Blast Furnace on:

[Wikipedia]

[Google]

[Amazon]

A blast furnace is a type of metallurgical furnace used for

Blast furnaces operate on the principle of chemical reduction whereby carbon monoxide converts iron oxides to elemental iron. Blast furnaces differ from bloomeries and

Blast furnaces operate on the principle of chemical reduction whereby carbon monoxide converts iron oxides to elemental iron. Blast furnaces differ from bloomeries and  The main chemical reaction producing the molten iron is:

:Fe2O3 + 3CO → 2Fe + 3CO2

This reaction might be divided into multiple steps, with the first being that preheated air blown into the furnace reacts with the carbon in the form of coke to produce

The main chemical reaction producing the molten iron is:

:Fe2O3 + 3CO → 2Fe + 3CO2

This reaction might be divided into multiple steps, with the first being that preheated air blown into the furnace reacts with the carbon in the form of coke to produce

Cast iron has been found in China dating to the 5th century BC, but the earliest extant blast furnaces in China date to the 1st century AD and in the West from the

Cast iron has been found in China dating to the 5th century BC, but the earliest extant blast furnaces in China date to the 1st century AD and in the West from the

The oldest known blast furnaces in the West were built in Dürstel in Switzerland, the Märkische Sauerland in Germany, and at

The oldest known blast furnaces in the West were built in Dürstel in Switzerland, the Märkische Sauerland in Germany, and at

'Henry "Stamped Out Industrial Revolution"'

, ''

Due to the increased demand for iron for casting cannons, the blast furnace came into widespread use in France in the mid 15th century.

The direct ancestor of those used in France and England was in the Namur region, in what is now Wallonia (Belgium). From there, they spread first to the

Due to the increased demand for iron for casting cannons, the blast furnace came into widespread use in France in the mid 15th century.

The direct ancestor of those used in France and England was in the Namur region, in what is now Wallonia (Belgium). From there, they spread first to the

Modern furnaces are equipped with an array of supporting facilities to increase efficiency, such as ore storage yards where barges are unloaded. The raw materials are transferred to the stockhouse complex by ore bridges, or rail hoppers and ore transfer cars. Rail-mounted scale cars or computer controlled weight hoppers weigh out the various raw materials to yield the desired hot metal and slag chemistry. The raw materials are brought to the top of the blast furnace via a

Modern furnaces are equipped with an array of supporting facilities to increase efficiency, such as ore storage yards where barges are unloaded. The raw materials are transferred to the stockhouse complex by ore bridges, or rail hoppers and ore transfer cars. Rail-mounted scale cars or computer controlled weight hoppers weigh out the various raw materials to yield the desired hot metal and slag chemistry. The raw materials are brought to the top of the blast furnace via a

How a Blast Furnace Works

steel.org. There are different ways in which the raw materials are charged into the blast furnace. Some blast furnaces use a "double bell" system where two "bells" are used to control the entry of raw material into the blast furnace. The purpose of the two bells is to minimize the loss of hot gases in the blast furnace. First, the raw materials are emptied into the upper or small bell which then opens to empty the charge into the large bell. The small bell then closes, to seal the blast furnace, while the large bell rotates to provide specific distribution of materials before dispensing the charge into the blast furnace. A more recent design is to use a "bell-less" system. These systems use multiple hoppers to contain each raw material, which is then discharged into the blast furnace through valves. These valves are more accurate at controlling how much of each constituent is added, as compared to the skip or conveyor system, thereby increasing the efficiency of the furnace. Some of these bell-less systems also implement a discharge chute in the throat of the furnace (as with the Paul Wurth top) in order to precisely control where the charge is placed. The iron making blast furnace itself is built in the form of a tall structure, lined with The

The

File:Alto horno antiguo Sestao.jpg, Abandoned blast furnace in

American Iron and Steel InstituteBlast Furnace animation Extensive picture gallery about all methods of making and shaping of iron and steel in North America and Europe. In German and English.Schematic diagram of blast furnace and Cowper stove

{{DEFAULTSORT:Blast Furnace Industrial furnaces Industrial Revolution Metallurgy Chinese inventions Steelmaking Smelting Firing techniques Industrial buildings

smelting

Smelting is a process of applying heat to ore, to extract a base metal. It is a form of extractive metallurgy. It is used to extract many metals from their ores, including silver, iron, copper, and other base metals. Smelting uses heat and a ...

to produce industrial metals, generally pig iron, but also others such as lead

Lead is a chemical element with the symbol Pb (from the Latin ) and atomic number 82. It is a heavy metal that is denser than most common materials. Lead is soft and malleable, and also has a relatively low melting point. When freshly cu ...

or copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkis ...

. ''Blast'' refers to the combustion air being "forced" or supplied above atmospheric pressure.

In a blast furnace, fuel ( coke), ores, and flux (limestone

Limestone ( calcium carbonate ) is a type of carbonate sedimentary rock which is the main source of the material lime. It is composed mostly of the minerals calcite and aragonite, which are different crystal forms of . Limestone forms whe ...

) are continuously supplied through the top of the furnace, while a hot blast of air

The atmosphere of Earth is the layer of gases, known collectively as air, retained by Earth's gravity that surrounds the planet and forms its planetary atmosphere. The atmosphere of Earth protects life on Earth by creating pressure allowing f ...

(sometimes with oxygen

Oxygen is the chemical element with the symbol O and atomic number 8. It is a member of the chalcogen group in the periodic table, a highly reactive nonmetal, and an oxidizing agent that readily forms oxides with most elements as ...

enrichment) is blown into the lower section of the furnace through a series of pipes called tuyeres

A tuyere or tuyère (; ) is a tube, nozzle or pipe through which air is blown into a furnace or hearth.W. K. V. Gale, The iron and Steel industry: a dictionary of terms (David and Charles, Newton Abbot 1972), 216–217.

Air or oxygen is inj ...

, so that the chemical reactions

A chemical reaction is a process that leads to the chemical transformation of one set of chemical substances to another. Classically, chemical reactions encompass changes that only involve the positions of electrons in the forming and breaking ...

take place throughout the furnace as the material falls downward. The end products are usually molten metal and slag phases tapped from the bottom, and waste gases (flue gas

Flue gas is the gas exiting to the atmosphere via a flue, which is a pipe or channel for conveying exhaust gases from a fireplace, oven, furnace, boiler or steam generator. Quite often, the flue gas refers to the combustion exhaust gas produc ...

) exiting from the top of the furnace. The downward flow of the ore along with the flux in contact with an upflow of hot, carbon monoxide

Carbon monoxide (chemical formula CO) is a colorless, poisonous, odorless, tasteless, flammable gas that is slightly less dense than air. Carbon monoxide consists of one carbon atom and one oxygen atom connected by a triple bond. It is the simple ...

-rich combustion gases is a countercurrent exchange

Countercurrent exchange is a mechanism occurring in nature and mimicked in industry and engineering, in which there is a crossover of some property, usually heat or some chemical, between two flowing bodies flowing in opposite directions to each ...

and chemical reaction process.

In contrast, air furnaces (such as reverberatory furnace

A reverberatory furnace is a metallurgical or process furnace that isolates the material being processed from contact with the fuel, but not from contact with combustion gases. The term ''reverberation'' is used here in a generic sense of ''re ...

s) are naturally aspirated, usually by the convection

Convection is single or multiphase fluid flow that occurs spontaneously due to the combined effects of material property heterogeneity and body forces on a fluid, most commonly density and gravity (see buoyancy). When the cause of the conve ...

of hot gases in a chimney flue

A chimney is an architectural ventilation structure made of masonry, clay or metal that isolates hot toxic exhaust gases or smoke produced by a boiler, stove, furnace, incinerator, or fireplace from human living areas. Chimneys are typi ...

. According to this broad definition, bloomeries for iron, blowing houses for tin

Tin is a chemical element with the symbol Sn (from la, stannum) and atomic number 50. Tin is a silvery-coloured metal.

Tin is soft enough to be cut with little force and a bar of tin can be bent by hand with little effort. When bent, t ...

, and smelt mills for lead

Lead is a chemical element with the symbol Pb (from the Latin ) and atomic number 82. It is a heavy metal that is denser than most common materials. Lead is soft and malleable, and also has a relatively low melting point. When freshly cu ...

would be classified as blast furnaces. However, the term has usually been limited to those used for smelting iron ore to produce pig iron, an intermediate material used in the production of commercial iron and steel, and the shaft furnaces used in combination with sinter plants in base metals smelting.

Blast furnaces are estimated to have been responsible for over 4% of global greenhouse gas emissions

Greenhouse gas emissions from human activities strengthen the greenhouse effect, contributing to climate change. Most is carbon dioxide from burning fossil fuels: coal, oil, and natural gas. The largest emitters include coal in China and ...

between 1900 and 2015, but are difficult to decarbonize.

