Steam generator (nuclear power) on:

[Wikipedia]

[Google]

[Amazon]

A steam generator (aka nuclear steam raising plant ('NSRP')) is a

In commercial power plants, there are two to four steam generators per reactor; each steam generator can measure up to in height and weigh as much as 800 tons. Each steam generator can contain anywhere from 3,000 to 16,000 tubes, each about in diameter. The coolant (treated water), which is maintained at high pressure to prevent boiling, is pumped through the nuclear reactor core. Heat transfer takes place between the reactor core and the circulating water and the coolant is then pumped through the primary tube side of the steam generator by coolant pumps before returning to the reactor core. This is referred to as the primary loop.

That water flowing through the steam generator boils water on the shell side (which is kept at a lower pressure than the primary side) to produce steam. This is referred to as the secondary loop. The secondary-side steam is delivered to the

In commercial power plants, there are two to four steam generators per reactor; each steam generator can measure up to in height and weigh as much as 800 tons. Each steam generator can contain anywhere from 3,000 to 16,000 tubes, each about in diameter. The coolant (treated water), which is maintained at high pressure to prevent boiling, is pumped through the nuclear reactor core. Heat transfer takes place between the reactor core and the circulating water and the coolant is then pumped through the primary tube side of the steam generator by coolant pumps before returning to the reactor core. This is referred to as the primary loop.

That water flowing through the steam generator boils water on the shell side (which is kept at a lower pressure than the primary side) to produce steam. This is referred to as the secondary loop. The secondary-side steam is delivered to the

Outline History of Nuclear Energy

, World Nuclear Association (2014) Once peaceful nuclear reactors were legalized for use as power plants, power corporations jumped at the opportunity to utilize the growing development of nuclear powered steam generators. Westinghouse built one of the first nuclear power plants, the Yankee Rowe nuclear power station (NPS), which also used a nuclear powered steam generator, in 1960. This power plant had a one hundred MWe (mega watt electric) output. By comparison, some modern plants have over 1100 MWe output. Eventually, other international companies such as

Westinghouse and

Westinghouse and

Evolution of CANDU Steam Generators – a Historical View

Nuclear Regulatory Committee (March 21, 2014) {{DEFAULTSORT:Steam Generator (Nuclear Power) Nuclear power plant components Boilers

heat exchanger

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contac ...

used to convert water into steam

Steam is water vapor, often mixed with air or an aerosol of liquid water droplets. This may occur due to evaporation or due to boiling, where heat is applied until water reaches the enthalpy of vaporization. Saturated or superheated steam is inv ...

from heat produced in a nuclear reactor core. It is used in pressurized water reactor

A pressurized water reactor (PWR) is a type of light-water nuclear reactor. PWRs constitute the large majority of the world's nuclear power plants (with notable exceptions being the UK, Japan, India and Canada).

In a PWR, water is used both as ...

s (PWRs), between the primary and secondary coolant

A coolant is a substance, typically liquid, that is used to reduce or regulate the temperature of a system. An ideal coolant has high thermal capacity, low viscosity, is low-cost, non-toxic, chemically inert and neither causes nor promotes corr ...

loops. It is also used in liquid metal cooled reactor

A liquid metal cooled nuclear reactor (LMR) is a type of nuclear reactor where the primary coolant is a liquid metal. Liquid metal cooled reactors were first adapted for breeder reactor power generation. They have also been used to power nuclear ...

s (LMRs), pressurized heavy-water reactor

A pressurized heavy-water reactor (PHWR) is a nuclear reactor that uses heavy water (deuterium oxide D2O) as its coolant and neutron moderator. PHWRs frequently use natural uranium as fuel, but sometimes also use very low enriched uranium. The h ...

s (PHWRs), and gas-cooled reactor

A gas-cooled reactor (GCR) is a nuclear reactor that uses graphite as a neutron moderator and a gas (carbon dioxide or helium in extant designs) as coolant. Although there are many other types of reactor cooled by gas, the terms ''GCR'' and to a l ...

s (GCRs).

In typical PWR designs, the primary coolant is high-purity water, kept under high pressure so it cannot boil. This primary coolant is pumped through the reactor core where it absorbs heat from the fuel rods. It then passes through the steam generator, where it transfers its heat (via conduction through metal) to lower-pressure water which is allowed to boil.

