Scientific management on:

[Wikipedia]

[Google]

[Amazon]

Scientific management is a theory of

Scientific management is a theory of

Taylorism led to

Taylorism led to

Infoblatt Taylorismus. Frederick Winslow Taylor stellte Theorien zur Optimierung der Arbeit bzw. Unternehmen auf.

' Leipzig: Klett Verlag. * * * * Koch, S. (2011). ''Einführung in das Management von Geschäftsprozessen.'' Berling Heidelberg: Springer Verlag. * Laube, H. (2014)

In: ''Der Spiegel.'' * McGaughey, Ewan, 'Behavioral Economics and Labor Law' (2014

LSE Legal Studies Working Paper No. 20/2014

* * * * * * .

Also available from Project Gutenberg

'' * * * *

''Eight Scenarios for Work in the Future.''

in ''Futurist,'' v17 n3 pp. 24–29 Jun 1983, reprinted in Cornish, Edward and World Future Society (1985

''Habitats tomorrow: homes and communities in an exciting new era : selections from The futurist''

pp. 14–19 * * * . ''"Shop Management" began as an address by Taylor to a meeting of the ASME, which published it in pamphlet form. The link here takes the reader to a 1912 republication by Harper & Brothers

Also available from Project Gutenberg

''

''Special Collections: F.W. Taylor Collection''

''Stevens Institute of Technology has an extensive collection at its library.'' {{Authority control History of business Production and manufacturing Management theory Industrial and organizational psychology

Scientific management is a theory of

Scientific management is a theory of management

Management (or managing) is the administration of organizations, whether businesses, nonprofit organizations, or a Government agency, government bodies through business administration, Nonprofit studies, nonprofit management, or the political s ...

that analyzes and synthesizes workflow

Workflow is a generic term for orchestrated and repeatable patterns of activity, enabled by the systematic organization of resources into processes that transform materials, provide services, or process information. It can be depicted as a seque ...

s. Its main objective is improving economic efficiency

In microeconomics, economic efficiency, depending on the context, is usually one of the following two related concepts:

* Allocative or Pareto efficiency: any changes made to assist one person would harm another.

* Productive efficiency: no addit ...

, especially labor productivity. It was one of the earliest attempts to apply science to the engineering

Engineering is the practice of using natural science, mathematics, and the engineering design process to Problem solving#Engineering, solve problems within technology, increase efficiency and productivity, and improve Systems engineering, s ...

of processes in management. Scientific management is sometimes known as Taylorism after its pioneer, Frederick Winslow Taylor

Frederick Winslow Taylor (March 20, 1856 – March 21, 1915) was an American mechanical engineer. He was widely known for his methods to improve industrial efficiency. He was one of the first management consulting, management consultants. In 190 ...

. Mitcham, Carl and Adam, Briggle ''Management'' in Mitcham (2005) p. 1153

Taylor began the theory's development in the United States during the 1880s and 1890s within manufacturing

Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of the

secondary sector of the economy. The term may refer ...

industries, especially steel. Its peak of influence came in the 1910s. Although Taylor died in 1915, by the 1920s scientific management was still influential but had entered into competition

Competition is a rivalry where two or more parties strive for a common goal which cannot be shared: where one's gain is the other's loss (an example of which is a zero-sum game). Competition can arise between entities such as organisms, indi ...

and syncretism

Syncretism () is the practice of combining different beliefs and various school of thought, schools of thought. Syncretism involves the merging or religious assimilation, assimilation of several originally discrete traditions, especially in the ...

with opposing or complementary ideas.

Although scientific management as a distinct theory or school of thought was obsolete by the 1930s, most of its themes are still important parts of industrial engineering

Industrial engineering (IE) is concerned with the design, improvement and installation of integrated systems of people, materials, information, equipment and energy. It draws upon specialized knowledge and skill in the mathematical, physical, an ...

and management today. These include: analysis; synthesis; logic

Logic is the study of correct reasoning. It includes both formal and informal logic. Formal logic is the study of deductively valid inferences or logical truths. It examines how conclusions follow from premises based on the structure o ...

; rationality

Rationality is the quality of being guided by or based on reason. In this regard, a person acts rationally if they have a good reason for what they do, or a belief is rational if it is based on strong evidence. This quality can apply to an ab ...

; empiricism

In philosophy, empiricism is an epistemological view which holds that true knowledge or justification comes only or primarily from sensory experience and empirical evidence. It is one of several competing views within epistemology, along ...

; work ethic

Work ethic is a belief that work and diligence have a moral benefit and an inherent ability, virtue or value to strengthen character and individual abilities. Desire or determination to work serves as the foundation for values centered on the i ...

; efficiency through elimination of wasteful activities (as in '' muda'', '' muri'' and '' mura''); standardization

Standardization (American English) or standardisation (British English) is the process of implementing and developing technical standards based on the consensus of different parties that include firms, users, interest groups, standards organiza ...

of best practice

A best practice is a method or technique that has been generally accepted as superior to alternatives because it tends to produce superior results. Best practices are used to achieve quality as an alternative to mandatory standards. Best practice ...

s; disdain for tradition preserved merely for its own sake or to protect the social status

Social status is the relative level of social value a person is considered to possess. Such social value includes respect, honour, honor, assumed competence, and deference. On one hand, social scientists view status as a "reward" for group members ...

of particular workers with particular skill sets; the transformation of craft production into mass production

Mass production, also known as mass production, series production, series manufacture, or continuous production, is the production of substantial amounts of standardized products in a constant flow, including and especially on assembly lines ...

; and knowledge transfer

Knowledge transfer refers to transferring an awareness of facts or practical skills from one entity to another.Kjell Arne Røvik (2016). "Knowledge Transfer as Translation: Review and Elements of an Instrumental Theory." ''International Journa ...

between workers and from workers into tools, processes, and documentation.

Name

Taylor's own names for his approach initially included "shop management" and "process management". However, "scientific management" came to national attention in 1910 when attorneyLouis Brandeis

Louis Dembitz Brandeis ( ; November 13, 1856 – October 5, 1941) was an American lawyer who served as an Associate Justice of the Supreme Court of the United States, associate justice on the Supreme Court of the United States from 1916 to ...

(then not yet Supreme Court justice) popularized the term..

Brandeis had sought a consensus term for the approach with the help of practitioners like Henry L. Gantt and Frank B. Gilbreth. Brandeis then used the consensus of "SCIENTIFIC management" when he argued before the Interstate Commerce Commission (ICC) that a proposed increase in railroad rates was unnecessary despite an increase in labor costs; he alleged scientific management would overcome railroad inefficiencies (The ICC ruled against the rate increase, but also dismissed as insufficiently substantiated that concept the railroads were necessarily inefficient.) Taylor recognized the nationally known term "scientific management" as another good name for the concept, and adopted it in the title of his influential 1911 monograph.

