because while most of the linear PBI are partly or entirely dissolved in strong protonic acids (for instance, sulfuric acid or methanesulfonic acid), contradictory observations of solubilities have been recorded among weaker acids like formic acid, and in non-acidic media, such as the aprotic amide-type solvents and dimethyl sulfoxide. For example, one type of PBI prepared in phosphoric acid was found by Iwakura et al. to be partially soluble in formic acid, but completely soluble in dimethyl sulfoxide and dimethylacetamide, whereas Varma and Veena reported the same polymer type to dissolve completely in formic acid, yet only partially in dimethyl sulfoxide or dimethylacetamide.

Thermal stability

Imidazole

Imidazole (ImH) is an organic compound with the formula C3N2H4. It is a white or colourless solid that is soluble in water, producing a mildly alkaline solution. In chemistry, it is an aromatic heterocycle, classified as a diazole, and has non-a ...

derivatives are known to be stable compounds. Many of them are resistant to the most drastic treatments with acids and bases and not easily oxidized. The high decomposition temperature and high stability at over 400 °C suggests a polymer with benzimidazole as the repeating unit may also show high heat stability.

Polybenzimidazole and itaromatic derivatives

can withstand temperatures in excess of about 500 °C without softening and degrading. The polymer synthesized from

isophthalic acid

Isophthalic acid is an organic compound with the formula C6H4(CO2H)2. This colorless solid is an isomer of phthalic acid and terephthalic acid. The main industrial uses of purified isophthalic acid (PIA) are for the production of polyethylene te ...

and 3,3'-diaminobenzidine is not melted by exposure to a temperature of 770 °C and loses only 30% of its weight after exposure to high temperature up to 900 °C for several hours.

Flame resistance

A property of a material needed to be considered before putting it into application isflammability

A combustible material is something that can burn (i.e., ''combust'') in air. A combustible material is flammable if it ignites easily at ambient temperatures. In other words, a combustible material ignites with some effort and a flammable mat ...

, which demonstrates how easily one material can ignite and combust under the realistic operating conditions. This may affect its application in varied areas, such as in construction, plant design, and interior decoration. A number of quantitative assessments of flammability exist, such as limiting oxygen index The limiting oxygen index (LOI) is the minimum concentration of oxygen, expressed as a percentage, that will support combustion of a polymer. It is measured by passing a mixture of oxygen and nitrogen over a burning specimen, and reducing the oxy ...

(LOI), i.e., the minimum oxygen concentration at which a given sample can be induced to burn in a candle like configuration. These permit estimation of a 'ranking' comparison of flammability

A combustible material is something that can burn (i.e., ''combust'') in air. A combustible material is flammable if it ignites easily at ambient temperatures. In other words, a combustible material ignites with some effort and a flammable mat ...

. Data shows that PBI is a highly flame resistant material compared to common polymers.

Moisture regain

PBI's moisture regain is useful in protective clothing; this makes the clothing comfortable to wear, in sharp contrast to other synthetic polymers. The moisture regain ability of PBI (13%) compares favorably with cotton (16%).Synthesis

The preparation of PBI(IV) can be achieved bycondensation reaction

In organic chemistry, a condensation reaction is a type of chemical reaction in which two molecules are combined to form a single molecule, usually with the loss of a small molecule such as water. If water is lost, the reaction is also known as a ...

of diphenyl isophthalate (I) and 3,3’,4,4’-tetraaminodiphenyl (II) (Figure 1). The spontaneous cyclization of the intermediately formed amino-amide (III) to PBI (IV) provided a much more stable amide linkage. This synthetic method was first used in the lab and later developed into a two step process. In a typical synthesis, starting materials were heated at 270 °C for 1.5 h to form the PBI prepolymer and later the prepolymer was heated at 360 °C for another 1 h to form the final commercial-grade product.

The reason for the second step is due to the formation of the by-product phenol and water in the first step creating voluminous foam, which leads to the volume expansion of several times of the original. This is the issue that must be considered by the industrial manufacturers. This foam can be reduced by conducting the polycondensation at a high temperature around 200 °C and under the pressure of 2.1-4.2 MPa. The foam can also be controlled by adding high boiling point liquids such as diphenylether or cetane to the polycondensation. The boiling point can make the liquid stay in the first stage of polycondensation but evaporate in the second stage of solid condensation. The disadvantage of this method is that there are still some liquids which remain in the PBI and it is hard to remove them completely.