Purpose

Unlike PWRs,boiling water reactor

A boiling water reactor (BWR) is a type of nuclear reactor used for the generation of electrical power. It is the second most common type of electricity-generating nuclear reactor after the pressurized water reactor (PWR).

BWR are thermal neutro ...

s (BWRs) do not use steam generators. The primary coolant is allowed to boil directly in the reactor core, and the steam is simply passed through a steam turbine. While theoretically simple, this has a downside for maintenance. While passing through the core, primary coolant water is subjected to high neutron flux. This activates oxygen and dissolved nitrogen

Nitrogen is a chemical element; it has Symbol (chemistry), symbol N and atomic number 7. Nitrogen is a Nonmetal (chemistry), nonmetal and the lightest member of pnictogen, group 15 of the periodic table, often called the Pnictogen, pnictogens. ...

in the water. The major reaction is: an atom of oxygen-16 absorbs 1 neutron and emits 1 proton, becoming nitrogen-16. Nitrogen-16 has a 7-second half-life and produces a gamma ray when it decays back to oxygen-16. The 7-second half-life is long enough for the water to circulate out of the reactor. In a BWR, this means that the water may be in the steam turbine when it releases its gamma rays. Although no long-lived radioisotopes are produced by this reaction, the gamma radiation means that humans cannot be present in a BWR's turbine hall during reactor operation and for a short time afterwards.

By contrast, in a PWR, the steam generator separates the activated primary coolant water from the secondary coolant which passes through the steam turbine. Thus, humans can freely access a PWR's turbines and other steam plant components during operation. This reduces maintenance cost and improves up-time.

Description

turbine

A turbine ( or ) (from the Greek , ''tyrbē'', or Latin ''turbo'', meaning vortex) is a rotary mechanical device that extracts energy from a fluid flow and converts it into useful work. The work produced can be used for generating electrical ...

s to make electricity

Electricity is the set of physical phenomena associated with the presence and motion of matter possessing an electric charge. Electricity is related to magnetism, both being part of the phenomenon of electromagnetism, as described by Maxwel ...

. The steam is subsequently condensed via cooled water from a tertiary loop and returned to the steam generator to be heated once again. The tertiary cooling water may be recirculated to cooling tower

A cooling tower is a device that rejects waste heat to the atmosphere through the cooling of a coolant stream, usually a water stream, to a lower temperature. Cooling towers may either use the evaporation of water to remove heat and cool the ...

s where it sheds waste heat

Waste heat is heat that is produced by a machine, or other process that uses energy, as a byproduct of doing work. All such processes give off some waste heat as a fundamental result of the laws of thermodynamics. Waste heat has lower utility ...

before returning to condense more steam. Once-through tertiary cooling may otherwise be provided by a river, lake, or ocean. This primary, secondary, tertiary cooling scheme is the basis of the pressurized water reactor, which is the most common nuclear power plant design worldwide.

In other types of reactors, such as the pressurised heavy water reactors of the CANDU

The CANDU (CANada Deuterium Uranium) is a Canadian pressurized heavy-water reactor design used to generate electric power. The acronym refers to its deuterium oxide (heavy water) neutron moderator, moderator and its use of (originally, natural ...

design, the primary fluid is heavy water

Heavy water (deuterium oxide, , ) is a form of water (molecule), water in which hydrogen atoms are all deuterium ( or D, also known as ''heavy hydrogen'') rather than the common hydrogen-1 isotope (, also called ''protium'') that makes up most o ...

. Liquid metal cooled reactor

A liquid metal cooled nuclear reactor (LMR) is a type of nuclear reactor where the primary coolant is a liquid metal. Liquid metal cooled reactors were first adapted for breeder reactor power generation. They have also been used to power nuclear ...

s such as the Russian BN-600 reactor

The BN-600 reactor is a sodium-cooled fast breeder reactor, built at the Beloyarsk Nuclear Power Station, in Zarechny, Sverdlovsk Oblast, Russia. It has a 600 MWe gross capacity and a 560 MWe net capacity, provided to the Middle Urals power ...

use a liquid metal, such as sodium, as the primary coolant. These also use heat exchangers between primary metal coolant and the secondary water coolant, and thus their secondary and tertiary cooling is similar to a PWR.

