Wool-spinning on:

[Wikipedia]

[Google]

[Amazon]

Spinning is a twisting technique to form

The

The

In a

In a

The cultivation of cotton as well as the knowledge of its spinning and weaving in

The cultivation of cotton as well as the knowledge of its spinning and weaving in

Trowbridge medieval spinning industry

{{Authority control Textile engineering History of the textile industry

yarn

Yarn is a long continuous length of interlocked fibres, used in sewing, crocheting, knitting, weaving, embroidery, ropemaking, and the production of textiles. Thread is a type of yarn intended for sewing by hand or machine. Modern manu ...

from fiber

Fiber or fibre (from la, fibra, links=no) is a natural or artificial substance that is significantly longer than it is wide. Fibers are often used in the manufacture of other materials. The strongest engineering materials often incorpora ...

s. The fiber intended is drawn out, twisted, and wound onto a bobbin. A few popular fibers that are spun into yarn other than cotton

Cotton is a soft, fluffy staple fiber that grows in a boll, or protective case, around the seeds of the cotton plants of the genus '' Gossypium'' in the mallow family Malvaceae. The fiber is almost pure cellulose, and can contain minor pe ...

, which is the most popular, are viscose

Rayon is a semi-synthetic fiber, made from natural sources of regenerated cellulose, such as wood and related agricultural products. It has the same molecular structure as cellulose. It is also called viscose. Many types and grades of viscose ...

(the most common form of rayon), and synthetic polyester. Originally done by hand using a spindle whorl, starting in the 500s AD the spinning wheel

A spinning wheel is a device for spinning thread or yarn from fibres. It was fundamental to the cotton textile industry prior to the Industrial Revolution. It laid the foundations for later machinery such as the spinning jenny and spinning f ...

became the predominant spinning tool across Asia and Europe. The spinning jenny

The spinning jenny is a multi- spindle spinning frame, and was one of the key developments in the industrialization of textile manufacturing during the early Industrial Revolution. It was invented in 1764 or 1765 by James Hargreaves in Sta ...

and spinning mule

The spinning mule is a machine used to spin cotton and other fibres. They were used extensively from the late 18th to the early 20th century in the mills of Lancashire and elsewhere. Mules were worked in pairs by a minder, with the help of tw ...

, invented in the late 1700s, made mechanical spinning far more efficient than spinning by hand, and especially made cotton manufacturing one of the most important industries of the Industrial Revolution

The Industrial Revolution was the transition to new manufacturing processes in Great Britain, continental Europe, and the United States, that occurred during the period from around 1760 to about 1820–1840. This transition included going f ...

.

Process

The

The yarn

Yarn is a long continuous length of interlocked fibres, used in sewing, crocheting, knitting, weaving, embroidery, ropemaking, and the production of textiles. Thread is a type of yarn intended for sewing by hand or machine. Modern manu ...

issuing from the drafting rollers passes through a thread-guide, round a traveller that is free to rotate around a ring, and then onto a tube or bobbin, which is carried on to a spindle

Spindle may refer to:

Textiles and manufacturing

* Spindle (textiles), a straight spike to spin fibers into yarn

* Spindle (tool), a rotating axis of a machine tool

Biology

* Common spindle and other species of shrubs and trees in genus ''Euony ...

, the axis of which passes through a center of the ring.

The spindle is driven (usually at an angular velocity that is either constant or changes only slowly), and the traveller is dragged around a ring by the loop of yarn passing round it.

If the drafting rollers were stationary, the angular velocity of the traveller would be the same as that of the spindle, and each revolution of the spindle would cause one turn of a twist to be inserted in the loop of yarn between the roller nip and the traveller.

In spinning, however, the yarn is continually issuing from the rollers of the drafting system and, under these circumstances, the angular velocity of the traveller is less than that of the spindle by an amount that is just sufficient to allow the yarn to be wound onto the bobbin at the same rate as that at which it issues from the drafting rollers.

Each revolution of the traveller now inserts one turn of twist into the loop of yarn between the roller nip and the traveller but, in equilibrium, the number of turns of twist in the loop of yarn remains constant as the twisted yarn is passing through the traveller at a corresponding rate.