While changing the tetramine and acid, a number of different aromatic poly benzimidazoles have been synthesized. The following table (Table 1) lists some of the combination possibilities that have been synthesized in the literature. Some of the combinations have actually been translated into fibers on a small scale. However, the only significant progress that has been made to date is with PBI.

The most common form of PBI used in industry is the fiber form. The fiber process following polymerization is shown in the figure. The polymer is made into solution using dimethylacetamide as solvent. The solution is filtered and converted into fiber using a high temperature dry-spinning process. The fiber is subsequently drawn at elevated temperature to get desired mechanical properties. It is then sulfonated and made into staple using conventional crimping and cutting techniques.

The most common form of PBI used in industry is the fiber form. The fiber process following polymerization is shown in the figure. The polymer is made into solution using dimethylacetamide as solvent. The solution is filtered and converted into fiber using a high temperature dry-spinning process. The fiber is subsequently drawn at elevated temperature to get desired mechanical properties. It is then sulfonated and made into staple using conventional crimping and cutting techniques.

Applications

Before the 1980s, the major applications of PBI were fire-blocking, thermal protective apparel, and reverse osmosis membranes. Its applications became various by the 1990s when molded PBI parts and microporous membranes were developed.Protective apparel

The thermal stability, flame resistance, and moisture regain of PBI and its conventional textile processing character enable it to be processed on conventional staple fiber textile equipment. These characteristics lead to one of the most important applications of PBI: protective apparel. PBI filaments were fabricated into protective clothing like firefighters' gear and astronauts' suits. PBI filaments are dry spun from dimethylacetamide containing lithium chloride. After washing and drying the resulting yarn is golden brown. PBI fiber is an excellent candidate for applications in severe environments due to its combination of thermal, chemical and textile properties. Flame and thermal resistance are the critical properties of protective apparel. This kind of apparel applications includes firefighter's protective apparel, astronaut's suits, aluminized crash rescue gear, industrial worker's apparel, and suits for racing car drivers.

PBI fiber is an excellent candidate for applications in severe environments due to its combination of thermal, chemical and textile properties. Flame and thermal resistance are the critical properties of protective apparel. This kind of apparel applications includes firefighter's protective apparel, astronaut's suits, aluminized crash rescue gear, industrial worker's apparel, and suits for racing car drivers.  PBI-blended fabrics have been the preferred choice of active fire departments across the Americas and around the world for over 30 years. From New York, San Diego, San Francisco, Philadelphia, Seattle, Nashville to São Paulo, Belin, Hong Kong and many more. The high decomposition temperature at which PBI starts to degrade is 1300 °F, exceeding Nomex/Kevlar blends (Nomex being at 700 °F and Kevlar at 1100 °F), thus offering superior break-open and thermal protection.

PBI-blended fabrics have been the preferred choice of active fire departments across the Americas and around the world for over 30 years. From New York, San Diego, San Francisco, Philadelphia, Seattle, Nashville to São Paulo, Belin, Hong Kong and many more. The high decomposition temperature at which PBI starts to degrade is 1300 °F, exceeding Nomex/Kevlar blends (Nomex being at 700 °F and Kevlar at 1100 °F), thus offering superior break-open and thermal protection.

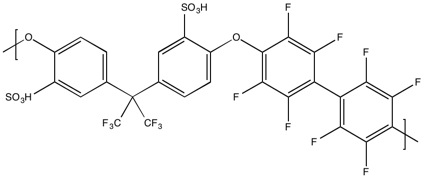

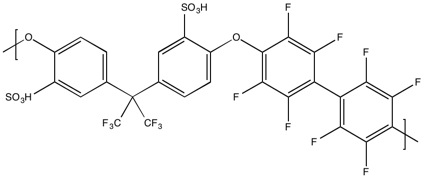

PBI membranes

PBI has been used as the membranes for various separation purposes. Traditionally, PBI was used semi-permeable membranes for electrodialysis, reverse osmosis or ultrafiltration. PBI has also used for gas separations. due to its close chain packing since PBI has rigidity structure and strong hydrogen bonding. PBI membranes are dense, with very low gas permeability. To be proton conductive, PBI usually is doped with acid. The higher level of the acid doping, the more conductive PBI is. But one problem raised is the mechanical strength of PBI decreases at the same time. The optimum doping level is thus a compromise between these two effects. Thus, multiple methods such as ionic cross-linking, covalent cross-linking and composite membranes have been researched to optimize the doping level at which PBI has an improved conductivity without sacrificing mechanical strength. Sulfonated partially fluorinated arylene main chain polymer exhibit good thermal and extended stability, high proton conductivities, less acid swelling, reasonable mechanical strength.

