Tunnel crankshaft on:

[Wikipedia]

[Google]

[Amazon]

A tunnel crankcase, tunnel crankshaft or disc-webbed crankshaft engine is a design feature of a

With the development of the high-speed diesel engine around 1930, powerful diesel engines became available in the sizes previously used by lower-powered petrol engines. In particular, their high BMEP and high torque led to high forces on the crankshaft bearings. These forces were greater than could be sustained by the small

With the development of the high-speed diesel engine around 1930, powerful diesel engines became available in the sizes previously used by lower-powered petrol engines. In particular, their high BMEP and high torque led to high forces on the crankshaft bearings. These forces were greater than could be sustained by the small

A later development was to enlarge the main bearings sufficiently to be larger than the entire crank web. This now permitted the use of a one piece crankshaft

A tunnel crankshaft is considered to be a 'tunnel' if the outside diameter ''over the outer race of the installed bearings'' is larger than the maximum size of the webs. Early, or smaller, engines may have had crankshafts with bearing journalsThe 'journal' is the part of the ''shaft'' forming the bearing, the ''bearing races'' are a separate component that fits over this. smaller than this, but were still considered as such because they were larger when the bearings were fitted.

To avoid passing the entire crankshaft through the bearings, the bearing diameters were usually stepped in size, in a conical progression. Each bearing now only needed to be slid through the length of its own width, being small enough to pass easily through any preceding housings. This meant that the crankshaft could only be inserted from one end of the crankcase.

A later development was to enlarge the main bearings sufficiently to be larger than the entire crank web. This now permitted the use of a one piece crankshaft

A tunnel crankshaft is considered to be a 'tunnel' if the outside diameter ''over the outer race of the installed bearings'' is larger than the maximum size of the webs. Early, or smaller, engines may have had crankshafts with bearing journalsThe 'journal' is the part of the ''shaft'' forming the bearing, the ''bearing races'' are a separate component that fits over this. smaller than this, but were still considered as such because they were larger when the bearings were fitted.

To avoid passing the entire crankshaft through the bearings, the bearing diameters were usually stepped in size, in a conical progression. Each bearing now only needed to be slid through the length of its own width, being small enough to pass easily through any preceding housings. This meant that the crankshaft could only be inserted from one end of the crankcase.

; Bearing diameter

Larger bearings can support the loads of these higher-force engines.

; Use of roller bearings

These can cope with the greater forces and higher speeds of the new high-speed engines.

; Assembly

The crankshaft can be inserted into an assembled crankcase, rather than the bearing caps being assembled around it. This is usually done by rotating the crankcase end-upwards and then lowering the crankshaft vertically into it.

This was a noted feature of some 1960s Maybach engines, used for diesel locomotives.

; Reduced crankshaft length

The length previously required for one web + bearing + web group is now replaced by a single bearing length, also acting as both webs.

As this reduced crankshaft length also reduces the spacing between cylinders, it was one factor in encouraging the use of tunnel crankshafts in

; Bearing diameter

Larger bearings can support the loads of these higher-force engines.

; Use of roller bearings

These can cope with the greater forces and higher speeds of the new high-speed engines.

; Assembly

The crankshaft can be inserted into an assembled crankcase, rather than the bearing caps being assembled around it. This is usually done by rotating the crankcase end-upwards and then lowering the crankshaft vertically into it.

This was a noted feature of some 1960s Maybach engines, used for diesel locomotives.

; Reduced crankshaft length

The length previously required for one web + bearing + web group is now replaced by a single bearing length, also acting as both webs.

