magnet wire on:

[Wikipedia]

[Google]

[Amazon]

Magnet wire or enameled wire is a

Breakdown voltage depends on the thickness of the covering, which can be of 3 types: Grade 1, Grade 2 and Grade 3. Higher grades have thicker insulation and thus higher

Breakdown voltage depends on the thickness of the covering, which can be of 3 types: Grade 1, Grade 2 and Grade 3. Higher grades have thicker insulation and thus higher

A

A

copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pink ...

(Cu) or aluminium

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. It ha ...

(Al) wire coated with a very thin layer of insulation. It is used in the construction of transformer

A transformer is a passive component that transfers electrical energy from one electrical circuit to another circuit, or multiple circuits. A varying current in any coil of the transformer produces a varying magnetic flux in the transformer' ...

s, inductors, motors, generators,

speakers, hard disk head actuators, electromagnet

An electromagnet is a type of magnet in which the magnetic field is produced by an electric current. Electromagnets usually consist of wire wound into a coil. A current through the wire creates a magnetic field which is concentrated in ...

s, electric guitar pickups and other applications that require tight coils of insulated wire.

The wire itself is most often fully annealed, electrolytically refined copper. Aluminium magnet wire is sometimes used for large transformers and motors. The insulation is typically made of tough polymer

A polymer (; Greek '' poly-'', "many" + '' -mer'', "part")

is a substance or material consisting of very large molecules called macromolecules, composed of many repeating subunits. Due to their broad spectrum of properties, both synthetic a ...

film materials rather than vitreous enamel

Vitreous enamel, also called porcelain enamel, is a material made by fusing powdered glass to a substrate by firing, usually between . The powder melts, flows, and then hardens to a smooth, durable vitreous coating. The word comes from the Lati ...

, as the name might suggest.

Construction

Conductor

The most suitable materials for magnet wire applications are unalloyed pure metals, particularly copper. When factors such as chemical, physical, and mechanical property requirements are considered, copper is considered the first choice conductor for magnet wire. Most often, magnet wire is composed of fully annealed, electrolytically refined copper to allow closer winding when making electromagnetic coils. High-purity oxygen-free copper grades are used for high-temperature applications in reducing atmospheres or in motors or generators cooled by hydrogen gas. Aluminium magnet wire is sometimes used as an alternative for large transformers and motors, mainly for economical reasons. Because of its lower electrical conductivity, aluminium wire requires a 1.6-times larger cross sectional area than a copper wire to achieve comparable DC resistance.Insulation

Although described as "enameled", enameled wire is not, in fact, coated with a layer ofenamel paint

Enamel paint is paint that air-dries to a hard, usually glossy, finish, used for coating surfaces that are outdoors or otherwise subject to hard wear or variations in temperature; it should not be confused with decorated objects in "painted ename ...

or vitreous enamel

Vitreous enamel, also called porcelain enamel, is a material made by fusing powdered glass to a substrate by firing, usually between . The powder melts, flows, and then hardens to a smooth, durable vitreous coating. The word comes from the Lati ...

made of fused glass powder. Modern magnet wire typically uses one to four layers (in the case of quad-film type wire) of polymer

A polymer (; Greek '' poly-'', "many" + '' -mer'', "part")

is a substance or material consisting of very large molecules called macromolecules, composed of many repeating subunits. Due to their broad spectrum of properties, both synthetic a ...

film insulation, often of two different compositions, to provide a tough, continuous insulating layer.

Magnet wire insulating films use (in order of increasing temperature range) polyvinyl formal

Formvar refers to any of several thermoplastic resins that are polyvinyl formals, which are polymers formed from polyvinyl alcohol and formaldehyde as copolymers with polyvinyl acetate. They are typically used as coatings, adhesives, and molding m ...

(Formvar), polyurethane, polyamide

A polyamide is a polymer with repeating units linked by amide bonds.

Polyamides occur both naturally and artificially. Examples of naturally occurring polyamides are proteins, such as wool and silk. Artificially made polyamides can be made th ...

, polyester

Polyester is a category of polymers that contain the ester functional group in every repeat unit of their main chain. As a specific material, it most commonly refers to a type called polyethylene terephthalate (PET). Polyesters include natura ...

, polyester- polyimide, polyamide-polyimide (or amide-imide), and polyimide. Polyimide insulated magnet wire is capable of operation at up to . The insulation of thicker square or rectangular magnet wire is often augmented by wrapping it with a high-temperature polyimide or fiberglass tape, and completed windings are often vacuum impregnated with an insulating varnish to improve insulation strength and long-term reliability of the winding.

