Squish Band on:

[Wikipedia]

[Google]

[Amazon]

Squish is an effect in

Squish is an effect in

Retrieved 16 June 2013. In an engine designed to use the squish effect, at top dead centre the piston crown comes very close (typically less than 1 mm) to the cylinder head. The gases are suddenly "squished" out within the

''Progress Report for Combustion and Emission Control for Advanced CIDI Engines''.

United States Office of Transportation Technologies,

Squish is an effect in

Squish is an effect in internal combustion engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal c ...

s which creates sudden turbulence of the air-fuel mixture as the piston approaches top dead centre

In a reciprocating engine, the dead centre is the position of a piston in which it is either farthest from, or nearest to, the crankshaft. The former is known as Top Dead Centre (TDC) while the latter is known as Bottom Dead Centre (BDC).

...

(TDC)."The Combustion Chamber"Retrieved 16 June 2013. In an engine designed to use the squish effect, at top dead centre the piston crown comes very close (typically less than 1 mm) to the cylinder head. The gases are suddenly "squished" out within the

combustion chamber

A combustion chamber is part of an internal combustion engine in which the fuel/air mix is burned. For steam engines, the term has also been used for an extension of the firebox which is used to allow a more complete combustion process.

Intern ...

, creating turbulence which promotes thorough air-fuel mixing, a factor beneficial to efficient combustion

Combustion, or burning, is a high-temperature exothermic redox chemical reaction between a fuel (the reductant) and an oxidant, usually atmospheric oxygen, that produces oxidized, often gaseous products, in a mixture termed as smoke. Combus ...

. Squish effect may be found in side-valve

A flathead engine, also known as a sidevalve engine''American Rodder'', 6/94, pp.45 & 93. or valve-in-block engine is an internal combustion engine with its poppet valves contained within the engine block, instead of in the cylinder head, as ...

, OHV

An overhead valve (OHV) engine, sometimes called a ''pushrod engine'', is a piston engine whose valves are located in the cylinder head above the combustion chamber. This contrasts with earlier flathead engines, where the valves were located bel ...

and OHC engines, including engines with a Heron cylinder head

A Heron cylinder head, or simply Heron head, is a design for the combustion chambers of the cylinder head on an internal combustion piston engine, named for engine designer S.D.Heron. The head is machined flat, with recesses only for inlet and exh ...

. Squish effect may be found in any fuel type internal combustion piston engine. Squish piston engines are also found in both two stroke

A two-stroke (or two-stroke cycle) engine is a type of internal combustion engine that completes a power cycle with two strokes (up and down movements) of the piston during one power cycle, this power cycle being completed in one revolution of t ...

and four stroke

A four-stroke (also four-cycle) engine is an internal combustion (IC) engine in which the piston completes four separate strokes while turning the crankshaft. A stroke refers to the full travel of the piston along the cylinder, in either directi ...

engines.

Turbulence in the combustion chamber due to this squish helps with air-fuel mixing, cylinder wall heat transfer, thermal efficiency

In thermodynamics, the thermal efficiency (\eta_) is a dimensionless performance measure of a device that uses thermal energy, such as an internal combustion engine, steam turbine, steam engine, boiler, furnace, refrigerator, ACs etc.

For a ...

, and overall engine performance. Heat transfer

Heat transfer is a discipline of thermal engineering that concerns the generation, use, conversion, and exchange of thermal energy (heat) between physical systems. Heat transfer is classified into various mechanisms, such as thermal conduction, ...

is aided when the combustion gasses swirl around and heat the cylinder wall and the cooling system more efficiently. This efficiency and swirling can also reduce the amount of soot

Soot ( ) is a mass of impure carbon particles resulting from the incomplete combustion of hydrocarbons. It is more properly restricted to the product of the gas-phase combustion process but is commonly extended to include the residual pyrolysed ...

production.

