Silicon Nitride on:

[Wikipedia]

[Google]

[Amazon]

Silicon nitride is a chemical compound of the elements

The α- and β- have trigonal (

The α- and β- have trigonal (

Silicon nitride bearings are both full ceramic bearings and ceramic hybrid bearings with balls in ceramics and races in steel. Silicon nitride

Silicon nitride bearings are both full ceramic bearings and ceramic hybrid bearings with balls in ceramics and races in steel. Silicon nitride

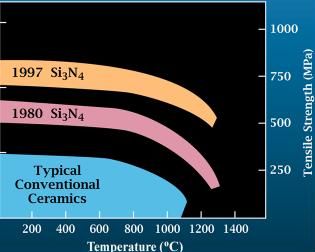

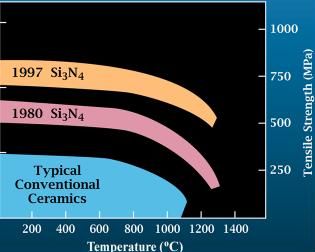

Silicon nitride has long been used in high-temperature applications. In particular, it was identified as one of the few monolithic ceramic materials capable of surviving the severe thermal shock and thermal gradients generated in hydrogen/oxygen rocket engines. To demonstrate this capability in a complex configuration, NASA scientists used advanced rapid prototyping technology to fabricate a one-inch-diameter, single-piece combustion chamber/nozzle (thruster) component. The thruster was hot-fire tested with hydrogen/oxygen propellant and survived five cycles including a 5-minute cycle to a 1320 °C material temperature.

In 2010 silicon nitride was used as the main material in the thrusters of the

Silicon nitride has long been used in high-temperature applications. In particular, it was identified as one of the few monolithic ceramic materials capable of surviving the severe thermal shock and thermal gradients generated in hydrogen/oxygen rocket engines. To demonstrate this capability in a complex configuration, NASA scientists used advanced rapid prototyping technology to fabricate a one-inch-diameter, single-piece combustion chamber/nozzle (thruster) component. The thruster was hot-fire tested with hydrogen/oxygen propellant and survived five cycles including a 5-minute cycle to a 1320 °C material temperature.

In 2010 silicon nitride was used as the main material in the thrusters of the

Silicon nitride is often used as an insulator and chemical barrier in manufacturing

Silicon nitride is often used as an insulator and chemical barrier in manufacturing

silicon

Silicon is a chemical element with the symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic luster, and is a tetravalent metalloid and semiconductor. It is a member of group 14 in the periodic ...

and nitrogen

Nitrogen is the chemical element with the symbol N and atomic number 7. Nitrogen is a nonmetal and the lightest member of group 15 of the periodic table, often called the pnictogens. It is a common element in the universe, estimated at se ...

. is the most thermodynamically stable and commercially important of the silicon nitrides, and the term "silicon nitride" commonly refers to this specific composition. It is a white, high-melting-point solid that is relatively chemically inert, being attacked by dilute HF and hot . It is very hard (8.5 on the mohs scale

The Mohs scale of mineral hardness () is a qualitative ordinal scale, from 1 to 10, characterizing scratch resistance of various minerals through the ability of harder material to scratch softer material.

The scale was introduced in 1812 by ...

). It has a high thermal stability with strong optical nonlinearities for all-optical applications.

