Self-adhesive on:

[Wikipedia]

[Google]

[Amazon]

Pressure-sensitive adhesive (PSA, self-adhesive, self-stick adhesive) is a type of nonreactive

Pressure-sensitive adhesive (PSA, self-adhesive, self-stick adhesive) is a type of nonreactive

Pressure-sensitive adhesives are designed for either permanent or removable applications. Examples of permanent applications include safety labels for power equipment, foil tape for

Pressure-sensitive adhesives are designed for either permanent or removable applications. Examples of permanent applications include safety labels for power equipment, foil tape for

Pressure-sensitive adhesive (PSA, self-adhesive, self-stick adhesive) is a type of nonreactive

Pressure-sensitive adhesive (PSA, self-adhesive, self-stick adhesive) is a type of nonreactive adhesive

Adhesive, also known as glue, cement, mucilage, or paste, is any non-metallic substance applied to one or both surfaces of two separate items that binds them together and resists their separation.

The use of adhesives offers certain advant ...

which forms a bond when pressure is applied to bond the adhesive with a surface. No solvent, water, or heat is needed to activate the adhesive.

It is used in pressure-sensitive tapes, labels, glue dots Glue dots are pressure-sensitive adhesive dots, used in various different applications, such as sticking credit cards to paper, arts and crafts, and as a safe adhesive for children to use, without needing a hot glue gun. Glue dots are globules of ad ...

, sticker

A sticker is a type of label: a piece of printed paper, plastic, vinyl, or other material with temporary or permanent pressure sensitive adhesive on one side. It can be used for decoration or for functional purposes, depending on the situation. ...