A steam generator's heat-exchange tubes have an important safety role, because they separate radioactive

Radioactive decay (also known as nuclear decay, radioactivity, radioactive disintegration, or nuclear disintegration) is the process by which an unstable atomic nucleus loses energy by radiation. A material containing unstable nuclei is conside ...

and non-radioactive fluid systems. (The primary coolant becomes briefly radioactive from its exposure to the core, and also has trace amounts of longer-lived radioactive isotopes dissolved in it, such as dissolved atoms of iron from pipes.) Because the primary coolant is at higher pressure, a ruptured heat-exchange tube would cause primary coolant to leak into the secondary loop. Typically this would require the plant to shutdown for repair. To avoid such primary-secondary leaks, steam generator tubes are periodically inspected by eddy-current testing, and individual tubes can be plugged to remove them from operation. As with many nuclear components, mechanical engineers determine the inspection frequency using the known rates of corrosion and crack propagation in the material. If an inspection finds that a tube wall is thin enough that it might corrode through before the next scheduled inspection, the tube is plugged. (Plugging a tube is typically easier than attempting to repair it. There are many small heat-exchange tubes, and steam generators are designed with excess tubes to allow some to be plugged.)

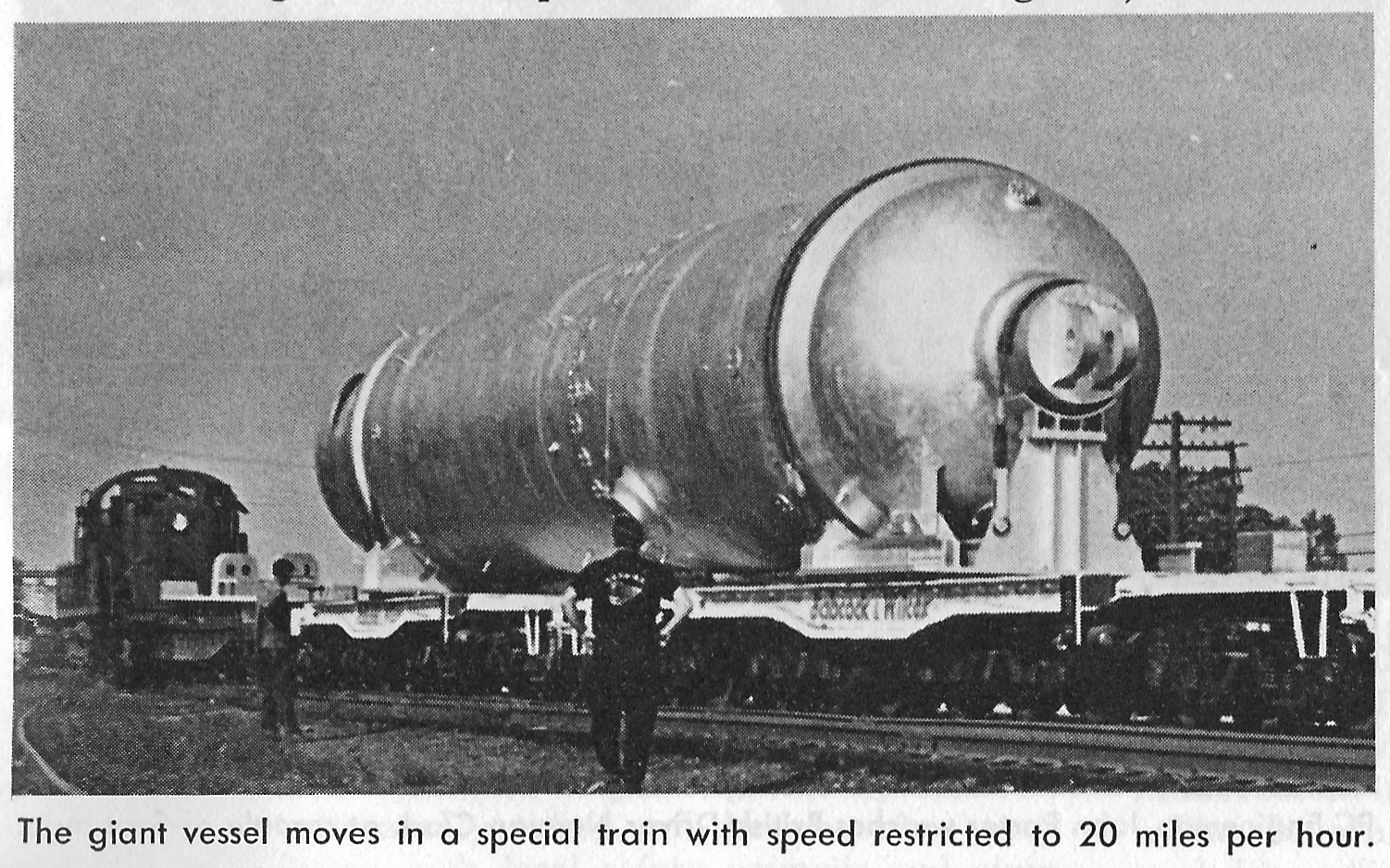

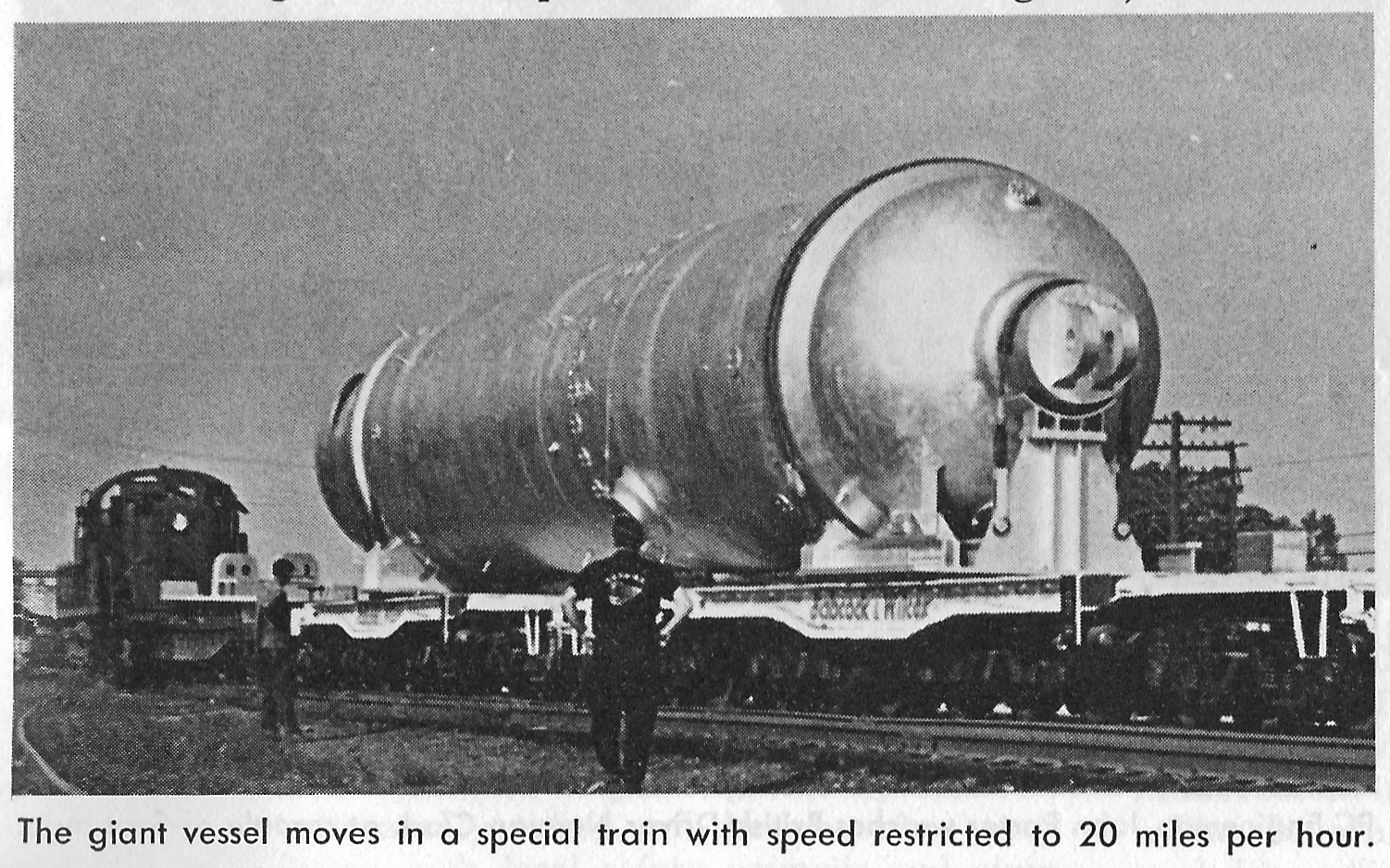

Entire steam generators are often replaced in plant mid-life, which is a major undertaking. Most U.S. PWR plants have had steam generators replaced.

History

The nuclear powered steam generator started as a power plant for the firstnuclear submarine

A nuclear submarine is a submarine powered by a nuclear reactor, but not necessarily nuclear-armed.

