expeller pressing on:

[Wikipedia]

[Google]

[Amazon]

Expeller pressing (also called oil pressing) is a mechanical method for extracting oil from raw materials. The raw materials are squeezed under high pressure in a single step. When used for the extraction of food oils, typical raw materials are nuts,

Expeller pressing (also called oil pressing) is a mechanical method for extracting oil from raw materials. The raw materials are squeezed under high pressure in a single step. When used for the extraction of food oils, typical raw materials are nuts,

seed

In botany, a seed is a plant structure containing an embryo and stored nutrients in a protective coat called a ''testa''. More generally, the term "seed" means anything that can be Sowing, sown, which may include seed and husk or tuber. Seeds ...

s and algae

Algae ( , ; : alga ) is an informal term for any organisms of a large and diverse group of photosynthesis, photosynthetic organisms that are not plants, and includes species from multiple distinct clades. Such organisms range from unicellular ...

, which are supplied to the press in a continuous feed. As the raw material is pressed, friction causes it to heat. In the case of harder nuts, which require higher pressure, the material temperature can exceed 120 °F (49 °C). "Expeller" is a trademarked term of Anderson International Corporation since 1900, although it has become genericized, is often confused with screw press equipment in general, and does not indicate whether oil extraction is done hot or cold.

Description

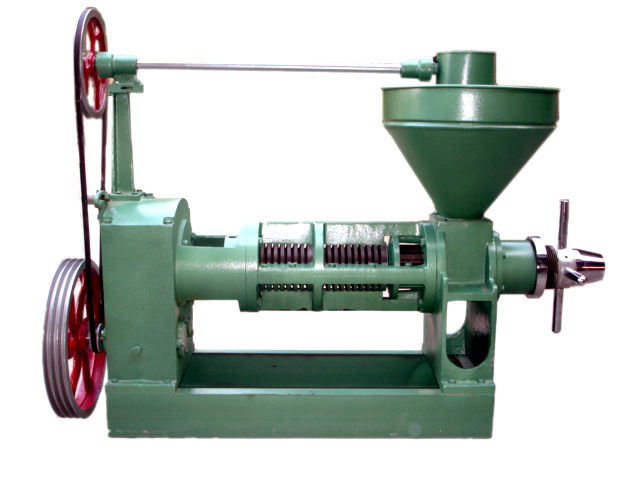

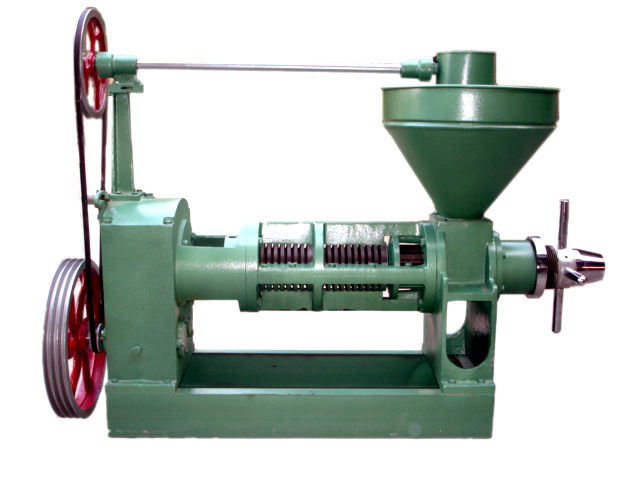

An expeller press is a screw-type machine that mainly presses oil seeds through a caged barrel-like cavity. Some other materials processed with an expeller press include meat by-products,synthetic rubber

A synthetic rubber is an artificial elastomer. They are polymers synthesized from petroleum byproducts. About of rubber is produced annually in the United States, and of that amount two thirds are synthetic. Synthetic rubber, just like natural ru ...

and animal feeds.

Raw materials enter one side of the press and waste products exit the other side. The machine uses friction and continuous pressure from the screw drive to move and compress the seed material. The oil seeps through small openings that do not allow seed fiber solids to pass. Afterward, the seeds are formed into a hardened press cake, which is removed from the machine.

Pressure involved in expeller pressing creates heat in the range of . Raw materials are typically heated up to to make the pressing more efficient; otherwise the pressing itself will heat the oil to . Some manufacturers use a cooling apparatus to reduce this temperature to protect certain properties of the oils being extracted – a process called ''cold-pressed'' where the extraction temperature is less than .