Production

Silicon nitride is prepared by heating powdered silicon between 1300 °C and 1400 °C in a nitrogen atmosphere: :3 Si + 2 → The silicon sample weight increases progressively due to the chemical combination of silicon and nitrogen. Without an iron catalyst, the reaction is complete after several hours (~7), when no further weight increase due to nitrogen absorption (per gram of silicon) is detected. In addition to , several other silicon nitride phases (with chemical formulas corresponding to varying degrees of nitridation/Si oxidation state) have been reported in the literature. These include the gaseous disilicon mononitride (), silicon mononitride (SiN) and silicon sesquinitride (), each of which are stoichiometric phases. As with other refractories, the products obtained in these high-temperature syntheses depends on the reaction conditions (e.g. time, temperature, and starting materials including the reactants and container materials), as well as the mode of purification. However, the existence of the sesquinitride has since come into question. It can also be prepared by diimide route: : + 6 → + 4 (s) at 0 °C :3 → + + 3 (g) at 1000 °C Carbothermal reduction of silicon dioxide in a nitrogen atmosphere at 1400–1450 °C has also been examined: :3 + 6 C + 2 → + 6 CO The nitridation of silicon powder was developed in the 1950s, following the "rediscovery" of silicon nitride and was the first large-scale method for powder production. However, use of low-purity raw silicon caused contamination of silicon nitride bysilicate

In chemistry, a silicate is any member of a family of polyatomic anions consisting of silicon and oxygen, usually with the general formula , where . The family includes orthosilicate (), metasilicate (), and pyrosilicate (, ). The name is a ...

s and iron

Iron () is a chemical element with symbol Fe (from la, ferrum) and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, right in ...

. The diimide decomposition results in amorphous silicon nitride, which needs further annealing under nitrogen at 1400–1500 °C to convert it to a crystalline powder; this is now the second-most-important route for commercial production. The carbothermal reduction was the earliest used method for silicon nitride production and is now considered as the most-cost-effective industrial route to high-purity silicon nitride powder.

Electronic-grade silicon nitride films are formed using chemical vapor deposition

Chemical vapor deposition (CVD) is a vacuum deposition method used to produce high quality, and high-performance, solid materials. The process is often used in the semiconductor industry to produce thin films.

In typical CVD, the wafer (subst ...

(CVD), or one of its variants, such as plasma-enhanced chemical vapor deposition (PECVD):

:3 (g) + 4 (g) → (s) + 12 (g) at 750–850°C

:3 (g) + 4 (g) → (s) + 12 HCl(g)

:3 (g) + 4 (g) → (s) + 6 HCl(g) + 6 (g)

For deposition of silicon nitride layers on semiconductor (usually silicon) substrates, two methods are used:

#Low pressure chemical vapor deposition (LPCVD) technology, which works at rather high temperature and is done either in a vertical or in a horizontal tube furnace, or

#Plasma-enhanced chemical vapor deposition (PECVD) technology, which works at rather low temperature and vacuum conditions.

Since the lattice constants of silicon nitride and silicon are different, tension or stress can occur, depending on the deposition process. Especially when using PECVD technology this tension can be reduced by adjusting deposition parameters.

Silicon nitride nanowires can also be produced by sol-gel method using carbothermal reduction followed

by nitridation of silica gel, which contains ultrafine carbon particles. The particles can be produced by decomposition of dextrose

Glucose is a simple sugar with the molecular formula . Glucose is overall the most abundant monosaccharide, a subcategory of carbohydrates. Glucose is mainly made by plants and most algae during photosynthesis from water and carbon dioxide, usin ...

in the temperature range 1200–1350 °C. The possible synthesis reactions are:

:(s) + C(s) → SiO(g) + CO(g) ''and''

:3 SiO(g) + 2 (g) + 3 CO(g) → (s) + 3 (g) ''or''

:3 SiO(g) + 2 (g) + 3 C(s) → (s) + 3 CO(g).

Processing

Silicon nitride is difficult to produce as a bulk material—it cannot be heated over 1850 °C, which is well below itsmelting point

The melting point (or, rarely, liquefaction point) of a substance is the temperature at which it changes state from solid to liquid. At the melting point the solid and liquid phase exist in equilibrium. The melting point of a substance depen ...