Molded PBI resin

Molded PBIresin

In polymer chemistry and materials science, resin is a solid or highly viscous substance of plant or synthetic origin that is typically convertible into polymers. Resins are usually mixtures of organic compounds. This article focuses on n ...

has compressive strength 58 ksi

Olajide Olayinka Williams "JJ" Olatunji (born 19 June 1993), known professionally as KSI, is an English YouTuber and rapper. He is a co-founder and member of the British YouTube group known as the Sidemen. He is the CEO of Misfits Boxing and ...

and a tensile strength of 23 ksi

Olajide Olayinka Williams "JJ" Olatunji (born 19 June 1993), known professionally as KSI, is an English YouTuber and rapper. He is a co-founder and member of the British YouTube group known as the Sidemen. He is the CEO of Misfits Boxing and ...

, a flexural strength of 32 ksi

Olajide Olayinka Williams "JJ" Olatunji (born 19 June 1993), known professionally as KSI, is an English YouTuber and rapper. He is a co-founder and member of the British YouTube group known as the Sidemen. He is the CEO of Misfits Boxing and ...

, a ductile compressive failure mode and the density

Density (volumetric mass density or specific mass) is the substance's mass per unit of volume. The symbol most often used for density is ''ρ'' (the lower case Greek letter rho), although the Latin letter ''D'' can also be used. Mathematical ...

of 1.3 g/cm3. The PBI resin comprises a recurring structural unit represented by the following figure.

According to the Composite Materials Research Group at the

University of Wyoming

The University of Wyoming (UW) is a public land-grant research university in Laramie, Wyoming. It was founded in March 1886, four years before the territory was admitted as the 44th state, and opened in September 1887. The University of Wyoming ...

, PBI resin parts maintain significant tensile

In physics, tension is described as the pulling force transmitted axially by the means of a string, a rope, chain, or similar object, or by each end of a rod, truss member, or similar three-dimensional object; tension might also be described as ...

properties and compressive strength to . PBI resin parts are also potential materials for the chemical process and oil recovery industries which have demands of thermal stability

In thermodynamics, thermal stability describes the stability of a water body and its resistance to mixing.Schmidt, W. 1928. Über Temperatur und Stabilitätsverhältnisse von Seen. Geogr. Ann 10: 145 - 177. It is the amount of work needed to t ...

and chemical resistance

The chemical resistance of a material or surface can be determined in compliance with ISO 2812 Paints and varnishes – Determination of resistance to liquids – Part 1: Immersion in liquids other than water (ISO 2812-1:2007); German Version EN I ...

. In these areas, PBI resin has been successfully applied in demanding sealing, for instance, valve seats, stem seals, hydraulic seals and backup rings. In the aerospace industry, PBI resin has high strength and short term high temperature resistance advantages. In the industrial sector, PBI resin's high dimensional stability as well as retention of electrical properties at high temperature make it used as a thermal and electrical insulator.

Fuel cell electrolyte

Polybenzimidazole is able to be complexed bystrong acids

Acid strength is the tendency of an acid, symbolised by the chemical formula HA, to dissociate into a proton, H+, and an anion, A-. The dissociation of a strong acid in solution is effectively complete, except in its most concentrated solutions ...

because of its basic character. Complexation by phosphoric acid

Phosphoric acid (orthophosphoric acid, monophosphoric acid or phosphoric(V) acid) is a colorless, odorless phosphorus-containing solid, and inorganic compound with the chemical formula . It is commonly encountered as an 85% aqueous solution, w ...

makes it a proton conductive material. This renders the possible application to high temperature fuel cells. Cell performance test show a good stability in performance for 200 h runs at 150 °C. However, gel PBI membranes made in the PPA Process show good stability for greater than 17,000 hours at 160 °C. Application in direct methanol fuel cells may be also of interest because of a better selectivity water/methanol compared to existing membranes. Wainright, Wang et al. reported that PBI doped with phosphoric acid

Phosphoric acid (orthophosphoric acid, monophosphoric acid or phosphoric(V) acid) is a colorless, odorless phosphorus-containing solid, and inorganic compound with the chemical formula . It is commonly encountered as an 85% aqueous solution, w ...

was utilized as a high temperature fuel cell electrolyte. The doped PBI high temperature fuel cell electrolyte has several advantages. The elevated temperature increases the kinetic rates of the fuel cell reactions. It also can reduce the problem of the catalyst poisoning Catalyst poisoning refers to the partial or total deactivation of a catalyst by a chemical compound. Poisoning refers specifically to chemical deactivation, rather than other mechanisms of catalyst degradation such as thermal decomposition or physic ...