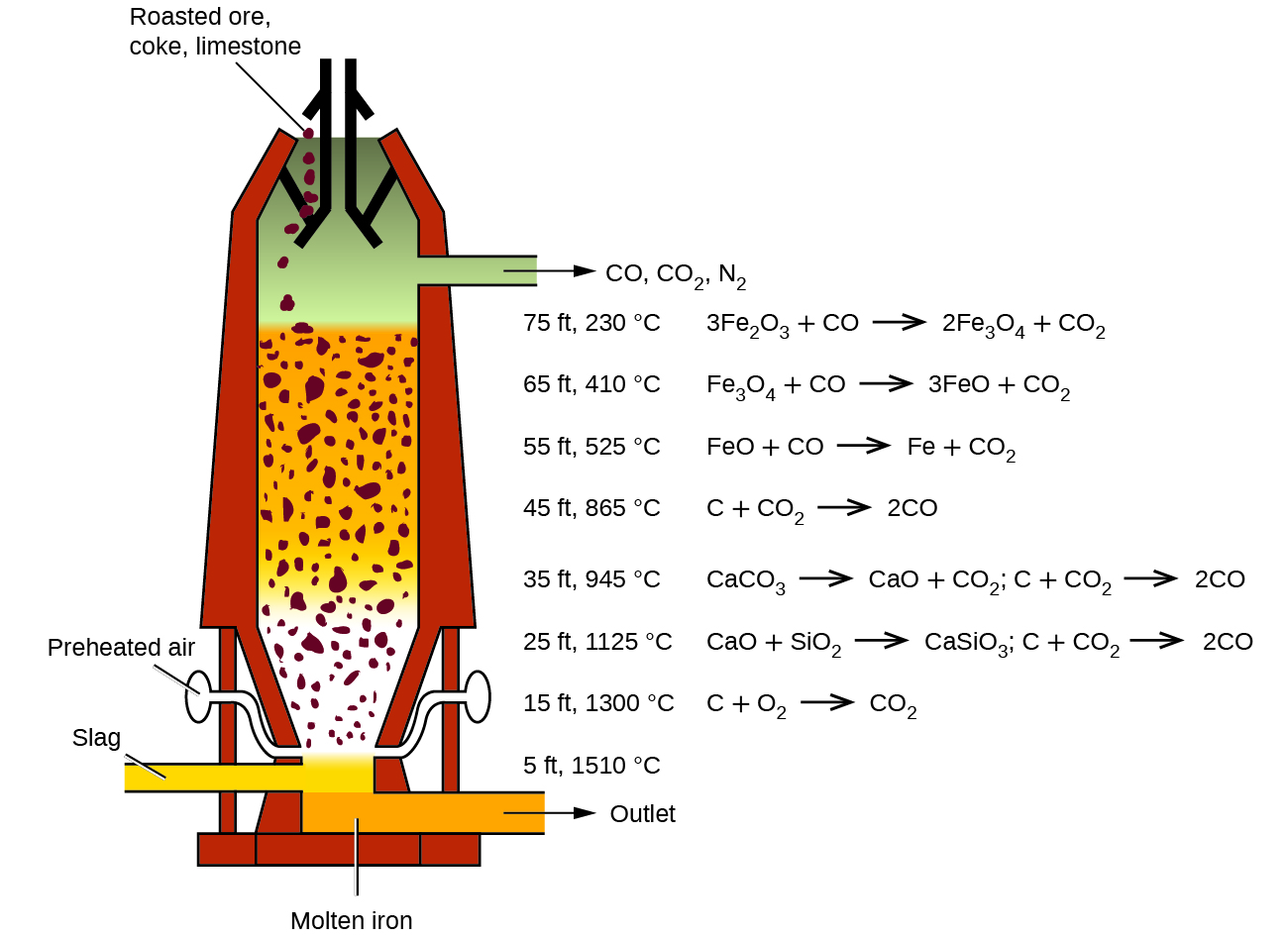

Process engineering and chemistry

Blast furnaces operate on the principle of chemical reduction whereby carbon monoxide converts iron oxides to elemental iron. Blast furnaces differ from bloomeries and

Blast furnaces operate on the principle of chemical reduction whereby carbon monoxide converts iron oxides to elemental iron. Blast furnaces differ from bloomeries and reverberatory furnace

A reverberatory furnace is a metallurgical or process furnace that isolates the material being processed from contact with the fuel, but not from contact with combustion gases. The term ''reverberation'' is used here in a generic sense of ''re ...

s in that in a blast furnace, flue gas is in direct contact with the ore and iron, allowing carbon monoxide to diffuse into the ore and reduce the iron oxide. The blast furnace operates as a countercurrent exchange

Countercurrent exchange is a mechanism occurring in nature and mimicked in industry and engineering, in which there is a crossover of some property, usually heat or some chemical, between two flowing bodies flowing in opposite directions to each ...

process whereas a bloomery does not. Another difference is that bloomeries operate as a batch process whereas blast furnaces operate continuously for long periods. Continuous operation is also preferred because blast furnaces are difficult to start and stop. Also, the carbon in pig iron lowers the melting point below that of steel or pure iron; in contrast, iron does not melt in a bloomery.

Silica

Silicon dioxide, also known as silica, is an oxide of silicon with the chemical formula , most commonly found in nature as quartz and in various living organisms. In many parts of the world, silica is the major constituent of sand. Silica is ...

has to be removed from the pig iron. It reacts with calcium oxide

Calcium oxide (CaO), commonly known as quicklime or burnt lime, is a widely used chemical compound. It is a white, caustic, alkaline, crystalline solid at room temperature. The broadly used term "''lime''" connotes calcium-containing inorganic ...

(burned limestone) and forms silicates, which float to the surface of the molten pig iron as "slag". Historically, to prevent contamination from sulfur, the best quality iron was produced with charcoal.

The downward moving column of ore, flux, coke or charcoal and reaction products must be sufficiently porous for the flue gas to pass through. To ensure this permeability the particle size of the coke or charcoal is of great relevance. Therefore, the coke must be strong enough so it will not be crushed by the weight of the material above it. Besides the physical strength of its particles, the coke must also be low in sulfur, phosphorus

Phosphorus is a chemical element with the symbol P and atomic number 15. Elemental phosphorus exists in two major forms, white phosphorus and red phosphorus, but because it is highly reactive, phosphorus is never found as a free element on Ear ...

, and ash.

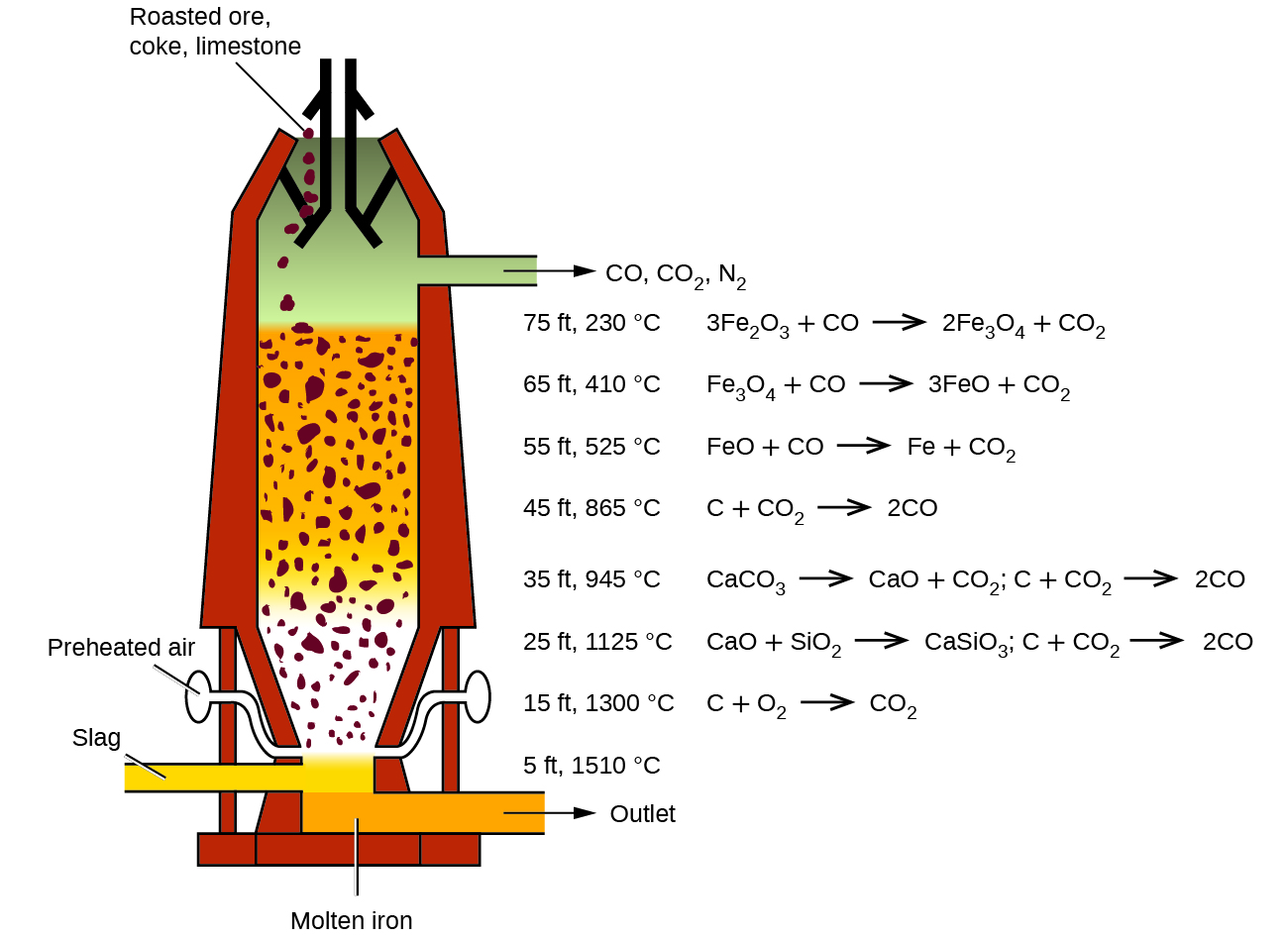

The main chemical reaction producing the molten iron is:

:Fe2O3 + 3CO → 2Fe + 3CO2

This reaction might be divided into multiple steps, with the first being that preheated air blown into the furnace reacts with the carbon in the form of coke to produce

The main chemical reaction producing the molten iron is:

:Fe2O3 + 3CO → 2Fe + 3CO2

This reaction might be divided into multiple steps, with the first being that preheated air blown into the furnace reacts with the carbon in the form of coke to produce carbon monoxide

Carbon monoxide (chemical formula CO) is a colorless, poisonous, odorless, tasteless, flammable gas that is slightly less dense than air. Carbon monoxide consists of one carbon atom and one oxygen atom connected by a triple bond. It is the simple ...

and heat:

:2 C(s) + O2(g) → 2 CO(g)

The hot carbon monoxide is the reducing agent for the iron ore and reacts with the iron oxide to produce molten iron and carbon dioxide

Carbon dioxide ( chemical formula ) is a chemical compound made up of molecules that each have one carbon atom covalently double bonded to two oxygen atoms. It is found in the gas state at room temperature. In the air, carbon dioxide is trans ...