Types of fibre

Artificial fibres are made by extruding a polymer through a spinneret into a medium where it hardens. Wet spinning ( rayon) uses a coagulating medium. In dry spinning ( acetate and triacetate), the polymer is contained in a solvent that evaporates in the heated exit chamber. In melt spinning (nylons and polyesters) the extruded polymer is cooled in gas or air and sets. All these fibres will be of great length, often kilometers long. Natural fibres derive from animals (sheep, goat, rabbit,silk

Silk is a natural protein fiber, some forms of which can be woven into textiles. The protein fiber of silk is composed mainly of fibroin and is produced by certain insect larvae to form cocoons. The best-known silk is obtained from the ...

worm), minerals ( asbestos), or plants (cotton, flax, sisal

Sisal (, ) (''Agave sisalana'') is a species of flowering plant native to southern Mexico, but widely cultivated and naturalized in many other countries. It yields a stiff fibre used in making rope and various other products. The term sisal may ...

). These vegetable fibres can come from the seed (cotton), the stem (known as bast fibre

Bast fibre (also called phloem fibre or skin fibre) is plant fibre collected from the phloem (the "inner bark", sometimes called "skin") or bast surrounding the stem of certain dicotyledonous plants. It supports the conductive cells of the phl ...

s: they include flax, hemp, and jute) or the leaf (sisal

Sisal (, ) (''Agave sisalana'') is a species of flowering plant native to southern Mexico, but widely cultivated and naturalized in many other countries. It yields a stiff fibre used in making rope and various other products. The term sisal may ...

). Many processes are needed before a clean even staple is obtained. With the exception of silk, each of these fibres is short, only centimetres in length, and each has a rough surface that enables it to bond with similar staples.

Artificial fibres can be processed as long fibres or batched and cut so they can be processed like a natural fibre.

Methods

Ring spinning

Ring spinning is a spindle-based method of spinning fibres, such as cotton, flax or wool, to make a yarn. The ring frame developed from the throstle frame, which in its turn was a descendant of Arkwright's water frame. Ring spinning is a continu ...

is one of the most common spinning methods in the world. Other systems include air-jet and open-end spinning, a technique where the staple fiber

A staple fiber is a textile fiber of discrete length. The opposite is a filament fiber, which comes in continuous lengths. Staple length is a characteristic fiber length of a sample of staple fibers. It is an essential criterion in yarn spinning ...

is blown by air into a rotor and attaches to the tail of formed yarn that is continually being drawn out of the chamber. Other methods of break spinning use needles and electrostatic

Electrostatics is a branch of physics that studies electric charges at rest ( static electricity).

Since classical times, it has been known that some materials, such as amber, attract lightweight particles after rubbing. The Greek word for amb ...

forces.

The processes to make short-staple yarn (typically spun from fibers from ) are blending, opening, carding, pin-drafting, roving

A roving is a long and narrow bundle of fiber. Rovings are produced during the process of making spun yarn from wool fleece, raw cotton, or other fibres. Their main use is as fibre prepared for spinning, but they may also be used for specialised ...

, spinning, and—if desired—plying and dyeing

Dyeing is the application of dyes or pigments on textile materials such as fibers, yarns, and fabrics with the goal of achieving color with desired color fastness. Dyeing is normally done in a special solution containing dyes and particular c ...

. In long staple spinning, the process may start with stretch-break of tow, a continuous "rope" of synthetic fiber. In open-end and air-jet spinning, the roving operation is eliminated. The spinning frame winds yarn around a bobbin. Generally, after this step the yarn is wound to a cone for knitting or weaving.