Design Types

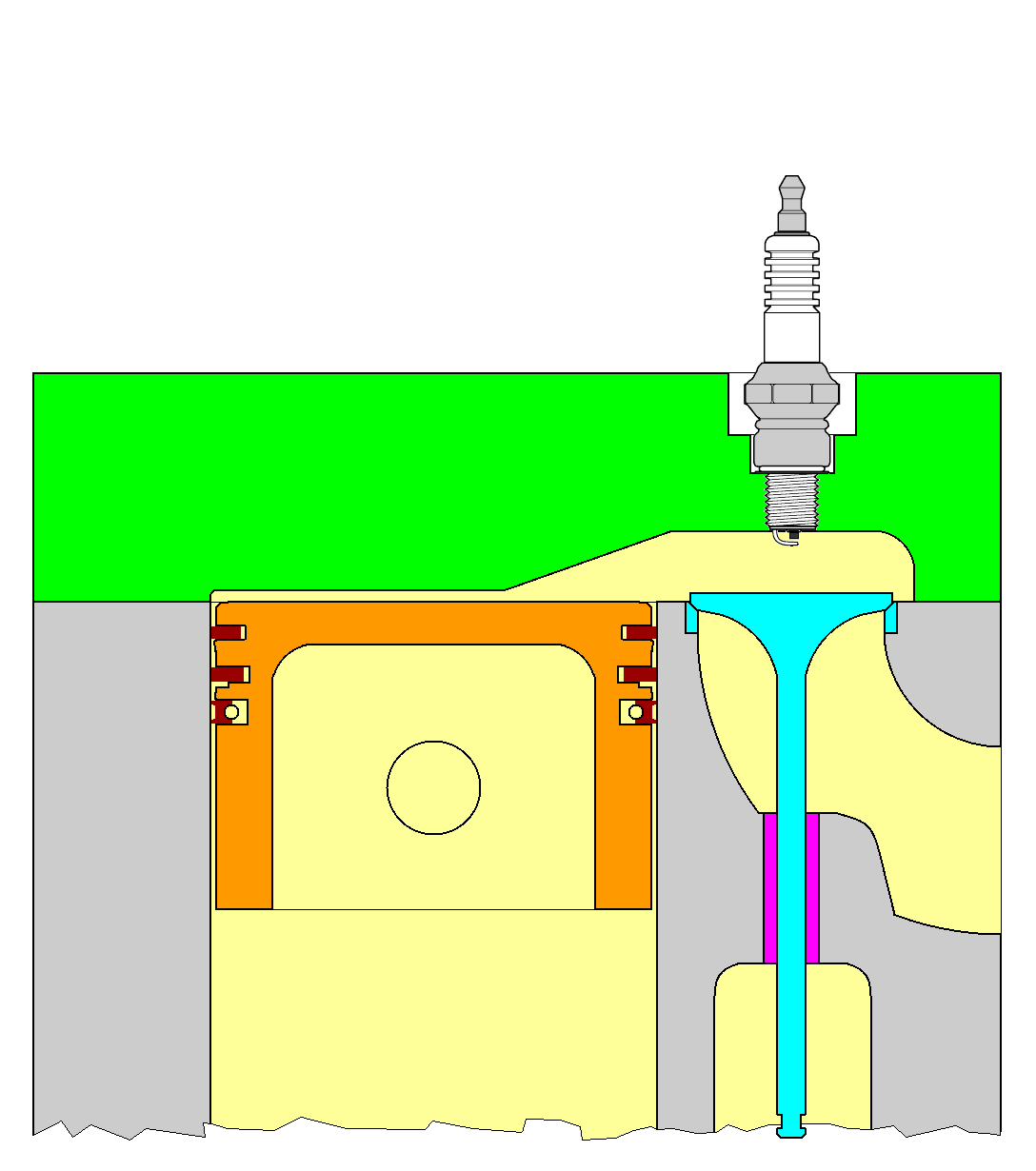

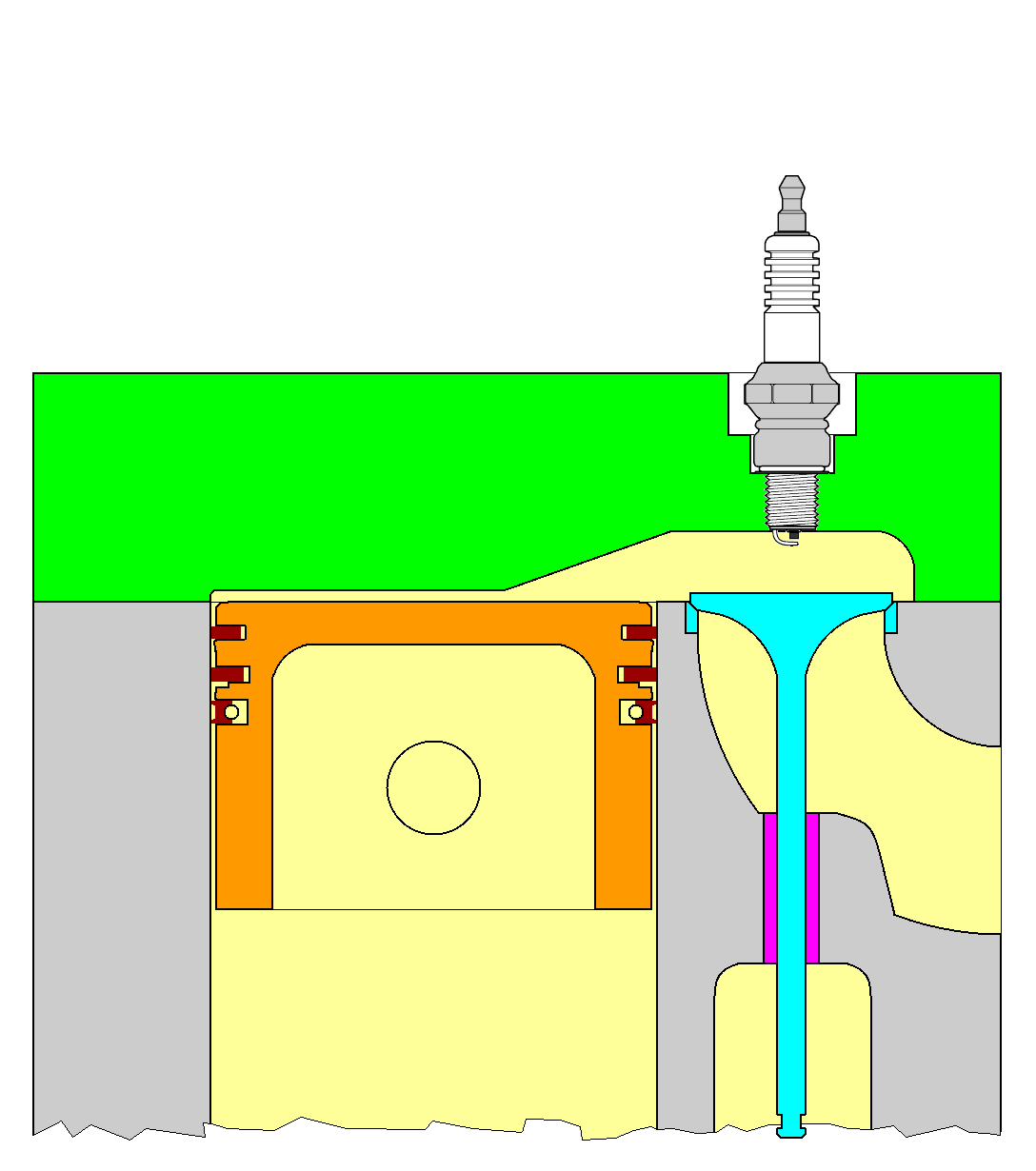

Squish piston engines are achieved by modifying an engine's head, block, or the piston crown. Some engine designs include combinations of these different design types. These combinations are used when certain design parameters that attribute the shape and constraints of the combustion chamber.Modified Head

Modified head squish piston engines utilise a space in the head to make an air pocket for squishing and combustion to occur. Depending on the shape of the pocket and what type of engine, the valve position must be skewed to ensure that both the intake and exhaust valve can fit in the pocket. Modified head squish piston engines can also be made to fit the application on aflathead engine

A flathead engine, also known as a sidevalve engine''American Rodder'', 6/94, pp.45 & 93. or valve-in-block engine is an internal combustion engine with its poppet valves contained within the engine block, instead of in the cylinder head, as ...

as well as overhead camshaft

An overhead camshaft (OHC) engine is a piston engine where the camshaft is located in the cylinder head above the combustion chamber. This contrasts with earlier overhead valve engines (OHV), where the camshaft is located below the combustion cha ...

and two stroke engines.

Modified Block

Modified block squish piston engines utilise a space in the block to create a pocket for squishing and combustion to occur. These squish piston engines are otherwise referred to as flat head engines. These types of engines are not very common anymore because of the inherent issues with insufficient air flow into the engine which directly affects the compression ratio. This design is mostly used in small, low cost applications.Modified Piston