Nuclear submarines have considerable performance advantages over "conventional" (typically diesel-electric) submarines. Nuclear propulsion ...

, the USS ''Nautilus'' (SSN-571). It was designed and built by the Westinghouse Electric Company

Westinghouse Electric Company LLC is an American nuclear power company formed in 1999 from the nuclear power division of the original Westinghouse Electric Corporation. It offers nuclear products and services to utilities internationally, includ ...

power company for the submarine; from there the company started its development and research of nuclear-powered steam generators. (The reference to Westinghouse's role in the Nautilus as well as later reference to Babcock and Wilcox (B&W) is factually incorrect. B&W had a relationship with the U.S. Navy from the late 19th century. It provided components, materials and process development for the Manhattan Project during WWII. It created its Atomic Energy Division in 1953 specifically to provide primary system nuclear power components to the Nautilus under subcontract with Westinghouse. At that time B&W was world-renowned for both high pressure boilers and steam generators https://www.bwxt.com/about/history). , World Nuclear Association (2014)

Babcock & Wilcox

Babcock & Wilcox Enterprises, Inc. is an American energy technology and service provider that is active and has operations in many international markets with its headquarters in Akron, Ohio. Historically, the company is best known for their stea ...

and Combustion Engineering

Combustion Engineering (C-E) was a multi-national American-based engineering firm that developed nuclear steam supply power systems in the United States. Originally headquartered in New York City, C-E moved its corporate offices to Stamford, Connec ...