. Depending on the temperature in the different parts of the furnace (warmest at the bottom) the iron is reduced in several steps. At the top, where the temperature usually is in the range between 200 °C and 700 °C, the iron oxide is partially reduced to iron(II,III) oxide, Fe3O4.

:3 Fe2O3(s) + CO(g) → 2 Fe3O4(s) + CO2(g)

The temperatures 850 °C, further down in the furnace, the iron(II,III) is reduced further to iron(II) oxide:

:Fe3O4(s) + CO(g) → 3 FeO(s) + CO2(g)

Hot carbon dioxide, unreacted carbon monoxide, and nitrogen

Nitrogen is the chemical element with the symbol N and atomic number 7. Nitrogen is a nonmetal and the lightest member of group 15 of the periodic table, often called the pnictogens. It is a common element in the universe, estimated at se ...

from the air pass up through the furnace as fresh feed material travels down into the reaction zone. As the material travels downward, the counter-current gases both preheat the feed charge and decompose the limestone to calcium oxide

Calcium oxide (CaO), commonly known as quicklime or burnt lime, is a widely used chemical compound. It is a white, caustic, alkaline, crystalline solid at room temperature. The broadly used term "''lime''" connotes calcium-containing inorganic ...

and carbon dioxide:

:CaCO3(s) → CaO(s) + CO2(g)

The calcium oxide formed by decomposition reacts with various acidic impurities in the iron (notably silica

Silicon dioxide, also known as silica, is an oxide of silicon with the chemical formula , most commonly found in nature as quartz and in various living organisms. In many parts of the world, silica is the major constituent of sand. Silica is ...

), to form a fayalitic slag which is essentially calcium silicate, :

:SiO2 + CaO → CaSiO3Dr. K. E. Lee, Form Two Science (Biology Chemistry Physics)

As the iron(II) oxide moves down to the area with higher temperatures, ranging up to 1200 °C degrees, it is reduced further to iron metal:

:FeO(s) + CO(g) → Fe(s) + CO2(g)

The carbon dioxide formed in this process is re-reduced to carbon monoxide by the coke:

:C(s) + CO2(g) → 2 CO(g)

The temperature-dependent equilibrium controlling the gas atmosphere in the furnace is called the Boudouard reaction:

::2CO CO2 + C

The " pig iron" produced by the blast furnace has a relatively high carbon content of around 4–5% and usually contains too much sulphur, making it very brittle, and of limited immediate commercial use. Some pig iron is used to make cast iron

Cast iron is a class of iron– carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impur ...

. The majority of pig iron produced by blast furnaces undergoes further processing to reduce the carbon and sulphur content and produce various grades of steel used for construction materials, automobiles, ships and machinery. Desulphurisation usually takes place during the transport of the liquid steel to the steelworks. This is done by adding ''calcium oxide'', which reacts with the iron sulfide

Iron sulfide or Iron sulphide can refer to range of chemical compounds composed of iron and sulfur.

Minerals

By increasing order of stability:

* Iron(II) sulfide, FeS

* Greigite, Fe3S4 (cubic)

* Pyrrhotite, Fe1−xS (where x = 0 to 0.2) (monocli ...

contained in the pig iron to form calcium sulfide

Calcium sulfide is the chemical compound with the formula Ca S. This white material crystallizes in cubes like rock salt. CaS has been studied as a component in a process that would recycle gypsum, a product of flue-gas desulfurization. Like m ...

(called ''lime desulfurization''). In a further process step, the so-called basic oxygen steelmaking

Basic oxygen steelmaking (BOS, BOP, BOF, or OSM), also known as Linz-Donawitz steelmaking or the oxygen converter processBrock and Elzinga, p. 50. is a method of primary steelmaking in which carbon-rich molten pig iron is made into steel. Blowin ...

, the carbon is oxidized by blowing oxygen onto the liquid pig iron to form ''crude steel''.

Although the efficiency of blast furnaces is constantly evolving, the chemical process inside the blast furnace remains the same. One of the biggest drawbacks of the blast furnaces is the inevitable carbon dioxide production as iron is reduced from iron oxides by carbon and as of 2016, there is no economical substitute – steelmaking is one of the largest industrial contributors of the CO2 emissions in the world (see greenhouse gases

A greenhouse gas (GHG or GhG) is a gas that absorbs and emits radiant energy within the thermal infrared range, causing the greenhouse effect. The primary greenhouse gases in Earth's atmosphere are water vapor (), carbon dioxide (), methane ...

). Several alternatives are being investigated such as plastic waste, biomass or hydrogen as reducing agent, which can substantially reduce the carbon emissions.

The challenge set by the greenhouse gas emissions of the blast furnace is being addressed in an ongoing European Program called ULCOS (Ultra Low CO2 Steelmaking

Steelmaking is the process of producing steel from iron ore and carbon/or scrap. In steelmaking, impurities such as nitrogen, silicon, phosphorus, sulfur and excess carbon (the most important impurity) are removed from the sourced iron, and alloy ...

). Several new process routes have been proposed and investigated in depth to cut specific emissions ( per ton of steel) by at least 50%. Some rely on the capture and further storage (CCS) of , while others choose decarbonizing iron and steel production, by turning to hydrogen, electricity and biomass. In the nearer term, a technology that incorporates CCS into the blast furnace process itself and is called the Top-Gas Recycling Blast Furnace is under development, with a scale-up to a commercial size blast furnace under way.

History

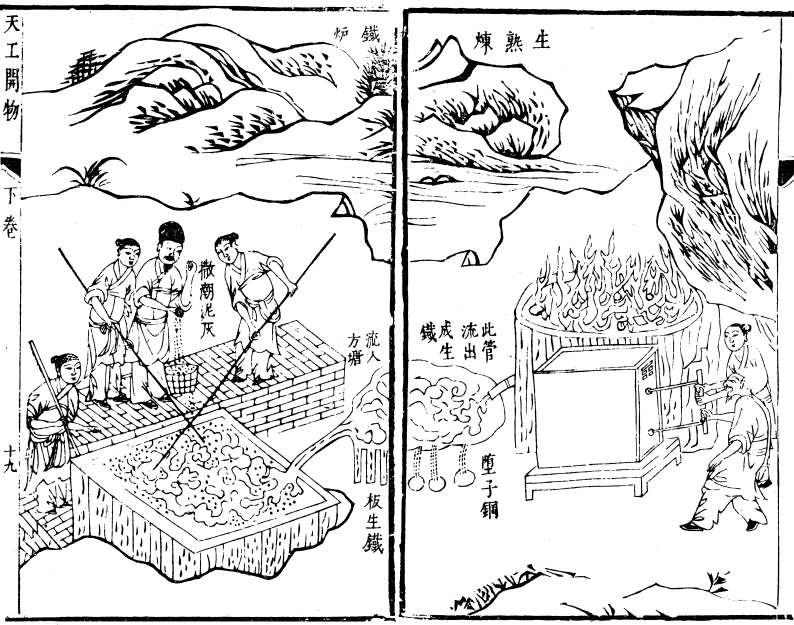

Cast iron has been found in China dating to the 5th century BC, but the earliest extant blast furnaces in China date to the 1st century AD and in the West from the

Cast iron has been found in China dating to the 5th century BC, but the earliest extant blast furnaces in China date to the 1st century AD and in the West from the High Middle Ages

The High Middle Ages, or High Medieval Period, was the period of European history that lasted from AD 1000 to 1300. The High Middle Ages were preceded by the Early Middle Ages and were followed by the Late Middle Ages, which ended around AD 150 ...

. They spread from the region around Namur in Wallonia

Wallonia (; french: Wallonie ), or ; nl, Wallonië ; wa, Waloneye or officially the Walloon Region (french: link=no, Région wallonne),; nl, link=no, Waals gewest; wa, link=no, Redjon walone is one of the three regions of Belgium—alo ...

(Belgium) in the late 15th century, being introduced to England in 1491. The fuel used in these was invariably charcoal. The successful substitution of coke for charcoal is widely attributed to English inventor Abraham Darby in 1709. The efficiency of the process was further enhanced by the practice of preheating the combustion air (hot blast

Hot blast refers to the preheating of air blown into a blast furnace or other metallurgical process. As this considerably reduced the fuel consumed, hot blast was one of the most important technologies developed during the Industrial Revolution. ...

