dip pen nanolithography on:

[Wikipedia]

[Google]

[Amazon]

Dip pen nanolithography (DPN) is a

Dip pen nanolithography (DPN) is a

Liquid inks can be any material that is liquid at deposition conditions. The liquid deposition properties are determined by the interactions between the liquid and the tip, the liquid and the surface, and the viscosity of the liquid itself. These interactions limit the minimum feature size of the liquid ink to about 1 micrometre, depending on the contact angle of the liquid. Higher viscosities offer greater control over feature size and are desirable. Unlike molecular inks, it is possible to perform multiplexed depositions using a carrier liquid. For example, using a viscous buffer, it is possible to directly deposit multiple proteins simultaneously.

*1-10 micrometre feature resolution

*Multiplexed depositions

*Less restrictive ink/surface requirements

*Direct deposition of high viscosity materials

Liquid inks can be any material that is liquid at deposition conditions. The liquid deposition properties are determined by the interactions between the liquid and the tip, the liquid and the surface, and the viscosity of the liquid itself. These interactions limit the minimum feature size of the liquid ink to about 1 micrometre, depending on the contact angle of the liquid. Higher viscosities offer greater control over feature size and are desirable. Unlike molecular inks, it is possible to perform multiplexed depositions using a carrier liquid. For example, using a viscous buffer, it is possible to directly deposit multiple proteins simultaneously.

*1-10 micrometre feature resolution

*Multiplexed depositions

*Less restrictive ink/surface requirements

*Direct deposition of high viscosity materials

# Biosensor Functionalization - Directly place multiple capture domains on a single

# Biosensor Functionalization - Directly place multiple capture domains on a single

* Plasmonics and Metamaterials

* Cell and tissue screening

* Plasmonics and Metamaterials

* Cell and tissue screening

The criticism most often directed at DPN is the patterning speed. The reason for this has more to do with how it is compared to other techniques rather than any inherent weaknesses. For example, the soft lithography method,

The criticism most often directed at DPN is the patterning speed. The reason for this has more to do with how it is compared to other techniques rather than any inherent weaknesses. For example, the soft lithography method,

Dip pen nanolithography (DPN) is a

Dip pen nanolithography (DPN) is a scanning probe lithography

Scanning probe lithography (SPL) describes a set of nanolithographic methods to pattern material on the nanoscale using scanning probes. It is a direct-write, mask-less approach which bypasses the diffraction limit and can reach resolutions belo ...

technique where an atomic force microscope (AFM) tip is used to create patterns directly on a range of substances with a variety of inks. A common example of this technique is exemplified by the use of alkane thiolates to imprint onto a gold surface. This technique allows surface patterning on scales of under 100 nanometers. DPN is the nanotechnology analog of the dip pen

A dip pen or nib pen or pen nib usually consists of a metal nib with capillary channels like those of fountain pen nibs, mounted in a handle or holder, often made of wood. Other materials can be used for the holder, including bone, metal and pla ...

(also called the quill pen

A quill is a writing tool made from a moulted flight feather (preferably a primary wing-feather) of a large bird. Quills were used for writing with ink before the invention of the dip pen, the metal- nibbed pen, the fountain pen, and, eventuall ...

), where the tip of an atomic force microscope cantilever

A cantilever is a rigid structural element that extends horizontally and is supported at only one end. Typically it extends from a flat vertical surface such as a wall, to which it must be firmly attached. Like other structural elements, a cant ...

acts as a "pen," which is coated with a chemical compound or mixture acting as an "ink," and put in contact with a substrate, the "paper."