In a

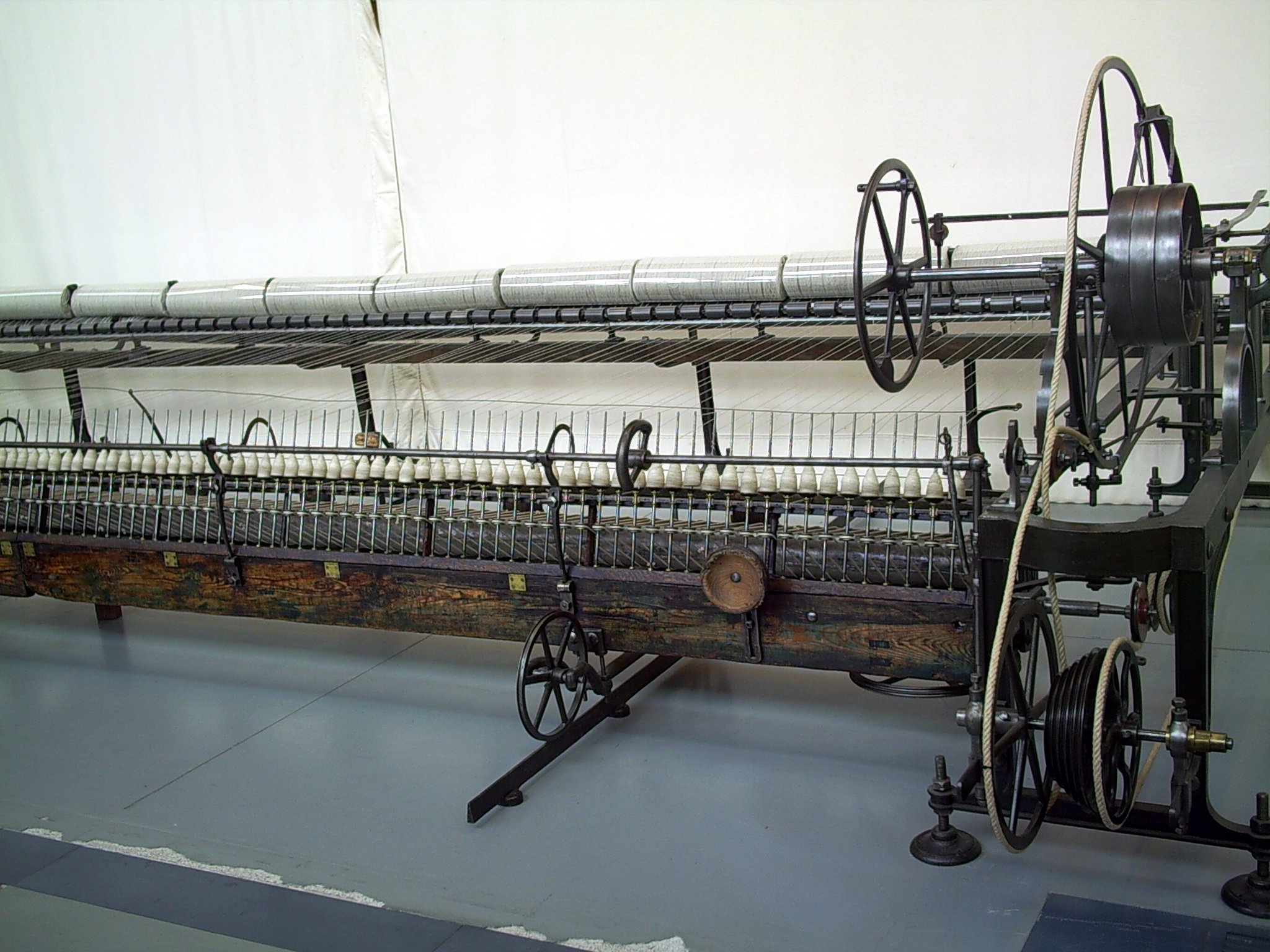

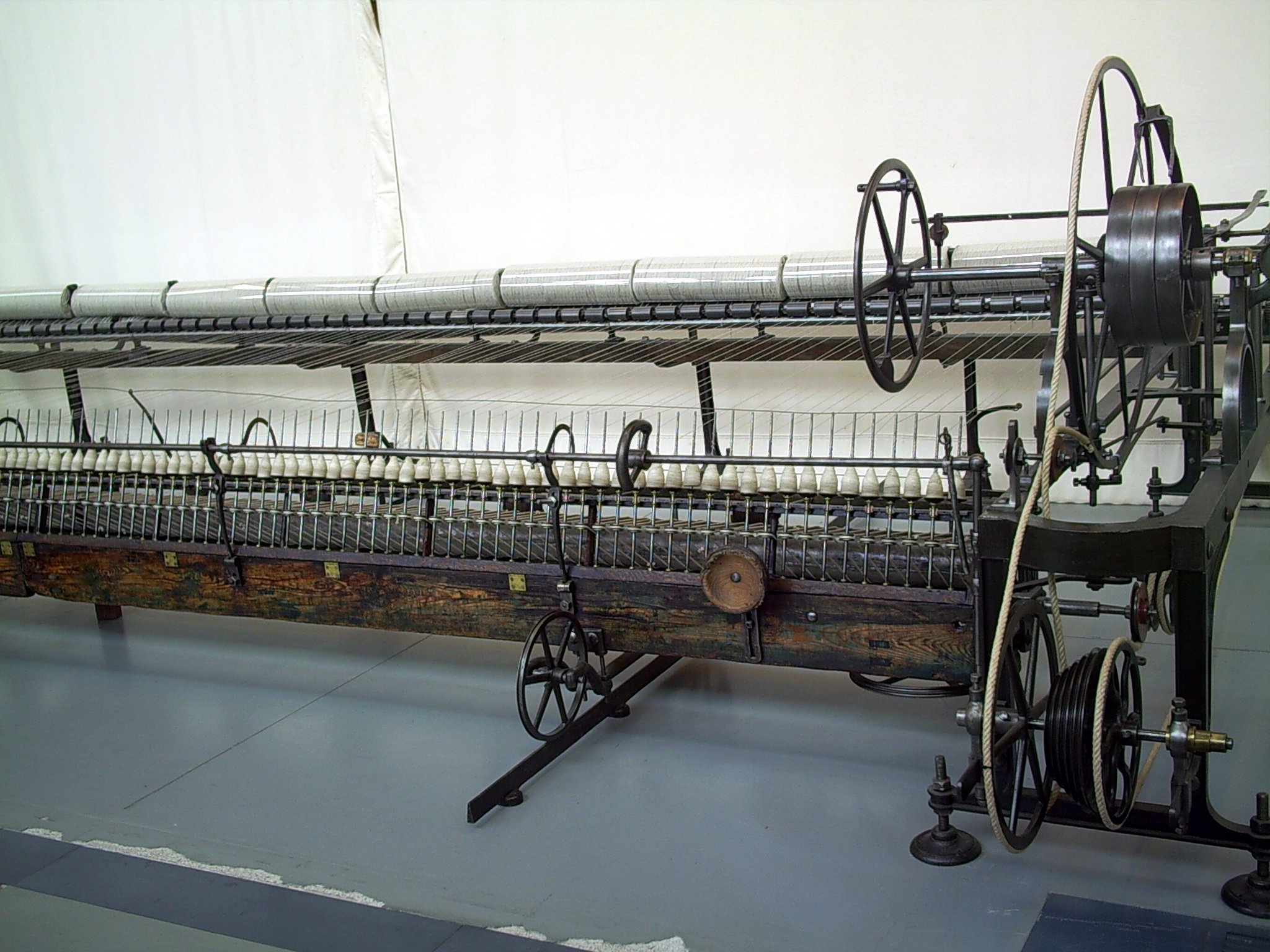

In a spinning mule

The spinning mule is a machine used to spin cotton and other fibres. They were used extensively from the late 18th to the early 20th century in the mills of Lancashire and elsewhere. Mules were worked in pairs by a minder, with the help of tw ...

, the roving is pulled off bobbins and sequentially fed through rollers operating at several different speeds, thinning the roving at a consistent rate. The yarn is twisted through the spinning of the bobbin as the carriage moves out, and is rolled onto a cop as the carriage returns. Mule spinning produces a finer thread than ring spinning. Spinning by the mule machine is an intermittent process as the frame advances and returns. It is the descendant of a device invented in 1779 by Samuel Crompton

Samuel Crompton (3 December 1753 – 26 June 1827) was an English inventor and pioneer of the spinning industry. Building on the work of James Hargreaves and Richard Arkwright he invented the spinning mule, a machine that revolutionised th ...

, and produces a softer, less twisted thread that is favored for fines and for weft

Warp and weft are the two basic components used in weaving to turn thread or yarn into fabric. The lengthwise or longitudinal warp yarns are held stationary in tension on a frame or loom while the transverse weft (sometimes woof) is dra ...

.

The ring was a descendant of the Arkwright water frame