), patented by Scottish inventor James Beaumont Neilson

James Beaumont Neilson (22 June 1792 – 18 January 1865) was a Scottish inventor whose hot-blast process greatly increased the efficiency of smelting iron.

Life

He was the son of the engineer Walter Neilson, a millwright and later engin ...

in 1828.

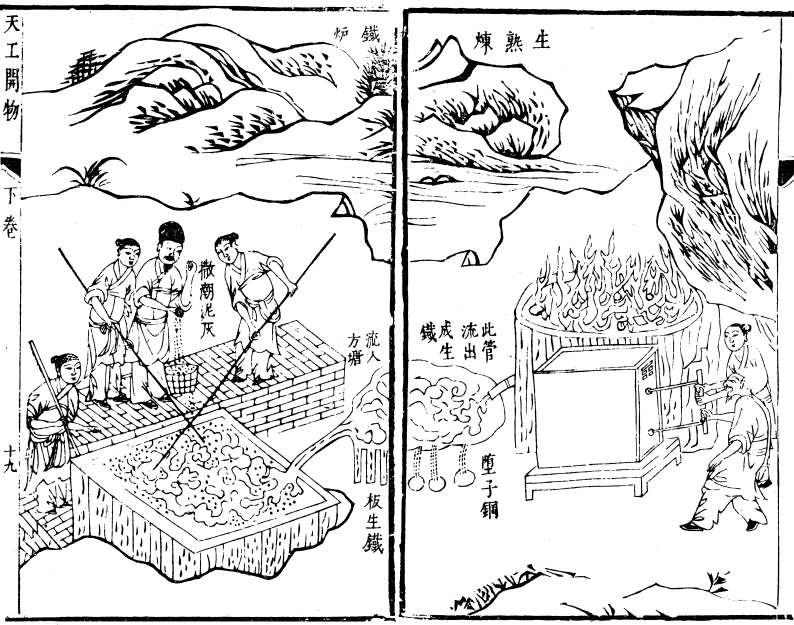

China

Archaeological evidence shows that bloomeries appeared in China around 800 BC. Originally it was thought that the Chinese started casting iron right from the beginning, but this theory has since been debunked by the discovery of 'more than ten' iron digging implements found in the tomb of Duke Jing of Qin (d. 537 BC), whose tomb is located inFengxiang County

Fengxiang District (), formerly, Fengxiang County and its ancient name is Yong county (雍县), is a district administered by Baoji City in the west of Shaanxi province, China. The county covers an area of and as of 2004 had a population of 510, ...

, Shaanxi

Shaanxi (alternatively Shensi, see § Name) is a landlocked province of China. Officially part of Northwest China, it borders the province-level divisions of Shanxi (NE, E), Henan (E), Hubei (SE), Chongqing (S), Sichuan (SW), Gansu (W), N ...

(a museum exists on the site today). There is however no evidence of the bloomery in China after the appearance of the blast furnace and cast iron. In China, blast furnaces produced cast iron, which was then either converted into finished implements in a cupola furnace, or turned into wrought iron in a fining hearth.

Although cast iron

Cast iron is a class of iron– carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impur ...

farm tools and weapons were widespread in China by the 5th century BC, employing workforces of over 200 men in iron smelters from the 3rd century onward, the earliest blast furnaces constructed were attributed to the Han Dynasty

The Han dynasty (, ; ) was an imperial dynasty of China (202 BC – 9 AD, 25–220 AD), established by Liu Bang (Emperor Gao) and ruled by the House of Liu. The dynasty was preceded by the short-lived Qin dynasty (221–207 BC) and a warr ...

in the 1st century AD.Ebrey, p. 30. These early furnaces had clay walls and used phosphorus

Phosphorus is a chemical element with the symbol P and atomic number 15. Elemental phosphorus exists in two major forms, white phosphorus and red phosphorus, but because it is highly reactive, phosphorus is never found as a free element on Ear ...

-containing minerals as a flux. Chinese blast furnaces ranged from around two to ten meters in height, depending on the region. The largest ones were found in modern Sichuan

Sichuan (; zh, c=, labels=no, ; zh, p=Sìchuān; alternatively romanized as Szechuan or Szechwan; formerly also referred to as "West China" or "Western China" by Protestant missions) is a province in Southwest China occupying most of the ...

and Guangdong

Guangdong (, ), alternatively romanized as Canton or Kwangtung, is a coastal province in South China on the north shore of the South China Sea. The capital of the province is Guangzhou. With a population of 126.01 million (as of 2020) ...

, while the 'dwarf" blast furnaces were found in Dabieshan. In construction, they are both around the same level of technological sophistication

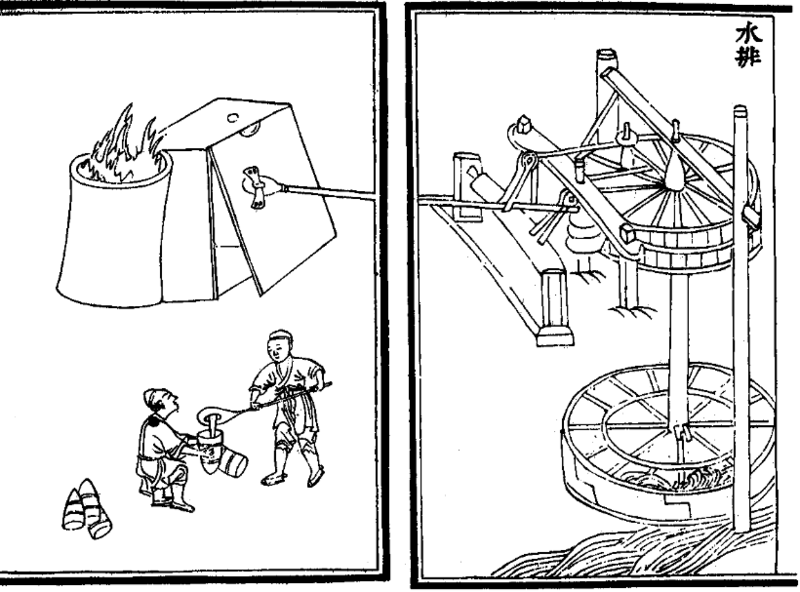

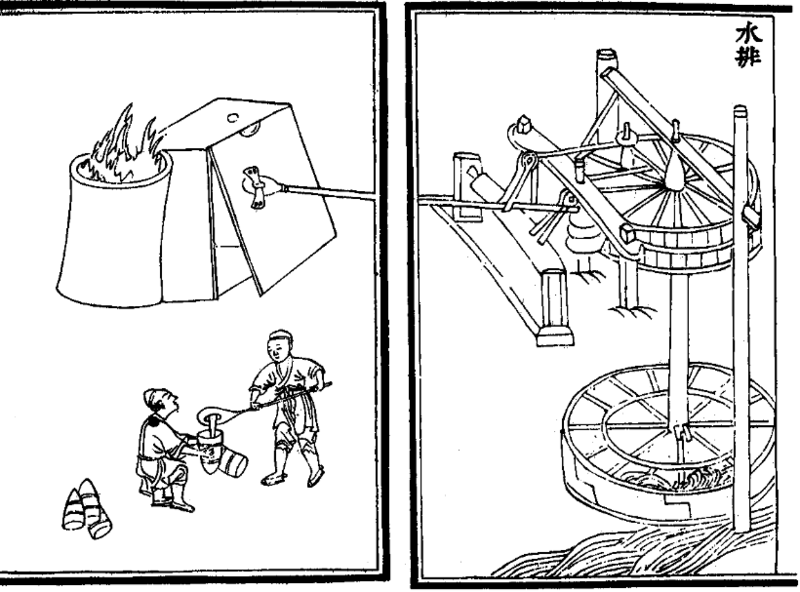

The effectiveness of the Chinese human and horse powered blast furnaces was enhanced during this period by the engineer Du Shi

Du Shi (, d. 38'' Book of Later Han'', vol. 31Crespigny, 183.) was a Chinese hydrologist, inventor, mechanical engineer, metallurgist, and politician of the Eastern Han Dynasty. Du Shi is credited with being the first to apply hydraulic power ( ...

(c. AD 31), who applied the power of waterwheels to piston-bellows

A bellows or pair of bellows is a device constructed to furnish a strong blast of air. The simplest type consists of a flexible bag comprising a pair of rigid boards with handles joined by flexible leather sides enclosing an approximately airtig ...

in forging cast iron. Early water-driven reciprocators for operating blast furnaces were built according to the structure of horse powered reciprocators that already existed. That is, the circular motion of the wheel, be it horse driven or water driven, was transferred by the combination of a belt drive, a crank-and-connecting-rod, other connecting rods

A connecting rod, also called a 'con rod', is the part of a piston engine which connects the piston to the crankshaft. Together with the crank, the connecting rod converts the reciprocating motion of the piston into the rotation of the cranksha ...

, and various shafts, into the reciprocal motion necessary to operate a push bellow.. Donald Wagner suggests that early blast furnace and cast iron production evolved from furnaces used to melt bronze. Certainly, though, iron was essential to military success by the time the State of Qin had unified China (221 BC). Usage of the blast and cupola furnace remained widespread during the Song

A song is a musical composition intended to be performed by the human voice. This is often done at distinct and fixed pitches (melodies) using patterns of sound and silence. Songs contain various forms, such as those including the repetit ...

and Tang Dynasties. By the 11th century, the Song Dynasty

The Song dynasty (; ; 960–1279) was an imperial dynasty of China that began in 960 and lasted until 1279. The dynasty was founded by Emperor Taizu of Song following his usurpation of the throne of the Later Zhou. The Song conquered the rest ...