by adsorbed carbon monoxide

Carbon monoxide (chemical formula CO) is a colorless, poisonous, odorless, tasteless, flammable gas that is slightly less dense than air. Carbon monoxide consists of one carbon atom and one oxygen atom connected by a triple bond. It is the simple ...

and it minimizes problems due to electrode flooding. PBI/H3PO4 is conductive even in low relative humidity and it allows less crossover of the methanol at the same time. These contribute PBI/H3PO4 to be superior to some traditional polymer electrolytes such as Nafion

Nafion is a brand name for a sulfonated tetrafluoroethylene based fluoropolymer-copolymer discovered in the late 1960s by Dr. Walther Grot of DuPont. Nafion is a brand of the Chemours company. It is the first of a class of synthetic polymers with ...

. Additionally, PBI/H3PO4 maintains good mechanical strength and toughness. Its modulus is three order of magnitudes greater than that of Nafion

Nafion is a brand name for a sulfonated tetrafluoroethylene based fluoropolymer-copolymer discovered in the late 1960s by Dr. Walther Grot of DuPont. Nafion is a brand of the Chemours company. It is the first of a class of synthetic polymers with ...

. This means that the thinner films can be used, thus reducing ohmic loss.

Asbestos replacement

Previously, only asbestos could perform well in high-temperature gloves for uses such as foundries,aluminum

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. It ha ...

extrusion, and metal treatment. However, trials have been performed which show that PBI adequately functions as an asbestos replacement. Moreover, a safety garment manufacturer reported that gloves containing PBI outlasted asbestos by two to nine times with an effective cost. Gloves containing PBI fibers are softer and more supple than those made of asbestos, offering the worker greater mobility and comfort, even if the fabric

Textile is an umbrella term that includes various fiber-based materials, including fibers, yarns, filaments, threads, different fabric types, etc. At first, the word "textiles" only referred to woven fabrics. However, weaving is not th ...

becomes charred. Further, PBI fiber avoids the chronic toxicity Chronic toxicity, the development of adverse effects as a result of long term exposure to a contaminant or other stressor, is an important aspect of aquatic toxicology. Adverse effects associated with chronic toxicity can be directly lethal but are ...

problems associated with asbestos because it is processed on standard textile

Textile is an umbrella term that includes various fiber-based materials, including fibers, yarns, filaments, threads, different fabric types, etc. At first, the word "textiles" only referred to woven fabrics. However, weaving is not the ...

and glove fabricating equipment. PBI also can also be a good substitute for asbestos in several areas of glass manufacturing.

Flue gas filtration

PBI's chemical, thermal and physical properties demonstrate that it can be a promising material as a flue gas filter fabric for coal-fired boilers. Few fabrics can survive in the acidic and high-temperature environment encountered in coal-fired boiler flue gas. The filter bags also must be able to bear the abrasion from the periodic cleaning to remove accumulated dust. PBI fabric has a good abrasion resistance property. The acid and abrasion resistance and thermal stability properties make PBI a competitor for this application.References

Appendix of properties

PBI fiber characteristics

The chemical formula of poly ,2’-(m-phenylen)-5,5’ bibenzimidazol(PBI) is believed to be: ( H-C=CH-C=CH-CH=C-N=C-sub>2- =CH-C=CH-CH=CH-n OR (C20N4H12)n ofMolar mass

In chemistry, the molar mass of a chemical compound is defined as the mass of a sample of that compound divided by the amount of substance which is the number of moles in that sample, measured in moles. The molar mass is a bulk, not molecular, ...

308.336 ± 0.018 g/ mol.

Chemical resistance

It is dyeable to dark shades with basic dyes following caustic pretreatment and resistant to most chemicals.Electrical properties

Features low electrical conductivity and low static electricity buildup.Mechanical properties

Features abrasion resistance.Physical Properties

Additional features: will not ignite or smolder (burn slowly without flame),mildew

Mildew is a form of fungus. It is distinguished from its closely related counterpart, mould, largely by its colour: moulds appear in shades of black, blue, red, and green, whereas mildew is white. It appears as a thin, superficial growth consi ...

- and age-resistant, resistant to sparks and welding spatter.

Thermal Properties

Other features: continuous temperature: , does not melt but degrades around the temperature: under pyrolysis, retains fiber integrity and suppleness up to .External links

Polybenzimidazole (PBI) - Material Information

{{DEFAULTSORT:Polybenzimidazole Fiber Flame retardant fabrics Organic polymers Synthetic fibers