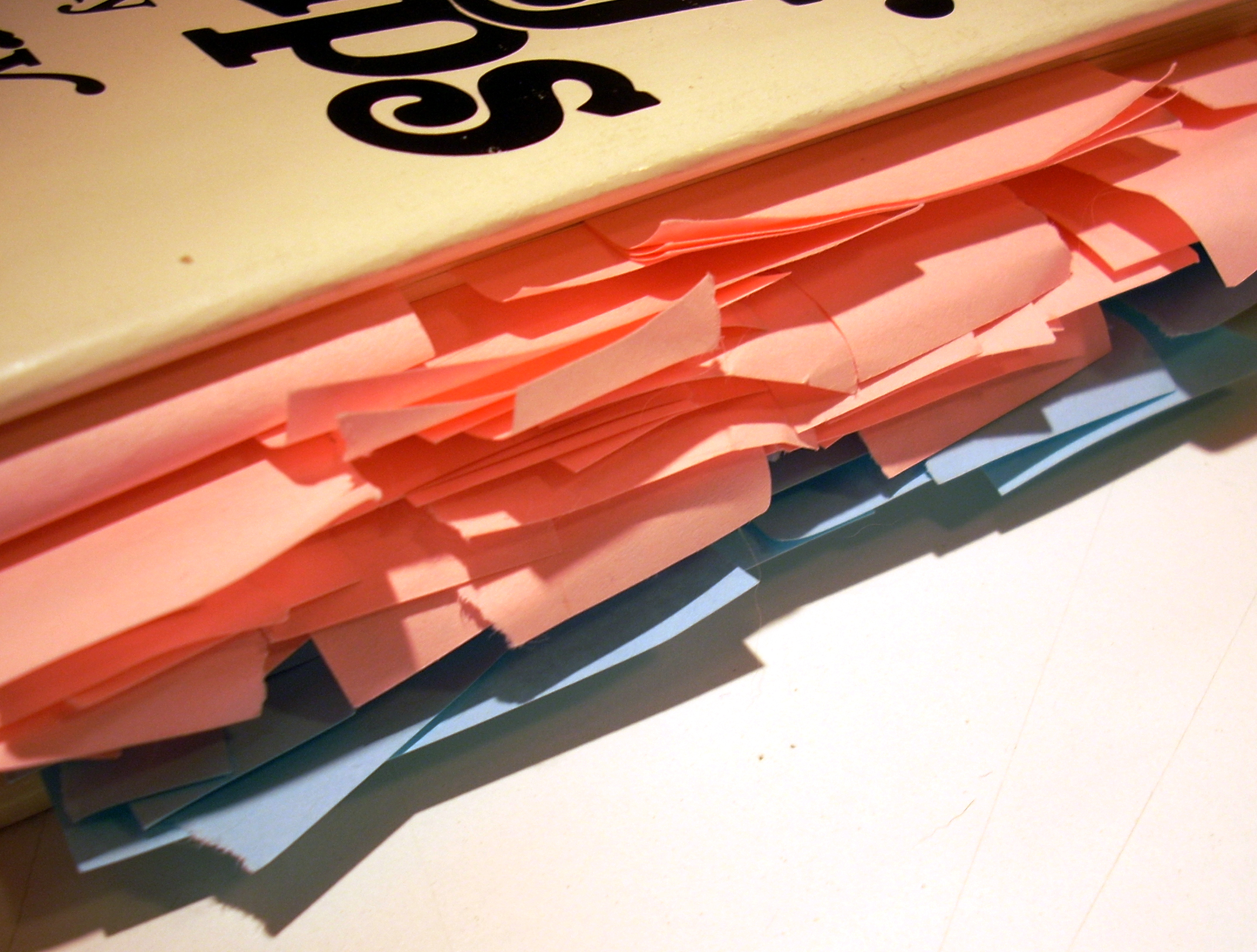

s, sticky note

A Post-it Note (or sticky note) is a small piece of paper with a re-adherable strip of glue on its back, made for temporarily attaching notes to documents and other surfaces. A low-tack pressure-sensitive adhesive allows the notes to be easil ...

pads, automobile trim, and a wide variety of other products.

As the name "pressure-sensitive" indicates, the degree of bond is influenced by the amount of pressure which is used to apply the adhesive to the surface.

Surface factors such as smoothness, surface energy

In surface science, surface free energy (also interfacial free energy or surface energy) quantifies the disruption of intermolecular bonds that occurs when a surface is created. In solid-state physics, surfaces must be intrinsically less energe ...

, removal of contaminants, etc. are also important to proper bonding.

PSAs are usually designed to form a bond and hold properly at room temperatures. PSAs typically reduce or lose their tack at low temperatures and reduce their shear holding ability at high temperatures; special adhesives are made to function at high or low temperatures.

Structural and pressure-sensitive adhesives

Adhesives may be broadly divided in two classes: structural and pressure-sensitive. To form a permanent bond, structural adhesives harden via processes such asevaporation

Evaporation is a type of vaporization that occurs on the surface of a liquid as it changes into the gas phase. High concentration of the evaporating substance in the surrounding gas significantly slows down evaporation, such as when humidi ...

of solvent (for example, white glue), reaction with UV radiation (as in dental adhesives), chemical reaction (such as two part epoxy

Epoxy is the family of basic components or cured end products of epoxy resins. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. The epoxide functional group is also coll ...

), or cooling (as in hot melt). In contrast, pressure-sensitive adhesives (PSAs) form a bond simply by the application of light pressure to marry the adhesive with the adherend.

Pressure-sensitive adhesives are designed with a balance between flow and resistance to flow. The bond forms because the adhesive is soft enough to flow, or wet, the adherend. The bond has strength because the adhesive is hard enough to resist flow when stress is applied to the bond. Once the adhesive and the adherend are in proximity, there are also molecular interactions such as van der Waals forces involved in the bond, which contribute significantly to the ultimate bond strength. PSAs exhibit viscoelastic ( viscous and elastic) properties, both of which are used for proper bonding.

In contrast with structural adhesives, whose strength is evaluated as lap shear strength, pressure-sensitive adhesives are characterized by their shear and peel resistance as well as their initial tack. These properties are dependent, among other things, on the formulation, coating thickness, rub-down and temperature.

"''Permanent''" pressure-sensitive adhesives are initially pressure-sensitive and removable (for example to recover mislabeled goods) but after hours or days change their properties, by becoming less or not viscous, or by increasing the bond strength, so that the bond becomes permanent.

Effects of shape

The adhesive bonding of a tape or label can be affected by its shape. Tapes with pointed corners start to detach at those corners; adhesive strength can be improved by rounding the corners.Applications

Pressure-sensitive adhesives are designed for either permanent or removable applications. Examples of permanent applications include safety labels for power equipment, foil tape for

Pressure-sensitive adhesives are designed for either permanent or removable applications. Examples of permanent applications include safety labels for power equipment, foil tape for HVAC

Heating, ventilation, and air conditioning (HVAC) is the use of various technologies to control the temperature, humidity, and purity of the air in an enclosed space. Its goal is to provide thermal comfort and acceptable indoor air quality. HV ...

duct work, automotive interior trim assembly, and sound/vibration damping films. Some high performance permanent PSAs exhibit high adhesion values and can support kilograms of weight per square centimeter of contact area, even at elevated temperature. These build adhesion to a permanent bond after several hours or days.

Removal

Removable adhesives are designed to form a temporary bond, and ideally can be removed after months or years without leaving residue on the adherend. Removable adhesives are used in applications such as surface protection films,masking tape

Masking tape, also known as painter's tape, is a type of pressure-sensitive tape made of a thin and easy-to-tear paper, and an easily released pressure-sensitive adhesive. It is available in a variety of widths. It is used mainly in painting, to ...

s, bookmark and note papers, price marking labels, promotional graphics materials, and for skin contact (wound care dressings, EKG electrodes, athletic tape, transdermal drug patches, etc.). Some removable adhesives are designed to repeatedly stick and unstick. They have low adhesion and generally cannot support much weight.