History

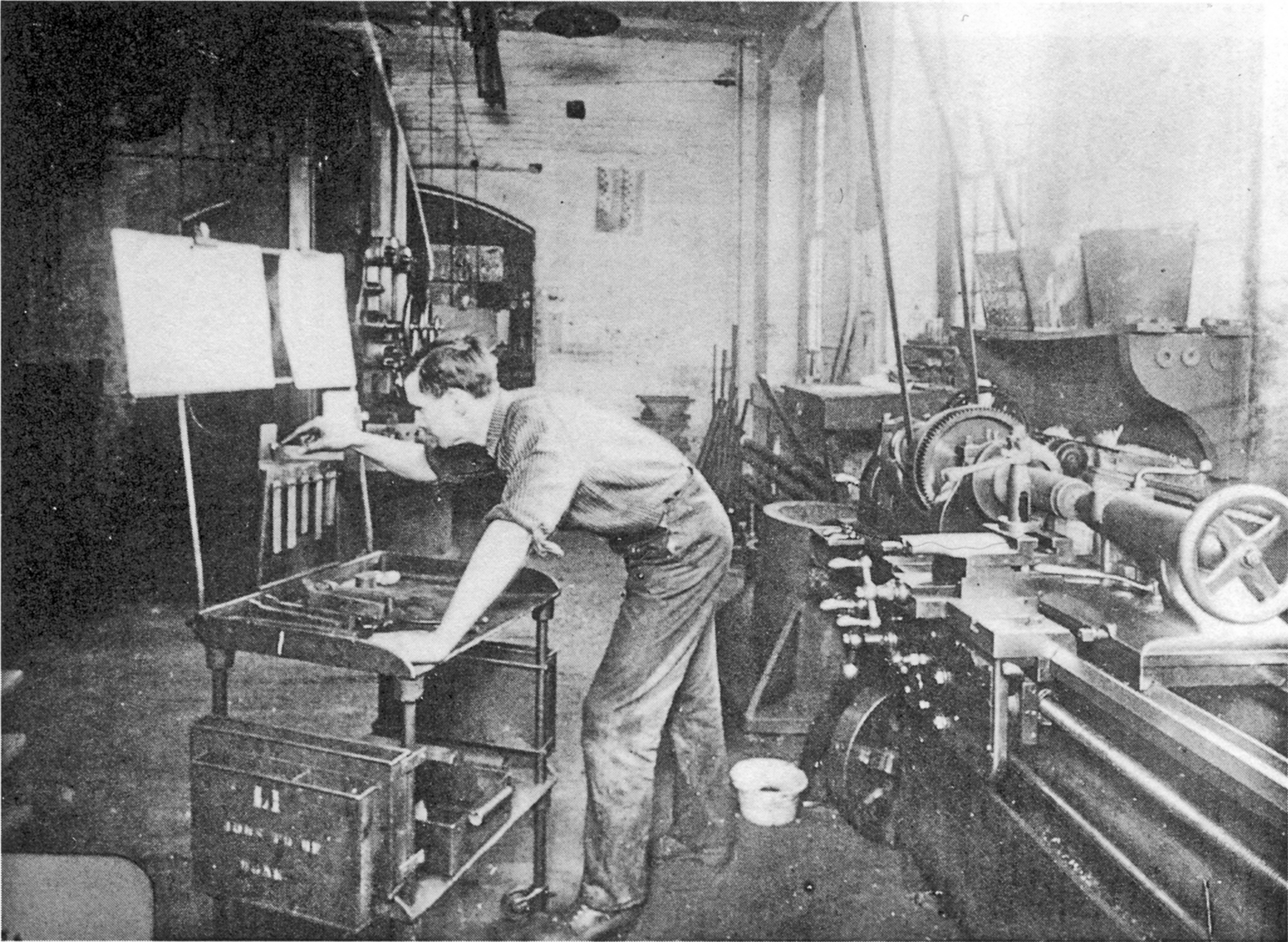

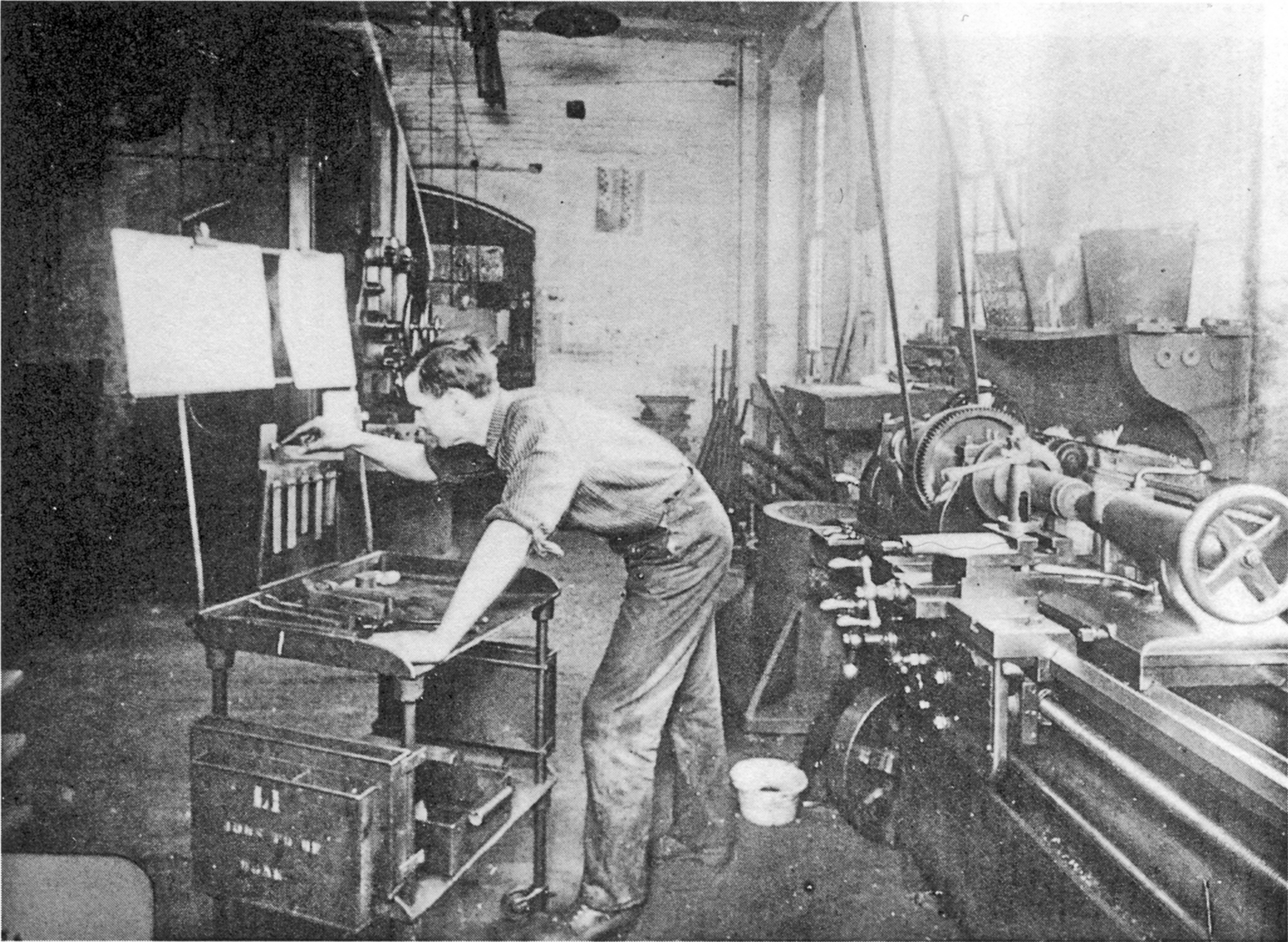

The Midvale Steel Company, "one of America's great armor plate making plants," was the birthplace of scientific management. In 1877, Frederick W. Taylor started as a clerk in Midvale, but advanced to foreman in 1880. As foreman, Taylor was "constantly impressed by the failure of his eam membersto produce more than about one-third of hat he deemeda good day's work". Taylor determined to discover, by scientific methods, how long it should take men to perform each given piece of work; and it was in the fall of 1882 that he started to put the first features of scientific management into operation. Horace Bookwalter Drury, in his 1918 work, ''Scientific management: A History and Criticism'', identified seven other leaders in the movement, most of whom learned of and extended scientific management from Taylor's efforts: * Henry L. Gantt (1861–1919) * Carl G. Barth (1860–1939) * Horace K. Hathaway (1878–1944) * Morris L. Cooke (1872–1960) * Sanford E. Thompson (1867–1949) * Frank B. Gilbreth (1868–1924). Gilbreth's independent work on "motion study" is on record as early as 1885; after meeting Taylor in 1906 and being introduced to scientific management, Gilbreth devoted his efforts to introducing scientific management into factories. Gilbreth and his wife Lillian Moller Gilbreth (1878–1972) performed micro-motion studies using stop-motion cameras as well as developing the profession of industrial/organizational psychology. * Harrington Emerson (1853–1931) began determining what industrial plants' products and costs were compared to what they ought to be in 1895. Emerson did not meet Taylor until December 1900, and the two never worked together. Emerson's testimony in late 1910 to the Interstate Commerce Commission brought the movement to national attention and instigated serious opposition. Emerson contended the railroads might save $1,000,000 a day by paying greater attention to efficiency of operation. By January 1911, a leading railroad journal began a series of articles denying they were inefficiently managed. When steps were taken to introduce scientific management at the government-owned Rock Island Arsenal in early 1911, it was opposed by Samuel Gompers, founder and President of theAmerican Federation of Labor

The American Federation of Labor (A.F. of L.) was a national federation of labor unions in the United States that continues today as the AFL-CIO. It was founded in Columbus, Ohio, in 1886 by an alliance of craft unions eager to provide mutual ...

(an alliance of craft unions). When a subsequent attempt was made to introduce the bonus system into the government's Watertown Arsenal foundry during the summer of 1911, the entire force walked out for a few days. Congressional investigations followed, resulting in a ban on the use of time studies and pay premiums in Government service.

Taylor's death in 1915 at age 59 left the movement without its original leader. In management literature today, the term "scientific management" mostly refers to the work of Taylor and his disciples ("classical", implying "no longer current, but still respected for its seminal value") in contrast to newer, improved iterations of efficiency-seeking methods. Today, task-oriented optimization of work tasks is nearly ubiquitous in industry.

Scientific Management Principles

Frederick Taylor tackled the challenge of making a business productive and profitable in his years of service and research in a steel company. He believed in a scientific solution. In his "Shop Management" article, Taylor explained that there were two facts that appeared "most noteworthy" in the field of management: (a) "Great unevenness": the lack of uniformity in what is called "the management", (b) The lack of relation between good (shop) management and the pay. He added,"The art of management has been defined, "''as knowing exactly what you want men to do, and then seeing that they do it in the best and cheapest way''"."In this regard, he highlighted that although there is "no concise definition" for this art, "the relations between employers and men form without question the most important part of this art". He then continued that a good management must in long run give satisfaction to both managers and workers. Taylor emphasized that he was advocating "high wages" and "low labor cost" as "the foundation of the best management". Discussing the pays for different classes of workers and what he called a "first-class" workman, he compared different scenarios of workmanship and their pros and cons. For best management, he asserted with ample reasons that managers in an organization should follow the following guideline:

(a) Each worker should be given the highest grade of work they are capable of. (b) Each worker should be demanded the work that a first-grade worker can do and thrive. (c) When each worker works at the pace of a first-grade worker, they should be paid 30% to 100% beyond the average of their class.While Taylor stated that sharing "the equitable division of the profits" is required in an organization, he believed that management could unite high wages with a low labor cost by application of the following principles:

(a) A large daily task: Each worker in the organization, should have a clearly defined task. (b) Standard Conditions: Each worker should be given standard conditions and appliances that will enable him to perform his tasks. (c) High pay for success: Each worker should be rewarded when he accomplishes their task. (d) Loss in case of failure: When a worker fails, he should know that he would share the loss.In Scientific Management, the responsibility of the success or failure of an organization is not solely on the shoulder of the workers, as it is in the old management systems. According to Scientific Management, the managers are taking half of the burden by being responsible for securing the proper work conditions for workers' prosperity. In his book "Principles of Scientific Management", Taylor formally introduced his methodically investigated theory of Scientific Management. Although he explained the details of Scientific Management in his works, he did not provide its concise definition. Shortly before his death, Taylor approved the following summary and definition of Scientific Management that Hoxie prepared:

"Scientific management is a system devised by industrial engineers for the purpose of serving the common interests of employers, workmen and society at large through the elimination of avoidable wastes, the general improvement of the processes and methods of production, and the just and scientific distribution of the product."Taylor indicated that Scientific Management consisted of four underlying principles:

1) the development of a true science: We must scientifically analyze all parts of a job. This consists of examining the elements and steps that required to carry out the work, as well as measuring the optimum time for each task. We also need to know the working time per day for a qualified worker. 2) the scientific selection of the workers: The most suitable person for the job is selected. 3) the scientific education and training of the workers: There is a clear division of work and responsibility between managers and workers. While workers are carrying out the job with quality and workmanship, managers are responsible for planning, supervision, and proper training of the workers. 4) cooperation between managers and workers: Managers and workers scientific cooperation is required to ensure the proper and high-quality execution of the jobs.There are various tools that would enable us to serve these principles, such as time and motion study, functional foremanship, standardization of tools and movements of workers for each type of work, clear instructions for workers, and cost accounting. There are many other features, tools, and methods that Taylor developed and recommended during his job at the steel plant and research, which have footprints in other fields, such as accounting and Engineering. Some of his concepts, studies, and findings has led to intellectual revolution in organization management. Taylor made contributions to various fields such as work measurement, production planning and control, process design, quality control, ergonomics, and human engineering.

