Thermosonic Bonding on:

[Wikipedia]

[Google]

[Amazon]

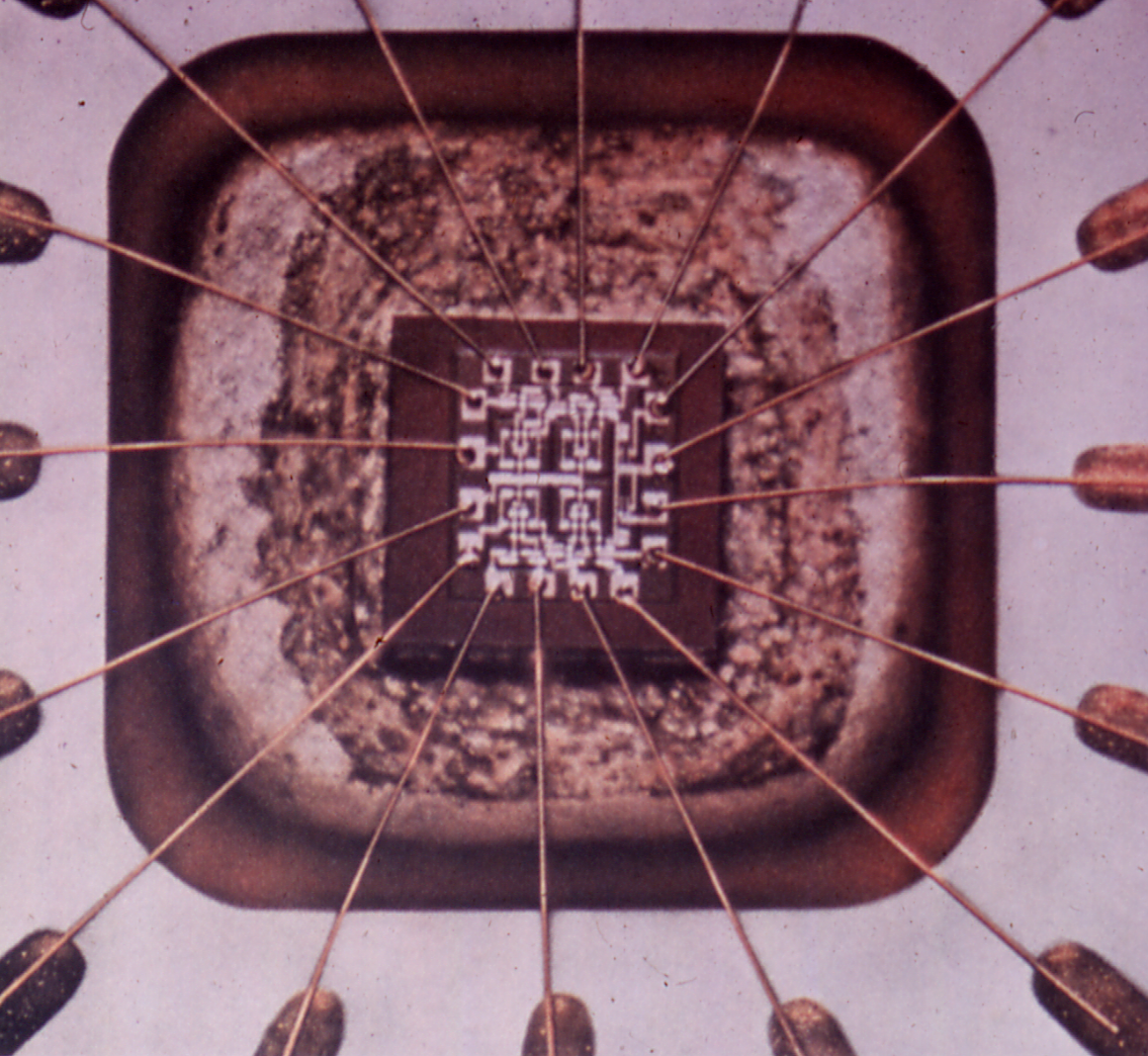

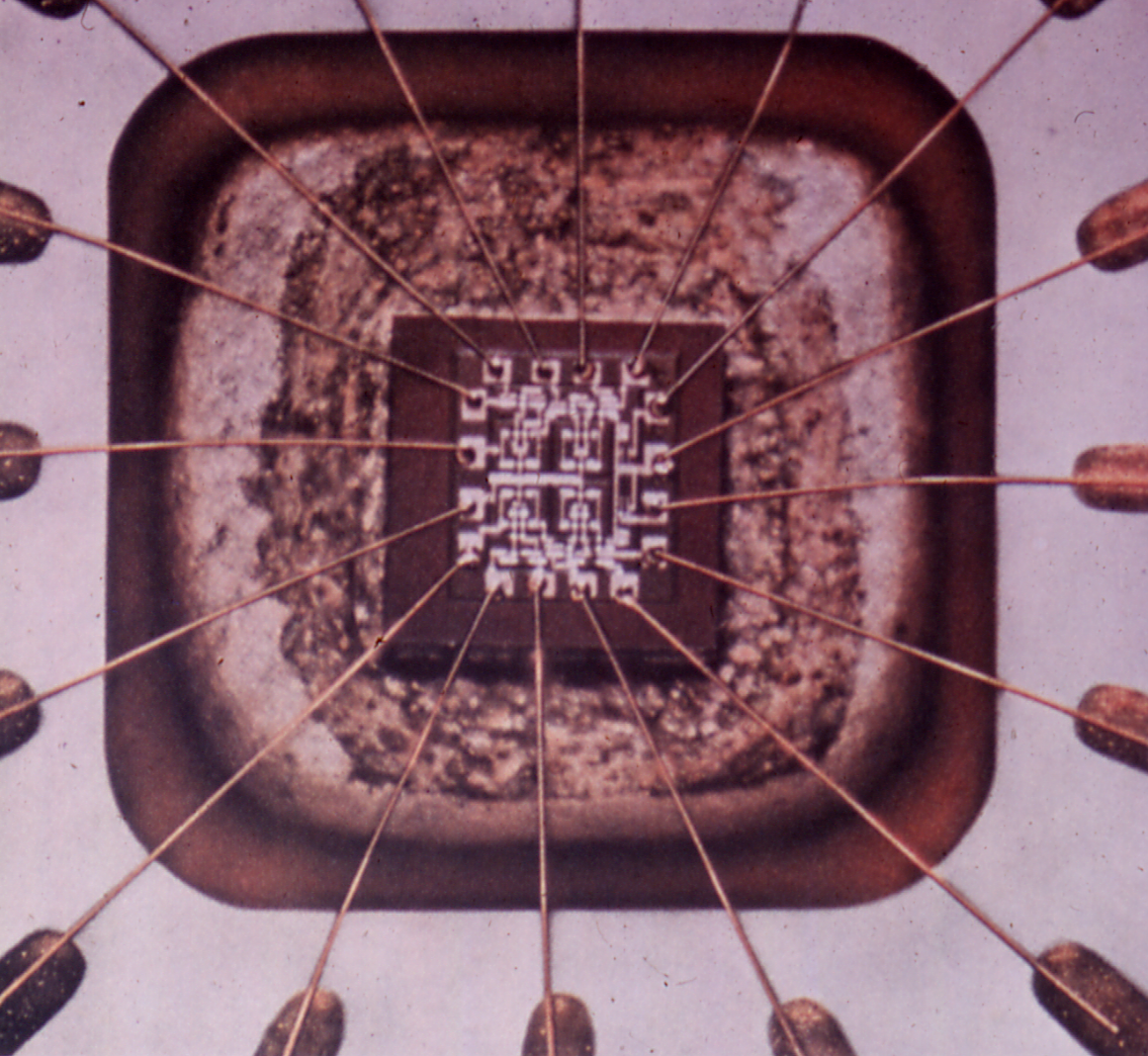

Thermosonic bonding is widely used to wire bond silicon

A thermosonic bond falls in the category of a solid state metallic bond which is formed by mating two metal surfaces well below their respective melting points. Coucoulas introduced Thermosonic bonding which significantly improved upon the bond-reliability produced by available commercial solid-state bonding machines where he pre-heated the lead wire (and/or metallized silicon chip) prior to introducing an ultrasonic energy cycle. In addition to thermal softening the lead wire, the subsequent delivery of ultrasonic energy produced further softening by interacting at the atomic lattice level of the heated wire (known as ultrasonic softening). These two independent softening mechanisms (pre-heating lead wire and delivering the ultrasonic energy at the atomic lattice level) eliminated the incidences of cracking the fragile and costly silicon chip which were observed by Coucoulas when using earlier commercially available solid-state bonding machines. The improvement occurs because pre-heating and ultrasonic softening the lead-wire dramatically facilitated its deformation in forming the required contact area while using a relatively low set of bonding parameters. Depending on the temperature level and material properties of the lead wire, the onset of