Sometimes clean removal of pressure sensitive tape can be difficult without damaging the substrate that it is adhered to. Pulling at a slow rate and with a low angle of peel helps reduce surface damage. PSA residue can be softened with certain organic solvents

A solvent (s) (from the Latin '' solvō'', "loosen, untie, solve") is a substance that dissolves a solute, resulting in a solution. A solvent is usually a liquid but can also be a solid, a gas, or a supercritical fluid. Water is a solvent for p ...

or heat. Extreme cold ( dry ice, freeze spray, etc.) can cause viscoelastic materials to change to a glass phase; thus it is useful for removing many types of PSAs.

Manufacture

Pressure-sensitive adhesives are manufactured with either a liquid carrier or in 100% solid form. Articles such as tapes and labels are made from liquid PSAs by coating the adhesive on a support and evaporating the organic solvent or water carrier, usually in a hot air dryer. The dry adhesive may be further heated to initiate a cross-linking reaction and increase molecular weight. 100% solid PSAs may be low viscosity polymers that are coated and then reacted with radiation to increase molecular weight and form the adhesive (radiation cured PSA); or they may be high-viscosity materials that are heated to reduce viscosity enough to allow coating, and then cooled to their final form ( hot melt PSA, HMPSA).Composition

PSAs are usually based on anelastomer

An elastomer is a polymer with viscoelasticity (i.e. both viscosity and elasticity) and with weak intermolecular forces, generally low Young's modulus and high failure strain compared with other materials. The term, a portmanteau of ''elastic p ...

compounded with a suitable tackifier (e.g., a rosin ester). The elastomers can be based on acrylics, which can have sufficient tack on their own and do not require a tackifier.

Styrene block copolymers (SBC), also called styrene copolymer adhesives and rubber-based adhesives, have good low-temperature flexibility, high elongation, and high heat resistance. They are frequently used in hot melt adhesive applications, where the composition retains tack even when solidified; however non-pressure-sensitive formulations are also used. They usually have A-B-A structure, with an elastic rubber segment between two rigid plastic endblocks. High-strength film formers as standalone, increase cohesion and viscosity as an additive. Water-resistant, soluble in some organic solvents; cross-linking improves solvent resistance. Resins associating with endblocks (cumarone-indene, α-methyl styrene, vinyl toluene, aromatic hydrocarbons, etc.) improve adhesion and alter viscosity. Resins associating to the midblocks (aliphatic olefins, rosin esters, polyterpenes, terpene phenolics) improve adhesion, processing and pressure-sensitive properties. Addition of plasticizers reduces cost, improves pressure-sensitive tack, decrease melt viscosity, decrease hardness, and improves low-temperature flexibility. The A-B-A structure promotes a phase separation of the polymer, binding together the endblocks, with the central elastic parts acting as cross-links; SBCs do not require additional cross-linking.

Styrene- butadiene-styrene (SBS) is used in high-strength PSA applications, styrene-ethylene/ butylene-styrene (SEBS) in low self-adhering non-woven applications, and styrene-ethylene/propylene (SEP) and styrene-isoprene

Isoprene, or 2-methyl-1,3-butadiene, is a common volatile organic compound with the formula CH2=C(CH3)−CH=CH2. In its pure form it is a colorless volatile liquid. Isoprene is an unsaturated hydrocarbon. It is produced by many plants and animals ...

-styrene (SIS) are used in low-viscosity high-tack PSA applications.

See also

*Blu-Tack

Blu Tack is a reusable putty-like pressure-sensitive adhesive produced by Bostik, commonly used to attach lightweight objects (such as posters or sheets of paper) to walls, doors or other dry surfaces. Traditionally blue, it is also av ...

* Contact mechanics

* Dynamic mechanical analysis

* Glue dots Glue dots are pressure-sensitive adhesive dots, used in various different applications, such as sticking credit cards to paper, arts and crafts, and as a safe adhesive for children to use, without needing a hot glue gun. Glue dots are globules of ad ...

* Gaffer tape

* List of adhesive tapes

* Post-it note

* Rheology

* Self-adhesive stamp

A self-adhesive stamp is a postage stamp with a pressure-sensitive adhesive that does not require moistening in order to adhere to paper. They are usually issued on a removable backing paper.

Stamp collectors criticized the format, because the ...

* Viscoelasticity

* Pressure-sensitive paper

A label (as distinct from signage) is a piece of paper, plastic film, cloth, metal, or other material affixed to a container or product, on which is written or printed information or symbols about the product or item. Information printed dir ...

References

Further reading

* "Pressure-Sensitive Adhesives and Applications", Istvan Benedek, 2004, * "Pressure Sensitive Adhesive Tapes", J. Johnston, PSTC, 2003, * "Pressure Sensitive Formulation", I. Benedek, VSP, 2000, {{DEFAULTSORT:Pressure Sensitive Adhesive Adhesives Stationery