Pursuit of economic efficiency

Flourishing in the late 19th and early 20th century, scientific management built on earlier pursuits ofeconomic efficiency

In microeconomics, economic efficiency, depending on the context, is usually one of the following two related concepts:

* Allocative or Pareto efficiency: any changes made to assist one person would harm another.

* Productive efficiency: no addit ...

. While it was prefigured in the folk wisdom of thrift, it favored empirical methods

Empirical research is research using empirical evidence. It is also a way of gaining knowledge by means of direct and indirect observation or experience. Empiricism values some research more than other kinds. Empirical evidence (the record of o ...

to determine efficient procedures rather than perpetuating established traditions. Thus it was followed by a profusion of successors in applied science, including time and motion study

A time and motion study (or time–motion study) is a business efficiency technique combining the ''time study'' work of Frederick Winslow Taylor with the ''motion study'' work of Frank and Lillian Gilbreth (the same couple as is best known t ...

, the Efficiency Movement (which was a broader cultural echo of scientific management's impact on business managers specifically), Fordism

Fordism is an industrial engineering and manufacturing system that serves as the basis of modern social and labor-economic systems that support industrialized, standardized mass production and mass consumption. The concept is named after Henry ...

, operations management

Operations management is concerned with designing and controlling the production (economics), production of good (economics), goods and service (economics), services, ensuring that businesses are efficiency, efficient in using resources to meet ...

, operations research

Operations research () (U.S. Air Force Specialty Code: Operations Analysis), often shortened to the initialism OR, is a branch of applied mathematics that deals with the development and application of analytical methods to improve management and ...

, industrial engineering

Industrial engineering (IE) is concerned with the design, improvement and installation of integrated systems of people, materials, information, equipment and energy. It draws upon specialized knowledge and skill in the mathematical, physical, an ...

, management science

Management science (or managerial science) is a wide and interdisciplinary study of solving complex problems and making strategic decisions as it pertains to institutions, corporations, governments and other types of organizational entities. It is ...

, manufacturing engineering

Manufacturing engineering or production engineering is a branch of professional engineering that shares many common concepts and ideas with other fields of engineering such as mechanical, chemical, electrical, and industrial engineering.

Manufac ...

, logistics

Logistics is the part of supply chain management that deals with the efficient forward and reverse flow of goods, services, and related information from the point of origin to the Consumption (economics), point of consumption according to the ...

, business process management

Business process management (BPM) is the discipline in which people use various methods to Business process discovery, discover, Business process modeling, model, Business analysis, analyze, measure, improve, optimize, and Business process auto ...

, business process reengineering

Business process re-engineering (BPR) is a business management strategy originally pioneered in the early 1990s, focusing on the analysis and design of workflows and business processes within an organization. BPR aims to help organizations fund ...

, lean manufacturing

Lean manufacturing is a methods of production, method of manufacturing goods aimed primarily at reducing times within the Operations management#Production systems, production system as well as response times from suppliers and customers. It is ...

, and Six Sigma. There is a fluid continuum linking scientific management with the later fields, and the different approaches often display a high degree of compatibility.

Taylor rejected the notion, which was universal in his day and still held today, that the trades, including manufacturing, were resistant to analysis and could only be performed by craft production methods. In the course of his empirical studies, Taylor examined various kinds of manual labor

Manual labour (in Commonwealth English, manual labor in American English) or manual work is physical work done by humans, in contrast to labour by machines and working animals. It is most literally work done with the hands (the word ''manual'' ...

. For example, most bulk materials handling was manual at the time; material handling equipment as we know it today was mostly not developed yet. He looked at shovel

A shovel is a tool used for digging, lifting, and moving bulk materials, such as soil, coal, gravel, snow, sand, or ore. Most shovels are hand tools consisting of a broad blade fixed to a medium-length handle. Shovel blades are usually made ...

ing in the unloading of railroad car

A railroad car, railcar (American English, American and Canadian English), railway wagon, railway carriage, railway truck, railwagon, railcarriage or railtruck (British English and International Union of Railways, UIC), also called a tra ...

s full of ore; lifting and carrying in the moving of iron pigs at steel mills; the manual inspection of bearing balls; and others. He discovered many concepts that were not widely accepted at the time. For example, by observing workers, he decided that labor should include rest breaks so that the worker has time to recover from fatigue, either physical (as in shoveling or lifting) or mental (as in the ball inspection case). Workers were allowed to take more rests during work, and productivity increased as a result.

Subsequent forms of scientific management were articulated by Taylor's disciples, such as Henry Gantt

Henry Laurence Gantt (; May 20, 1861 – November 23, 1919) was an American mechanical engineer and management consultant who is best known for his work in the development of scientific management. He created the Gantt chart in the 1910s.

Gant ...

; other engineers and managers, such as Benjamin S. Graham; and other theorists, such as Max Weber

Maximilian Carl Emil Weber (; ; 21 April 186414 June 1920) was a German Sociology, sociologist, historian, jurist, and political economy, political economist who was one of the central figures in the development of sociology and the social sc ...

. Taylor's work also contrasts with other efforts, including those of Henri Fayol and those of Frank Gilbreth, Sr. and Lillian Moller Gilbreth (whose views originally shared much with Taylor's but later diverged in response to Taylorism's inadequate handling of human relations).

Soldiering

Scientific management requires a high level of managerial control over employee work practices and entails a higher ratio of managerial workers to laborers than previous management methods. Such detail-oriented management may cause friction between workers and managers. Taylor observed that some workers were more talented than others, and that even smart ones were often unmotivated. He observed that most workers who are forced to perform repetitive tasks tend to work at the slowest rate that goes unpunished. This slow rate of work has been observed in many industries and many countries. and has been called by various terms.. Taylor used the term "soldiering", a term that reflects the way conscripts may approach following orders, and observed that, when paid the same amount, workers will tend to do the amount of work that the slowest among them does.. Taylor describes soldiering as "the greatest evil with which the working-people ... are now afflicted". This reflects the idea that workers have a vested interest in their own well-being, and do not benefit from working above the defined rate of work when it will not increase their remuneration. He, therefore, proposed that the work practice that had been developed in most work environments was crafted, intentionally or unintentionally, to be very inefficient in its execution. He posited that time and motion studies combined with rational analysis and synthesis could uncover one best method for performing any particular task, and that prevailing methods were rarely equal to these best methods. Crucially, Taylor himself prominently acknowledged that if each employee's compensation was linked to their output, theirproductivity

Productivity is the efficiency of production of goods or services expressed by some measure. Measurements of productivity are often expressed as a ratio of an aggregate output to a single input or an aggregate input used in a production proce ...

would go up. Thus his compensation plans usually included piece rates. In contrast, some later adopters of time and motion studies ignored this aspect and tried to get large productivity gains while passing little or no compensation gains to the workforce, which contributed to resentment against the system.

