Chemical Pulping on:

[Wikipedia]

[Google]

[Amazon]

Paper chemicals designate a group of

Surface Size

which is applied using a size press. The advantage of surface sizing is that it does not interfere with the backend water chemistry.

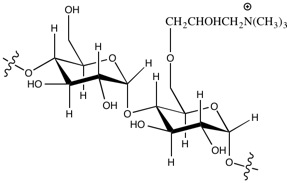

To enhance the paper's strength, cationic starch is added to wet pulp in the manufacturing process. Starch has a similar chemical structure as the cellulose fibre of the pulp, and the surface of both the starch and fibre are negatively charged. By adding cationic (positive charged) starch, the fibre can bind with the starch and thus also increase the interconnections between the fibres. The positively charged portion of the starch is usually formed by quaternary ammonium cations. Quaternary salts that are used include 2.3-epoxy propyl trimethyl ammoniumchloride (EPTAC, also known as or Glytac Quab, GMAC™) and (3-chloro-2-hydroxypropyl) trimethyl ammonium chloride (CHPTAC, also known as Quat 188, Quab 188, Reagens™).

To enhance the paper's strength, cationic starch is added to wet pulp in the manufacturing process. Starch has a similar chemical structure as the cellulose fibre of the pulp, and the surface of both the starch and fibre are negatively charged. By adding cationic (positive charged) starch, the fibre can bind with the starch and thus also increase the interconnections between the fibres. The positively charged portion of the starch is usually formed by quaternary ammonium cations. Quaternary salts that are used include 2.3-epoxy propyl trimethyl ammoniumchloride (EPTAC, also known as or Glytac Quab, GMAC™) and (3-chloro-2-hydroxypropyl) trimethyl ammonium chloride (CHPTAC, also known as Quat 188, Quab 188, Reagens™).

List of chemicals used in pulp and paper making

{{Authority control Papermaking Chemical processes Cellulose Pulp and paper industry

chemicals

A chemical substance is a form of matter having constant chemical composition and characteristic properties. Some references add that chemical substance cannot be separated into its constituent elements by physical separation methods, i.e., wit ...

that are used for paper manufacturing, or modify the properties of paper

Paper is a thin sheet material produced by mechanically or chemically processing cellulose fibres derived from wood, rags, grasses or other vegetable sources in water, draining the water through fine mesh leaving the fibre evenly distrib ...

. These chemicals can be used to alter the paper in many ways, including changing its color and brightness

Brightness is an attribute of visual perception in which a source appears to be radiating or reflecting light. In other words, brightness is the perception elicited by the luminance of a visual target. The perception is not linear to luminan ...

, or by increasing its strength and resistance to water. The chemicals can be defined on basis of their usage in the process.

Chemical usage is not only for imparting properties to paper but to handle the water cycles in the process, conditioning of fabrics, cleaning of equipment and several other applications.

Chemicals used in paper manufacturing

Pulping

Chemical pulping involves dissolving lignin in order to extract the cellulose from the wood fiber. The different processes of chemical pulping include the Kraft process, which uses caustic soda and sodium sulfide and is the most common; alternatively, the use of sulfurous acid is known as the sulfite process, the neutral sulfite semichemical is treated as a third process separate from sulfite, andsoda pulping

Soda pulping is a chemical process for making wood pulp with sodium hydroxide as the cooking chemical. In the ''Soda-AQ'' process, anthraquinone (AQ) may be used as a pulping additive to decrease the carbohydrate degradation. The soda process gives ...

which is the least ecologically hazardous utilizing sodium hydroxide or anthraquinone

Anthraquinone, also called anthracenedione or dioxoanthracene, is an aromatic organic compound with formula . Isomers include various quinone derivatives. The term anthraquinone however refers to the isomer, 9,10-anthraquinone (IUPAC: 9,10-dioxoan ...

.

Caustic soda

Sodium hydroxide, also known as lye and caustic soda, is an inorganic compound with the formula NaOH. It is a white solid ionic compound consisting of sodium cations and hydroxide anions .

Sodium hydroxide is a highly caustic base and alkali ...

is added to increase the pH in the pulping

Pulp is a Lignocellulosic biomass, lignocellulosic fibrous material prepared by chemically or mechanically separating cellulose fibers from wood, fiber crops, Paper recycling, waste paper, or cotton paper, rags. Mixed with water and other chemica ...

process of fibers. The higher pH of the paper-fiber solution causes the fibers to smoothen and swell, which is important for the grinding process of the fibers.