Chinese iron industry made a switch of resources from charcoal to coke in casting iron and steel, sparing thousands of acres of woodland from felling. This may have happened as early as the 4th century AD.

The primary advantage of the early blast furnace was in large scale production and making iron implements more readily available to peasants. Cast iron is more brittle than wrought iron or steel, which required additional fining and then cementation or co-fusion to produce, but for menial activities such as farming it sufficed. By using the blast furnace, it was possible to produce larger quantities of tools such as ploughshares more efficiently than the bloomery. In areas where quality was important, such as warfare, wrought iron and steel were preferred. Nearly all Han period weapons are made of wrought iron or steel, with the exception of axe-heads, of which many are made of cast iron.

Blast furnaces were also later used to produce gunpowder

Gunpowder, also commonly known as black powder to distinguish it from modern smokeless powder, is the earliest known chemical explosive. It consists of a mixture of sulfur, carbon (in the form of charcoal) and potassium nitrate (saltpeter). Th ...

weapons such as cast iron bomb shells and cast iron cannon

A cannon is a large- caliber gun classified as a type of artillery, which usually launches a projectile using explosive chemical propellant. Gunpowder ("black powder") was the primary propellant before the invention of smokeless powder ...

s during the Song dynasty

The Song dynasty (; ; 960–1279) was an imperial dynasty of China that began in 960 and lasted until 1279. The dynasty was founded by Emperor Taizu of Song following his usurpation of the throne of the Later Zhou. The Song conquered the rest ...

.

Medieval Europe

The simplest forge, known as the Corsican, was used prior to the advent ofChristianity

Christianity is an Abrahamic monotheistic religion based on the life and teachings of Jesus of Nazareth. It is the world's largest and most widespread religion with roughly 2.38 billion followers representing one-third of the global pop ...

. Examples of improved bloomeries are the (sometimes called wolf-furnace), which remained until the beginning of the 19th century. Instead of using natural draught, air was pumped in by a ''trompe

A trompe is a water-powered air compressor, commonly used before the advent of the electric-powered compressor. A trompe is somewhat like an airlift pump working in reverse.

Trompes were used to provide compressed air for bloomery furnaces ...

'', resulting in better quality iron and an increased capacity. This pumping of air in with bellows is known as ''cold blast'', and it increases the fuel efficiency of the bloomery and improves yield. They can also be built bigger than natural draught bloomeries.

Oldest European blast furnaces

The oldest known blast furnaces in the West were built in Dürstel in Switzerland, the Märkische Sauerland in Germany, and at

The oldest known blast furnaces in the West were built in Dürstel in Switzerland, the Märkische Sauerland in Germany, and at Lapphyttan

Lapphyttan or Lapphyttejarn in Norberg Municipality, Sweden, may be regarded as the type site for the Medieval Blast Furnace. Its date is probably between 1150 and 1350. It produced cast iron, which was then fined to make ferritic wrought iron c ...

in Sweden, where the complex was active between 1205 and 1300. At Noraskog in the Swedish parish of Järnboås, traces of even earlier blast furnaces have been found, possibly from around 1100. These early blast furnaces, like the Chinese

Chinese can refer to:

* Something related to China

* Chinese people, people of Chinese nationality, citizenship, and/or ethnicity

**''Zhonghua minzu'', the supra-ethnic concept of the Chinese nation

** List of ethnic groups in China, people of ...

examples, were very inefficient compared to those used today. The iron from the Lapphyttan complex was used to produce balls of wrought iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag inclusions (up to 2% by weight), which give it a wood-like "grain" ...

known as osmonds, and these were traded internationally – a possible reference occurs in a treaty with Novgorod from 1203 and several certain references in accounts of English customs from the 1250s and 1320s. Other furnaces of the 13th to 15th centuries have been identified in Westphalia

Westphalia (; german: Westfalen ; nds, Westfalen ) is a region of northwestern Germany and one of the three historic parts of the state of North Rhine-Westphalia. It has an area of and 7.9 million inhabitants.

The territory of the regio ...

.

The technology required for blast furnaces may have either been transferred from China, or may have been an indigenous innovation. Al-Qazvini in the 13th century and other travellers subsequently noted an iron industry in the Alburz Mountains to the south of the Caspian Sea

The Caspian Sea is the world's largest inland body of water, often described as the world's largest lake or a full-fledged sea. An endorheic basin, it lies between Europe and Asia; east of the Caucasus, west of the broad steppe of Central Asia ...

. This is close to the silk route

The Silk Road () was a network of Eurasian trade routes active from the second century BCE until the mid-15th century. Spanning over 6,400 kilometers (4,000 miles), it played a central role in facilitating economic, cultural, political, and reli ...

, so that the use of technology derived from China is conceivable. Much later descriptions record blast furnaces about three metres high. As the Varangian

The Varangians (; non, Væringjar; gkm, Βάραγγοι, ''Várangoi'';Varangian

" Online Etymo ...

" Online Etymo ...

Rus' people

The Rusʹ (Old East Slavic: Рѹсь; Belarusian, Russian, Rusyn, and Ukrainian: Русь; Old Norse: '' Garðar''; Greek: Ῥῶς, ''Rhos'') were a people in early medieval eastern Europe. The scholarly consensus holds that they were or ...

from Scandinavia

Scandinavia; Sámi languages: /. ( ) is a subregion in Northern Europe, with strong historical, cultural, and linguistic ties between its constituent peoples. In English usage, ''Scandinavia'' most commonly refers to Denmark, Norway, and Swe ...

traded with the Caspian (using their Volga trade route

In the Middle Ages, the Volga trade route connected Northern Europe and Northwestern Russia with the Caspian Sea and the Sasanian Empire, via the Volga River. The Rus used this route to trade with Muslim countries on the southern shores of the ...

), it is possible that the technology reached Sweden by this means. The step from bloomery to true blast furnace is not big. Simply just building a bigger furnace and using bigger bellows to increase the volume of the blast and hence the amount of oxygen leads inevitably into higher temperatures, bloom melting into liquid iron, and cast iron flowing from the smelters. The Vikings are known to have used double bellows, which greatly increases the volumetric flow of the blast.

The Caspian region may also have been the source for the design of the furnace at Ferriere, described by Filarete

Antonio di Pietro Aver(u)lino (; – ), known as Filarete (; from grc, φιλάρετος, meaning "lover of excellence"), was a Florentine Renaissance architect, sculptor, medallist, and architectural theorist. He is perhaps best remembered for ...

, involving a water-powered bellows at in Valdidentro in northern Italy in 1226. In a two-stage process the molten iron was tapped twice a day into water, thereby granulating it.

Cistercian contributions

The General Chapter of the Cistercian monks spread some technological advances across Europe. This may have included the blast furnace, as the Cistercians are known to have been skilled metallurgists.Woods, p. 34. According to Jean Gimpel, their high level of industrial technology facilitated the diffusion of new techniques: "Every monastery had a model factory, often as large as the church and only several feet away, and waterpower drove the machinery of the various industries located on its floor." Iron ore deposits were often donated to the monks along with forges to extract the iron, and after a time surpluses were offered for sale. The Cistercians became the leading iron producers inChampagne

Champagne (, ) is a sparkling wine originated and produced in the Champagne wine region of France under the rules of the appellation, that demand specific vineyard practices, sourcing of grapes exclusively from designated places within it, ...

, France, from the mid-13th century to the 17th century,Gimpel, p. 67. also using the phosphate

In chemistry, a phosphate is an anion, salt, functional group or ester derived from a phosphoric acid. It most commonly means orthophosphate, a derivative of orthophosphoric acid .

The phosphate or orthophosphate ion is derived from phosph ...

-rich slag from their furnaces as an agricultural fertilizer

A fertilizer (American English) or fertiliser (British English; see spelling differences) is any material of natural or synthetic origin that is applied to soil or to plant tissues to supply plant nutrients. Fertilizers may be distinct from ...

.

Archaeologists are still discovering the extent of Cistercian technology.Woods, p. 36. At Laskill, an outstation of Rievaulx Abbey

Rievaulx Abbey was a Cistercian abbey in Rievaulx, near Helmsley, in the North York Moors National Park, North Yorkshire, England. It was one of the great abbeys in England until it was seized in 1538 under Henry VIII during the Dissolutio ...

and the only medieval blast furnace so far identified in Britain

Britain most often refers to:

* The United Kingdom, a sovereign state in Europe comprising the island of Great Britain, the north-eastern part of the island of Ireland and many smaller islands

* Great Britain, the largest island in the United King ...

, the slag produced was low in iron content.Woods, p. 37. Slag from other furnaces of the time contained a substantial concentration of iron, whereas Laskill is believed to have produced cast iron quite efficiently.David Derbyshire'Henry "Stamped Out Industrial Revolution"'

, ''

The Daily Telegraph

''The Daily Telegraph'', known online and elsewhere as ''The Telegraph'', is a national British daily broadsheet newspaper published in London by Telegraph Media Group and distributed across the United Kingdom and internationally.

It was f ...