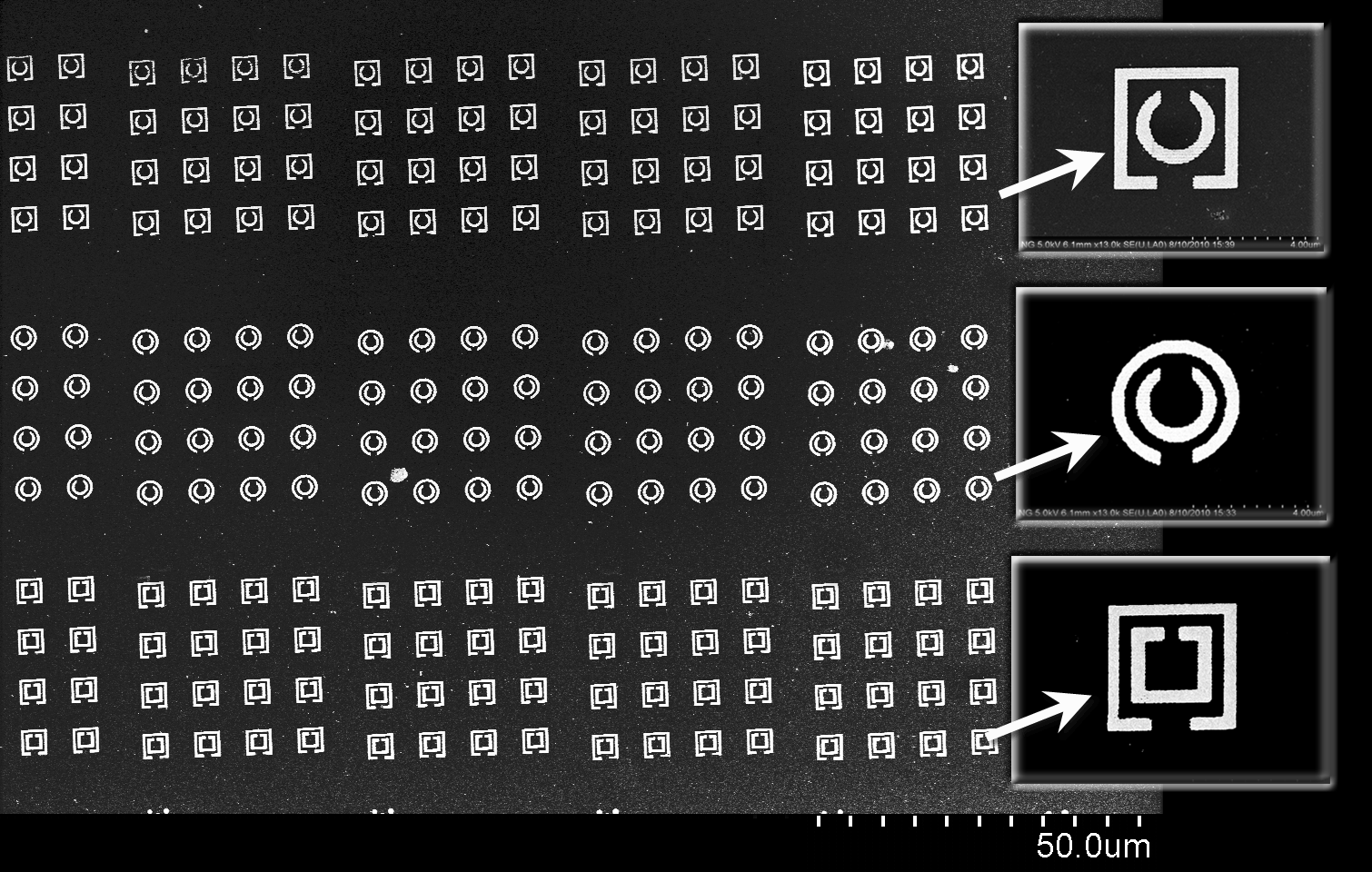

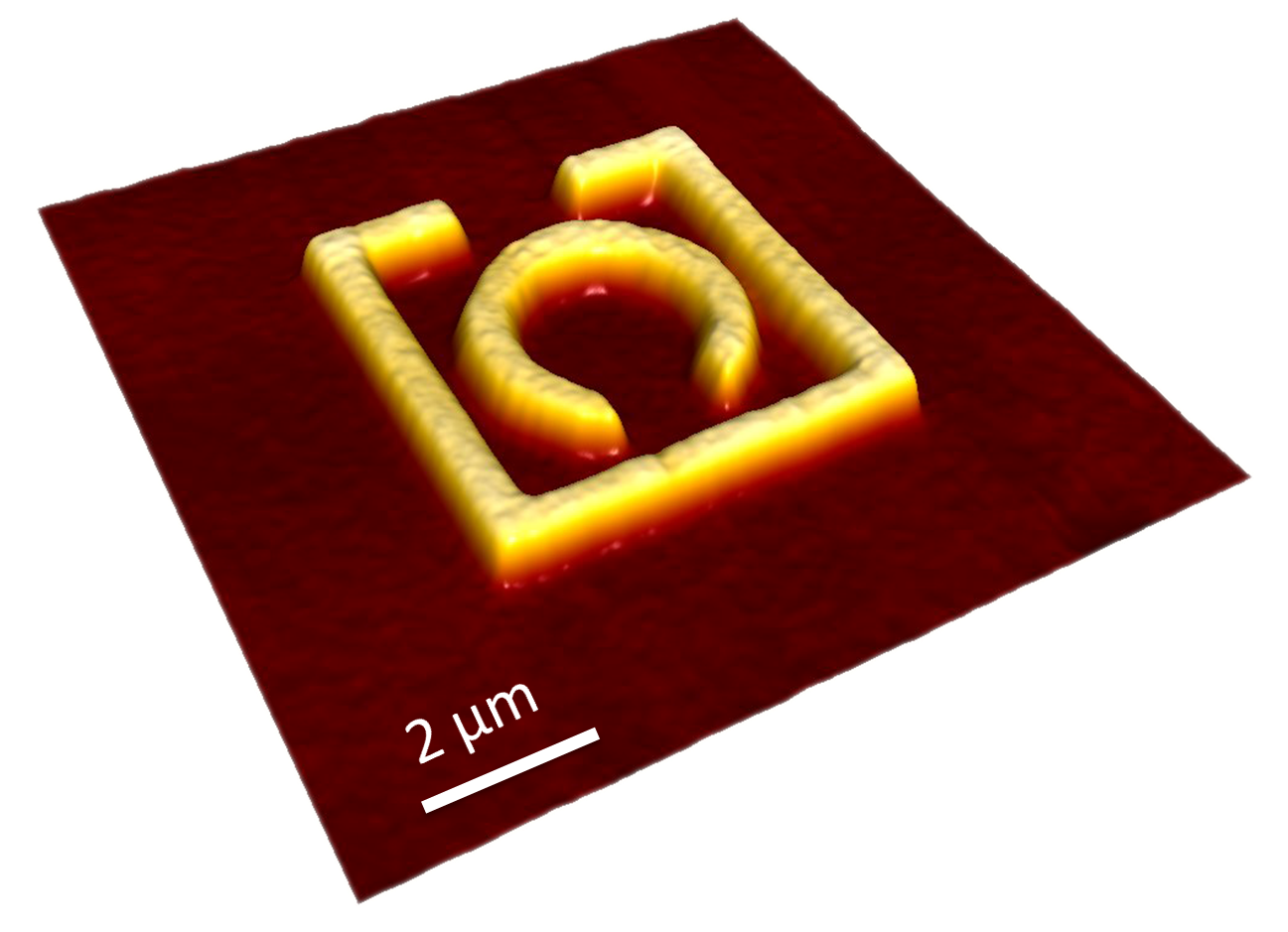