, due to dissociation to silicon and nitrogen. Therefore, application of conventional hot press sintering techniques is problematic. Bonding of silicon nitride powders can be achieved at lower temperatures through adding materials called sintering aids or "binders", which commonly induce a degree of liquid phase sintering. A cleaner alternative is to use spark plasma sintering Spark plasma sintering (SPS), also known as field assisted sintering technique (FAST) or pulsed electric current sintering (PECS), or plasma pressure compaction (P2C) is a sintering technique.

The main characteristic of SPS is that the pulsed or u ...

, where heating is conducted very rapidly (seconds) by passing pulses of electric current through the compacted powder. Dense silicon nitride compacts have been obtained by this techniques at temperatures 1500–1700 °C.

Crystal structure and properties

There exist threecrystallographic

Crystallography is the experimental science of determining the arrangement of atoms in crystalline solids. Crystallography is a fundamental subject in the fields of materials science and solid-state physics (condensed matter physics). The wor ...

structures of silicon nitride (), designated as α, β and γ phases. The α and β phases are the most common forms of , and can be produced under normal pressure condition. The γ phase can only be synthesized under high pressures and temperatures and has a hardness of 35 GPa.

The α- and β- have trigonal (

The α- and β- have trigonal (Pearson symbol

The Pearson symbol, or Pearson notation, is used in crystallography as a means of describing a crystal structure, and was originated by W. B. Pearson. The symbol is made up of two letters followed by a number. For example:

* Diamond structure ...

hP28, space group P31c, No. 159) and hexagonal

In geometry, a hexagon (from Greek , , meaning "six", and , , meaning "corner, angle") is a six-sided polygon. The total of the internal angles of any simple (non-self-intersecting) hexagon is 720°.

Regular hexagon

A '' regular hexagon'' has ...

(hP14, P63, No. 173) structures, respectively, which are built up by corner-sharing tetrahedra

In geometry, a tetrahedron (plural: tetrahedra or tetrahedrons), also known as a triangular pyramid, is a polyhedron composed of four triangular faces, six straight edges, and four vertex corners. The tetrahedron is the simplest of all th ...

. They can be regarded as consisting of layers of silicon and nitrogen atoms in the sequence ABAB... or ABCDABCD... in β- and α-, respectively. The AB layer is the same in the α and β phases, and the CD layer in the α phase is related to AB by a c-glide plane. The tetrahedra in β- are interconnected in such a way that tunnels are formed, running parallel with the c axis of the unit cell. Due to the c-glide plane that relates AB to CD, the α structure contains cavities instead of tunnels. The cubic γ- is often designated as c modification in the literature, in analogy with the cubic modification of boron nitride (c-BN). It has a spinel

Spinel () is the magnesium/aluminium member of the larger spinel group of minerals. It has the formula in the cubic crystal system. Its name comes from the Latin word , which means ''spine'' in reference to its pointed crystals.

Properties

S ...

-type structure in which two silicon atoms each coordinate six nitrogen atoms octahedrally, and one silicon atom coordinates four nitrogen atoms tetrahedrally.

The longer stacking sequence results in the α-phase having higher hardness than the β-phase. However, the α-phase is chemically unstable compared with the β-phase. At high temperatures when a liquid phase is present, the α-phase always transforms into the β-phase. Therefore, β- is the major form used in ceramics. Abnormal grain growth may occur in doped β-, whereby abnormally large elongated grains form in a matrix of finer equiaxed grains and can serve as a technique to enhance fracture toughness in this material by crack bridging. Abnormal grain growth in doped silicon nitride arises due to additive-enhanced diffusion and results in composite microstructures, which can also be considered as “in-situ composites” or “self-reinforced materials.

In addition to the crystalline polymorphs of silicon nitride, glassy amorphous materials may be formed as the pyrolysis products of preceramic polymers The term preceramic polymer refers to one of various polymeric compounds, which through pyrolysis under appropriate conditions (generally in the absence of oxygen) are converted to ceramic compounds, having high thermal and chemical stability. Ce ...