'' (21 June 2002); cited by Woods. Its date is not yet clear, but it probably did not survive until Henry VIII's Dissolution of the Monasteries in the late 1530s, as an agreement (immediately after that) concerning the "smythes" with the Earl of Rutland

Earl () is a rank of the nobility in the United Kingdom. The title originates in the Old English word ''eorl'', meaning "a man of noble birth or rank". The word is cognate with the Scandinavian form ''jarl'', and meant "chieftain", particular ...

in 1541 refers to blooms. Nevertheless, the means by which the blast furnace spread in medieval Europe has not finally been determined.

Origin and spread of early modern blast furnaces

Pays de Bray

The Pays de Bray (, literally ''Land of Bray'') is a small (about 750 km²) natural region of France situated to the north-east of Rouen, straddling the French departments of the Seine-Maritime and the Oise (historically divided among the ...

on the eastern boundary of Normandy

Normandy (; french: link=no, Normandie ; nrf, Normaundie, Nouormandie ; from Old French , plural of ''Normant'', originally from the word for "northman" in several Scandinavian languages) is a geographical and cultural region in Northwestern ...

and from there to the Weald

The Weald () is an area of South East England between the parallel chalk escarpments of the North and the South Downs. It crosses the counties of Hampshire, Surrey, Sussex and Kent. It has three separate parts: the sandstone "High Weald" in the ...

of Sussex, where the first furnace (called Queenstock) in Buxted

Buxted is a village and civil parish in the Wealden district of East Sussex in England. The parish is situated on the Weald, north of Uckfield; the settlements of Five Ash Down, Heron's Ghyll and High Hurstwood are included within its boundarie ...

was built in about 1491, followed by one at Newbridge in Ashdown Forest

Ashdown Forest is an ancient area of open heathland occupying the highest sandy ridge-top of the High Weald Area of Outstanding Natural Beauty. It is situated some south of London in the county of East Sussex, England. Rising to an elevation

o ...

in 1496. They remained few in number until about 1530 but many were built in the following decades in the Weald, where the iron industry perhaps reached its peak about 1590. Most of the pig iron from these furnaces was taken to finery forge

A finery forge is a forge used to produce wrought iron from pig iron by decarburization in a process called "fining" which involved liquifying cast iron in a fining hearth and removing carbon from the molten cast iron through oxidation. Finery ...

s for the production of bar iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag inclusions (up to 2% by weight), which give it a wood-like "grain" t ...

.

The first British furnaces outside the Weald appeared during the 1550s, and many were built in the remainder of that century and the following ones. The output of the industry probably peaked about 1620, and was followed by a slow decline until the early 18th century. This was apparently because it was more economic to import iron from Sweden and elsewhere than to make it in some more remote British locations. Charcoal that was economically available to the industry was probably being consumed as fast as the wood to make it grew.

The first blast furnace in Russia opened in 1637 near Tula and was called the Gorodishche Works. The blast furnace spread from there to central Russia and then finally to the Urals

The Ural Mountains ( ; rus, Ура́льские го́ры, r=Uralskiye gory, p=ʊˈralʲskʲɪjə ˈɡorɨ; ba, Урал тауҙары) or simply the Urals, are a mountain range that runs approximately from north to south through western ...

.

Coke blast furnaces

In 1709, atCoalbrookdale

Coalbrookdale is a village in the Ironbridge Gorge in Shropshire, England, containing a settlement of great significance in the history of iron ore smelting. It lies within the civil parish called the Gorge.

This is where iron ore was first s ...

in Shropshire, England, Abraham Darby began to fuel a blast furnace with coke instead of charcoal. Coke's initial advantage was its lower cost, mainly because making coke required much less labor than cutting trees and making charcoal, but using coke also overcame localized shortages of wood, especially in Britain and on the Continent. Metallurgical grade coke will bear heavier weight than charcoal, allowing larger furnaces.

A disadvantage is that coke contains more impurities than charcoal, with sulfur being especially detrimental to the iron's quality. Coke's impurities were more of a problem before hot blast reduced the amount of coke required and before furnace temperatures were hot enough to make slag from limestone free flowing. (Limestone ties up sulfur. Manganese may also be added to tie up sulfur.)

Coke iron was initially only used for foundry

A foundry is a factory that produces metal castings. Metals are cast into shapes by melting them into a liquid, pouring the metal into a mold, and removing the mold material after the metal has solidified as it cools. The most common metals pr ...

work, making pots and other cast iron goods. Foundry work was a minor branch of the industry, but Darby's son built a new furnace at nearby Horsehay, and began to supply the owners of finery forge

A finery forge is a forge used to produce wrought iron from pig iron by decarburization in a process called "fining" which involved liquifying cast iron in a fining hearth and removing carbon from the molten cast iron through oxidation. Finery ...

s with coke pig iron for the production of bar iron. Coke pig iron was by this time cheaper to produce than charcoal pig iron. The use of a coal-derived fuel in the iron industry was a key factor in the British Industrial Revolution

The Industrial Revolution was the transition to new manufacturing processes in Great Britain, continental Europe, and the United States, that occurred during the period from around 1760 to about 1820–1840. This transition included going f ...

. Darby's original blast furnace has been archaeologically excavated and can be seen in situ at Coalbrookdale, part of the Ironbridge Gorge Museums. Cast iron from the furnace was used to make girder

A girder () is a support beam used in construction. It is the main horizontal support of a structure which supports smaller beams. Girders often have an I-beam cross section composed of two load-bearing ''flanges'' separated by a stabilizing ...

s for the world's first iron bridge in 1779. The Iron Bridge

The Iron Bridge is a cast iron arch bridge that crosses the River Severn in Shropshire, England. Opened in 1781, it was the first major bridge in the world to be made of cast iron. Its success inspired the widespread use of cast iron as a st ...

crosses the River Severn

, name_etymology =

, image = SevernFromCastleCB.JPG

, image_size = 288

, image_caption = The river seen from Shrewsbury Castle

, map = RiverSevernMap.jpg

, map_size = 288

, map_c ...

at Coalbrookdale and remains in use for pedestrians.

Steam-powered blast

The steam engine was applied to power blast air, overcoming a shortage of water power in areas where coal and iron ore were located. This was first done at Coalbrookdale where a steam engine replaced a horse-powered pump in 1742. Such engines were used to pump water to a reservoir above the furnace. The first engines used to blow cylinders directly was supplied byBoulton and Watt

Boulton & Watt was an early British engineering and manufacturing firm in the business of designing and making marine and stationary steam engines. Founded in the English West Midlands around Birmingham in 1775 as a partnership between the Eng ...

to John Wilkinson's New Willey Furnace. This powered a cast iron blowing cylinder, which had been invented by his father Isaac Wilkinson

Isaac Wilkinson (baptism, baptised 6 May 1695 - 31 January 1784) was an England, English industrialist, one of the founders of the iron industry and pioneer of the Industrial Revolution. However, his business ethics were precarious and his commerci ...

. He patented such cylinders in 1736, to replace the leather bellows, which wore out quickly. Isaac was granted a second patent, also for blowing cylinders, in 1757. The steam engine and cast iron blowing cylinder led to a large increase in British iron production in the late 18th century.

Hot blast

Hot blast

Hot blast refers to the preheating of air blown into a blast furnace or other metallurgical process. As this considerably reduced the fuel consumed, hot blast was one of the most important technologies developed during the Industrial Revolution. ...

was the single most important advance in fuel efficiency of the blast furnace and was one of the most important technologies developed during the Industrial Revolution

The Industrial Revolution was the transition to new manufacturing processes in Great Britain, continental Europe, and the United States, that occurred during the period from around 1760 to about 1820–1840. This transition included going f ...

. Hot blast was patented by James Beaumont Neilson

James Beaumont Neilson (22 June 1792 – 18 January 1865) was a Scottish inventor whose hot-blast process greatly increased the efficiency of smelting iron.

Life

He was the son of the engineer Walter Neilson, a millwright and later engin ...

at Wilsontown Ironworks in Scotland in 1828. Within a few years of the introduction, hot blast was developed to the point where fuel consumption was cut by one-third using coke or two-thirds using coal, while furnace capacity was also significantly increased. Within a few decades, the practice was to have a "stove" as large as the furnace next to it into which the waste gas (containing CO) from the furnace was directed and burnt. The resultant heat was used to preheat the air blown into the furnace.Birch, pp. 181–189.

Hot blast enabled the use of raw anthracite coal, which was difficult to light, to the blast furnace. Anthracite was first tried successfully by George Crane at Ynyscedwyn Ironworks in south Wales in 1837. It was taken up in America by the Lehigh Crane Iron Company at Catasauqua, Pennsylvania

Catasauqua, referred to colloquially as Catty, is a borough in Lehigh County, Pennsylvania. Catasauqua's population was 6,518 at the 2020 census. It is a suburb of Allentown in the Lehigh Valley, which had a population of 861,899 and was the 68th ...

, in 1839. Anthracite use declined when very high capacity blast furnaces requiring coke were built in the 1870s.