Self-supporting coils are wound with wire coated with at least two layers, the outermost being a thermoplastic that bonds the turns together when heated.

Other types of insulation such as fiberglass yarn with varnish, aramid

Aramid fibers, short for aromatic polyamide, are a class of heat-resistant and strong synthetic fibers. They are used in aerospace and military applications, for ballistic-rated body armor fabric and ballistic composites, in marine cordage, mar ...

paper, kraft paper, mica, and polyester film are also widely used across the world for various applications like transformers and reactors.

In the audio industry, wires made from silver

Silver is a chemical element with the symbol Ag (from the Latin ', derived from the Proto-Indo-European ''h₂erǵ'': "shiny" or "white") and atomic number 47. A soft, white, lustrous transition metal, it exhibits the highest electrical ...

(Ag) instead of copper are sometimes used. Various other insulators such as cotton (sometimes permeated with some kind of coagulating agent/thickener, such as beeswax

Beeswax (''cera alba'') is a natural wax produced by honey bees of the genus ''Apis''. The wax is formed into scales by eight wax-producing glands in the abdominal segments of worker bees, which discard it in or at the hive. The hive work ...

) and polytetrafluoroethylene (Teflon) can be found. Older insulation materials include cotton, paper, or silk, but these are only useful for low-temperature applications (up to ).

For ease of manufacturing, some low-temperature-grade magnet wire has insulation that can be removed by the heat of soldering

Soldering (; ) is a process in which two or more items are joined by melting and putting a filler metal ( solder) into the joint, the filler metal having a lower melting point than the adjoining metal. Unlike welding, soldering does not inv ...

. This means that electrical connections at the ends can be made without stripping off the insulation first, disadvantage however is that it can melt accidentally.