The water frame is a spinning frame that is powered by a water-wheel. Water frames in general have existed since Ancient Egypt times. Richard Arkwright, who patented the technology in 1769, designed a model for the production of cotton thread; ...

of 1769 and creates yarn in a continuous process. The yarn is coarser, has a greater twist, and is stronger, making it more suitable for warp

Warp, warped or warping may refer to:

Arts and entertainment Books and comics

* WaRP Graphics, an alternative comics publisher

* ''Warp'' (First Comics), comic book series published by First Comics based on the play ''Warp!''

* Warp (comics), a ...

. Ring spinning is slow due to the distance the thread must pass around the ring. Similar methods have improved on this including flyer and bobbin and cap spinning.

The pre-industrial techniques of hand spinning

Spinning is an ancient textile arts, textile art in which fibre crop, plant, animal fibre, animal or synthetic fibre, synthetic fibres are drawn out and twisted together to form yarn. For thousands of years, fibre was spun by hand using simple ...

with a spindle or spinning wheel

A spinning wheel is a device for spinning thread or yarn from fibres. It was fundamental to the cotton textile industry prior to the Industrial Revolution. It laid the foundations for later machinery such as the spinning jenny and spinning f ...

continue to be practiced as handicraft or hobby and enable wool or unusual vegetable and animal staples to be used.