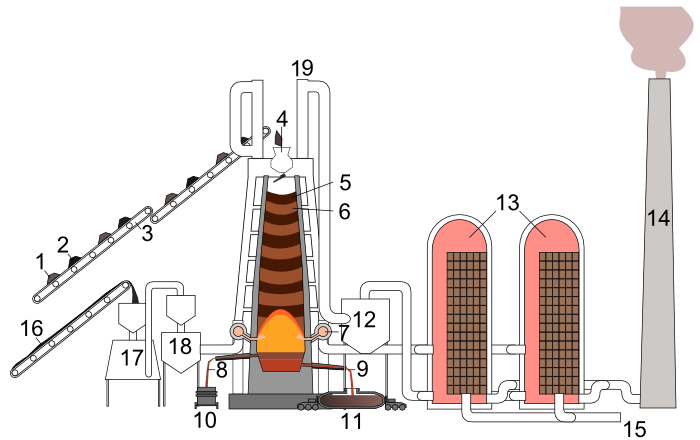

Modern applications of the blast furnace

Iron blast furnaces

The blast furnace remains an important part of modern iron production. Modern furnaces are highly efficient, includingCowper stove

A regenerative heat exchanger, or more commonly a regenerator, is a type of heat exchanger where heat from the hot fluid is intermittently stored in a thermal storage medium before it is transferred to the cold fluid. To accomplish this the hot fl ...

s to pre-heat the blast air and employ recovery systems to extract the heat from the hot gases exiting the furnace. Competition in industry drives higher production rates. The largest blast furnace in the world is in South Korea, with a volume around . It can produce around of iron per year.

This is a great increase from the typical 18th-century furnaces, which averaged about per year. Variations of the blast furnace, such as the Swedish electric blast furnace, have been developed in countries which have no native coal resources.

According to Global Energy Monitor

Global Energy Monitor (GEM) is a San Francisco-based non-governmental organization which catalogs fossil fuel and renewable energy projects worldwide. GEM shares information in support of clean energy and its data and reports on energy trends ...

the blast furnace is likely to become obsolete to meet climate change

In common usage, climate change describes global warming—the ongoing increase in global average temperature—and its effects on Earth's climate system. Climate change in a broader sense also includes previous long-term changes to ...

objectives of reducing carbon dioxide emission, but BHP

BHP Group Limited (formerly known as BHP Billiton) is an Australian multinational mining, metals, natural gas petroleum public company that is headquartered in Melbourne, Victoria, Australia.

The Broken Hill Proprietary Company was founded ...

disagrees. An alternative process involving direct reduced iron

Direct reduced iron (DRI), also called sponge iron, is produced from the direct reduction of iron ore (in the form of lumps, pellets, or fines) into iron by a reducing gas or elemental carbon produced from natural gas or coal. Many ores are suit ...

is likely to succeed it, but this also needs to use a blast furnace to melt the iron and remove the gangue

In mining, gangue () is the commercially worthless material that surrounds, or is closely mixed with, a wanted mineral in an ore deposit. It is thus distinct from overburden, which is the waste rock or materials overlying an ore or mineral body ...

(impurities) unless the ore is very high quality.

Oxygen blast furnace

The oxygen blast furnace (OBF) process has been extensively studied theoretically because of the potentials of promising energy conservation and CO2 emission reduction. This type may be the most suitable for use with CCS.the main blast furnace has of three levels of reduction zones reduction zone (523–973k),slag formation zone (1073–1273k), combustion zone (1773–1873k)Lead blast furnaces

Blast furnaces are currently rarely used in copper smelting, but modern lead smelting blast furnaces are much shorter than iron blast furnaces and are rectangular in shape.R J Sinclair, ''The Extractive Metallurgy of Lead'' (The Australasian Institute of Mining and Metallurgy: Melbourne, 2009), 75. The overall shaft height is around 5 to 6 m.R J Sinclair, ''The Extractive Metallurgy of Lead'' (The Australasian Institute of Mining and Metallurgy: Melbourne, 2009), 77. Modern lead blast furnaces are constructed using water-cooled steel or copper jackets for the walls, and have no refractory linings in the side walls. The base of the furnace is a hearth of refractory material (bricks or castable refractory). Lead blast furnaces are often open-topped rather than having the charging bell used in iron blast furnaces. The blast furnace used at theNyrstar

Nyrstar is a global multi-metals business, with a market leading position in zinc and lead and growing positions in other base and precious metals, such as copper, gold and silver. Nyrstar has mining and smelting operations located in Europe, North ...

Port Pirie

Port Pirie is a small city on the east coast of the Spencer Gulf in South Australia, north of the state capital, Adelaide. The city has an expansive history which dates back to 1845. Port Pirie was the first proclaimed regional city in South A ...

lead smelter differs from most other lead blast furnaces in that it has a double row of tuyeres rather than the single row normally used. The lower shaft of the furnace has a chair shape with the lower part of the shaft being narrower than the upper. The lower row of tuyeres being located in the narrow part of the shaft. This allows the upper part of the shaft to be wider than the standard.

Zinc blast furnaces (Imperial Smelting Furnaces)

The blast furnaces used in the Imperial Smelting Process ("ISP") were developed from the standard lead blast furnace, but are fully sealed.R J Sinclair, ''The Extractive Metallurgy of Lead'' (The Australasian Institute of Mining and Metallurgy: Melbourne, 2009), 89. This is because the zinc produced by these furnaces is recovered as metal from the vapor phase, and the presence of oxygen in the off-gas would result in the formation of zinc oxide. Blast furnaces used in the ISP have a more intense operation than standard lead blast furnaces, with higher air blast rates per m2 of hearth area and a higher coke consumption. Zinc production with the ISP is more expensive than with electrolytic zinc plants, so several smelters operating this technology have closed in recent years. However, ISP furnaces have the advantage of being able to treat zinc concentrates containing higher levels of lead than can electrolytic zinc plants.Manufacture of stone wool

Stone wool orrock wool

Mineral wool is any fibrous material formed by spinning or drawing molten mineral or rock materials such as slag and ceramics.

Applications of mineral wool include thermal insulation (as both structural insulation and pipe insulation), filt ...

is a spun mineral fibre used as an insulation product and in hydroponic

Hydroponics is a type of horticulture and a subset of hydroculture which involves growing plants, usually crops or medicinal plants, without soil, by using water-based mineral nutrient solutions in aqueous solvents. Terrestrial or aquatic plant ...

s. It is manufactured in a blast furnace fed with diabase rock which contains very low levels of metal oxides. The resultant slag is drawn off and spun to form the rock wool product. Very small amounts of metals are also produced which are an unwanted by-product.

Modern iron process

Modern furnaces are equipped with an array of supporting facilities to increase efficiency, such as ore storage yards where barges are unloaded. The raw materials are transferred to the stockhouse complex by ore bridges, or rail hoppers and ore transfer cars. Rail-mounted scale cars or computer controlled weight hoppers weigh out the various raw materials to yield the desired hot metal and slag chemistry. The raw materials are brought to the top of the blast furnace via a

Modern furnaces are equipped with an array of supporting facilities to increase efficiency, such as ore storage yards where barges are unloaded. The raw materials are transferred to the stockhouse complex by ore bridges, or rail hoppers and ore transfer cars. Rail-mounted scale cars or computer controlled weight hoppers weigh out the various raw materials to yield the desired hot metal and slag chemistry. The raw materials are brought to the top of the blast furnace via a skip

Skip or Skips may refer to:

Acronyms

* SKIP (Skeletal muscle and kidney enriched inositol phosphatase), a human gene

* Simple Key-Management for Internet Protocol

* SKIP of New York (Sick Kids need Involved People), a non-profit agency aidi ...

car powered by winches or conveyor belts.American Iron and Steel Institute (2005)How a Blast Furnace Works

steel.org. There are different ways in which the raw materials are charged into the blast furnace. Some blast furnaces use a "double bell" system where two "bells" are used to control the entry of raw material into the blast furnace. The purpose of the two bells is to minimize the loss of hot gases in the blast furnace. First, the raw materials are emptied into the upper or small bell which then opens to empty the charge into the large bell. The small bell then closes, to seal the blast furnace, while the large bell rotates to provide specific distribution of materials before dispensing the charge into the blast furnace. A more recent design is to use a "bell-less" system. These systems use multiple hoppers to contain each raw material, which is then discharged into the blast furnace through valves. These valves are more accurate at controlling how much of each constituent is added, as compared to the skip or conveyor system, thereby increasing the efficiency of the furnace. Some of these bell-less systems also implement a discharge chute in the throat of the furnace (as with the Paul Wurth top) in order to precisely control where the charge is placed. The iron making blast furnace itself is built in the form of a tall structure, lined with

refractory

In materials science, a refractory material or refractory is a material that is resistant to decomposition by heat, pressure, or chemical attack, and retains strength and form at high temperatures. Refractories are polycrystalline, polyphase, ...

brick, and profiled to allow for expansion of the charged materials as they heat during their descent, and subsequent reduction in size as melting starts to occur. Coke, limestone

Limestone ( calcium carbonate ) is a type of carbonate sedimentary rock which is the main source of the material lime. It is composed mostly of the minerals calcite and aragonite, which are different crystal forms of . Limestone forms whe ...

flux, and iron ore (iron oxide) are charged into the top of the furnace in a precise filling order which helps control gas flow and the chemical reactions inside the furnace. Four "uptakes" allow the hot, dirty gas high in carbon monoxide content to exit the furnace throat, while "bleeder valves" protect the top of the furnace from sudden gas pressure surges. The coarse particles in the exhaust gas settle in the "dust catcher" and are dumped into a railroad car or truck for disposal, while the gas itself flows through a venturi scrubber

A venturi scrubber is designed to effectively use the energy from a high-velocity inlet gas stream to atomize the liquid being used to scrub the gas stream. This type of technology is a part of the group of air pollution controls collectively refe ...

and/or electrostatic precipitators and a gas cooler to reduce the temperature of the cleaned gas.

The "casthouse" at the bottom half of the furnace contains the bustle pipe, water cooled copper tuyeres and the equipment for casting the liquid iron and slag. Once a "taphole" is drilled through the refractory clay plug, liquid iron and slag flow down a trough through a "skimmer" opening, separating the iron and slag. Modern, larger blast furnaces may have as many as four tapholes and two casthouses. Once the pig iron and slag has been tapped, the taphole is again plugged with refractory clay.