Productivity, automation, and unemployment

Taylorism led to

Taylorism led to productivity

Productivity is the efficiency of production of goods or services expressed by some measure. Measurements of productivity are often expressed as a ratio of an aggregate output to a single input or an aggregate input used in a production proce ...

increases, meaning fewer workers or working hours were needed to produce the same amount of goods. In the short term, productivity increases like those achieved by Taylor's efficiency techniques can cause considerable disruption. Labor relations

Labour relations in practice is a subarea within human resource management, and the main components of it include collective bargaining, application and oversight of collective agreement obligations, and dispute resolution. Academically, employe ...

often become contentious over whether the financial benefits will accrue to owners in the form of increased profits, or workers in the form of increased wages. As a result of decomposition and documentation of manufacturing processes, companies employing Taylor's methods might be able to hire lower-skill workers, enlarging the pool of workers and thus lowering wages and job security

Job security is the probability that an individual will keep their job; a job with a high level of security is such that a person with the job would have a small chance of losing it. Many factors threaten job security: globalization, outsourcing ...

.

In the long term, most economists consider productivity increases as a benefit to the economy overall, and necessary to improve the standard of living

Standard of living is the level of income, comforts and services available to an individual, community or society. A contributing factor to an individual's quality of life, standard of living is generally concerned with objective metrics outsid ...

for consumers in general. By the time Taylor was doing his work, improvements in agricultural productivity had freed up a large portion of the workforce for the manufacturing sector, allowing those workers in turn to buy new types of consumer goods instead of working as subsistence farmer

Subsistence agriculture occurs when farmers grow crops on smallholdings to meet the needs of themselves and their families. Subsistence agriculturalists target farm output for survival and for mostly local requirements. Planting decisions occu ...

s. In later years, increased manufacturing efficiency would free up large sections of the workforce for the service sector

The tertiary sector of the economy, generally known as the service sector, is the third of the three economic sectors in the three-sector model (also known as the economic cycle). The others are the primary sector (raw materials) and the ...

. If captured as profits or wages, the money generated by more-productive companies would be spent on new goods and services; if free market competition forces prices down close to the cost of production, consumers effectively capture the benefits and have more money to spend on new goods and services. Either way, new companies and industries spring up to profit from increased demand, and due to freed-up labor are able to hire workers. But the long-term benefits are no guarantee that individual displaced workers will be able to get new jobs that paid them as well or better as their old jobs, as this may require access to education or job training, or moving to different part of the country where new industries are growing. Inability to obtain new employment due to mismatches like these is known as structural unemployment

Structural unemployment is a form of involuntary unemployment caused by a mismatch between the skills that workers in the economy can offer, and the skills demanded of workers by employers (also known as the skills gap). Structural unemployment is ...

, and economists debate to what extent this is happening in the long term, if at all, as well as the impact on income inequality for those who do find jobs.

Though not foreseen by early proponents of scientific management, detailed decomposition and documentation of an optimal production method also makes automation

Automation describes a wide range of technologies that reduce human intervention in processes, mainly by predetermining decision criteria, subprocess relationships, and related actions, as well as embodying those predeterminations in machine ...

of the process easier, especially physical processes that would later use industrial control systems and numerical control

Computer numerical control (CNC) or CNC machining is the automated control of machine tools by a computer. It is an evolution of numerical control (NC), where machine tools are directly managed by data storage media such as punched cards or ...

. Widespread economic globalization also creates opportunity for work to be outsourced to lower-wage areas, with knowledge transfer

Knowledge transfer refers to transferring an awareness of facts or practical skills from one entity to another.Kjell Arne Røvik (2016). "Knowledge Transfer as Translation: Review and Elements of an Instrumental Theory." ''International Journa ...

made easier if an optimal method is already clearly documented. Especially when wages or wage differentials are high, automation and offshoring

Offshoring is the relocation of a business process from one country to another—typically an operational process, such as manufacturing, or supporting processes, such as accounting. Usually this refers to a company business, although state gover ...

can result in significant productivity gains and similar questions of who benefits and whether or not technological unemployment

The term technological unemployment is used to describe the loss of jobs caused by technological change. It is a key type of structural unemployment. Technological change typically includes the introduction of labour-saving "mechanical-muscle" ...

is persistent. Because automation is often best suited to tasks that are repetitive and boring, and can also be used for tasks that are dirty, dangerous, and demeaning, proponents believe that in the long run it will free up human workers for more creative, safer, and more enjoyable work.

Taylorism and unions

The early history of labor relations with scientific management in the U.S. was described by Horace Bookwalter Drury: In 1911, organized labor erupted with strong opposition to scientific management, including from Samuel Gompers, founder and president of the American Federation of Labor (AFL). Once the time-and-motion men had completed their studies of a particular task, the workers had very little opportunity for further thinking, experimenting, or suggestion-making. Taylorism was criticized for turning the worker into an "automaton" or "machine", making work monotonous and unfulfilling by doing one small and rigidly defined piece of work instead of using complex skills with the whole production process done by one person. "The further 'progress' of industrial development... increased the anomic or forced division of labor," the opposite of what Taylor thought would be the effect. Some workers also complained about being made to work at a faster pace and producing goods of lower quality. The Watertown Arsenal in Massachusetts provides an example of the application and repeal of the Taylor system in the workplace, due to worker opposition. In the early 20th century, neglect in the Watertown shops included overcrowding, dim lighting, lack of tools and equipment, and questionable management strategies in the eyes of the workers. Frederick W. Taylor and Carl G. Barth visited Watertown in April 1909 and reported on their observations at the shops. Their conclusion was to apply the Taylor system of management to the shops to produce better results. Efforts to install the Taylor system began in June 1909. Over the years of time study and trying to improve the efficiency of workers, criticisms began to evolve. Workers complained of having to compete with one another, feeling strained and resentful, and feeling excessively tired after work. In June 1913, employees of the Watertown Arsenal petitioned to abolish the practice of scientific management there. A number of magazine writers inquiring into the effects of scientific management found that the "conditions in shops investigated contrasted favorably with those in other plants". A committee of the U.S. House of Representatives investigated and reported in 1912, advocating standardization and systematizing, but not a stop-watch time study without consent of workmen. Scientific management gave production managers a dangerously high level of uncontrolled power.. After an attitude survey of the workers revealed a high level of resentment and hostility towards scientific management, the Senate banned Taylor's methods at the arsenal. Taylor had a largely negative view of unions, and believed they only led to decreased productivity. Efforts to resolve conflicts with workers included methods of scientific collectivism, making agreements with unions, and the personnel management movement.Relationship to Fordism

It is often assumed thatFordism

Fordism is an industrial engineering and manufacturing system that serves as the basis of modern social and labor-economic systems that support industrialized, standardized mass production and mass consumption. The concept is named after Henry ...

derives from Taylor's work. Taylor apparently made this assumption himself when visiting the Ford Motor Company

Ford Motor Company (commonly known as Ford) is an American multinational corporation, multinational automobile manufacturer headquartered in Dearborn, Michigan, United States. It was founded by Henry Ford and incorporated on June 16, 1903. T ...