Bleaching

In the production of white paper, the wood pulp is bleached to remove any color from the trace amounts of lignin that was not extracted in the chemical pulping process. There are three predominant methods of bleaching: # Elemental chlorine bleaching useschlorine

Chlorine is a chemical element with the symbol Cl and atomic number 17. The second-lightest of the halogens, it appears between fluorine and bromine in the periodic table and its properties are mostly intermediate between them. Chlorine i ...

and hypochlorite.

# Elemental chlorine-free bleaching is more environmentally friendly since it eliminates the use of hypochlorite and replaces chlorine with chlorine dioxide

Chlorine dioxide is a chemical compound with the formula ClO2 that exists as yellowish-green gas above 11 °C, a reddish-brown liquid between 11 °C and −59 °C, and as bright orange crystals below −59 °C. It is usually ...

or sodium chlorate

Sodium chlorate is an inorganic compound with the chemical formula Na ClO3. It is a white crystalline powder that is readily soluble in water. It is hygroscopic. It decomposes above 300 °C to release oxygen and leaves sodium chloride. Sever ...

.

# Totally chlorine-free bleaching utilizes oxygen

Oxygen is the chemical element with the symbol O and atomic number 8. It is a member of the chalcogen group in the periodic table, a highly reactive nonmetal, and an oxidizing agent that readily forms oxides with most elements as ...

and hydrogen peroxide

Hydrogen peroxide is a chemical compound with the formula . In its pure form, it is a very pale blue liquid that is slightly more viscous than water. It is used as an oxidizer, bleaching agent, and antiseptic, usually as a dilute solution (3%� ...

. This is the most environmentally friendly process since it eliminates all chlorinated pollutants.

Sizing

Most paper types must have some water-resistance to maintain a specific writing quality and printability. Until 1980, the typical manner of adding this resistance was by using arosin

Rosin (), also called colophony or Greek pitch ( la, links=no, pix graeca), is a solid form of resin obtained from pines and some other plants, mostly conifers, produced by heating fresh liquid resin to vaporize the volatile liquid terpene comp ...

in combination with alum. When the paper industry started using chalk instead of china clay

Kaolinite ( ) is a clay mineral, with the chemical composition Al2 Si2 O5( OH)4. It is an important industrial mineral. It is a layered silicate mineral, with one tetrahedral sheet of silica () linked through oxygen atoms to one octahedra ...

as filler, the paper chemistry had to switch to a neutral process. At several places AKD ( alkyl ketene dimer) and ASA ( alkenyl succinic anhydride) are used. Latest development is to usSurface Size

which is applied using a size press. The advantage of surface sizing is that it does not interfere with the backend water chemistry.

Strengthening

Wet-strength

Wet-strength additives ensure that paper retains its strength when it gets wet. This is especially important intissue paper

Tissue paper or simply tissue is a lightweight paper or, light crêpe paper. Tissue can be made from recycled paper pulp on a paper machine.

Tissue paper is very versatile, and different kinds of tissue are made to best serve these purposes, w ...

. Chemicals typically used for this purpose include epichlorohydrin, melamine

Melamine is an organic compound with the formula C3H6N6. This white solid is a trimer of cyanamide, with a 1,3,5-triazine skeleton. Like cyanamide, it contains 67% nitrogen by mass, and its derivatives have fire retardant properties due t ...

, urea formaldehyde and polyimines. These substances polymerize in the paper and result in the construction of a strengthening network.

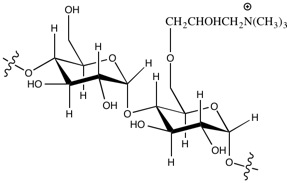

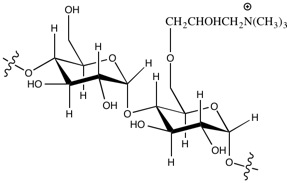

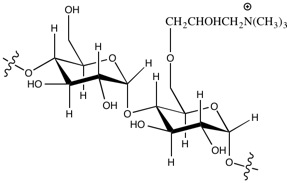

To enhance the paper's strength, cationic starch is added to wet pulp in the manufacturing process. Starch has a similar chemical structure as the cellulose fibre of the pulp, and the surface of both the starch and fibre are negatively charged. By adding cationic (positive charged) starch, the fibre can bind with the starch and thus also increase the interconnections between the fibres. The positively charged portion of the starch is usually formed by quaternary ammonium cations. Quaternary salts that are used include 2.3-epoxy propyl trimethyl ammoniumchloride (EPTAC, also known as or Glytac Quab, GMAC™) and (3-chloro-2-hydroxypropyl) trimethyl ammonium chloride (CHPTAC, also known as Quat 188, Quab 188, Reagens™).