Efficiency

Expeller processing cannot remove every last trace of liquid (usually oil) from the raw material. A significant amount remains trapped inside the cake remaining after pressing. In most small-scale rural situations this is of little importance, as the remaining cake after oil extraction finds uses in local dishes, in the manufacture of secondary products, or in animal feed. Some raw materials do not release oil by expelling, the most notable being rice bran. To remove oil from commodities that do not respond to expelling or to extract the final traces of oil after expelling, it is necessary to usesolvent extraction

A solvent (from the Latin language, Latin ''wikt:solvo#Latin, solvō'', "loosen, untie, solve") is a substance that dissolves a solute, resulting in a Solution (chemistry), solution. A solvent is usually a liquid but can also be a solid, a gas ...

.

Design

Continuous screw

The earliest expeller presses utilized a continuous screw design. The compression screws were much like the screws of ascrew conveyor

A screw conveyor or auger conveyor is a mechanism that uses a rotating helical screw (simple machine), screw blade, called a "''flighting''", usually within a tube, to move liquid or granular materials. They are used in many bulk handling in ...

—that is, the helicoid flighting started at one end and ended at the other.

Interrupted screw

Valerius Anderson invented the interrupted screw design and patented it in the year 1900. Anderson observed that in the continuous flighting arrangement of a compression screw, there are tendencies for slippery materials either to co-rotate with the screw or to pass through with minimal dewatering. He wrote that " brewers' slops,slaughterhouse

In livestock agriculture and the meat industry, a slaughterhouse, also called an abattoir (), is a facility where livestock animals are slaughtered to provide food. Slaughterhouses supply meat, which then becomes the responsibility of a mea ...

refuse" and other "soft and mushy" materials dewater poorly in continuous screw presses.

His invention consisted of putting interruptions in the flighting of a compression screw. It was much like having a hanger bearing in a screw conveyor: there is no flighting on the shaft at that point, so material tends to stop moving and pile up. It is only after solids accumulate in the gap that the downstream flighting catches material. When this happens, material is forced along its way. The result is better dewatering and thus a more consistent press cake.

Resistor teeth

After the 1900 patent, a major improvement was made with the addition of resistor teeth. Fitted into the gaps where there is no flighting, these teeth increase the agitation within the press, further diminishing co-rotation tendencies.Expanded applications

Applications of the interrupted screw design expanded to conditions of constant feed, at constant consistency. If either the consistency or the flow rate diminished, squeezing would diminish until it was inadequate for proper moisture removal. At the same time, if the consistency increased, the press could jam. To counteract these tendencies, it was necessary to build a heavy press, frequently with a costly variable speed drive. A ''Kern Kraft'' press provides a screw that will grindsoybean

The soybean, soy bean, or soya bean (''Glycine max'') is a species of legume native to East Asia, widely grown for its edible bean. Soy is a staple crop, the world's most grown legume, and an important animal feed.

Soy is a key source o ...

s more efficiently than a screw used for pressing canola

file:CanolaBlooms.JPG, Close-up of canola blooms

file:Canola Flower.jpg, Canola flower

Rapeseed oil is one of the oldest known vegetable oils. There are both Edible oil, edible and industrial forms produced from rapeseed, the seed of several ...

and other smaller seeds.

In contrast, it was found that the interruptions in the flighting of the Anderson screw would provide cushion within the press. If consistency decreased, compression was still effective. A plug of sufficiently solid material had to build up at each interruption before solids could progress toward the discharge. This self-correcting performance prevents wet material from purging at the cake discharge. It is achieved without varying the speed of the screw.

The economic advantages of these characteristics led to interrupted screw presses being used to dewater fibrous materials. Examples would be alfalfa

Alfalfa () (''Medicago sativa''), also called lucerne, is a perennial plant, perennial flowering plant in the legume family Fabaceae. It is cultivated as an important forage crop in many countries around the world. It is used for grazing, hay, ...

, corn

Maize (; ''Zea mays''), also known as corn in North American English, is a tall stout Poaceae, grass that produces cereal grain. It was domesticated by indigenous peoples of Mexico, indigenous peoples in southern Mexico about 9,000 years ago ...

husk

Husk (or hull) in botany is the outer shell or coating of a seed. In the United States, the term husk often refers to the leafy outer covering of an Ear (botany), ear of maize (corn) as it grows on the plant. Literally, a husk or hull includes t ...

, and, more recently, paper mill

A paper mill is a factory devoted to making paper from vegetable fibres such as wood pulp, old rags, and other ingredients. Prior to the invention and adoption of the Fourdrinier machine and other types of paper machine that use an endless belt ...

fibers.

See also

* Algaculture oil extraction * Dewatering screw press * Oil millReferences

{{Reflist Oils High lipid content microalgae Liquid-solid separation