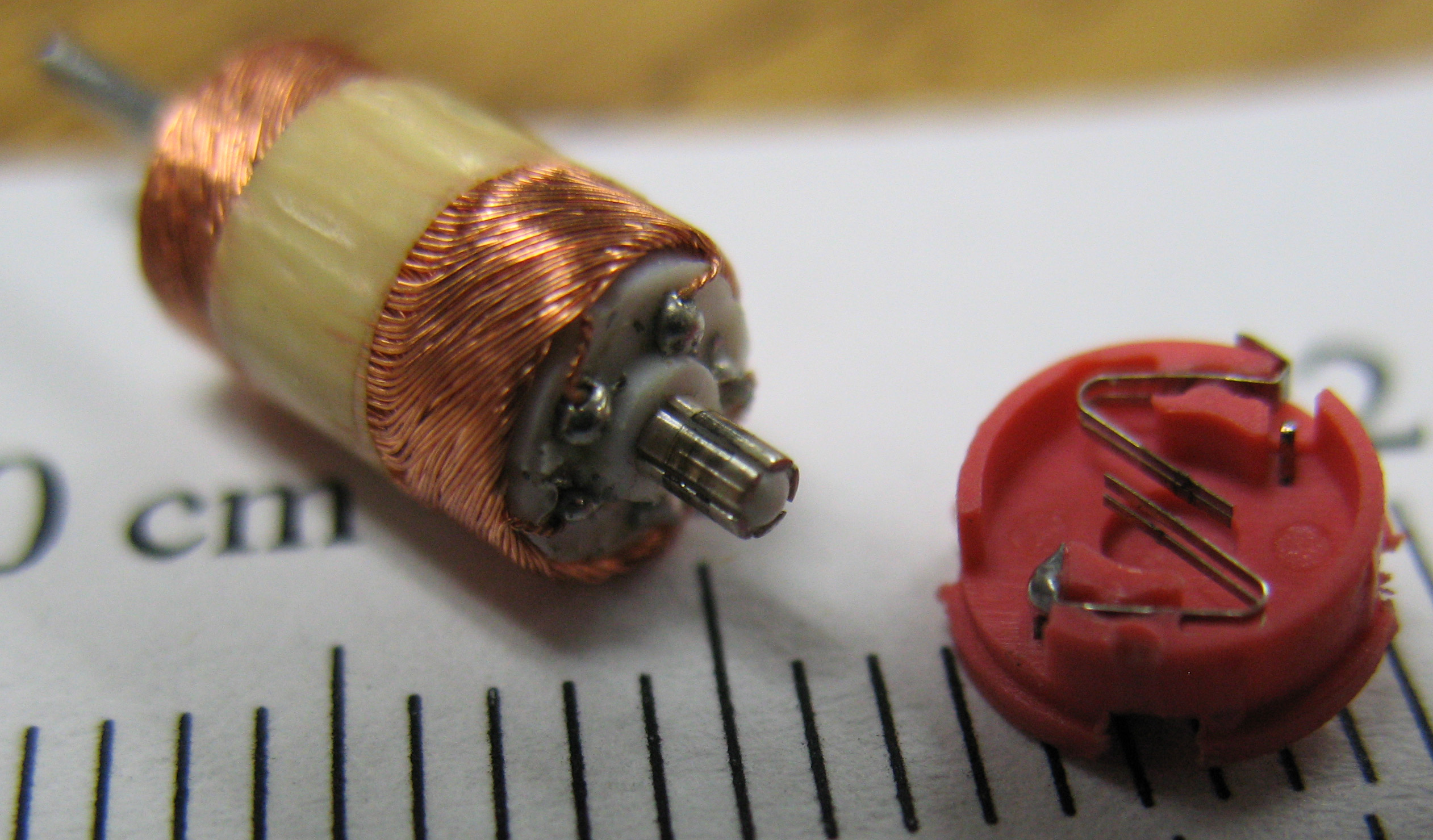

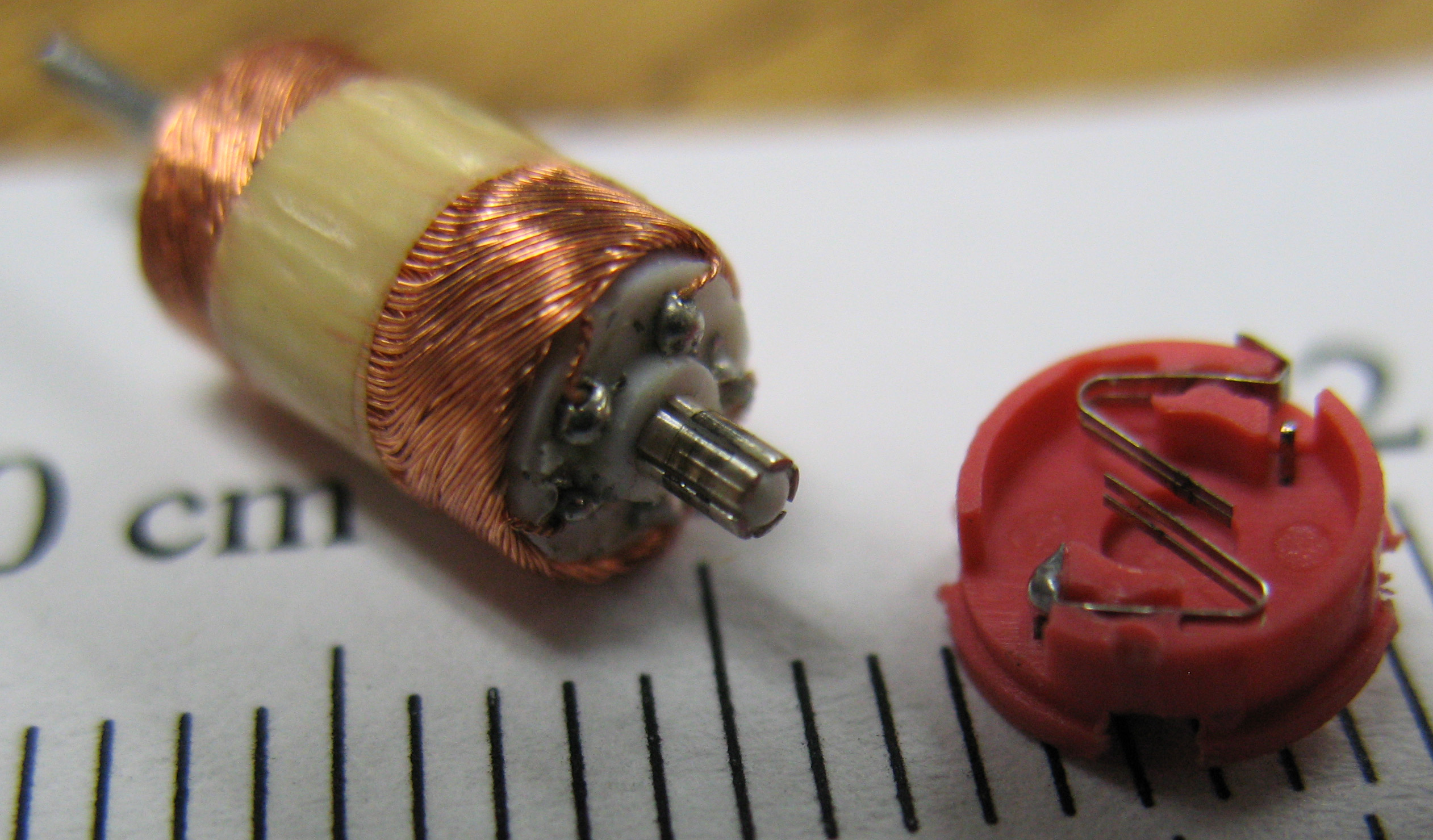

Cross-section

Smaller diameter magnet wire usually has a round cross-section. This kind of wire is used for things such as electric guitar pickups. Thicker magnet wire is often square, rectangular or hexagonal (with rounded corners) in cross section, packing more efficiently and having greater structural stability andthermal conductivity

The thermal conductivity of a material is a measure of its ability to conduct heat. It is commonly denoted by k, \lambda, or \kappa.

Heat transfer occurs at a lower rate in materials of low thermal conductivity than in materials of high thermal ...

across adjacent turns.

Classification

Like other wire, magnet wire is classified by diameter ( AWG number, SWG or millimeters) or area (square millimeters), temperature class, and insulation class. Breakdown voltage depends on the thickness of the covering, which can be of 3 types: Grade 1, Grade 2 and Grade 3. Higher grades have thicker insulation and thus higher

Breakdown voltage depends on the thickness of the covering, which can be of 3 types: Grade 1, Grade 2 and Grade 3. Higher grades have thicker insulation and thus higher breakdown voltages

The breakdown voltage of an insulator is the minimum voltage that causes a portion of an insulator to experience electrical breakdown and become electrically conductive.

For diodes, the breakdown voltage is the minimum reverse voltage that ma ...

.

The temperature class indicates the temperature of the wire at which it has a 20,000 hour service life

A product's service life is its period of use in service. Several related terms describe more precisely a product's life, from the point of manufacture, storage, and distribution, and eventual use.

Service life has been defined as "a product's ...

. At lower temperatures the service life of the wire is longer (about a factor of two for every 10 °C lower temperature). Common temperature classes are , , , and .

Current density

In practice maximum current density can vary from 2.5 A/mm2 for a wire isolated from free air to 6 A/mm2 for a wire in free air. If the wire is carrying high frequency currents (above 10 kHz) the skin effect may affect the distribution of the current across the section by concentrating the current on the surface of the conductor. If active cooling is provided by blowing air or circulating water much higher current densities can be achieved - proportionally to the effectiveness of cooling. An aluminium wire must have 1.6 times the cross sectional area as a copper wire to achieve comparable DC resistance. Due to this, copper magnet wires contribute to improving energy efficiency in equipment such as electric motors.Applications