A thermosonic bond falls in the category of a solid state metallic bond which is formed by mating two metal surfaces well below their respective melting points. Coucoulas introduced Thermosonic bonding which significantly improved upon the bond-reliability produced by available commercial solid-state bonding machines where he pre-heated the lead wire (and/or metallized silicon chip) prior to introducing an ultrasonic energy cycle. In addition to thermal softening the lead wire, the subsequent delivery of ultrasonic energy produced further softening by interacting at the atomic lattice level of the heated wire (known as ultrasonic softening). These two independent softening mechanisms (pre-heating lead wire and delivering the ultrasonic energy at the atomic lattice level) eliminated the incidences of cracking the fragile and costly silicon chip which were observed by Coucoulas when using earlier commercially available solid-state bonding machines. The improvement occurs because pre-heating and ultrasonic softening the lead-wire dramatically facilitated its deformation in forming the required contact area while using a relatively low set of bonding parameters. Depending on the temperature level and material properties of the lead wire, the onset of

"Packaging Of Power LEDs Using Thermosonic Bonding Of Au-Au Interconnects"

Surface Mount Technology Association International Conference.

integrated circuits

An integrated circuit or monolithic integrated circuit (also referred to as an IC, a chip, or a microchip) is a set of electronic circuits on one small flat piece (or "chip") of semiconductor material, usually silicon. Large numbers of tiny ...

into computers. Alexander Coucoulas was named "Father of Thermosonic Bonding" by George Harman, the world's foremost authority on wire bonding, where he referenced Coucoulas's leading edge publications in his book, ''Wire Bonding In Microelectronics''.Coucoulas, A., Trans. Metallurgical Society Of AIME, "Ultrasonic Welding of Aluminum Leads to Tantalum Thin Films", 1966, pp. 587–589. abstract https://sites.google.com/site/coucoulasthermosonicbondaltaCoucoulas, A., "Hot Work Ultrasonic Bonding – A Method Of Facilitating Metal Flow By Restoration Processes", Proc. 20th IEEE Electronic Components Conf. Washington, D.C., May 1970, pp. 549–556.https://sites.google.com/site/hotworkultrasonicbonding Owing to the well proven reliability of thermosonic bonds, it is extensively used to connect the central processing unit

A central processing unit (CPU), also called a central processor, main processor or just processor, is the electronic circuitry that executes instructions comprising a computer program. The CPU performs basic arithmetic, logic, controlling, an ...

s (CPUs), which are encapsulated silicon integrated circuits

An integrated circuit or monolithic integrated circuit (also referred to as an IC, a chip, or a microchip) is a set of electronic circuits on one small flat piece (or "chip") of semiconductor material, usually silicon. Large numbers of tiny ...

that serve as the "brains" of today's computers.

Description

A thermosonic bond is formed using a set of parameters which include ultrasonic, thermal and mechanical (force) energies. A thermosonic bonding machine includes a magnetostrictive or piezoelectric-type transducer which is used to convert electrical energy into vibratory motion which is known aspiezoelectricity

Piezoelectricity (, ) is the electric charge that accumulates in certain solid materials—such as crystals, certain ceramics, and biological matter such as bone, DNA, and various proteins—in response to applied mechanical stress. The word ''p ...