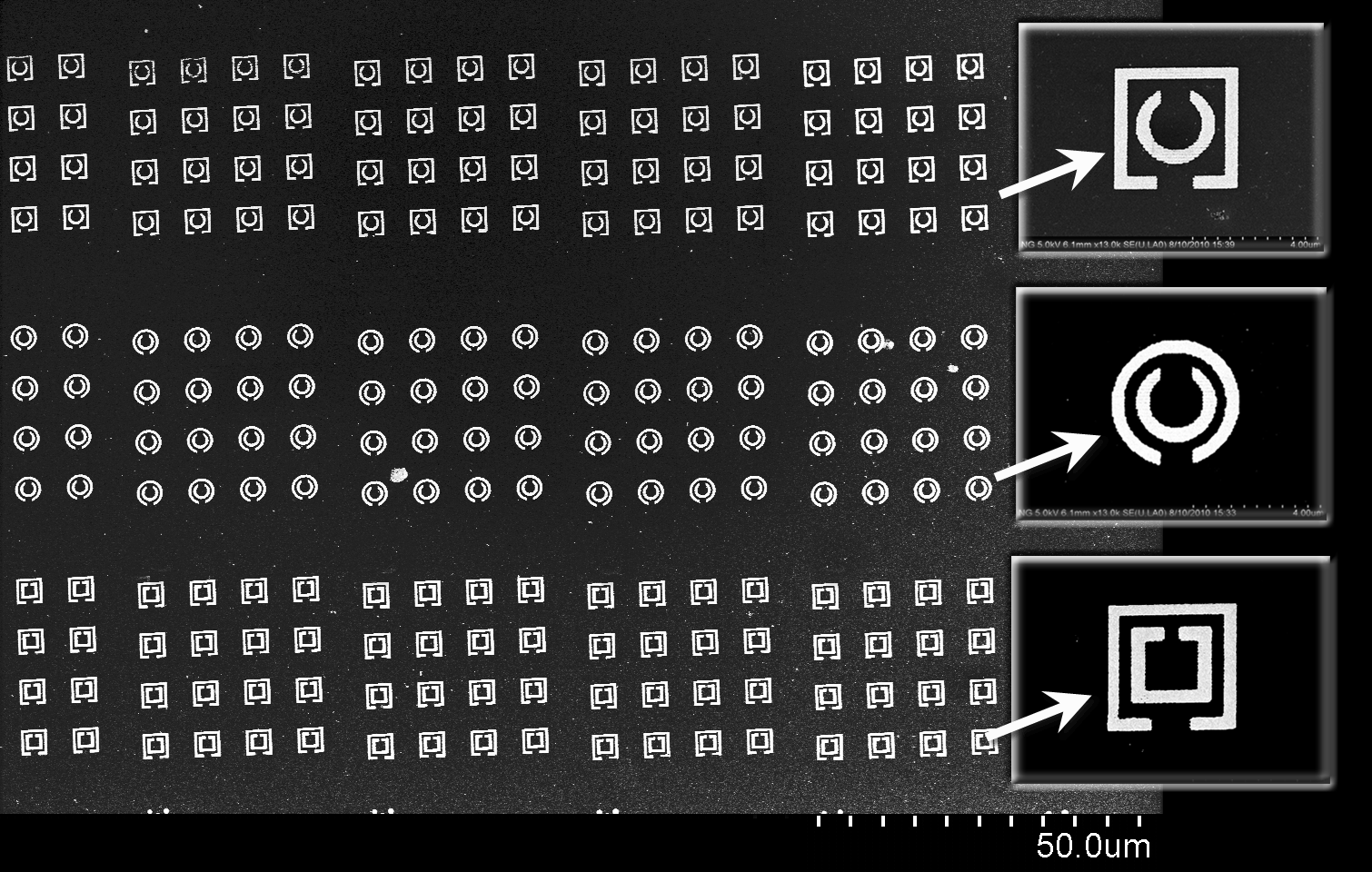

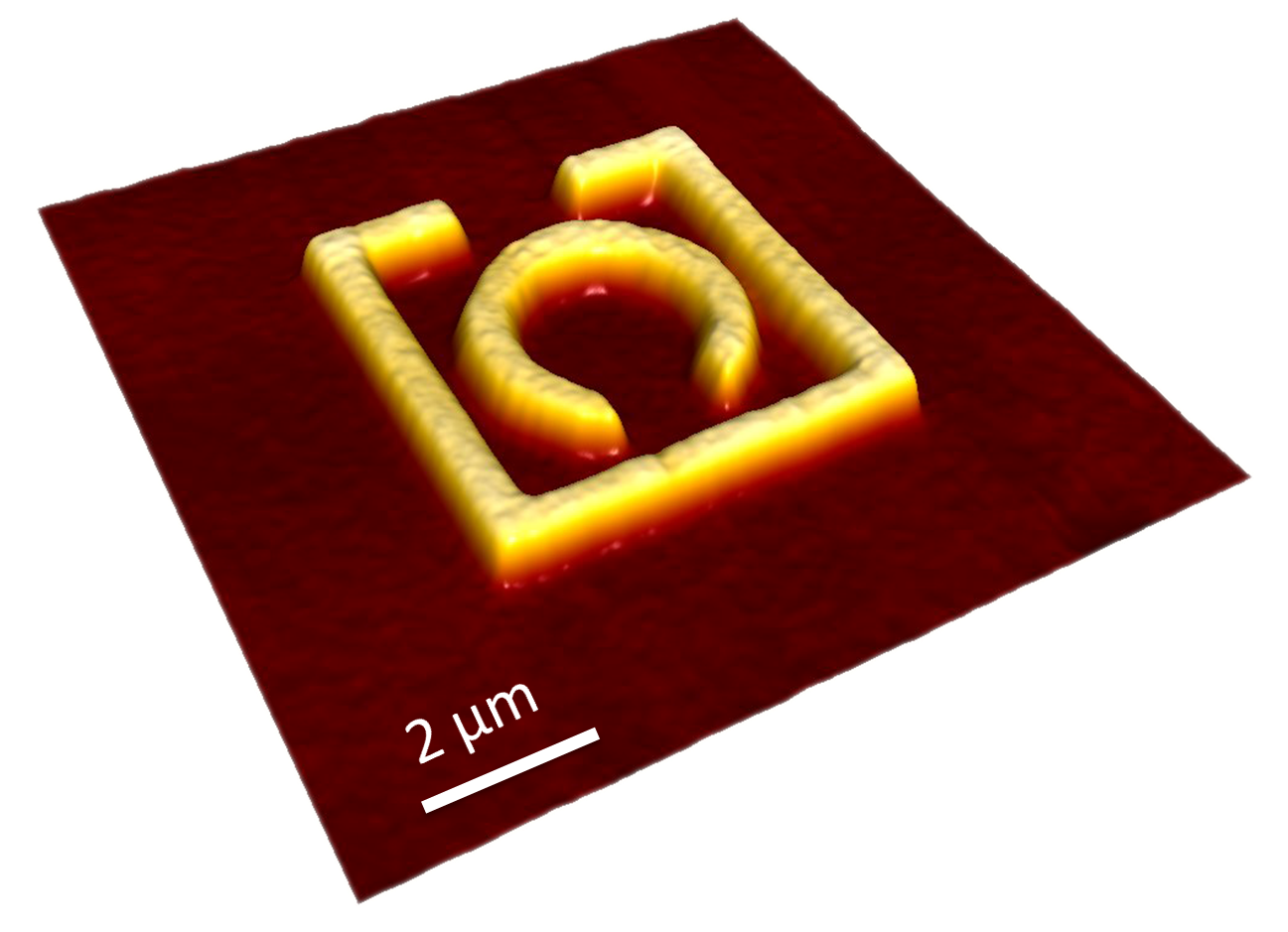

DPN enables direct deposition of nanoscale materials onto a substrate in a flexible manner. Recent advances have demonstrated massively parallel patterning using two-dimensional arrays of 55,000 tips.