, most often containing varying amounts of residual carbon (hence they are more appropriately considered as silicon carbonitrides). Specifically, polycarbosilazane can be readily converted to an amorphous form of silicon carbonitride based material upon pyrolysis, with valuable implications in the processing of silicon nitride materials through processing techniques more commonly used for polymers.

Applications

In general, the main issue with applications of silicon nitride has not been technical performance, but cost. As the cost has come down, the number of production applications is accelerating.Automobile industry

One of the major applications of sintered silicon nitride is in automobile industry as a material for engine parts. Those include, indiesel engine

The diesel engine, named after Rudolf Diesel, is an internal combustion engine in which ignition of the fuel is caused by the elevated temperature of the air in the cylinder due to mechanical compression; thus, the diesel engine is a so-cal ...

s, glowplug

A glowplug (alternatively spelled as glow plug or glow-plug) is a heating device used to aid in starting diesel engines. In cold weather, high-speed diesel engines can be difficult to start because the mass of the cylinder block and cylinder he ...

s for faster start-up; precombustion chambers (swirl chambers) for lower emissions, faster start-up and lower noise; turbocharger

In an internal combustion engine, a turbocharger (often called a turbo) is a forced induction device that is powered by the flow of exhaust gases. It uses this energy to compress the intake gas, forcing more air into the engine in order to pro ...

for reduced engine lag and emissions. In spark-ignition engines, silicon nitride is used for rocker arm

In the context of an internal combustion engine, a rocker arm is a valvetrain component that typically transfers the motion of a pushrod to the corresponding intake/exhaust valve.

Rocker arms in automobiles are typically made from stamped steel ...

pads for lower wear

Wear is the damaging, gradual removal or deformation of material at solid surfaces. Causes of wear can be mechanical (e.g., erosion) or chemical (e.g., corrosion). The study of wear and related processes is referred to as tribology.

Wear in ...

, turbocharger turbines for lower inertia and less engine lag, and in exhaust gas control valves for increased acceleration. As examples of production levels, there is an estimated more than 300,000 sintered silicon nitride turbochargers made annually.

Bearings

Silicon nitride bearings are both full ceramic bearings and ceramic hybrid bearings with balls in ceramics and races in steel. Silicon nitride

Silicon nitride bearings are both full ceramic bearings and ceramic hybrid bearings with balls in ceramics and races in steel. Silicon nitride ceramic

A ceramic is any of the various hard, brittle, heat-resistant and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcelain, ...

s have good shock

Shock may refer to:

Common uses Collective noun

*Shock, a historic commercial term for a group of 60, see English numerals#Special names

* Stook, or shock of grain, stacked sheaves

Healthcare

* Shock (circulatory), circulatory medical emerge ...

resistance compared to other ceramics. Therefore, ball bearings made of silicon nitride ceramic are used in performance bearings. A representative example is use of silicon nitride bearings in the main engines of the NASA's Space Shuttle

The Space Shuttle is a retired, partially reusable low Earth orbital spacecraft system operated from 1981 to 2011 by the U.S. National Aeronautics and Space Administration (NASA) as part of the Space Shuttle program. Its official program n ...

.

Since silicon nitride ball bearings are harder than metal, this reduces contact with the bearing track. This results in 80% less friction, 3 to 10 times longer lifetime, 80% higher speed, 60% less weight, the ability to operate with lubrication starvation, higher corrosion resistance and higher operation temperature, as compared to traditional metal bearings. Silicon nitride balls weigh 79% less than tungsten carbide

Tungsten carbide (chemical formula: WC) is a chemical compound (specifically, a carbide) containing equal parts of tungsten and carbon atoms. In its most basic form, tungsten carbide is a fine gray powder, but it can be pressed and formed into ...

balls. Silicon nitride ball bearings can be found in high end automotive bearings, industrial bearings, wind turbine

A wind turbine is a device that converts the kinetic energy of wind into electrical energy. Hundreds of thousands of large turbines, in installations known as wind farms, now generate over 650 gigawatts of power, with 60 GW added each year. ...

s, motorsports, bicycles, rollerblades and skateboards. Silicon nitride bearings are especially useful in applications where corrosion or electric or magnetic fields prohibit the use of metals, for example, in tidal flow meters, where seawater attack is a problem, or in electric field seekers.