. The vibratory motion travels along the coupler system, a portion which is tapered to serve as the velocity transformer. The velocity transformer amplifies the oscillatory motion and delivers it to a heated bonding tip. It is akin to a friction bond, since the introduction of ultrasonic energy (via a bonding tool vertically attached to an ultrasonic transformer or horn) simultaneously delivers a force and vibratory or scrubbing motion to the interfacial contact points between a pre-heated deforming lead-wire and the metallized pads of a silicon integrated circuit. In addition to the delivery of thermal energy, the transmission of ultrasonic vibratory energy creates an ultrasonic softening effect by interacting at the atomic lattice level of the preheated lead wire. These two softening effects dramatically facilitates the lead wire deformation by forming the desirable contact area using relatively low temperatures and forces. As a result of the frictional action and ultrasonic softening induced in the preheated lead wire during the bonding cycle, thermosonic bonding can be used to reliably bond high melting point lead wires (such as gold and lower cost aluminum and copper) using relatively low bonding parameters. This ensures that the fragile and costly silicon integrated circuit chip is not exposed to potentially damaging conditions by having to use higher bonding parameters (ultrasonic energy, temperatures or mechanical forces) to deform the lead wire in forming the required contact area during the bonding process.

Background

A thermosonic bond falls in the category of a solid state metallic bond which is formed by mating two metal surfaces well below their respective melting points. Coucoulas introduced Thermosonic bonding which significantly improved upon the bond-reliability produced by available commercial solid-state bonding machines where he pre-heated the lead wire (and/or metallized silicon chip) prior to introducing an ultrasonic energy cycle. In addition to thermal softening the lead wire, the subsequent delivery of ultrasonic energy produced further softening by interacting at the atomic lattice level of the heated wire (known as ultrasonic softening). These two independent softening mechanisms (pre-heating lead wire and delivering the ultrasonic energy at the atomic lattice level) eliminated the incidences of cracking the fragile and costly silicon chip which were observed by Coucoulas when using earlier commercially available solid-state bonding machines. The improvement occurs because pre-heating and ultrasonic softening the lead-wire dramatically facilitated its deformation in forming the required contact area while using a relatively low set of bonding parameters. Depending on the temperature level and material properties of the lead wire, the onset of

A thermosonic bond falls in the category of a solid state metallic bond which is formed by mating two metal surfaces well below their respective melting points. Coucoulas introduced Thermosonic bonding which significantly improved upon the bond-reliability produced by available commercial solid-state bonding machines where he pre-heated the lead wire (and/or metallized silicon chip) prior to introducing an ultrasonic energy cycle. In addition to thermal softening the lead wire, the subsequent delivery of ultrasonic energy produced further softening by interacting at the atomic lattice level of the heated wire (known as ultrasonic softening). These two independent softening mechanisms (pre-heating lead wire and delivering the ultrasonic energy at the atomic lattice level) eliminated the incidences of cracking the fragile and costly silicon chip which were observed by Coucoulas when using earlier commercially available solid-state bonding machines. The improvement occurs because pre-heating and ultrasonic softening the lead-wire dramatically facilitated its deformation in forming the required contact area while using a relatively low set of bonding parameters. Depending on the temperature level and material properties of the lead wire, the onset of recrystallization (metallurgy)

In materials science, recrystallization is a process by which deformed grains are replaced by a new set of defect-free grains that nucleate and grow until the original grains have been entirely consumed. Recrystallization is usually accompanied b ...

or hot working

In metallurgy, hot working refers to processes where metals are plastically deformed above their recrystallization temperature. Being above the recrystallization temperature allows the material to recrystallize during deformation. This is impor ...

of the deforming wire can occur while it is forming the required contact area. Recrystallization takes place in the strain hardening region of the lead wire where it aids in the softening effect. If the wire was ultrasonically deformed at room temperature, it would tend to extensively strain hardened (cold working

In metallurgy, cold forming or cold working is any metalworking process in which metal is shaped below its recrystallization temperature, usually at the ambient temperature. Such processes are contrasted with hot working techniques like hot roll ...

) and therefore tend to transmit damaging mechanical stresses to the silicon chip. Thermosonic bonding, initially referred to as Hot Work Ultrasonic Bonding by Alexander Coucoulas, was found to bond a wide range of conductive metals such as aluminum and copper wires to tantalum and palladium thin films deposited on aluminum oxide and glass substrates all of which simulated the metallized silicon chip.