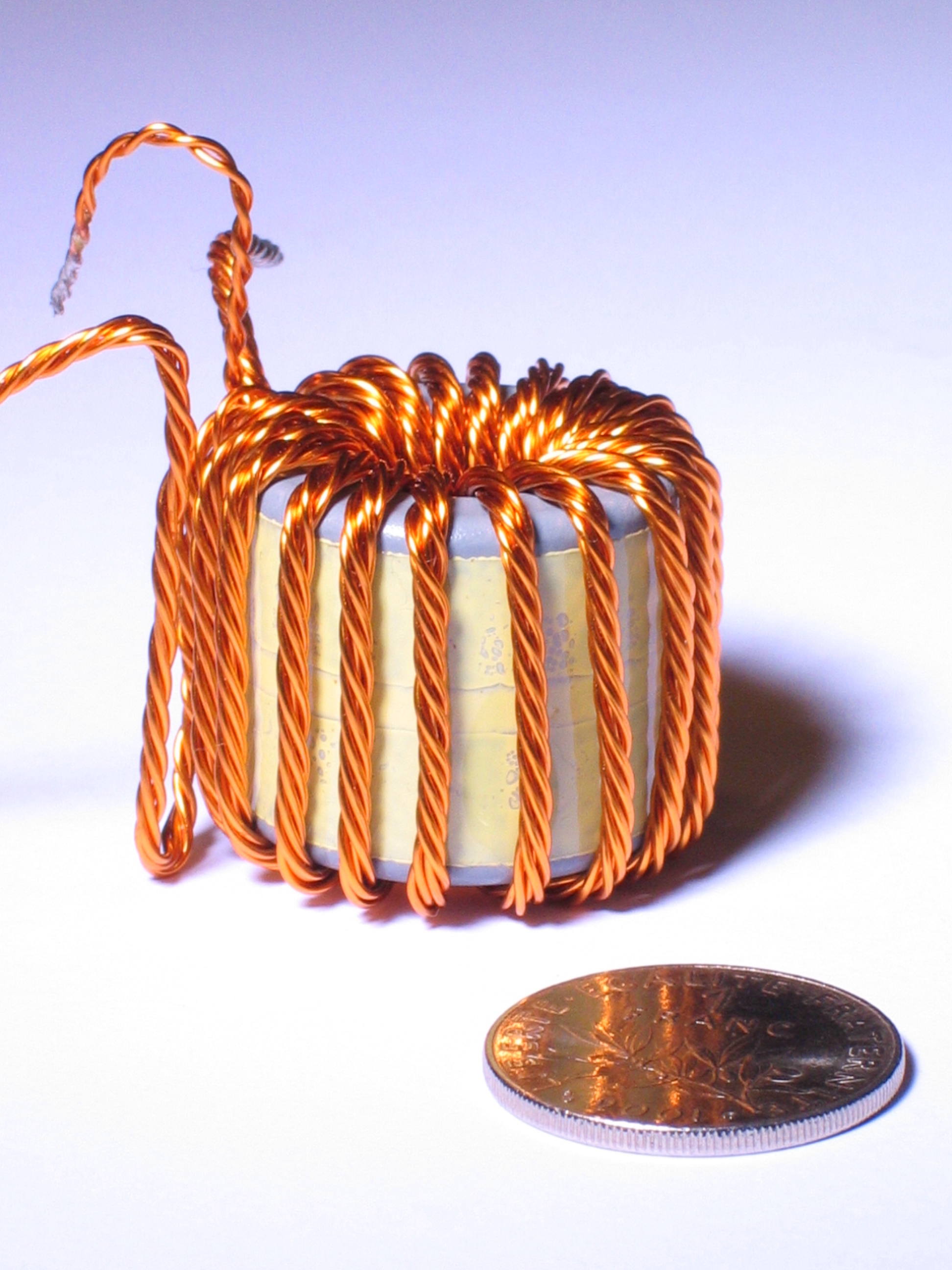

Magnet wire is used in windings ofelectric motor

An electric motor is an electrical machine that converts electrical energy into mechanical energy. Most electric motors operate through the interaction between the motor's magnetic field and electric current in a wire winding to generate f ...

s, transformer

A transformer is a passive component that transfers electrical energy from one electrical circuit to another circuit, or multiple circuits. A varying current in any coil of the transformer produces a varying magnetic flux in the transformer' ...

s, inductor

An inductor, also called a coil, choke, or reactor, is a passive two-terminal electrical component that stores energy in a magnetic field when electric current flows through it. An inductor typically consists of an insulated wire wound into a c ...

s, generators, headphones, loudspeaker

A loudspeaker (commonly referred to as a speaker or speaker driver) is an electroacoustic transducer that converts an electrical audio signal into a corresponding sound. A ''speaker system'', also often simply referred to as a "speaker" or ...

coils, hard drive head positioners, electromagnet

An electromagnet is a type of magnet in which the magnetic field is produced by an electric current. Electromagnets usually consist of wire wound into a coil. A current through the wire creates a magnetic field which is concentrated in ...

s, and other devices.Joseph, Günter, 1999, Copper: Its Trade, Manufacture, Use, and Environmental Status, edited by Kundig, Konrad J.A., ASM International Vol. 2.03, Electrical ConductorsPops, Horace, 1995, Physical Metallurgy of Electrical Conductors, in Nonferrous Wire Handbook, Volume 3: Principles and Practice, The Wire Association International, pp. 7-22

In electric motors

Electric motor

An electric motor is an electrical machine that converts electrical energy into mechanical energy. Most electric motors operate through the interaction between the motor's magnetic field and electric current in a wire winding to generate f ...

s convert electrical energy into mechanical motion, usually through the interaction of magnetic fields and current-carrying conductors. Electric motors are found in numerous diverse applications, such as fans, blowers, pumps, machines, household appliances, power tools, and disk drives. The very largest electric motors with ratings in the thousands of kilowatts are used in such applications as the propulsion of large ships. The smallest motors move the hands in electric wristwatches.