Si3N4 was first demonstrated as a superior bearing in 1972 but did not reach production until nearly 1990 because of challenges associated with reducing the cost.

Since 1990, the cost has been reduced substantially as production volume has increased. Although bearings are still 2–5 times more expensive than the best steel bearings, their superior performance and life are justifying rapid adoption. Around 15–20 million bearing balls were produced in the U.S. in 1996 for machine tools and many other applications. Growth is estimated at 40% per year, but could be even higher if ceramic bearings are selected for consumer applications such as in-line skates and computer disk drives.

NASA testing says ceramic-hybrid bearings exhibit much lower fatigue (wear) life than standard all-steel bearings.

High-temperature material

Silicon nitride has long been used in high-temperature applications. In particular, it was identified as one of the few monolithic ceramic materials capable of surviving the severe thermal shock and thermal gradients generated in hydrogen/oxygen rocket engines. To demonstrate this capability in a complex configuration, NASA scientists used advanced rapid prototyping technology to fabricate a one-inch-diameter, single-piece combustion chamber/nozzle (thruster) component. The thruster was hot-fire tested with hydrogen/oxygen propellant and survived five cycles including a 5-minute cycle to a 1320 °C material temperature.

In 2010 silicon nitride was used as the main material in the thrusters of the

Silicon nitride has long been used in high-temperature applications. In particular, it was identified as one of the few monolithic ceramic materials capable of surviving the severe thermal shock and thermal gradients generated in hydrogen/oxygen rocket engines. To demonstrate this capability in a complex configuration, NASA scientists used advanced rapid prototyping technology to fabricate a one-inch-diameter, single-piece combustion chamber/nozzle (thruster) component. The thruster was hot-fire tested with hydrogen/oxygen propellant and survived five cycles including a 5-minute cycle to a 1320 °C material temperature.

In 2010 silicon nitride was used as the main material in the thrusters of the JAXA

The is the Japanese national air and space agency. Through the merger of three previously independent organizations, JAXA was formed on 1 October 2003. JAXA is responsible for research, technology development and launch of satellites into o ...

space probe Akatsuki

may refer to:

* Akatsuki (spacecraft), an uncrewed Venus orbiter

* , any of three classes of destroyers of the Imperial Japanese Navy

* , any of three destroyers of the Imperial Japanese Navy

* ''Akatsuki'' (train), operated between Kyoto and N ...

.

Silicon nitride was used for the "microshutters" developed for the Near Infrared Spectrograph aboard the James Webb Space Telescope

The James Webb Space Telescope (JWST) is a space telescope which conducts infrared astronomy. As the largest optical telescope in space, its high resolution and sensitivity allow it to view objects too old, distant, or faint for the Hubble Sp ...

. According to NASA: The "operating temperature is cryogenic so the device has to be able to operate at extremely cold temperatures. Another challenge was developing shutters that would be able to: open and close repeatedly without fatigue; open individually; and open wide enough to meet the science requirements of the instrument. Silicon nitride was chosen for use in the microshutters, because of its high strength and resistance to fatigue." This microshutter system allows the instrument to observe and analyze up to 100 celestial objects simultaneously.

Medical

Silicon nitride has many orthopedic applications. The material is also an alternative toPEEK

Polyether ether ketone (PEEK) is a colourless organic thermoplastic polymer in the polyaryletherketone (PAEK) family, used in engineering applications. The polymer was first developed in November 1978, later being introduced to the market by ...

(polyether ether ketone) and titanium

Titanium is a chemical element with the symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resistant to corrosion i ...