Applications of this technology currently range through chemistry, materials science, and the life sciences, and include such work as ultra high density biological nanoarrays, and additive photomask

A photomask is an opaque plate with holes or transparencies that allow light to shine through in a defined pattern. They are commonly used in photolithography and the production of integrated circuits (ICs or "chips") in particular. Masks are used ...

repair.

Development

The uncontrollable transfer of a molecular 'ink' from a coated AFM tip to a substrate was first reported by Jaschke and Butt in 1995, but they erroneously concluded that alkanethiols could not be transferred to gold substrates to form stable nanostructures. A research group atNorthwestern University

Northwestern University is a private research university in Evanston, Illinois. Founded in 1851, Northwestern is the oldest chartered university in Illinois and is ranked among the most prestigious academic institutions in the world.

Charte ...

, US led by Chad Mirkin

Chad Alexander Mirkin (born November 23, 1963) is an American chemist. He is the George B. Rathmann professor of chemistry, professor of medicine, professor of materials science and engineering, professor of biomedical engineering, and professo ...

independently studied the process and determined that under the appropriate conditions, molecules could be transferred to a wide variety of surfaces to create stable chemically-adsorbed monolayers in a high resolution lithographic process they termed "DPN". Mirkin and his coworkers hold the patents on this process, and the patterning technique has expanded to include liquid "inks". It is important to note that "liquid inks" are governed by a very different deposition mechanism when compared to "molecular inks".

Deposition materials

Molecular inks

Molecular inks are typically composed of small molecules that are coated onto a DPN tip and are delivered to the surface through a water meniscus. In order to coat the tips, one can either vapor coat the tip or dip the tips into a dilute solution containing the molecular ink. If one dip-coats the tips, the solvent must be removed prior to deposition. The deposition rate of a molecular ink is dependent on the diffusion rate of the molecule, which is different for each molecule. The size of the feature is controlled by the tip/surface dwell-time (ranging from milliseconds to seconds) and the size of the water meniscus, which is determined by the humidity conditions (assuming the tip's radius of curvature is much smaller than the meniscus). *Water meniscus mediated (exceptions do exist) *Nanoscale feature resolution (50 nm to 2000 nm) *No multiplexed depositions *Each molecular ink is limited to its corresponding substrateExamples

*Alkane thiols written to gold *Silanes (solid phase) written to glass or siliconLiquid inks

Liquid inks can be any material that is liquid at deposition conditions. The liquid deposition properties are determined by the interactions between the liquid and the tip, the liquid and the surface, and the viscosity of the liquid itself. These interactions limit the minimum feature size of the liquid ink to about 1 micrometre, depending on the contact angle of the liquid. Higher viscosities offer greater control over feature size and are desirable. Unlike molecular inks, it is possible to perform multiplexed depositions using a carrier liquid. For example, using a viscous buffer, it is possible to directly deposit multiple proteins simultaneously.

*1-10 micrometre feature resolution

*Multiplexed depositions

*Less restrictive ink/surface requirements

*Direct deposition of high viscosity materials

Liquid inks can be any material that is liquid at deposition conditions. The liquid deposition properties are determined by the interactions between the liquid and the tip, the liquid and the surface, and the viscosity of the liquid itself. These interactions limit the minimum feature size of the liquid ink to about 1 micrometre, depending on the contact angle of the liquid. Higher viscosities offer greater control over feature size and are desirable. Unlike molecular inks, it is possible to perform multiplexed depositions using a carrier liquid. For example, using a viscous buffer, it is possible to directly deposit multiple proteins simultaneously.

*1-10 micrometre feature resolution

*Multiplexed depositions

*Less restrictive ink/surface requirements

*Direct deposition of high viscosity materials

Examples

*Protein, peptide, and DNA patterning *Hydrogels

A gel is a semi-solid that can have properties ranging from soft and weak to hard and tough. Gels are defined as a substantially dilute cross-linked system, which exhibits no flow when in the steady-state, although the liquid phase may still dif ...

