Fluidized bed combustion on:

[Wikipedia]

[Google]

[Amazon]

Fluidized bed combustion (FBC) is a

Fluidized bed combustion (FBC) is a

National Energy Technology Laboratory

Simulation of a commercial CFB coal combustor

{{DEFAULTSORT:Fluidized Bed Combustion Power station technology Energy conversion Chemical processes Fluidization

Fluidized bed combustion (FBC) is a

Fluidized bed combustion (FBC) is a combustion

Combustion, or burning, is a high-temperature exothermic redox chemical reaction between a fuel (the reductant) and an oxidant, usually atmospheric oxygen, that produces oxidized, often gaseous products, in a mixture termed as smoke. Combus ...

technology used to burn solid fuel

Solid fuel refers to various forms of solid material that can be burnt to release energy, providing heat and light through the process of combustion. Solid fuels can be contrasted with liquid fuels and gaseous fuels. Common examples of solid fuel ...

s.

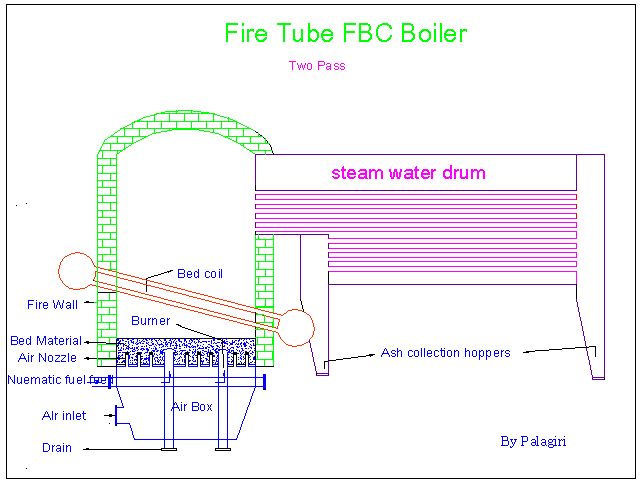

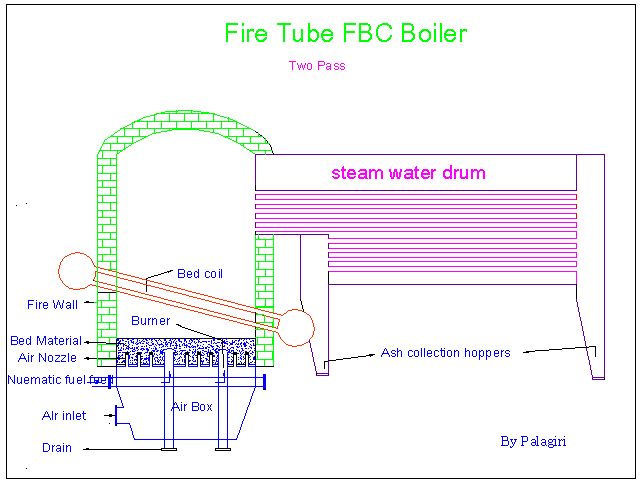

In its most basic form, fuel particles are suspended in a hot, bubbling fluidity bed of ash

Ash or ashes are the solid remnants of fires. Specifically, ''ash'' refers to all non-aqueous, non-gaseous residues that remain after something burns. In analytical chemistry, to analyse the mineral and metal content of chemical samples, ash ...

and other particulate materials (sand

Sand is a granular material composed of finely divided mineral particles. Sand has various compositions but is defined by its grain size. Sand grains are smaller than gravel and coarser than silt. Sand can also refer to a textural class ...

, limestone

Limestone ( calcium carbonate ) is a type of carbonate sedimentary rock which is the main source of the material lime. It is composed mostly of the minerals calcite and aragonite, which are different crystal forms of . Limestone forms w ...

etc.) through which jets of air are blown to provide the oxygen required for combustion or gasification. The resultant fast and intimate mixing of gas and solids promotes rapid heat transfer and chemical reactions within the bed. FBC plants are capable of burning a variety of low-grade solid fuels, including most types of coal, coal waste and woody biomass, at high efficiency and without the necessity for expensive fuel preparation (e.g., pulverising). In addition, for any given thermal duty, FBCs are smaller than the equivalent conventional furnace, so may offer significant advantages over the latter in terms of cost and flexibility.