's Michigan plants not too long before he died, but it is likely that the methods at Ford were evolved independently, and that any influence from Taylor's work was indirect at best.. Charles E. Sorensen, a principal of the company during its first four decades, disclaimed any connection at all. There was a belief at Ford, which remained dominant until Henry Ford II

Henry Ford II (September 4, 1917 – September 29, 1987), commonly known as Hank the Deuce, was an American businessman in the automotive industry. He was the oldest son of Edsel Ford I and oldest grandson of Henry Ford. He served as president ...

took over the company in 1945, that the world's experts were worthless, because if Ford had listened to them, it would have failed to attain its great successes. Henry Ford

Henry Ford (July 30, 1863 – April 7, 1947) was an American Technological and industrial history of the United States, industrialist and business magnate. As the founder of the Ford Motor Company, he is credited as a pioneer in making automob ...

felt that he had succeeded ''in spite of'', not ''because of'', experts, who had tried to stop him in various ways (disagreeing about price points, production methods, car features, business financing, and other issues). Sorensen thus was dismissive of Taylor and lumped him into the category of useless experts. Sorensen held the New England machine tool vendor Walter Flanders in high esteem and credits him for the efficient floorplan layout at Ford, claiming that Flanders knew nothing about Taylor. Flanders may have been exposed to the spirit of Taylorism elsewhere, and may have been influenced by it, but he did not cite it when developing his production technique. Regardless, the Ford team apparently did independently invent modern mass production techniques in the period of 1905–1915, and they themselves were not aware of any borrowing from Taylorism. Perhaps it is only possible with hindsight to see the zeitgeist that (indirectly) connected the budding Fordism to the rest of the efficiency movement during the decade of 1905–1915.

Adoption in planned economies

Scientific management appealed to managers ofplanned economies

A planned economy is a type of economic system where investment, production and the allocation of capital goods takes place according to economy-wide economic plans and production plans. A planned economy may use centralized, decentralized, ...

because central economic planning relies on the idea that the expenses that go into economic production can be precisely predicted and can be optimized by design.

Soviet Union

By 1913Vladimir Lenin

Vladimir Ilyich Ulyanov ( 187021 January 1924), better known as Vladimir Lenin, was a Russian revolutionary, politician and political theorist. He was the first head of government of Soviet Russia from 1917 until Death and state funeral of ...

wrote that the "most widely discussed topic today in Europe, and to some extent in Russia, is the 'system' of the American engineer, Frederick Taylor"; Lenin decried it as merely a "'scientific' system of sweating" more work from laborers. Again in 1914, Lenin derided Taylorism as "man's enslavement by the machine". However, after the Russian Revolutions brought him to power, Lenin wrote in 1918 that the "Russian is a bad worker ho mustlearn to work. The Taylor system... is a combination of the refined brutality of bourgeois exploitation and a number of the greatest scientific achievements in the field of analysing mechanical motions during work, the elimination of superfluous and awkward motions, the elaboration of correct methods of work, the introduction of the best system of accounting and control, etc. The Soviet Republic must at all costs adopt all that is valuable in the achievements of science and technology in this field."

In the Soviet Union

The Union of Soviet Socialist Republics. (USSR), commonly known as the Soviet Union, was a List of former transcontinental countries#Since 1700, transcontinental country that spanned much of Eurasia from 1922 until Dissolution of the Soviet ...

, Taylorism was advocated by Aleksei Gastev and ''nauchnaia organizatsia truda'' (''the movement for the scientific organization of labor''). It found support in both Vladimir Lenin

Vladimir Ilyich Ulyanov ( 187021 January 1924), better known as Vladimir Lenin, was a Russian revolutionary, politician and political theorist. He was the first head of government of Soviet Russia from 1917 until Death and state funeral of ...

and Leon Trotsky

Lev Davidovich Bronstein ( – 21 August 1940), better known as Leon Trotsky,; ; also transliterated ''Lyev'', ''Trotski'', ''Trockij'' and ''Trotzky'' was a Russian revolutionary, Soviet politician, and political theorist. He was a key figure ...

. Gastev continued to promote this system of labor management until his arrest and execution in 1939.. In the 1920s and 1930s, the Soviet Union enthusiastically embraced Fordism and Taylorism, importing American experts in both fields as well as American engineering firms to build parts of its new industrial infrastructure. The concepts of the Five Year Plan and the centrally planned economy can be traced directly to the influence of Taylorism on Soviet thinking. As scientific management was believed to epitomize American efficiency,. Joseph Stalin

Joseph Vissarionovich Stalin (born Dzhugashvili; 5 March 1953) was a Soviet politician and revolutionary who led the Soviet Union from 1924 until Death and state funeral of Joseph Stalin, his death in 1953. He held power as General Secret ...

even claimed that "the combination of the Russian revolutionary sweep with American efficiency is the essence of Leninism

Leninism (, ) is a political ideology developed by Russian Marxist revolutionary Vladimir Lenin that proposes the establishment of the Dictatorship of the proletariat#Vladimir Lenin, dictatorship of the proletariat led by a revolutionary Vangu ...

.", quoting .

Sorensen was one of the consultants who brought American know-how to the USSR during this era,. before the Cold War

The Cold War was a period of global Geopolitics, geopolitical rivalry between the United States (US) and the Soviet Union (USSR) and their respective allies, the capitalist Western Bloc and communist Eastern Bloc, which lasted from 1947 unt ...

made such exchanges unthinkable. As the Soviet Union developed and grew in power, both sides, the Soviets and the Americans, chose to ignore or deny the contribution that American ideas and expertise had made: the Soviets because they wished to portray themselves as creators of their own destiny and not indebted to a rival, and the Americans because they did not wish to acknowledge their part in creating a powerful communist rival. Anti-communism

Anti-communism is Political movement, political and Ideology, ideological opposition to communism, communist beliefs, groups, and individuals. Organized anti-communism developed after the 1917 October Revolution in Russia, and it reached global ...

had always enjoyed widespread popularity in America, and anti-capitalism

Anti-capitalism is a political ideology and movement encompassing a variety of attitudes and ideas that oppose capitalism. Anti-capitalists seek to combat the worst effects of capitalism and to eventually replace capitalism with an alternati ...

in Russia, but after World War II, they precluded any admission by either side that technologies or ideas might be either freely shared or clandestinely stolen.

East Germany

By the 1950s, scientific management had grown dated, but its goals and practices remained attractive and were also being adopted by theGerman Democratic Republic

East Germany, officially known as the German Democratic Republic (GDR), was a country in Central Europe from Foundation of East Germany, its formation on 7 October 1949 until German reunification, its reunification with West Germany (FRG) on ...

as it sought to increase efficiency in its industrial sectors. Workers engaged in a state-planned instance of process improvement, pursuing the same goals that were contemporaneously pursued in capitalist

Capitalism is an economic system based on the private ownership of the means of production and their use for the purpose of obtaining profit. This socioeconomic system has developed historically through several stages and is defined by ...

societies, as in the Toyota Production System

The Toyota Production System (TPS) is an integrated socio-technical system, developed by Toyota, that comprises its management philosophy and practices. The TPS is a management system that organizes manufacturing and logistics for the automobile ...