As this reduced crankshaft length also reduces the spacing between cylinders, it was one factor in encouraging the use of tunnel crankshafts in

Many small crankcase compression two-stroke engines have a crankshaft with large circular webs, similar to the tunnel crankshaft. However these webs are merely webs, not bearings, and their bearings are of conventional small diameter alongside the webs. These enlarged webs are used instead to increase the

Many small crankcase compression two-stroke engines have a crankshaft with large circular webs, similar to the tunnel crankshaft. However these webs are merely webs, not bearings, and their bearings are of conventional small diameter alongside the webs. These enlarged webs are used instead to increase the

diesel engine

The diesel engine, named after Rudolf Diesel, is an internal combustion engine in which ignition of the fuel is caused by the elevated temperature of the air in the cylinder due to mechanical compression; thus, the diesel engine is a so-ca ...

or petrol engine where the crankshaft is designed so that the main bearings (the bearings that support the crankshaft within the crankcase

In a piston engine, the crankcase is the housing that surrounds the crankshaft. In most modern engines, the crankcase is integrated into the engine block.

Two-stroke engines typically use a crankcase-compression design, resulting in the fuel/ ...

) are enlarged in diameter, such that they are now larger than the crank webs (the radial arms that link the big end bearings to the main bearings). They thus form the largest diameter of any part of the crankshaft. Rather than a conventional crankcase that has webs across it to support the narrow bearings of a conventional crankcase, the crankcase now has a large tunnel through it, hence the name.

Tunnel crankcases appeared in the 1930s with the first high-speed diesel engines. They were favoured by some makers more than others, notably Saurer

Adolph Saurer AG was a Swiss manufacturer of embroidery and textile machines, trucks and buses under the Saurer and Berna (beginning in 1929) brand names. Based in Arbon, Switzerland, the firm was active between 1903 and 1982. Their vehicles wer ...

in Switzerland and Maybach-Motorenbau GmbH

Maybach (, ) is a German luxury car brand that exists today as a part of Mercedes-Benz. The original company was founded in 1909 by Wilhelm Maybach and his son Karl Maybach, originally as a subsidiary of ''Luftschiffbau Zeppelin GmbH'', and ...

(now MTU) Friedrichshafen

Friedrichshafen ( or ; Low Alemannic: ''Hafe'' or ''Fridrichshafe'') is a city on the northern shoreline of Lake Constance (the ''Bodensee'') in Southern Germany, near the borders of both Switzerland and Austria. It is the district capital (''K ...

. They are described as both 'tunnel crankcases' and 'roller bearing

In mechanical engineering, a rolling-element bearing, also known as a rolling bearing, is a bearing which carries a load by placing rolling elements (such as balls or rollers) between two concentric, grooved rings called races. The relative m ...

cranks'; the two aspects are related and it is unclear as to which gave rise to the other.

Origins

whitemetal bearing

The white metals are a series of often decorative bright metal alloys used as a base for plated silverware, ornaments or novelties, as well as any of several lead-based or tin-based alloys used for things like bearings, jewellery, miniatur ...

s used for petrol engines. Although aircraft and sports car engines in the 1920s developed to have considerable power in a small space, these were high maintenance machines with regular servicing. The new diesels were intended for long commercial service where maintenance was a key cost to be reduced.

The need for an improved bearing technology led to the adoption of roller bearing

In mechanical engineering, a rolling-element bearing, also known as a rolling bearing, is a bearing which carries a load by placing rolling elements (such as balls or rollers) between two concentric, grooved rings called races. The relative m ...

s, rather than whitemetal. Although they might be considered esoteric today, ball and roller crankshaft bearings were already in use in the 1920s for such mundane engines as the Austin 7

The Austin 7 is an economy car that was produced from 1923 until 1939 in the United Kingdom by Austin. It was nicknamed the "Baby Austin" and was at that time one of the most popular cars produced for the British market and sold well abroad ...

.