*Sol gels

*Conductive inks

*Lipids

*Silanes (liquid phase) written to glass or silicon

Applications

In order to define a good DPN application, it is important to understand what DPN can do that other techniques can't. Direct-write techniques, like contact printing, can pattern multiple biological materials but it cannot create features with subcellular resolution. Many high-resolution lithography methods can pattern at sub-micrometre resolution, but these require high-cost equipment that were not designed for biomolecule deposition and cell culture.Microcontact printing

Microcontact printing (or μCP) is a form of soft lithography that uses the relief patterns on a master polydimethylsiloxane (PDMS) stamp or Urethane rubber micro stamp to form patterns of self-assembled monolayers (SAMs) of ink on the surface ...

can print biomolecules at ambient conditions, but it cannot pattern multiple materials with nanoscale registry.

Industrial applications

The following are some examples of how DPN is being applied to potential products. # Biosensor Functionalization - Directly place multiple capture domains on a single

# Biosensor Functionalization - Directly place multiple capture domains on a single biosensor

A biosensor is an analytical device, used for the detection of a chemical substance, that combines a biological component with a physicochemical detector.

The ''sensitive biological element'', e.g. tissue, microorganisms, organelles, cell rece ...

device

# Nanoscale Sensor Fabrication - Small, high-value sensors that can detect multiple targets

# Nanoscale Protein Chips - High-density protein arrays with increased sensitivity

Emerging applications

Cell engineering

DPN is emerging as a powerful research tool for manipulating cells at subcellular resolution * Stem cell differentiation * Subcellular drug delivery * Cell sorting * Surface gradients * Subcellular ECM protein patterns * Cell adhesionRapid prototyping

* Plasmonics and Metamaterials

* Cell and tissue screening

* Plasmonics and Metamaterials

* Cell and tissue screening

DPN properties

Direct write

DPN is a direct write technique so it can be used for top-down and bottom-up lithography applications. In top-down work, the tips are used to deliver an etch resist to a surface, which is followed by a standard etching process. In bottom-up applications, the material of interest is delivered directly to the surface via the tips.

Unique advantages

* Directed Placement - Directly print various materials onto existing nano and microstructures with nanoscale registry * Direct Write - Maskless creation of arbitrary patterns with feature resolutions from as small as 50 nm and as large as 10 micrometres * Biocompatible - Subcellular to nanoscale resolution at ambient deposition conditions * Scalable - Force independent, allowing for parallel depositionsThermal dip pen lithography

A heated probe tip version of Dip Pen Lithography has also been demonstrated, thermal Dip Pen Lithography (tDPL), to deposit nanoparticles.Woo, Dai, King & Sheehan "Maskless Nanoscale Writing of Nanoparticle-Polymer Composites and Nanoparticle Assemblies using Thermal Nanoprobes" NanoLetters (2009) Semiconductor, magnetic, metallic, or optically active nanoparticles can be written to a substrate via this method. The particles are suspended in a Poly(methyl methacrylate) (PMMA) or equivalent polymer matrix, and heated by the probe tip until they begin to flow. The probe tip acts as a nano-pen, and can pattern nanoparticles into a programmed structure. Depending on the size of the nanoparticles, resolutions of 78-400 nm were attained. An O2 plasma etch can be used to remove the PMMA matrix, and in the case of Iron Oxide nanoparticles, further reduce the resolution of lines to 10 nm. Advantages unique to tDPL are that it is a maskless additive process that can achieve very narrow resolutions, it can also easily write many types of nanoparticles without requiring special solution preparation techniques. However there are limitations to this method. The nanoparticles must be smaller than theradius of gyration ''Radius of gyration'' or gyradius of a body about the axis of rotation is defined as the radial distance to a point which would have a moment of inertia the same as the body's actual distribution of mass, if the total mass of the body were concentr ...

of the polymer, in the case of PMMA this is about 6 nm. Additionally, as nanoparticles increase in size viscosity increases, slowing the process. For a pure polymer deposition speeds of 200 μm/s are achievable. Adding nanoparticles reduces speeds to 2 μm/s, but is still faster than regular Dip Pen Lithography.