To enhance the paper's strength, cationic starch is added to wet pulp in the manufacturing process. Starch has a similar chemical structure as the cellulose fibre of the pulp, and the surface of both the starch and fibre are negatively charged. By adding cationic (positive charged) starch, the fibre can bind with the starch and thus also increase the interconnections between the fibres. The positively charged portion of the starch is usually formed by quaternary ammonium cations. Quaternary salts that are used include 2.3-epoxy propyl trimethyl ammoniumchloride (EPTAC, also known as or Glytac Quab, GMAC™) and (3-chloro-2-hydroxypropyl) trimethyl ammonium chloride (CHPTAC, also known as Quat 188, Quab 188, Reagens™).

Dry-strength

Dry-strength additives, or dry-strengthening agents, are chemicals that improve paper strength normal conditions. These improve the paper's compression strength, bursting strength, tensile breaking strength, and delamination resistance. Typical chemicals used include cationic starch andpolyacrylamide

Polyacrylamide (abbreviated as PAM) is a polymer with the formula (-CH2CHCONH2-). It has a linear-chain structure. PAM is highly water-absorbent, forming a soft gel when hydrated. In 2008, an estimated 750,000,000 kg were produced, mainly f ...

(PAM) derivatives. These substances work by binding fibers, often under the aid of aluminum

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. It ha ...

ions in paper sheet.

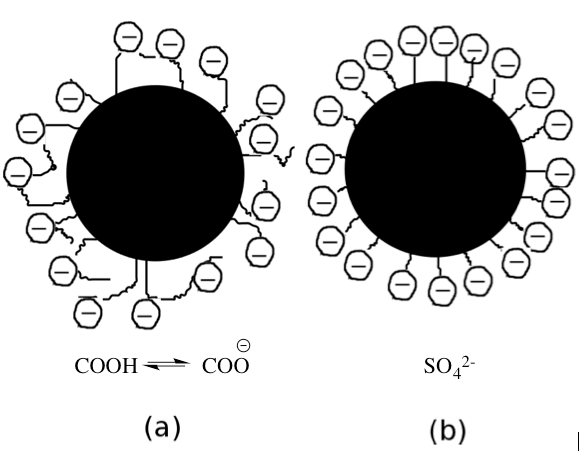

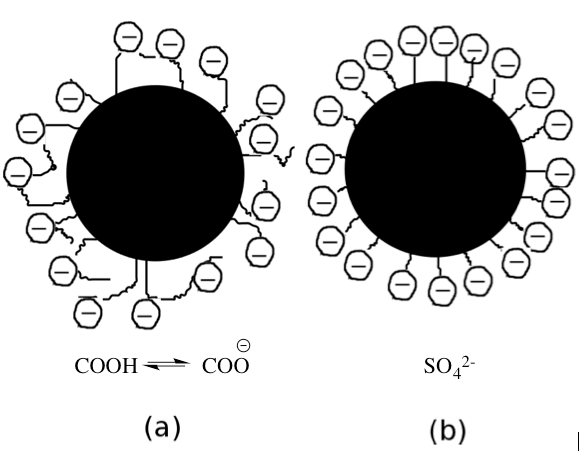

Binders

Binders promote the binding of pigment particles between themselves and the coating layer of the paper. Binders are spherical particles less than 1 µm in diameter. Common binders are styrene maleic anhydride copolymer or styrene-acrylate copolymer. The surface chemical composition is differentiated by theadsorption

Adsorption is the adhesion of atoms, ions or molecules from a gas, liquid or dissolved solid to a surface. This process creates a film of the ''adsorbate'' on the surface of the ''adsorbent''. This process differs from absorption, in which ...

of acrylic acid

Acrylic acid (IUPAC: propenoic acid) is an organic compound with the formula CH2=CHCOOH. It is the simplest unsaturated carboxylic acid, consisting of a vinyl group connected directly to a carboxylic acid terminus. This colorless liquid has a ...

or an anionic surfactant, both of which are used for stabilization of the dispersion in water. Co-binders, or thickeners, are generally water-soluble polymers that influence the paper's color viscosity, water retention, sizing, and gloss. Some common examples are carboxymethyl cellulose (CMC), cationic and anionic hydroxyethyl cellulose (EHEC), modified starch

Modified starch, also called starch derivatives, are prepared by physically, enzymatically, or chemically treating native starch to change its properties. Modified starches are used in practically all starch applications, such as in food produ ...