.

Criticism of rigor

Taylor believed that thescientific method

The scientific method is an Empirical evidence, empirical method for acquiring knowledge that has been referred to while doing science since at least the 17th century. Historically, it was developed through the centuries from the ancient and ...

of management included the calculations of exactly how much time it takes a man to do a particular task, or his rate of work. Critics of Taylor complained that such a calculation relies on certain arbitrary, non-scientific decisions such as what constituted the job, which men were timed, and under which conditions. Any of these factors are subject to change, and therefore can produce inconsistencies. Some dismiss so-called "scientific management" or Taylorism as pseudoscience

Pseudoscience consists of statements, beliefs, or practices that claim to be both scientific and factual but are incompatible with the scientific method. Pseudoscience is often characterized by contradictory, exaggerated or unfalsifiable cl ...

.

Others are critical of the representativeness

The representativeness heuristic is used when making judgments about the probability of an event being representational in character and essence of a known prototypical event. It is one of a group of heuristics (simple rules governing judgment or d ...

of the workers Taylor selected to take his measurements.

Variations of scientific management after Taylorism

In the 1900s

Taylorism was one of the first attempts to systematically treat management and process improvement as a scientific problem, and Taylor is considered a founder of modernindustrial engineering

Industrial engineering (IE) is concerned with the design, improvement and installation of integrated systems of people, materials, information, equipment and energy. It draws upon specialized knowledge and skill in the mathematical, physical, an ...

. Taylorism may have been the first "bottom-up" method and found a lineage of successors that have many elements in common. Later methods took a broader approach, measuring not only productivity but quality. With the advancement of statistical methods, quality assurance

Quality assurance (QA) is the term used in both manufacturing and service industries to describe the systematic efforts taken to assure that the product(s) delivered to customer(s) meet with the contractual and other agreed upon performance, design ...

and quality control

Quality control (QC) is a process by which entities review the quality of all factors involved in production. ISO 9000 defines quality control as "a part of quality management focused on fulfilling quality requirements".

This approach plac ...

began in the 1920s and 1930s. During the 1940s and 1950s, the body of knowledge for doing scientific management evolved into operations management

Operations management is concerned with designing and controlling the production (economics), production of good (economics), goods and service (economics), services, ensuring that businesses are efficiency, efficient in using resources to meet ...

, operations research

Operations research () (U.S. Air Force Specialty Code: Operations Analysis), often shortened to the initialism OR, is a branch of applied mathematics that deals with the development and application of analytical methods to improve management and ...

, and management cybernetics

Cybernetics is the transdisciplinary study of circular causal processes such as feedback and recursion, where the effects of a system's actions (its outputs) return as inputs to that system, influencing subsequent action. It is concerned with ...

. In the 1980s total quality management

Total quality management (TQM) is an organization-wide effort to "install and make a permanent climate where employees continuously improve their ability to provide on-demand products and services that customers will find of particular value." ...

became widely popular, growing from quality control

Quality control (QC) is a process by which entities review the quality of all factors involved in production. ISO 9000 defines quality control as "a part of quality management focused on fulfilling quality requirements".

This approach plac ...

techniques. In the 1990s "re-engineering" went from a simple word to a mystique. Today's Six Sigma and lean manufacturing

Lean manufacturing is a methods of production, method of manufacturing goods aimed primarily at reducing times within the Operations management#Production systems, production system as well as response times from suppliers and customers. It is ...

could be seen as new kinds of scientific management, although their evolutionary

Evolution is the change in the heritable characteristics of biological populations over successive generations. It occurs when evolutionary processes such as natural selection and genetic drift act on genetic variation, resulting in certa ...

distance from the original is so great that the comparison might be misleading. In particular, Shigeo Shingo

was a Japanese industrial engineer who was considered as the world’s leading expert on manufacturing practices and the Toyota Production System.

Life and work

After having worked as a technician specializing in fusions at the Taiwanese railw ...

, one of the originators of the Toyota Production System

The Toyota Production System (TPS) is an integrated socio-technical system, developed by Toyota, that comprises its management philosophy and practices. The TPS is a management system that organizes manufacturing and logistics for the automobile ...

, believed that this system and Japanese management culture in general should be seen as a kind of scientific management. These newer methods are all based on systematic analysis

Analysis (: analyses) is the process of breaking a complex topic or substance into smaller parts in order to gain a better understanding of it. The technique has been applied in the study of mathematics and logic since before Aristotle (38 ...

rather than relying on tradition and rule of thumb.

Other thinkers, even in Taylor's own time, also proposed considering the individual worker's needs, not just the needs of the process. Critics said that in Taylorism, "the worker was taken for granted as a cog in the machinery." James Hartness

James Hartness (September 3, 1861 – February 2, 1934) was an American business executive, inventor, mechanical engineer, entrepreneur, amateur astronomer, and politician who served as the List of Governors of Vermont, 58th governor of Vermont f ...

published ''The Human Factor in Works Management'' in 1912, while Frank Gilbreth and Lillian Moller Gilbreth offered their own alternatives to Taylorism. The human relations school of management (founded by the work of Elton Mayo

George Elton Mayo (26 December 1880 – 7 September 1949) was an Australian born psychologist, industrial researcher, and organizational theorist.Cullen, David O'Donald. ''A new way of statecraft: The career of Elton Mayo and the development ...

) evolved in the 1930s as a counterpoint or complement of scientific management. Taylorism focused on the organization of the work process, and human relations helped workers adapt to the new procedures.. Modern definitions of "quality control" like ISO-9000 include not only clearly documented and optimized manufacturing tasks, but also consideration of human factors like expertise, motivation, and organizational culture. The Toyota Production System

The Toyota Production System (TPS) is an integrated socio-technical system, developed by Toyota, that comprises its management philosophy and practices. The TPS is a management system that organizes manufacturing and logistics for the automobile ...

, from which lean manufacturing

Lean manufacturing is a methods of production, method of manufacturing goods aimed primarily at reducing times within the Operations management#Production systems, production system as well as response times from suppliers and customers. It is ...

in general is derived, includes "respect for people" and teamwork as core principles.

Peter Drucker

Peter Ferdinand Drucker (; ; November 19, 1909 – November 11, 2005) was an Austrian American management consultant, educator, and author, whose writings contributed to the philosophical and practical foundations of modern management theory. H ...

saw Frederick Taylor as the creator of knowledge management

Knowledge management (KM) is the set of procedures for producing, disseminating, utilizing, and overseeing an organization's knowledge and data. It alludes to a multidisciplinary strategy that maximizes knowledge utilization to accomplish organ ...