, which are used for spinal fusion devices. It is silicon nitride's hydrophilic

A hydrophile is a molecule or other molecular entity that is attracted to water molecules and tends to be dissolved by water.Liddell, H.G. & Scott, R. (1940). ''A Greek-English Lexicon'' Oxford: Clarendon Press.

In contrast, hydrophobes are n ...

, microtextured surface that contributes to the material's strength, durability and reliability compared to PEEK and titanium. Certain compositions of this material exhibit anti-bacterial, anti-fungal, or anti-viral properties.

Metal working and cutting tools

The first major application of was abrasive and cutting tools. Bulk, monolithic silicon nitride is used as a material for cutting tools, due to its hardness, thermal stability, and resistance towear

Wear is the damaging, gradual removal or deformation of material at solid surfaces. Causes of wear can be mechanical (e.g., erosion) or chemical (e.g., corrosion). The study of wear and related processes is referred to as tribology.

Wear in ...

. It is especially recommended for high speed machining

Machining is a process in which a material (often metal) is cut to a desired final shape and size by a controlled material-removal process. The processes that have this common theme are collectively called subtractive manufacturing, which utilizes ...

of cast iron

Cast iron is a class of iron– carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impuri ...

. Hot hardness, fracture toughness and thermal shock resistance mean that sintered silicon nitride can cut cast iron, hard steel and nickel based alloys with surface speeds up to 25 times quicker than those obtained with conventional materials such as tungsten carbide. The use of cutting tools has had a dramatic effect on manufacturing output. For example, face milling of gray cast iron with silicon nitride inserts doubled the cutting speed, increased tool life from one part to six parts per edge, and reduced the average cost of inserts by 50%, as compared to traditional tungsten carbide

Tungsten carbide (chemical formula: WC) is a chemical compound (specifically, a carbide) containing equal parts of tungsten and carbon atoms. In its most basic form, tungsten carbide is a fine gray powder, but it can be pressed and formed into ...

tools.

Electronics

integrated circuits

An integrated circuit or monolithic integrated circuit (also referred to as an IC, a chip, or a microchip) is a set of electronic circuits on one small flat piece (or "chip") of semiconductor material, usually silicon. Large numbers of tin ...

, to electrically isolate different structures or as an etch mask in bulk micromachining

Bulk micromachining is a process used to produce micromachinery or microelectromechanical systems (MEMS).

Unlike surface micromachining, which uses a succession of thin film deposition and selective etching, bulk micromachining defines structures ...

. As a passivation layer for microchips, it is superior to silicon dioxide

Silicon dioxide, also known as silica, is an oxide of silicon with the chemical formula , most commonly found in nature as quartz and in various living organisms. In many parts of the world, silica is the major constituent of sand. Silica is one ...

, as it is a significantly better diffusion barrier A diffusion barrier is a thin layer (usually micrometres thick) of metal usually placed between two other metals. It is done to act as a barrier to protect either one of the metals from corrupting the other..

Adhesion of a plated metal layer to it ...

against water molecules and sodium

Sodium is a chemical element with the symbol Na (from Latin ''natrium'') and atomic number 11. It is a soft, silvery-white, highly reactive metal. Sodium is an alkali metal, being in group 1 of the periodic table. Its only stable ...

ions, two major sources of corrosion and instability in microelectronics. It is also used as a dielectric

In electromagnetism, a dielectric (or dielectric medium) is an electrical insulator that can be polarised by an applied electric field. When a dielectric material is placed in an electric field, electric charges do not flow through the ma ...

between polysilicon

Polycrystalline silicon, or multicrystalline silicon, also called polysilicon, poly-Si, or mc-Si, is a high purity, polycrystalline form of silicon, used as a raw material by the solar photovoltaic and electronics industry.

Polysilicon is produce ...

layers in capacitor

A capacitor is a device that stores electrical energy in an electric field by virtue of accumulating electric charges on two close surfaces insulated from each other. It is a passive electronic component with two terminals.