, and dextrin

Dextrins are a group of low-molecular-weight carbohydrates produced by the hydrolysis of starch and glycogen. Dextrins are mixtures of polymers of D-glucose units linked by α-(1→4) or α-(1→6) glycosidic bonds.

Dextrins can be produced from ...

.

Styrene butadiene latex, Styrene acrylic, dextrin

Dextrins are a group of low-molecular-weight carbohydrates produced by the hydrolysis of starch and glycogen. Dextrins are mixtures of polymers of D-glucose units linked by α-(1→4) or α-(1→6) glycosidic bonds.

Dextrins can be produced from ...

, oxidized starch are used in coatings to bind the filler to the paper. Co-binders are natural products such as starch and CMC ( Carboxymethyl cellulose), that are used along with the synthetic binders, like styrene acrylic or styrene butadiene. Co-binders are used to reduce the cost of the synthetic binder and improve the water retention and rheology

Rheology (; ) is the study of the flow of matter, primarily in a fluid (liquid or gas) state, but also as "soft solids" or solids under conditions in which they respond with Plasticity (physics), plastic flow rather than deforming Elasticity (phy ...

of the coating.

Fillers

Mineral fillers are used to lower the consumption of more expensive binder material or to improve some properties of the paper.China clay

Kaolinite ( ) is a clay mineral, with the chemical composition Al2 Si2 O5( OH)4. It is an important industrial mineral. It is a layered silicate mineral, with one tetrahedral sheet of silica () linked through oxygen atoms to one octahedra ...

, calcium carbonate, titanium dioxide

Titanium dioxide, also known as titanium(IV) oxide or titania , is the inorganic compound with the chemical formula . When used as a pigment, it is called titanium white, Pigment White 6 (PW6), or CI 77891. It is a white solid that is insolub ...

, and talc

Talc, or talcum, is a clay mineral, composed of hydrated magnesium silicate with the chemical formula Mg3Si4O10(OH)2. Talc in powdered form, often combined with corn starch, is used as baby powder. This mineral is used as a thickening agent a ...

are common mineral fillers used in paper production.

Retention

A Retention agent is added to bind fillers to the paper. Fillers, such as calcium carbonate, usually have a weak surface charge. The retention agent is a polymer with high cationic, positively charged groups. An additional feature of a retention agent is to accelerate the dewatering in the wire section of thepaper machine

A paper machine (or paper-making machine) is an industrial machine which is used in the pulp and paper industry

to create paper in large quantities at high speed. Modern paper-making machines are based on the principles of the Fourdrinier Machin ...

. Polyethyleneimine and polyacrylamide are examples of chemicals used in this process.

Coating

Pigments

Pigment

A pigment is a colored material that is completely or nearly insoluble in water. In contrast, dyes are typically soluble, at least at some stage in their use. Generally dyes are often organic compounds whereas pigments are often inorganic compou ...

s that absorb in the yellow and red part of the visible spectrum can be added. As the dye absorbs light, the brightness of the paper will decrease, unlike the effect of an optical-brightening agent. To increase whiteness, a combination of pigments and an optical-brightening agent are often used. The most commonly used pigments are blue and violet dyes.

Optical-brightening agent

Optical brightener is used to make paper appear whiter. Optical-brightening agents usefluorescence

Fluorescence is the emission of light by a substance that has absorbed light or other electromagnetic radiation. It is a form of luminescence. In most cases, the emitted light has a longer wavelength, and therefore a lower photon energy, tha ...

to absorb invisible radiation from the ultraviolet

Ultraviolet (UV) is a form of electromagnetic radiation with wavelength from 10 nm (with a corresponding frequency around 30 PHz) to 400 nm (750 THz), shorter than that of visible light, but longer than X-rays. UV radiation ...

part of the light spectrum and re-emit the radiation as light in the visible blue range. The optical-brightening agent thus generates blue light that is added to the reflected light. The additional blue light offsets the yellowish tinge that would otherwise exist in the reflected light characteristics. It thus increases the brightness of the material (when the illumination includes ultraviolet radiation).

See also

*Deinking

Deinking is the industrial process of removing printing ink from paperfibers of recycled paper to make deinked pulp.

The key in the deinking process is the ability to detach ink from the fibers. This is achieved by a combination of mechanical ac ...

recycled paper

* Surface chemistry of paper

* Organosolv (pulping technique)

References

External links

List of chemicals used in pulp and paper making

{{Authority control Papermaking Chemical processes Cellulose Pulp and paper industry