Electric motors contain coils to produce the required magnetic fields. For a given size of motor frame, high conductivity material reduces the energy loss due to coil resistance. Poorer conductors generate more waste heat when transferring electrical energy into kinetic energy.

Because of its high electrical conductivity, copper is commonly used in coil windings, bearings, collectors, brushes, and connectors of motors, including the highest quality motors. Copper's greater conductivity versus other materials enhances the electrical energy efficiency of motors. For example, to reduce load losses in continuous-use induction-type motors above 1 horsepower

Horsepower (hp) is a unit of measurement of power, or the rate at which work is done, usually in reference to the output of engines or motors. There are many different standards and types of horsepower. Two common definitions used today are t ...

, manufacturers invariably use copper as the conducting material in windings. Aluminium is an alternate material in smaller horsepower motors, especially when motors are not used continuously.

One of the design elements of premium motors is the reduction of heat losses due to the electrical resistance of conductors. To improve the electrical energy efficiency of induction-type motors, load loss can be reduced by increasing the cross section of copper coils. A high efficiency motor will usually have 20% more copper in the stator winding than its standard counterpart.

Early developments in motor efficiency focused on reducing electrical losses by increasing the packing weight of stator windings. This made sense since electrical losses typically account for more than half of all energy losses, and stator losses account for approximately two‐thirds of electrical losses.

There are, however, disadvantages in increasing the electrical efficiency of motors through larger windings. This increases motor size and cost, which may not be desirable in applications such as appliances and in automobiles.The emerging electrical markets for copper, Bloomsbury Minerals Economics LTD, July 6, 2010

In transformers

transformer

A transformer is a passive component that transfers electrical energy from one electrical circuit to another circuit, or multiple circuits. A varying current in any coil of the transformer produces a varying magnetic flux in the transformer' ...

is a device that transfers electrical energy from one circuit to another through its coils (windings). The properties needed for motor windings are similar to those needed for transformers, but with the additional requirement to withstand mechanical vibration and centrifugal forces at operating temperatures.

Transformer windings are normally made from copper but aluminium is a suitable competitor where weight and first cost are decisive factors.

In North America, aluminium is the predominant choice of winding material for low-voltage, dry-type transformers larger than 15 kilovolt-amperes (kVA). In most other areas of the world, copper is the predominant winding material. Purchasing decisions are generally a function of loss valuations expressed in currency per kilowatt.

Copper used for the manufacture of transformer windings is in the form of wire for small products and strip for larger equipment. For small products, the wire must be strong enough to be wound without breakage, yet flexible enough to provide close-packed windings. Strip products must be of good surface quality so that insulating enamels do not break down under voltage. Good ductility is essential for the strip to be formed and packed while good strength is needed to withstand the high electro-mechanical stresses set up under occasional short-circuit conditions. Copper winding wires in transformers are compatible with all modern insulation materials, such as lacquer and enamel. Lacquers permit the close spacing of windings to give best efficiency in the coils.

A major engineering reason to choose copper windings over aluminium is space considerations. This is because a copper-wound transformer can be made smaller than aluminium transformers. To obtain equal ratings in aluminium transformers, a 66% larger cross-sectional area is required than for copper conductors. However, the use of larger-sized conductors results in the winding strength of aluminium being nearly equivalent to that of copper windings.

Connectivity is another important benefit of copper-wound transformers, as the oxide coating on the surface of aluminum makes soldering or otherwise connecting with it more difficult. Cleaning and brushing with a quality joint compound to prevent oxidation

Redox (reduction–oxidation, , ) is a type of chemical reaction in which the oxidation states of substrate change. Oxidation is the loss of electrons or an increase in the oxidation state, while reduction is the gain of electrons or ...

is not necessary with copper.

In generators

The trend in modern generators is to operate at higher temperatures and higher electrical conductivities with oxygen-free copper for field bars and magnetic wire in place of formerly used deoxidized copper.References

{{Electric transformers Wire Electric motors Electric transformers