The

The tuyere

A tuyere or tuyère (; ) is a tube, nozzle or pipe through which air is blown into a furnace or hearth.W. K. V. Gale, The iron and Steel industry: a dictionary of terms (David and Charles, Newton Abbot 1972), 216–217.

Air or oxygen is in ...

s are used to implement a hot blast

Hot blast refers to the preheating of air blown into a blast furnace or other metallurgical process. As this considerably reduced the fuel consumed, hot blast was one of the most important technologies developed during the Industrial Revolution. ...

, which is used to increase the efficiency of the blast furnace. The hot blast is directed into the furnace through water-cooled copper nozzles called tuyeres near the base. The hot blast temperature can be from 900 °C to 1300 °C (1600 °F to 2300 °F) depending on the stove design and condition. The temperatures they deal with may be 2000 °C to 2300 °C (3600 °F to 4200 °F). Oil

An oil is any nonpolar chemical substance that is composed primarily of hydrocarbons and is hydrophobic (does not mix with water) & lipophilic (mixes with other oils). Oils are usually flammable and surface active. Most oils are unsaturated ...

, tar

Tar is a dark brown or black viscous liquid of hydrocarbons and free carbon, obtained from a wide variety of organic materials through destructive distillation. Tar can be produced from coal, wood, petroleum, or peat. "a dark brown or black bi ...

, natural gas

Natural gas (also called fossil gas or simply gas) is a naturally occurring mixture of gaseous hydrocarbons consisting primarily of methane in addition to various smaller amounts of other higher alkanes. Low levels of trace gases like carbo ...

, powdered coal

Coal is a combustible black or brownish-black sedimentary rock, formed as rock strata called coal seams. Coal is mostly carbon with variable amounts of other elements, chiefly hydrogen, sulfur, oxygen, and nitrogen.

Coal is formed when ...

and oxygen

Oxygen is the chemical element with the symbol O and atomic number 8. It is a member of the chalcogen group in the periodic table, a highly reactive nonmetal, and an oxidizing agent that readily forms oxides with most elements as ...

can also be injected into the furnace at tuyere level to combine with the coke to release additional energy and increase the percentage of reducing gases present which is necessary to increase productivity.

The exhaust gasses of a blast furnace are generally cleaned in the dust collector

A dust collector is a system used to enhance the quality of air released from industrial and commercial processes by collecting dust and other impurities from air or gas. Designed to handle high-volume dust loads, a dust collector system consists ...

– such as an inertia

Inertia is the idea that an object will continue its current motion until some force causes its speed or direction to change. The term is properly understood as shorthand for "the principle of inertia" as described by Newton in his first law ...

l separator, a baghouse

A baghouse, also known as a baghouse filter, bag filter, or fabric filter is an air pollution control device and dust collector that removes particulates or gas released from commercial processes out of the air. Power plants, steel mills, pharmaceu ...

, or an electrostatic precipitator

An electrostatic precipitator (ESP) is a filterless device that removes fine particles, like dust and smoke, from a flowing gas using the force of an induced electrostatic charge minimally impeding the flow of gases through the unit.

In con ...

. Each type of dust collector has strengths and weaknesses – some collect fine particles, some coarse particles, some collect electrically charged particles. Effective exhaust clearing relies on multiple stages of treatment. Waste heat is usually collected from the exhaust gases, for example by the use of a Cowper stove

A regenerative heat exchanger, or more commonly a regenerator, is a type of heat exchanger where heat from the hot fluid is intermittently stored in a thermal storage medium before it is transferred to the cold fluid. To accomplish this the hot fl ...

, a variety of heat exchanger

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct conta ...

.

The IEA Green House Gas R&D Programme (IEAGHG) has shown that in an integrated steel plant, 70% of the is directly from the blast furnace gas (BFG). It is possible to use carbon capture technology on the BFG before the BFG goes on to be used for heat exchange processes within the plant. In 2000, the IEAGHG estimated using that chemical absorption to capture BFG would cost $35/t of (an additional $8–20/t of would be required for transportation and storage). This would make the entire steel production process in a plant 15–20% more expensive.

Environmental impact

The results showed thatglobal warming

In common usage, climate change describes global warming—the ongoing increase in global average temperature—and its effects on Earth's climate system. Climate change in a broader sense also includes previous long-term changes to E ...

potential and acidification

Acidification may refer to:

* Ocean acidification, decrease in the pH of the Earth's oceans

* Freshwater acidification, atmospheric depositions and soil leaching of SOx and NOx

* Soil acidification, buildup of hydrogen cations, which reduces the ...

potential were the most significant environmental impacts. On average producing a tonne of steel emits 1.8 tonnes of . However, a steel mill using a top gas recycling blast furnace (TGRBF) producing a tonne of steel will emit 0.8 to 1.3 tonnes of depending upon the recycle rate of the TGRBF.

Decommissioned blast furnaces as museum sites

For a long time, it was normal procedure for a decommissioned blast furnace to be demolished and either be replaced with a newer, improved one, or to have the entire site demolished to make room for follow-up use of the area. In recent decades, several countries have realized the value of blast furnaces as a part of their industrial history. Rather than being demolished, abandoned steel mills were turned into museums or integrated into multi-purpose parks. The largest number of preserved historic blast furnaces exists in Germany; other such sites exist in Spain, France, theCzech Republic

The Czech Republic, or simply Czechia, is a landlocked country in Central Europe. Historically known as Bohemia, it is bordered by Austria to the south, Germany to the west, Poland to the northeast, and Slovakia to the southeast. The ...

, Great Britain

Great Britain is an island in the North Atlantic Ocean off the northwest coast of continental Europe. With an area of , it is the largest of the British Isles, the largest European island and the ninth-largest island in the world. It i ...

. Japan, Luxembourg

Luxembourg ( ; lb, Lëtzebuerg ; french: link=no, Luxembourg; german: link=no, Luxemburg), officially the Grand Duchy of Luxembourg, ; french: link=no, Grand-Duché de Luxembourg ; german: link=no, Großherzogtum Luxemburg is a small lan ...

, Poland

Poland, officially the Republic of Poland, is a country in Central Europe. It is divided into 16 administrative provinces called voivodeships, covering an area of . Poland has a population of over 38 million and is the fifth-most populou ...

, Romania

Romania ( ; ro, România ) is a country located at the crossroads of Central, Eastern, and Southeastern Europe. It borders Bulgaria to the south, Ukraine to the north, Hungary to the west, Serbia to the southwest, Moldova to the east, and ...

, Mexico

Mexico (Spanish: México), officially the United Mexican States, is a country in the southern portion of North America. It is bordered to the north by the United States; to the south and west by the Pacific Ocean; to the southeast by Guatema ...

, Russia

Russia (, , ), or the Russian Federation, is a transcontinental country spanning Eastern Europe and Northern Asia. It is the largest country in the world, with its internationally recognised territory covering , and encompassing one-eig ...

and the United States

The United States of America (U.S.A. or USA), commonly known as the United States (U.S. or US) or America, is a country primarily located in North America. It consists of 50 states, a federal district, five major unincorporated territori ...

.

Gallery

Sestao

Sestao is a town and municipality of 27,296 inhabitants located in the province of Biscay, in the autonomous community of Basque Country, northern Spain. It is in the left bank of the Estuary of Bilbao and part of Bilbao's metropolitan area.

...

, Spain. The furnace itself is inside the central girderwork.

File:Old blast furnace gas cleaning plant 2012-05-02.jpg, Part of the gas cleaning system of a blast furnace in Monclova

Monclova (), is a city and the seat of the surrounding municipality of the same name in the northern Mexican state of Coahuila. According to the 2015 census, the city had 231,107 inhabitants. Its metropolitan area has 381,432 inhabitants and a ...

, Mexico. This one is about to be de-commissioned and replaced.

See also

*Basic oxygen furnace

Basic oxygen steelmaking (BOS, BOP, BOF, or OSM), also known as Linz-Donawitz steelmaking or the oxygen converter processBrock and Elzinga, p. 50. is a method of primary steelmaking in which carbon-rich molten pig iron is made into steel. Blowing ...

* Blast furnace zinc smelting process

*Crucible steel

Crucible steel is steel made by melting pig iron (cast iron), iron, and sometimes steel, often along with sand, glass, ashes, and other fluxes, in a crucible. In ancient times steel and iron were impossible to melt using charcoal or coal fires ...

* Extraction of iron

*Water gas

Water gas is a kind of fuel gas, a mixture of carbon monoxide and hydrogen. It is produced by "alternately hot blowing a fuel layer okewith air and gasifying it with steam". The caloric yield of this is about 10% of a modern syngas plant. F ...

, produced by a "steam blast"

* FINEX

* Flodin process

*Ironworks and steelworks in England

An ironworks or iron works is an industrial plant where iron is smelted and where heavy iron and steel products are made. The term is both singular and plural, i.e. the singular of ''ironworks'' is ''ironworks''.

Ironworks succeeded bloomer ...

, which covers ironworks of all kinds.

* Shaft furnace breather

References

Bibliography

* * * * * * *External links

American Iron and Steel Institute

{{DEFAULTSORT:Blast Furnace Industrial furnaces Industrial Revolution Metallurgy Chinese inventions Steelmaking Smelting Firing techniques Industrial buildings