Roller bearings require one-piece races for both inner and outer bearing tracks. Although split races are possible, they are expensive and difficult to fit.Split-race roller bearings have been used for the centre big-end bearing in the connecting rod of some three-cylinder steam locomotive

A steam locomotive is a locomotive that provides the force to move itself and other vehicles by means of the expansion of steam. It is fuelled by burning combustible material (usually coal, oil or, rarely, wood) to heat water in the loco ...

s. As the crank axle is complex and also includes the wheels, it is impossible to fit roller bearings to the centre in any other way. Whitemetal bearings were much more common, but were a recognised weak point of some classes, such as the LNER A4

The Class A4 is a class of streamlined 4-6-2 steam locomotive designed by Nigel Gresley for the London and North Eastern Railway in 1935. Their streamlined design gave them high-speed capability as well as making them instantly recognisable, and ...

A simpler means of fitting roller bearings is to enlarge the diameter of the bearing, so that it becomes larger than the entire crankshaft web. Assembly is now done by putting the outer race of the bearing over the crankshaft axially from one end, rather than by assembling two pieces radially.

An early development was the semi-tunnel crankshaft. This used large ball or roller bearings of the tunnel style for their centre bearings, but the end bearings (carrying the load of pistons on only a single side) remained with a small diameter bearing of conventional style. This reduced the bearing cost, and also reduced the linear speed of these smaller bearings. This was important as it also reduced the speed of the crankcase oil seals alongside them.

Roller bearing crankshafts were favoured in central Europe: Germany, Switzerland and Czechoslovakia, owing to the local development and predominance of rolling-element bearing

In mechanical engineering, a rolling-element bearing, also known as a rolling bearing, is a bearing which carries a load by placing rolling elements (such as balls or rollers) between two concentric, grooved rings called races. The relative m ...

s, in contrast to the improved metallurgy being developed for plain bearing

A plain bearing, or more commonly sliding contact bearing and slide bearing (in railroading sometimes called a solid bearing, journal bearing, or friction bearing), is the simplest type of bearing, comprising just a bearing surface and no roll ...

materials in the English-speaking world.

Maybach petrol engines

Tunnel crankshafts were only rarely applied topetrol engine

A petrol engine (gasoline engine in American English) is an internal combustion engine designed to run on petrol (gasoline). Petrol engines can often be adapted to also run on fuels such as liquefied petroleum gas and ethanol blends (such as '' ...

s. The development of large powerful engines, outside the rarefied aerospace material

Aerospace materials are materials, frequently metal alloys, that have either been developed for, or have come to prominence through their use for aerospace purposes.

These uses often require exceptional performance, strength or heat resistance, ...

s of aircraft engine

An aircraft engine, often referred to as an aero engine, is the power component of an aircraft propulsion system. Most aircraft engines are either piston engines or gas turbines, although a few have been rocket powered and in recent years ma ...

s, coincided with the development of practical lightweight diesel engines that tended to supplant petrol.

One market that remained with petrol was that of engines for airship

An airship or dirigible balloon is a type of aerostat or lighter-than-air aircraft that can navigate through the air under its own power. Aerostats gain their lift from a lifting gas that is less dense than the surrounding air.

In early ...

s, a market in which Maybach

Maybach (, ) is a German luxury car brand that exists today as a part of Mercedes-Benz. The original company was founded in 1909 by Wilhelm Maybach and his son Karl Maybach, originally as a subsidiary of '' Luftschiffbau Zeppelin GmbH'', a ...

was predominant. Although diesel engines were developed for airship use, these were generally unsuccessful. The British Beardmore Tornado was based on medium-speed diesel engine practice and was both heavy, underpowered and unreliable. Only Maybach

Maybach (, ) is a German luxury car brand that exists today as a part of Mercedes-Benz. The original company was founded in 1909 by Wilhelm Maybach and his son Karl Maybach, originally as a subsidiary of '' Luftschiffbau Zeppelin GmbH'', a ...

made significant use of tunnel crankshafts for petrol engines, with both its airship engines and also a number of World War II

World War II or the Second World War, often abbreviated as WWII or WW2, was a world war that lasted from 1939 to 1945. It involved the World War II by country, vast majority of the world's countries—including all of the great power ...

tank engines, such as the Maybach HL210 and HL230. These engines were used across all of the German medium and heavy tanks. Thousands of these engines were produced, although surviving examples are now extremely rare, particularly in working order.