The effect of ...

s in analog chips.

Silicon nitride deposited by LPCVD contains up to 8% hydrogen. It also experiences strong tensile stress, which may crack films thicker than 200 nm. However, it has higher resistivity and dielectric strength than most insulators commonly available in microfabrication (1016 Ω·cm and 10 MV/cm, respectively).

Not only silicon nitride, but also various ternary compounds of silicon, nitrogen and hydrogen (SiNxHy) are used as insulating layers. They are plasma deposited using the following reactions:

:2 (g) + (g) → 2 SiNH(s) + 3 (g)

:(g) + (g) → SiNH(s) + 3 (g)

These SiNH films have much less tensile stress, but worse electrical properties (resistivity 106 to 1015 Ω·cm, and dielectric strength 1 to 5 MV/cm), and are thermally stable to high temperatures under specific physical conditions.

Silicon nitride is also used in the xerographic process as one of the layers of the photo drum. Silicon nitride is also used as an ignition source for domestic gas appliances. Because of its good elastic properties, silicon nitride, along with silicon and silicon oxide, is the most popular material for cantilever

A cantilever is a rigid structural element that extends horizontally and is supported at only one end. Typically it extends from a flat vertical surface such as a wall, to which it must be firmly attached. Like other structural elements, a cant ...

s — the sensing elements of atomic force microscope

Atomic force microscopy (AFM) or scanning force microscopy (SFM) is a very-high-resolution type of scanning probe microscopy (SPM), with demonstrated resolution on the order of fractions of a nanometer, more than 1000 times better than the op ...

s.

Solar cells

Solar cell

A solar cell, or photovoltaic cell, is an electronic device that converts the energy of light directly into electricity by the photovoltaic effect, which is a physical and chemical phenomenon.

s are often coated with an anti-reflective coating

An antireflective, antiglare or anti-reflection (AR) coating is a type of optical coating applied to the surface of lenses, other optical elements, and photovoltaic cells to reduce reflection. In typical imaging systems, this improves the ef ...

. Silicon nitride can be used for this, and it is possible to adjust its index of refraction

In optics, the refractive index (or refraction index) of an optical medium is a dimensionless number that gives the indication of the light bending ability of that medium.

The refractive index determines how much the path of light is bent, or ...

by varying the parameters of the deposition process.

Photonic integrated circuits

Photonic integrated circuit

A photonic integrated circuit (PIC) or integrated optical circuit is a microchip containing two or more photonic components which form a functioning circuit. This technology detects, generates, transports, and processes light. Photonic integrated c ...

s can be produced with various materials, also called material platforms. Silicon nitride is one of those material platforms, next to, for example, Silicon Photonics

Silicon photonics is the study and application of photonic systems which use silicon as an optical medium. The silicon is usually patterned with sub-micrometre precision, into microphotonic components. These operate in the infrared, most c ...

and Indium Phosphide

Indium phosphide (InP) is a binary semiconductor composed of indium and phosphorus. It has a face-centered cubic (" zincblende") crystal structure, identical to that of GaAs and most of the III-V semiconductors.

Manufacturing

Indium phosphide ...

. Silicon Nitride photonic integrated circuits have a broad spectral coverage and features low light losses. This makes them highly suited to detectors, spectrometers, biosensors, and quantum computers. The lowest propagation losses reported in SiN (0.1 dB/cm down to 0.1 dB/m) have been achieved by LioniX International’s TriPleX waveguides.

History

The first preparation was reported in 1857 byHenri Etienne Sainte-Claire Deville

Henri is an Estonian, Finnish, French, German and Luxembourgish form of the masculine given name Henry.

People with this given name

; French noblemen

:'' See the ' List of rulers named Henry' for Kings of France named Henri.''