began their own programs for research and development of the nuclear power steam generator. (Again this is factually incorrect. B&W manufactured components for the first full-scale peacetime nuclear power plant in the US – the Shippingport Atomic Power Station in Pennsylvania, built during 1956-57. Westinghouse and GE were both deeply involved in this project but asserting that B&W was playing catch-up "eventually" is plainly incorrect. https://www.bwxt.com/about/history)

Types

Westinghouse and

Westinghouse and Combustion Engineering

Combustion Engineering (C-E) was a multi-national American-based engineering firm that developed nuclear steam supply power systems in the United States. Originally headquartered in New York City, C-E moved its corporate offices to Stamford, Connec ...

designs have vertical U-tubes with inverted tubes for the primary water. Canadian, Japanese, French, and German PWR suppliers use the vertical configuration as well. Russian VVER

The water-water energetic reactor (WWER), or VVER (from ) is a series of pressurized water reactor designs originally developed in the Soviet Union, and now Russia, by OKB Gidropress. The idea of such a reactor was proposed at the Kurchatov Instit ...

reactor designs use horizontal steam generators, which have the tubes mounted horizontally. Babcock & Wilcox

Babcock & Wilcox Enterprises, Inc. is an American energy technology and service provider that is active and has operations in many international markets with its headquarters in Akron, Ohio. Historically, the company is best known for their stea ...

plants (e.g., Three Mile Island) have smaller steam generators that force water through the top of the OTSGs (once-through steam generators; counter-flow to the feedwater) and out the bottom to be recirculated by the reactor coolant pumps. The horizontal design has proven to be less susceptible to degradation than the vertical U-tube design.