Maybach diesel engines

After the war, Maybach applied its knowledge of compact, high-speed engines to diesel engines, for the emerging market in diesel railway locomotives. These engines contrasted with those from other makers by being particularly powerful, both by weight and by volume. This was especially the case for the length, as Maybach's engines used a compact V layout at a time when most makers were still building long single-bank inline engines. Maybach's name became particularly associated with the tunnel crankcase design and these engines are still the best-known uses of the tunnel crankshaft. These engines were widely used in Germany, for locomotives such as the V200 class. In the UK they were both imported and also built locally under licence. Following German practice, these high-speed engines were used in conjunction with a hydraulic transmission, in order to produce a powerful, but lightweight locomotive, compared to the competing diesel-electric designs. The engines were also sold to the USA, although there they were used in the more established diesel-electric designs.Built-up and one-piece cranks

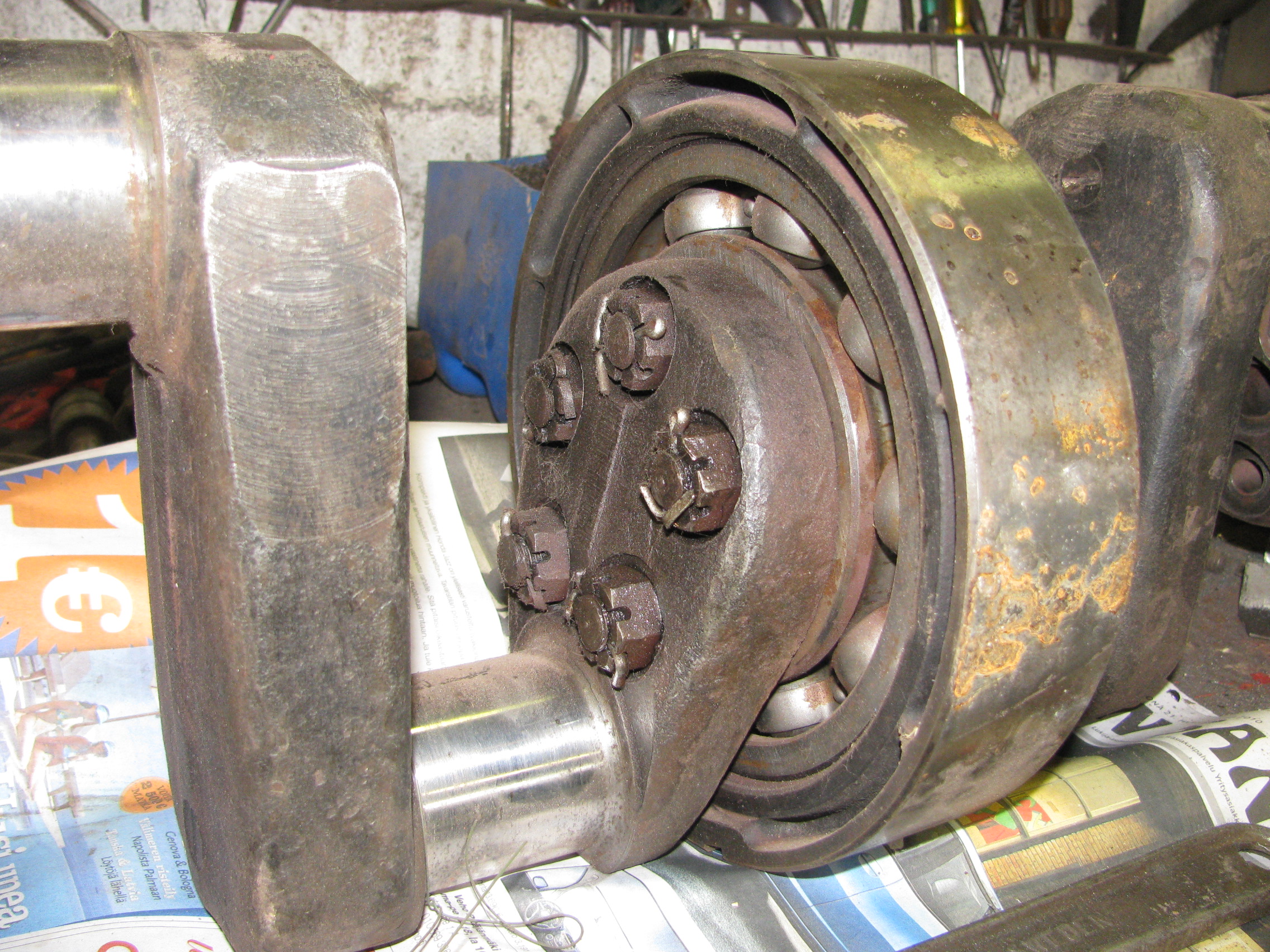

The first tunnel crankshafts were built-up with webs bolted to the side of the main bearings, much as for a conventional crankshaft, only larger (see cross-section illustration of the Saurer engine). Examples of these were also built by John Fowler & Co. in England. A later development was to enlarge the main bearings sufficiently to be larger than the entire crank web. This now permitted the use of a one piece crankshaft

A tunnel crankshaft is considered to be a 'tunnel' if the outside diameter ''over the outer race of the installed bearings'' is larger than the maximum size of the webs. Early, or smaller, engines may have had crankshafts with bearing journalsThe 'journal' is the part of the ''shaft'' forming the bearing, the ''bearing races'' are a separate component that fits over this. smaller than this, but were still considered as such because they were larger when the bearings were fitted.

To avoid passing the entire crankshaft through the bearings, the bearing diameters were usually stepped in size, in a conical progression. Each bearing now only needed to be slid through the length of its own width, being small enough to pass easily through any preceding housings. This meant that the crankshaft could only be inserted from one end of the crankcase.