Modified piston squish piston engines utilise a space in the piston to create an air pocket for squishing and combustion to occur. This is the most common way to create a squish piston engine because it is the smallest and easiest part to manufacture. These pockets can be made by making a recess in the piston crown. This is called a deep bowl piston. Others may use raised areas relative to the piston rings to create a different effect in the combustion chamber. This creates a different type of turbulence that goes down instead of up in the piston itself. To promote turbulence and mixing of the air–fuel mixture, the piston crown must have a recess parallel to the angle that the fuel is injected. It also requires a curve on the outer section of the piston crown. This design directs air from the squish area into the centre of the combustion chamber. This is where the squished air is mixed with the fuel from the injector creating a more evenly mixedair–fuel ratio

Air–fuel ratio (AFR) is the mass ratio of air to a solid, liquid, or gaseous fuel present in a combustion process. The combustion may take place in a controlled manner such as in an internal combustion engine or industrial furnace, or may result ...

. However this is only one design for a diesel engine. When looking at engines with more valves and different injector locations there are many different designs that increase the efficiency of the engine. There are also ways to modify the piston and give it intake and exhaust squish areas. This affects how the whole engine runs and the intake and exhaust velocity that in produced.

References

Bibliography

''Progress Report for Combustion and Emission Control for Advanced CIDI Engines''.

United States Office of Transportation Technologies,

United States Department of Energy

The United States Department of Energy (DOE) is an executive department of the U.S. federal government that oversees U.S. national energy policy and manages the research and development of nuclear power and nuclear weapons in the United Stat ...

{{Heat engines

Internal combustion engine