Beam pen lithography

A two dimensional array of ( PDMS) deformable transparent pyramid shaped tips are coated with an opaque layer of metal. The metal is then removed from the very tip of the pyramid, leaving an aperture for light to pass through. The array is then scanned across a surface and light is directed to the base of each pyramid via a micromirror array, which funnels the light toward the tip. Depending on the distance between the tips and the surface, light interacts with the surface in a near-field or far-field fashion, allowing sub-diffraction scale features (100 nm features with 400 nm light) or larger features to be fabricated.Common misconceptions

Direct comparisons to other techniques

The criticism most often directed at DPN is the patterning speed. The reason for this has more to do with how it is compared to other techniques rather than any inherent weaknesses. For example, the soft lithography method,

The criticism most often directed at DPN is the patterning speed. The reason for this has more to do with how it is compared to other techniques rather than any inherent weaknesses. For example, the soft lithography method, microcontact printing

Microcontact printing (or μCP) is a form of soft lithography that uses the relief patterns on a master polydimethylsiloxane (PDMS) stamp or Urethane rubber micro stamp to form patterns of self-assembled monolayers (SAMs) of ink on the surface ...

(μCP), is the current standard for low cost, bench-top micro and nanoscale patterning, so it is easy to understand why DPN is compared directly to microcontact printing. The problem is that the comparisons are usually based upon applications that are strongly suited to μCP, instead of comparing them to some neutral application. μCP has the ability to pattern one material over a large area in a single stamping step, just as photolithography can pattern over a large area in a single exposure. Of course DPN is slow when it is compared to the strength of another technique. DPN is a maskless direct write technique that can be used to create multiple patterns of varying size, shape, and feature resolution, all on a single substrate. No one would try to apply microcontact printing to such a project because then it would never be worth the time and money required to fabricate each master stamp for each new pattern. Even if they did, microcontact printing would not be capable of aligning multiple materials from multiple stamps with nanoscale registry. The best way to understand this misconception is to think about the different ways to apply photolithography and e-beam lithography. No one would try to use e-beam to solve a photolithography problem and then claim e-beam to be "too slow". Directly compared to photolithography's large area patterning capabilities, e-beam lithography is slow and yet, e-beam instruments can be found in every lab and nanofab in the world. The reason for this is because e-beam has unique capabilities that cannot be matched by photolithography, just as DPN has unique capabilities that cannot be matched by microcontact printing.

Connection to atomic force microscopy

DPN evolved directly from AFM so it is not a surprise that people often assume that any commercial AFM can perform DPN experiments. In fact, DPN does not require an AFM, and an AFM does not necessarily have real DPN capabilities. There is an excellent analogy with scanning electron microscopy (SEM) and electron beam (E-beam) lithography. E-beam evolved directly from SEM technology and both use a focused electron beam, but it is not possible to perform modernE-beam lithography

Electron-beam lithography (often abbreviated as e-beam lithography, EBL) is the practice of scanning a focused beam of electrons to draw custom shapes on a surface covered with an electron-sensitive film called a resist (exposing). The electron b ...

experiments on a SEM that lacks the proper lithography hardware and software components.

It is also important to consider one of the unique characteristics of DPN, namely its force independence. With virtually all ink/substrate combinations, the same feature size will be patterned no matter how hard the tip is pressing down against the surface.Exceptions exist when printing to soft materials – As long as robust SiN tips are used, there is no need for complicated feedback electronics, no need for lasers, no need for quad photo-diodes, and no need for an AFM.

See also

*Nanolithography

Nanolithography (NL) is a growing field of techniques within nanotechnology dealing with the engineering (patterning e.g. etching, depositing, writing, printing etc) of nanometer-scale structures on various materials.

The modern term reflects on ...

References

{{Nanolithography Lithography (microfabrication) Microtechnology Scanning probe microscopy Biological engineering Tissue engineering