A later development was to enlarge the main bearings sufficiently to be larger than the entire crank web. This now permitted the use of a one piece crankshaft

A tunnel crankshaft is considered to be a 'tunnel' if the outside diameter ''over the outer race of the installed bearings'' is larger than the maximum size of the webs. Early, or smaller, engines may have had crankshafts with bearing journalsThe 'journal' is the part of the ''shaft'' forming the bearing, the ''bearing races'' are a separate component that fits over this. smaller than this, but were still considered as such because they were larger when the bearings were fitted.

To avoid passing the entire crankshaft through the bearings, the bearing diameters were usually stepped in size, in a conical progression. Each bearing now only needed to be slid through the length of its own width, being small enough to pass easily through any preceding housings. This meant that the crankshaft could only be inserted from one end of the crankcase.

Advantages

; Bearing diameter

Larger bearings can support the loads of these higher-force engines.

; Use of roller bearings

These can cope with the greater forces and higher speeds of the new high-speed engines.

; Assembly

The crankshaft can be inserted into an assembled crankcase, rather than the bearing caps being assembled around it. This is usually done by rotating the crankcase end-upwards and then lowering the crankshaft vertically into it.

This was a noted feature of some 1960s Maybach engines, used for diesel locomotives.

; Reduced crankshaft length

The length previously required for one web + bearing + web group is now replaced by a single bearing length, also acting as both webs.

As this reduced crankshaft length also reduces the spacing between cylinders, it was one factor in encouraging the use of tunnel crankshafts in

; Bearing diameter

Larger bearings can support the loads of these higher-force engines.

; Use of roller bearings

These can cope with the greater forces and higher speeds of the new high-speed engines.

; Assembly

The crankshaft can be inserted into an assembled crankcase, rather than the bearing caps being assembled around it. This is usually done by rotating the crankcase end-upwards and then lowering the crankshaft vertically into it.