Applications

At present, the majority of connections to the silicon integrated circuit chip are made using thermosonic bondingHarman, G., ''Wire Bonding In Microelectronics'', McGraw-Hill, Ch. 2, p. 36 because it employs lower bonding temperatures, forces and dwell times thanthermocompression bonding Thermocompression bonding describes a wafer bonding technique and is also referred to as diffusion bonding, pressure joining, thermocompression welding or solid-state welding. Two metals, e.g. gold-Gold, gold (Au), are brought into atomic contact ap ...

, as well as lower vibratory energy levels and forces than ultrasonic bonding to form the required bond area. Therefore the use of thermosonic bonding eliminates damaging the relatively fragile silicon integrated circuit

An integrated circuit or monolithic integrated circuit (also referred to as an IC, a chip, or a microchip) is a set of electronic circuits on one small flat piece (or "chip") of semiconductor material, usually silicon. Large numbers of tiny ...

chip during the bonding cycle. The proven reliability of thermosonic bonding has made it the process of choice, since such potential failure modes could be costly whether they occur during the manufacturing stage or detected later, during an operational field-failure of a chip which had been connected inside a computer or a myriad of other microelectronic devices.

Thermosonic bonding is also used in the flip chip

Flip chip, also known as controlled collapse chip connection or its abbreviation, C4, is a method for interconnecting dies such as semiconductor devices, IC chips, integrated passive devices and microelectromechanical systems (MEMS), to externa ...

process which is an alternate method of electrically connecting silicon integrated circuits.

Josephson effect

In physics, the Josephson effect is a phenomenon that occurs when two superconductors are placed in proximity, with some barrier or restriction between them. It is an example of a macroscopic quantum phenomenon, where the effects of quantum mech ...

and superconducting interference (DC SQUID

True squid are molluscs with an elongated soft body, large eyes, eight arms, and two tentacles in the superorder Decapodiformes, though many other molluscs within the broader Neocoleoidea are also called squid despite not strictly fitting t ...

) devices use the thermosonic bonding process as well. In this case, other bonding methods would degrade or even destroy YBaCuO7 microstructures, such as microbridges, Josephson junctions and superconducting interference devices (DC SQUID

True squid are molluscs with an elongated soft body, large eyes, eight arms, and two tentacles in the superorder Decapodiformes, though many other molluscs within the broader Neocoleoidea are also called squid despite not strictly fitting t ...

).

When electrically connecting light-emitting diodes

A light-emitting diode (LED) is a semiconductor device that emits light when current flows through it. Electrons in the semiconductor recombine with electron holes, releasing energy in the form of photons. The color of the light (cor ...

with thermosonic bonding techniques, an improved performance of the device has been shown.Seck-Hoe Wong ''et al.'' (2006"Packaging Of Power LEDs Using Thermosonic Bonding Of Au-Au Interconnects"

Surface Mount Technology Association International Conference.

See also

*Flip chip

Flip chip, also known as controlled collapse chip connection or its abbreviation, C4, is a method for interconnecting dies such as semiconductor devices, IC chips, integrated passive devices and microelectromechanical systems (MEMS), to externa ...

*Semiconductor device fabrication

Semiconductor device fabrication is the process used to manufacture semiconductor devices, typically integrated circuit (IC) chips such as modern computer processors, microcontrollers, and memory chips such as NAND flash and DRAM that are pres ...

*Transistor

upright=1.4, gate (G), body (B), source (S) and drain (D) terminals. The gate is separated from the body by an insulating layer (pink).

A transistor is a semiconductor device used to Electronic amplifier, amplify or electronic switch, switch e ...

*SQUID

True squid are molluscs with an elongated soft body, large eyes, eight arms, and two tentacles in the superorder Decapodiformes, though many other molluscs within the broader Neocoleoidea are also called squid despite not strictly fitting t ...

*Light-emitting diodes

A light-emitting diode (LED) is a semiconductor device that emits light when current flows through it. Electrons in the semiconductor recombine with electron holes, releasing energy in the form of photons. The color of the light (cor ...

*LED lamps

An LED lamp or LED light bulb is an electric light that produces light using light-emitting diodes (LEDs). LED lamps are significantly more energy-efficient than equivalent incandescent lamps

and can be significantly more efficient than mos ...

References

{{reflist, 35em Semiconductor device fabrication Packaging (microfabrication)