History and economics

Meroë

Meroë (; also spelled ''Meroe''; Meroitic: or ; ar, مرواه, translit=Meruwah and ar, مروي, translit=Meruwi, label=none; grc, Μερόη, translit=Meróē) was an ancient city on the east bank of the Nile about 6 km north-east ...

reached a high level around the 4th century BC. The export of textiles was one of the sources of wealth for Meroë.

Hand spinning

Spinning is an ancient textile arts, textile art in which fibre crop, plant, animal fibre, animal or synthetic fibre, synthetic fibres are drawn out and twisted together to form yarn. For thousands of years, fibre was spun by hand using simple ...

was an important cottage industry in medieval Europe, where the wool spinners (most often women and children) would provide enough yarn to service the needs of the men who operated the looms or to sell on in the putting-out system

The putting-out system is a means of subcontracting work. Historically, it was also known as the workshop system and the domestic system. In putting-out, work is contracted by a central agent to subcontractors who complete the project via remote w ...

. After the invention of the spinning jenny

The spinning jenny is a multi- spindle spinning frame, and was one of the key developments in the industrialization of textile manufacturing during the early Industrial Revolution. It was invented in 1764 or 1765 by James Hargreaves in Sta ...

water frame

The water frame is a spinning frame that is powered by a water-wheel. Water frames in general have existed since Ancient Egypt times. Richard Arkwright, who patented the technology in 1769, designed a model for the production of cotton thread; ...

the demand was greatly reduced by mechanization. Its technology was specialized and costly and employed water as motive power. Spinning and weaving as cottage industries were displaced by dedicated manufactories, developed by industrialists and their investors; the spinning and weaving industries, once widespread, were concentrated where the sources of water, raw materials, and manpower were most readily available, particularly West Yorkshire

West Yorkshire is a metropolitan and ceremonial county in the Yorkshire and Humber Region of England. It is an inland and upland county having eastward-draining valleys while taking in the moors of the Pennines. West Yorkshire came into exi ...

. The British government was very protective of the technology and restricted its export. After World War I

World War I (28 July 1914 11 November 1918), often abbreviated as WWI, was one of the deadliest global conflicts in history. Belligerents included much of Europe, the Russian Empire, the United States, and the Ottoman Empire, with fightin ...

the colonies where the cotton was grown started to purchase and manufacture significant quantities of cotton spinning machinery. The next breakthrough was with the move over to break or open-end spinning, and then the adoption of artificial fibres

Synthetic fibers or synthetic fibres (in British English; see spelling differences) are fibers made by humans through chemical synthesis, as opposed to natural fibers that are directly derived from living organisms, such as plants (like cotton) ...

. By then most production had moved to Asia.

During the Industrial Revolution

The Industrial Revolution was the transition to new manufacturing processes in Great Britain, continental Europe, and the United States, that occurred during the period from around 1760 to about 1820–1840. This transition included going f ...

, spinners, doffer

A doffer is someone who removes ("doffs") bobbins, pirns or spindles holding spun fiber such as cotton or wool from a spinning frame and replaces them with empty ones. Historically, spinners, doffers, and sweepers each had separate tasks that w ...

s, and sweepers were employed in spinning mills from the 18th to 20th centuries. Many mill owners preferred to employ children due to their small size and agility.

See also

*Wet processing engineering

Wet Processing Engineering is one of the major streams in Textile Engineering or Textile manufacturing which refers to the engineering of textile chemical processes and associated applied science. The other three streams in textile engineering a ...

* Textile manufacturing

Textile Manufacturing or Textile Engineering is a major industry. It is largely based on the conversion of fibre into yarn, then yarn into fabric. These are then dyed or printed, fabricated into cloth which is then converted into useful goods ...

* Clothing technology

* Dref Friction Spinning

Friction Spinning or Dref Spinning is a textile technology that suitable for spinning coarse counts of yarns and technical core-wrapped yarns. Dref yarns are bulky, with low tensile strength making them suitable for blankets and mop yarns, the ...

* Spinster

''Spinster'' is a term referring to an unmarried woman who is older than what is perceived as the prime age range during which women usually marry. It can also indicate that a woman is considered unlikely to ever marry. The term originally den ...

* Blend (textile)

A blend is a mixture of two or more fibers. In yarn spinning, different compositions, lengths, diameters, or colors may be combined to create a blend. Blended textiles are fabrics or yarns produced with a combination of two or more types of diffe ...

* Yarn realisation

In textile spinning, yarn realisation (YR), or yarn recovery, is an operational parameter of yarn manufacturing. It is the percentage conversion of raw material to finished yarn. The rest of the waste fibers with less value are compared to the weig ...

References

Bibliography

*External links

Trowbridge medieval spinning industry

{{Authority control Textile engineering History of the textile industry