chopper pump on:

[Wikipedia]

[Google]

[Amazon]

A chopper pump is a

A chopper pump is a

The chopper pump was invented in 1950 by the Danish company Landia. The pump manufacturer

The chopper pump was invented in 1950 by the Danish company Landia. The pump manufacturer

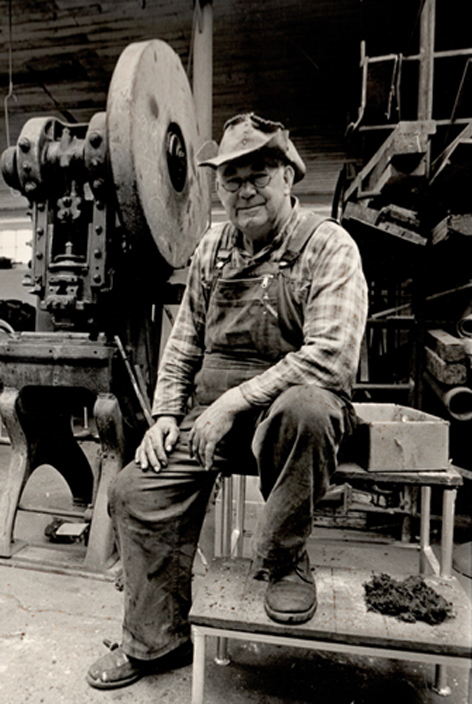

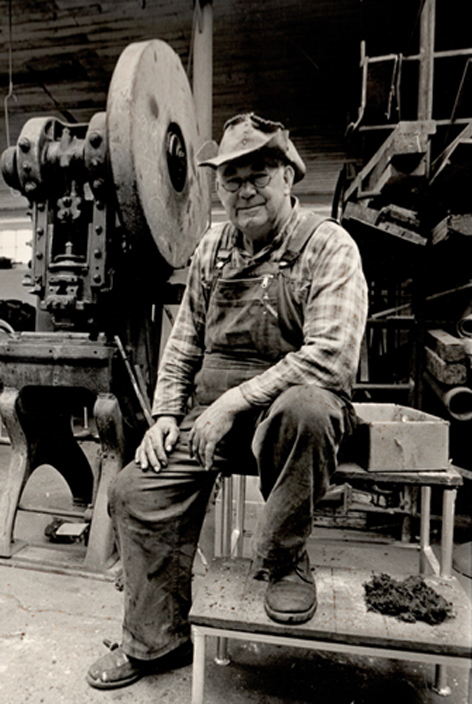

Christian Ølgaard

developed a pump with a special knife system to meet the need for macerating and pumping manure in agricultural applications. Manure with high solids content, containing straw and sawdust, would clog up other types of pumps, causing unstable operation in an environment which required high reliability. As the need for the pumping of difficult media expanded to other industries, so did the use of the chopper pump in both dry and submersible applications and in various industries, including meat, paper and food processing, as well as the automobile industry, biogas, chemical plants, municipal wastewater and prison lift stations.

"Straw Chopper stops road erosion"

February 1950, ''Popular Mechanics'', pg. 168.]

A chopper pump is a

A chopper pump is a centrifugal pump

Centrifugal pumps are used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. They are a sub-class of dynamic ...

which is equipped with a cutting system to facilitate chopping or maceration of solids that are present in the pumped liquid. The main advantage of this type of pump is that it prevents clogging of the pump itself and of the adjacent piping, as all the solids and stringy materials are macerated by the chopping system. Chopper pumps exist in various configurations, including submersible and dry-installed design and they are typically equipped with an electric motor

An electric motor is an electrical machine that converts electrical energy into mechanical energy. Most electric motors operate through the interaction between the motor's magnetic field and electric current in a wire winding to generate force ...

to run the impeller

An impeller or impellor is a rotor used to increase the pressure and flow of a fluid. It is the opposite of a turbine, which extracts energy from, and reduces the pressure of, a flowing fluid.

In pumps

An impeller is a rotating component ...

and to provide torque for the chopping system. Due to its high solids handling capabilities, the chopper pump is often used for pumping sewage, sludge, manure slurries, and other liquids that contain large or tough solids.

History

The chopper pump was invented in 1950 by the Danish company Landia. The pump manufacturer

The chopper pump was invented in 1950 by the Danish company Landia. The pump manufacturerChristian Ølgaard

developed a pump with a special knife system to meet the need for macerating and pumping manure in agricultural applications. Manure with high solids content, containing straw and sawdust, would clog up other types of pumps, causing unstable operation in an environment which required high reliability. As the need for the pumping of difficult media expanded to other industries, so did the use of the chopper pump in both dry and submersible applications and in various industries, including meat, paper and food processing, as well as the automobile industry, biogas, chemical plants, municipal wastewater and prison lift stations.

Working principle

A chopper pump is operated by a drive unit (e.g. electric motor, hydraulic motor, power takeoff (PTO)), which turns the impeller and the cutting system. An open impeller design is used to successfully pass the macerated solids or thick slurry. A set of hardened steel cutters is installed externally to the pump suction in order to macerate all solids prior to entering the hydraulic parts of the pump. A chopper pump should not be confused with agrinder pump

A grinder pump is a wastewater conveyance device. Waste from water-using household appliances (toilets, bathtubs, washing machines, etc.) flows through the home’s pipes into the grinder pump’s holding tank. Once the wastewater inside the tank ...

, which uses its impeller as part of the cutting mechanism. ''Grinder pumps'' are typically used for light weight sewage applications, whereas ''chopper pumps'' are used for tough solids handling applications.

The chopping system consists of a set of rotating cutters that are keyed to the shaft and work in conjunction with the stationary cutters, which are bolted to the suction plate. A system of mechanical seal

A mechanical seal is a device that helps join systems and mechanisms together by preventing leakage (e.g. in a pumping system), containing pressure, or excluding contamination. The effectiveness of a seal is dependent on adhesion in the case of ...

s are used to prevent the pumped liquid from entering the motor. The pump can either be connected to a pipe, flexible hose or lowered down a guide rail so that the pump sits on a coupling foot (aka base elbow), thereby connecting it to the discharge pipe.

Applications

Examples of applications where chopper pumps are commonly applied include: * Scum pumping at wastewater treatment plants * Sewage wet wells and lift stations; especially sewage containing wet wipes * Sludge pumping atbiogas

Biogas is a mixture of gases, primarily consisting of methane, carbon dioxide and hydrogen sulphide, produced from raw materials such as agricultural waste, manure, municipal waste, plant material, sewage, green waste and food waste. It is a ...

facilities

* Pumping agricultural manure (dairy, hog and poultry)

* Septage receiving stations

* Waste processing at slaughterhouses, poultry abattoir

A slaughterhouse, also called abattoir (), is a facility where animals are slaughtered to provide food. Slaughterhouses supply meat, which then becomes the responsibility of a packaging facility.

Slaughterhouses that produce meat that is no ...

s, fish processing plants, etc.

* Paper mills / pumping of pulp

* Highway Departments, to spread chopped hay to prevent soil erosion February 1950, ''Popular Mechanics'', pg. 168.]

See also

*Sewage pumping

Small-scale sewage pumping is normally done by a submersible pump.

This became popular in the early 1960s, when a guide rail system was developed to lift the submersible pump out of the pump station for repair, and ended the dirty and sometimes da ...

References and Notes

{{Sewerage Pumps