, because the aim of scientific management was to produce knowledge about how to improve work processes. Although the typical application of scientific management was manufacturing, Taylor himself advocated scientific management for all sorts of work, including the management of schools, universities and government. For example, Taylor believed scientific management could be extended to "the work of our salesmen". Shortly after his death, his acolyte Harlow S. Person began to lecture corporate audiences on the possibility of using Taylorism for "sales engineering". (Person was talking about what is now called sales process engineering

Sales process engineering is the systematic design of sales processes done in order to make sales more effective and efficient..

It can be applied in functions including sales, marketing, and customer service

Customer service is the assista ...

—engineering the processes that sales

Sales are activities related to selling or the number of goods sold in a given targeted time period. The delivery of a service for a cost is also considered a sale. A period during which goods are sold for a reduced price may also be referred ...

people use—not about what we call sales engineering

Sales engineering is a hybrid profession of sales and engineering that exists in industrial and commercial markets.

Buying decisions in these markets are made differently than those in many consumer contexts, being based more on technical informa ...

today.) This was a watershed insight in the history of corporate marketing

Marketing is the act of acquiring, satisfying and retaining customers. It is one of the primary components of Business administration, business management and commerce.

Marketing is usually conducted by the seller, typically a retailer or ma ...

.

In the 2000s

Google's methods of increasing productivity and output can be seen to be influenced by Taylorism as well. The Silicon Valley company is a forerunner in applying behavioral science (such as the motivations of purpose, mastery, and autonomy set out by Daniel Pink in his 2009 book '' Drive: The Surprising Truth About What Motivates Us'') to increase knowledge worker productivity. In classic scientific management as well as approaches like lean management where leaders facilitate and empower teams to continuously improve their standards and values. Leading high-tech companies use the concept of nudge management to increase productivity of employees. More and more business leaders start to make use of this new scientific management. Today's militaries employ all of the major goals and tactics of scientific management, if not under that name. Of the key points, all but wage incentives for increased output are used by modern military organizations. Wage incentives rather appear in the form of skill bonuses for enlistments. Scientific management has had an important influence in sports, where stop watches and motion studies rule the day. (Taylor himself enjoyed sports, especially tennis and golf. He and a partner won a national championship in doubles tennis. He invented improved tennis racquets and improved golf clubs, although other players liked to tease him for his unorthodox designs, and they did not catch on as replacements for the mainstream implements). Modern human resources can be seen to have begun in the scientific management era, most notably in the writings of Katherine M. H. Blackford. Practices descended from scientific management are currently used in offices and in medicine (e.g.managed care

In the United States, managed care or managed healthcare is a group of activities intended to reduce the cost of providing health care and providing health insurance while improving the quality of that care. It has become the predominant system o ...

) as well..

In countries with a post-industrial economy, manufacturing jobs are a relatively few, with most workers in the service sector

The tertiary sector of the economy, generally known as the service sector, is the third of the three economic sectors in the three-sector model (also known as the economic cycle). The others are the primary sector (raw materials) and the ...

. One approach to efficiency in information work is called digital Taylorism, which uses software to monitor the performance of employees who use computers all day.

See also

*American system of manufacturing

The American system of manufacturing was a set of manufacturing methods that evolved in the 19th century. The two notable features were the extensive use of interchangeable parts and mechanization for production, which resulted in more efficient u ...

* ''Cheaper by the Dozen

''Cheaper by the Dozen'' is a semi-autobiographical novel written by Frank Bunker Gilbreth Jr. and Ernestine Gilbreth Carey, published in 1948. The novel recounts the authors' childhood lives growing up in a household of 12 children. The bes ...

''

* Hawthorne effect

The Hawthorne effect is a type of human behavior reactivity in which individuals modify an aspect of their behavior in response to their awareness of being observed. The effect was discovered in the context of research conducted at the Hawthorn ...

* Henry Louis Le Châtelier (1850–1936), industrial chemist and author of French language texts on Taylorism

* ''Modern Times'' (film)

* ''The Pajama Game

''The Pajama Game'' is a musical based on the 1953 novel '' 7½ Cents'' by Richard Bissell.

The book is by George Abbott and Richard Bissell; the music and lyrics are by Richard Adler and Jerry Ross. Dances were staged by Bob Fosse in his chor ...

''

* ''Pandora's Box

Pandora's box is an artifact in Greek mythology connected with the myth of Pandora in Hesiod's c. 700 B.C. poem ''Works and Days''. Hesiod related that curiosity led her to open a container left in the care of her husband, thus releasing curses ...

''

* Hans Renold (1852–1943), credited with introducing Taylorism to Britain

* Stakhanovism

* Theory X and Theory Y

* Henry R. Towne (1844–1924), ASME President and author of the seminal ''The Engineer as An Economist'' (1886)

* Words per minute

Words per minute, commonly abbreviated as WPM (sometimes lowercased as wpm), is a measure of words processed in a minute, often used as a measurement of the speed of typing, reading or Morse code sending and receiving.

Alphanumeric entry

Since ...

* Exploitation

Notes

References

* . ;

*

* Bonazzi, G. (2014). ''Geschichte des organisatorischen Denkens''. Wiesbaden: Springer Fachmedien.

*

*

*

*

* Dumas, M., La Rosa, M., Mendling, J. & Reijers, H. (2013). ''Fundamentals of Business Process Management.'' Berlin Heidelberg: Springer Verlag.

* Freriks, R. (1996). ''Theoretische Modelle der Betriebsgröße im Maschinenbau. Koordination und Kontrollmechanismen bei organisatorischem Wachstum''. Opladen: Leske+ Budrich.

* .

*

*

* Hebeisen, W. (1999). ''F.W. Taylor und der Taylorismus. Über das Wirken und die Lehre Taylors und die Kritik am Taylorismus''. Zürich: vdf Hochschulverlag AG.

* Henke, J. (2004). Infoblatt Taylorismus. Frederick Winslow Taylor stellte Theorien zur Optimierung der Arbeit bzw. Unternehmen auf.

' Leipzig: Klett Verlag. * * * * Koch, S. (2011). ''Einführung in das Management von Geschäftsprozessen.'' Berling Heidelberg: Springer Verlag. * Laube, H. (2014)

In: ''Der Spiegel.'' * McGaughey, Ewan, 'Behavioral Economics and Labor Law' (2014

LSE Legal Studies Working Paper No. 20/2014

* * * * * * .

Also available from Project Gutenberg

'' * * * *

Further reading

* * Morf, Martin (1983''Eight Scenarios for Work in the Future.''

in ''Futurist,'' v17 n3 pp. 24–29 Jun 1983, reprinted in Cornish, Edward and World Future Society (1985

''Habitats tomorrow: homes and communities in an exciting new era : selections from The futurist''

pp. 14–19 * * * . ''"Shop Management" began as an address by Taylor to a meeting of the ASME, which published it in pamphlet form. The link here takes the reader to a 1912 republication by Harper & Brothers

Also available from Project Gutenberg

''

External links

''Special Collections: F.W. Taylor Collection''

''Stevens Institute of Technology has an extensive collection at its library.'' {{Authority control History of business Production and manufacturing Management theory Industrial and organizational psychology