* Henri I de Mon ...

and Friedrich Wöhler

Friedrich Wöhler () FRS(For) Hon FRSE (31 July 180023 September 1882) was a German chemist known for his work in inorganic chemistry, being the first to isolate the chemical elements beryllium and yttrium in pure metallic form. He was the fi ...

. In their method, silicon was heated in a crucible placed inside another crucible packed with carbon to reduce permeation of oxygen to the inner crucible. They reported a product they termed silicon nitride but without specifying its chemical composition. Paul Schuetzenberger first reported a product with the composition of the tetranitride, , in 1879 that was obtained by heating silicon with brasque (a paste made by mixing charcoal, coal, or coke with clay which is then used to line crucibles) in a blast furnace. In 1910, Ludwig Weiss and Theodor Engelhardt heated silicon under pure nitrogen to produce . E. Friederich and L. Sittig made Si3N4 in 1925 via carbothermal reduction under nitrogen, that is, by heating silica, carbon, and nitrogen at 1250–1300 °C.

Silicon nitride remained merely a chemical curiosity for decades before it was used in commercial applications. From 1948 to 1952, the Carborundum Company, Niagara Falls, New York, applied for several patent

A patent is a type of intellectual property that gives its owner the legal right to exclude others from making, using, or selling an invention for a limited period of time in exchange for publishing an enabling disclosure of the invention."A ...

s on the manufacture and application of silicon nitride. By 1958 Haynes Haynes may refer to:

People

*Haynes (surname)

Places

In Australia:

* Haynes, Western Australia

In Canada:

* Haynes, Alberta

In the United Kingdom:

*Haynes, Bedfordshire

**Haynes Church End

In the United States:

*Haynes, Arkansas

*Haynes, North D ...

(Union Carbide

Union Carbide Corporation is an American chemical corporation wholly owned subsidiary (since February 6, 2001) by Dow Chemical Company. Union Carbide produces chemicals and polymers that undergo one or more further conversions by customers befo ...

) silicon nitride was in commercial production for thermocouple

A thermocouple, also known as a "thermoelectrical thermometer", is an electrical device consisting of two dissimilar electrical conductors forming an electrical junction. A thermocouple produces a temperature-dependent voltage as a result of th ...

tubes, rocket nozzles, and boats and crucibles for melting metals. British work on silicon nitride, started in 1953, was aimed at high-temperature parts of gas turbines and resulted in the development of reaction-bonded silicon nitride and hot-pressed silicon nitride. In 1971, the Advanced Research Project Agency of the US Department of Defense

The United States Department of Defense (DoD, USDOD or DOD) is an executive branch department of the federal government charged with coordinating and supervising all agencies and functions of the government directly related to national sec ...

placed a US$17 million contract with Ford and Westinghouse for two ceramic gas turbines.

Even though the properties of silicon nitride were well known, its natural occurrence was discovered only in the 1990s, as tiny inclusions (about 2 μm

The micrometre ( international spelling as used by the International Bureau of Weights and Measures; SI symbol: μm) or micrometer ( American spelling), also commonly known as a micron, is a unit of length in the International System of Uni ...

× 0.5 μm in size) in meteorite

A meteorite is a solid piece of debris from an object, such as a comet, asteroid, or meteoroid, that originates in outer space and survives its passage through the atmosphere to reach the surface of a planet or moon. When the original object ...

s. The mineral was named nierite after a pioneer of mass spectrometry

Mass spectrometry (MS) is an analytical technique that is used to measure the mass-to-charge ratio of ions. The results are presented as a '' mass spectrum'', a plot of intensity as a function of the mass-to-charge ratio. Mass spectrometry is u ...

, Alfred O. C. Nier. This mineral may have been detected earlier, again exclusively in meteorites, by Soviet geologists.

References

Cited sources

* {{DEFAULTSORT:Silicon Nitride Ceramic materials Inorganic silicon compounds Nitrides Superhard materials Semiconductor fabrication materials