FBC reduces the amount of sulfur

Sulfur (or sulphur in British English) is a chemical element with the symbol S and atomic number 16. It is abundant, multivalent and nonmetallic. Under normal conditions, sulfur atoms form cyclic octatomic molecules with a chemical formul ...

emitted in the form of SO''x'' emissions. Limestone

Limestone ( calcium carbonate ) is a type of carbonate sedimentary rock which is the main source of the material lime. It is composed mostly of the minerals calcite and aragonite, which are different crystal forms of . Limestone forms w ...

is used to precipitate out sulfate during combustion, which also allows more efficient heat transfer from the boiler to the apparatus used to capture the heat energy (usually water tubes). The heated precipitate coming in direct contact with the tubes (heating by conduction) increases the efficiency. Since this allows coal plants to burn at cooler temperatures, less NO''x'' is also emitted. However, burning at low temperatures also causes increased polycyclic aromatic hydrocarbon

A polycyclic aromatic hydrocarbon (PAH) is a class of organic compounds that is composed of multiple aromatic rings. The simplest representative is naphthalene, having two aromatic rings and the three-ring compounds anthracene and phenanthrene. ...

emissions. FBC boilers can burn fuels other than coal, and the lower temperatures of combustion (800 °C / 1500 °F) have other added benefits as well.

Benefits

There are two reasons for the rapid increase of FBC in combustors. First, the liberty of choice in respect of fuels in general, not only the possibility of using fuels which are difficult to burn using other technologies, is an important advantage of fluidized bed combustion. The second reason, which has become increasingly important, is the possibility of achieving, during combustion, a low emission of nitric oxides and the possibility of removing sulfur in a simple manner by using limestone as bed material. Fluidized--bed combustion evolved from efforts to find a combustion process able to control pollutant emissions without external emission controls (such as scrubbers-flue gas desulfurization). The technology burns fuel at temperatures of 1,400 to 1,700 °F (750-900 °C), well below the threshold where nitrogen oxides form (at approximately 2,500 °F / 1400 °C, thenitrogen

Nitrogen is the chemical element with the symbol N and atomic number 7. Nitrogen is a nonmetal and the lightest member of group 15 of the periodic table, often called the pnictogens. It is a common element in the universe, estimated at se ...

and oxygen

Oxygen is the chemical element with the symbol O and atomic number 8. It is a member of the chalcogen group in the periodic table, a highly reactive nonmetal, and an oxidizing agent that readily forms oxides with most elements ...

atom

Every atom is composed of a nucleus and one or more electrons bound to the nucleus. The nucleus is made of one or more protons and a number of neutrons. Only the most common variety of hydrogen has no neutrons.

Every solid, liquid, gas, a ...

s in the combustion air combine to form nitrogen oxide Nitrogen oxide may refer to a binary compound of oxygen and nitrogen, or a mixture of such compounds:

Charge-neutral

*Nitric oxide (NO), nitrogen(II) oxide, or nitrogen monoxide

* Nitrogen dioxide (), nitrogen(IV) oxide

* Nitrogen trioxide (), or ...

pollutants); it also avoids the ash melting problems related to high combustion temperature. The mixing action of the fluidized bed brings the flue gases into contact with a sulfur

Sulfur (or sulphur in British English) is a chemical element with the symbol S and atomic number 16. It is abundant, multivalent and nonmetallic. Under normal conditions, sulfur atoms form cyclic octatomic molecules with a chemical formul ...

-absorbing chemical, such as limestone

Limestone ( calcium carbonate ) is a type of carbonate sedimentary rock which is the main source of the material lime. It is composed mostly of the minerals calcite and aragonite, which are different crystal forms of . Limestone forms w ...

or dolomite Dolomite may refer to:

*Dolomite (mineral), a carbonate mineral

*Dolomite (rock), also known as dolostone, a sedimentary carbonate rock

*Dolomite, Alabama, United States, an unincorporated community

*Dolomite, California, United States, an unincor ...

. More than 95% of the sulfur pollutants in coal can be captured inside the boiler by the sorbent. The reductions may be less substantial than they seem, however, as they coincide with dramatic increases in polycyclic aromatic hydrocarbons, and possibly other carbon compound emissions.

Commercial FBC units operate at competitive efficiencies, cost less than today's conventional boiler units, and have SO2 and NO2 emissions below levels mandated by Federal standards. However, they have some disadvantages such as erosion on the tubes inside the boiler, uneven temperature distribution caused by clogs on the air inlet of the bed, long starting times reaching up to 48 hours in some cases.

# FBC has a lower combustion temperature of 750 °C whereas an ordinary boiler operates at 850 °C.

# FBC has low sintering process (melting of Ash).

# Lower production of NOx due to lower temperature.

# Lower production of SOx due to capture by limestone.

# Higher combustion efficiency due to 10 times more heat transfer than other combustion processes because of burning particle.