Materials and construction

The materials that make up the turbine and pipes of a nuclear poweredsteam generator

Steam is water vapor, often mixed with air or an aerosol of liquid water droplets. This may occur due to evaporation or due to boiling, where heat is applied until water reaches the enthalpy of vaporization. Saturated or superheated steam is inv ...

are specially made and specifically designed to withstand the heat and radiation

In physics, radiation is the emission or transmission of energy in the form of waves or particles through space or a material medium. This includes:

* ''electromagnetic radiation'' consisting of photons, such as radio waves, microwaves, infr ...

of the reactor. The water tubes also have to be able to resist corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engine ...

from water for an extended period of time. The pipes that are used in American reactors are made of Inconel

Inconel is a nickel-chromium-based superalloy often utilized in extreme environments where components are subjected to high temperature, pressure or Mechanical load, mechanical loads. Inconel alloys are oxidation- and corrosion-resistant. When he ...

, either Alloy 600 or Alloy 690. Alloy 690 is made with extra chromium

Chromium is a chemical element; it has Symbol (chemistry), symbol Cr and atomic number 24. It is the first element in Group 6 element, group 6. It is a steely-grey, Luster (mineralogy), lustrous, hard, and brittle transition metal.

Chromium ...

and most facilities heat treat the metal to make it better able to resist heat and corrosion. The high nickel content in Alloy 600 and Alloy 690 make them well suited for resisting acids and high degrees of stress and temperature.

Degradation

The annealed, or heat treated, Alloy 600 was prone to tube denting and thinning due to water chemistry. Plants that used the Alloy 600 in their water tubes therefore had to install new water chemistry controllers and change the chemicals they put in the water. Due to this, pipe thinning has been taken care of, but on rare occasions, tube denting still occurs, causing leaks and ruptures. The only way to prevent this is regular maintenance and check-ups, but this forces the reactor to shut down. In some cases, plants replaced their Alloy 600 tubes with Alloy 690 tubes and a few plants were shut down. To prevent future problems, manufacturers of steam turbines fornuclear power plant

A nuclear power plant (NPP), also known as a nuclear power station (NPS), nuclear generating station (NGS) or atomic power station (APS) is a thermal power station in which the heat source is a nuclear reactor. As is typical of thermal power st ...

s have improved their fabrication techniques and used other materials, such as stainless steel

Stainless steel, also known as inox, corrosion-resistant steel (CRES), or rustless steel, is an iron-based alloy that contains chromium, making it resistant to rust and corrosion. Stainless steel's resistance to corrosion comes from its chromi ...

, to prevent tube denting.

Typical operating conditions

Steam generators in a "typical" PWR in the USA have the following operating conditions:Tube material

Various high-performance alloys andsuperalloys

A superalloy, or high-performance alloy, is an alloy with the ability to operate at a high fraction of its melting point. Key characteristics of a superalloy include mechanical strength, Creep (deformation), thermal creep deformation resistance, ...

have been used for steam generator tubing, including type 316 stainless steel

Stainless steel, also known as inox, corrosion-resistant steel (CRES), or rustless steel, is an iron-based alloy that contains chromium, making it resistant to rust and corrosion. Stainless steel's resistance to corrosion comes from its chromi ...

, Alloy 400, Alloy 600MA (mill annealed), Alloy 600TT (thermally treated), Alloy 690TT, and Alloy 800Mod.

See also

*Nuclear power plant

A nuclear power plant (NPP), also known as a nuclear power station (NPS), nuclear generating station (NGS) or atomic power station (APS) is a thermal power station in which the heat source is a nuclear reactor. As is typical of thermal power st ...

*Power station

A power station, also referred to as a power plant and sometimes generating station or generating plant, is an industrial facility for the electricity generation, generation of electric power. Power stations are generally connected to an electr ...

*Steam turbine

A steam turbine or steam turbine engine is a machine or heat engine that extracts thermal energy from pressurized steam and uses it to do mechanical work utilising a rotating output shaft. Its modern manifestation was invented by Sir Charles Par ...

References

External links

* John M. Dyke and Wm. J. GarlandEvolution of CANDU Steam Generators – a Historical View

Nuclear Regulatory Committee (March 21, 2014) {{DEFAULTSORT:Steam Generator (Nuclear Power) Nuclear power plant components Boilers