This was a noted feature of some 1960s Maybach engines, used for diesel locomotives.

; Reduced crankshaft length

The length previously required for one web + bearing + web group is now replaced by a single bearing length, also acting as both webs.

As this reduced crankshaft length also reduces the spacing between cylinders, it was one factor in encouraging the use of tunnel crankshafts in V engine

A V engine, sometimes called a Vee engine, is a common configuration for internal combustion engines. It consists of two cylinder banks—usually with the same number of cylinders in each bank—connected to a common crankshaft. These cylinder ...

s, where there is more axial distance available between adjacent cylinders. This further reduces the overall length of tunnel crankshaft engines.

; Increased crankshaft stiffness

The crankshaft, particularly along the webs, becomes wider and so stiffer.

Disadvantages

; Increased linear bearing speed By simple geometry, as the bearing diameter increases, so too does the linear speed at the bearing surface. This exceeds that possible for whitemetal bearings. Roller bearings were thus not only one reason for the enlarged tunnel crankshaft, but they were also made necessary by it. ; Crankshaft manufacturing The diameter and mass of the crankshaft is increased, such that it will no longer fit into standard crankshaft grinding machines and may require specialised machinery for their manufacture. Although the reduced length of the crankshaft may allow large engines to be built with shorter machinery. ; Crankshaft inertia The enlarged webs have greater mass, thus greater rotational inertia, particularly as they place this mass at the greatest radius away from the axis of the crankshaft. This gives an engine that is slower to accelerate, although it also means that the engine maintains a constant speed more easily under a rapidly varying load. For this reason, the tunnel crankshaft is most appropriate to engines running for long periods at constant speed, such as generator sets, railway locomotives and boats. They are not used for cars, where rapid acceleration and deceleration is needed. ; Crankcase rigidity The large amount of material removed from the crankcase to provide the tunnel does not allow as much space for stiffening webs across the crankcase, so the overall rigidity of the crankcase may be less.Two-stroke engines

Many small crankcase compression two-stroke engines have a crankshaft with large circular webs, similar to the tunnel crankshaft. However these webs are merely webs, not bearings, and their bearings are of conventional small diameter alongside the webs. These enlarged webs are used instead to increase the

Many small crankcase compression two-stroke engines have a crankshaft with large circular webs, similar to the tunnel crankshaft. However these webs are merely webs, not bearings, and their bearings are of conventional small diameter alongside the webs. These enlarged webs are used instead to increase the compression ratio

The compression ratio is the ratio between the volume of the cylinder and combustion chamber in an internal combustion engine at their maximum and minimum values.

A fundamental specification for such engines, it is measured two ways: the stat ...

of the engine. By filling more of the 'dead' crankcase volume, the ratio between the swept volume of the cylinder and the remaining crankcase volume is increased.

Some multi-cylinder two-stroke engines also use crankcase compression, almost all of them marine outboard motor

An outboard motor is a propulsion system for boats, consisting of a self-contained unit that includes engine, gearbox and propeller or jet drive, designed to be affixed to the outside of the transom. They are the most common motorised method o ...

s. In these engines, the separate crankcase volume for each cylinder must be kept separate. The webs are thus made circular, large and sealed by gas seals on their outer circumference. Again, these are not considered as tunnel crankshafts if the webs only carry a seal, but may be so if the large web also forms the bearing.

See also

* Eccentric, a similar approach for cranks that are ''driven by'' the axle, particularly for steam locomotive valve gear. The eccentric is enlarged in diameter until it too is bigger than the overall diameter of the crank web. *Undercut crankshaft

An undercut crankshaft is a form of crankshaft for piston engines, where the overall length of the crankshaft is shortened by overlapping the main bearings of the crankshaft with the big end bearings of the connecting rods.

Although this seems i ...

, a technique for shortening the overall length of a crankshaft by overlapping the bearings.

References

{{Reflist, colwidth=30em Diesel engine technology Crankshafts