# Less area is required for FBC due to high coefficient of convective heat transfer.

# Iso-thermal bed combustion as temperature in free belt and active belt remain constant.

Types

FBC systems fit into essentially two major groups, atmospheric systems (FBC) and pressurized systems (PFBC), and two minor subgroups, bubbling (BFB) and circulating fluidized bed ( CFB).Atmospheric Fluidized Bed Combustion

Atmospheric fluidized beds use limestone or dolomite to capture sulfur released by the combustion of coal. Jets of air suspend the mixture of sorbent and burning coal during combustion, converting the mixture into a suspension of red-hot particles that flow like a fluid. These boilers operate at atmospheric pressure.Pressurized Fluidized Bed Combustion

The first-generation PFBC system also uses a sorbent and jets of air to suspend the mixture of sorbent and burning coal during combustion. However, these systems operate at elevated pressures and produce a high-pressure gas stream at temperatures that can drive agas turbine

A gas turbine, also called a combustion turbine, is a type of continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part (known as the gas generator or core) and are, in the directio ...

. Steam generated from the heat in the fluidized bed is sent to a steam turbine

A steam turbine is a machine that extracts thermal energy from pressurized steam and uses it to do mechanical work on a rotating output shaft. Its modern manifestation was invented by Charles Parsons in 1884. Fabrication of a modern steam tu ...

, creating a highly efficient combined cycle

A combined cycle power plant is an assembly of heat engines that work in tandem from the same source of heat, converting it into mechanical energy. On land, when used to make electricity the most common type is called a combined cycle gas tur ...

system.

Advanced PFBC

* A 1½ generation PFBC system increases the gas turbine firing temperature by using natural gas in addition to the vitiated air from the PFB combustor. This mixture is burned in a topping combustor to provide higher inlet temperatures for greater combined cycle efficiency. However, this usesnatural gas

Natural gas (also called fossil gas or simply gas) is a naturally occurring mixture of gaseous hydrocarbons consisting primarily of methane in addition to various smaller amounts of other higher alkanes. Low levels of trace gases like carbon d ...

, usually a higher priced fuel than coal.

* APFBC. In more advanced second-generation PFBC systems, a pressurized carbonizer is incorporated to process the feed coal into fuel gas and char. The PFBC burns the char to produce steam and to heat combustion air for the gas turbine. The fuel gas from the carbonizer burns in a topping combustor linked to a gas turbine, heating the gases to the combustion turbine's rated firing temperature. Heat is recovered from the gas turbine exhaust in order to produce steam, which is used to drive a conventional steam turbine

A steam turbine is a machine that extracts thermal energy from pressurized steam and uses it to do mechanical work on a rotating output shaft. Its modern manifestation was invented by Charles Parsons in 1884. Fabrication of a modern steam tu ...

, resulting in a higher overall efficiency for the combined cycle

A combined cycle power plant is an assembly of heat engines that work in tandem from the same source of heat, converting it into mechanical energy. On land, when used to make electricity the most common type is called a combined cycle gas tur ...

power output. These systems are also called APFBC, or advanced circulating pressurized fluidized-bed combustion combined cycle systems. An APFBC system is entirely coal-fueled.

* GFBCC. Gasification fluidized-bed combustion combined cycle systems, GFBCC, have a pressurized circulating fluidized-bed (PCFB) partial gasifier feeding fuel syngas

Syngas, or synthesis gas, is a mixture of hydrogen and carbon monoxide, in various ratios. The gas often contains some carbon dioxide and methane. It is principly used for producing ammonia or methanol. Syngas is combustible and can be used as ...

to the gas turbine topping combustor. The gas turbine exhaust supplies combustion air for the atmospheric circulating fluidized-bed combustor that burns the char from the PCFB partial gasifier.

* CHIPPS. A CHIPPS system is similar, but uses a furnace instead of an atmospheric fluidized-bed combustor. It also has gas turbine air preheater tubes to increase gas turbine cycle efficiency. CHIPPS stands for combustion-based high performance power system.

See also

* Chemical looping combustion * Circulating fluidized bed *Fluidized bed reactor

A fluidized bed reactor (FBR) is a type of reactor device that can be used to carry out a variety of multiphase chemical reactions. In this type of reactor, a fluid (gas or liquid) is passed through a solid granular material (usually a catalyst) ...

* FutureGen

FutureGen was a project to demonstrate capture and sequestration of waste carbon dioxide from a coal-fired electrical generating station. The project (renamed FutureGen 2.0) was retrofitting a shuttered coal-fired power plant in Meredosia, Illin ...

zero-emissions coal-fired power plant

* Grate firing

* JEA Northside Generating Station (Jacksonville)

* Pulverised fuel firing A pulverized coal-fired boiler is an industrial or utility boiler that generates thermal energy by burning pulverized coal (also known as powdered coal or coal dust since it is as fine as face powder in cosmetic makeup) that is blown into the fireb ...

References (Requires update in links)

National Energy Technology Laboratory

Simulation of a commercial CFB coal combustor

{{DEFAULTSORT:Fluidized Bed Combustion Power station technology Energy conversion Chemical processes Fluidization