Scheil Equation on:

[Wikipedia]

[Google]

[Amazon]

In

Kozlov and Schmid-Fetzer have calculated numerically the derivative of the Scheil curve in an open paper https://iopscience.iop.org/article/10.1088/1757-899X/27/1/012001 and applied it to the growth restriction factor Q in Al-Si-Mg-Cu alloys.

Kozlov and Schmid-Fetzer have calculated numerically the derivative of the Scheil curve in an open paper https://iopscience.iop.org/article/10.1088/1757-899X/27/1/012001 and applied it to the growth restriction factor Q in Al-Si-Mg-Cu alloys.

33 (K)

metallurgy

Metallurgy is a domain of materials science and engineering that studies the physical and chemical behavior of metallic elements, their inter-metallic compounds, and their mixtures, which are known as alloys.

Metallurgy encompasses both the sc ...

, the Scheil-Gulliver equation (or Scheil equation) describes solute

In chemistry, a solution is a special type of homogeneous mixture composed of two or more substances. In such a mixture, a solute is a substance dissolved in another substance, known as a solvent. If the attractive forces between the solvent ...

redistribution during solidification

Freezing is a phase transition where a liquid turns into a solid when its temperature is lowered below its freezing point. In accordance with the internationally established definition, freezing means the solidification phase change of a liquid o ...

of an alloy

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductility, ...

.

Assumptions

Four key assumptions in Scheil analysis enable determination of phases present in a cast part. These assumptions are: # No diffusion occurs in solid phases once they are formed () # Infinitely fast diffusion occurs in the liquid at all temperatures by virtue of a high diffusion coefficient, thermalconvection

Convection is single or multiphase fluid flow that occurs spontaneously due to the combined effects of material property heterogeneity and body forces on a fluid, most commonly density and gravity (see buoyancy). When the cause of the convec ...

, Marangoni convection, etc. ()

# Equilibrium exists at the solid-liquid interface, and so compositions from the phase diagram

A phase diagram in physical chemistry, engineering, mineralogy, and materials science is a type of chart used to show conditions (pressure, temperature, volume, etc.) at which thermodynamically distinct phases (such as solid, liquid or gaseous ...

are valid

# Solidus and liquidus are straight segments

The fourth condition (straight solidus/liquidus segments) may be relaxed when numerical techniques are used, such as those used in CALPHAD software packages, though these calculations rely on calculated equilibrium phase diagrams. Calculated diagrams may include odd artifacts (i.e. retrograde solubility) that influence Scheil calculations.

Derivation

The hatched areas in the figure represent the amount of solute in the solid and liquid. Considering that the total amount of solute in the system must be conserved, the areas are set equal as follows: :. Since thepartition coefficient

In the physical sciences, a partition coefficient (''P'') or distribution coefficient (''D'') is the ratio of concentrations of a compound in a mixture of two immiscible solvents at equilibrium. This ratio is therefore a comparison of the solub ...

(related to solute distribution) is

: (determined from the phase diagram)

and mass must be conserved

:

the mass balance may be rewritten as

:.

Using the boundary condition

: at

the following integration may be performed:

:.

Integrating results in the Scheil-Gulliver equation for composition of the liquid during solidification:

:

or for the composition of the solid:

:.

Applications of the Scheil equation: Calphad Tools for the Metallurgy of Solidification

Nowadays, several Calphad softwares are available - in a framework ofcomputational thermodynamics Computational thermodynamics is the use of computers to simulate thermodynamic problems specific to materials science, particularly used in the construction of phase diagrams.

Several open and commercial programs exist to perform these operation ...

- to simulate solidification in systems with more than two components; these have recently been defined as Calphad Tools for the Metallurgy of Solidification. In recent years, Calphad-based methodologies have reached maturity in several important fields of metallurgy, and especially in solidification-related processes such as semi-solid casting, 3d printing, and welding, to name a few. While there are important studies devoted to the progress of Calphad methodology, there is still space for a systematization of the field, which proceeds from the ability of most Calphad-based software to simulate solidification curves and includes both fundamental and applied studies on solidification, to be substantially appreciated by a wider community than today. The three applied fields mentioned above could be widened by specific successful examples of simple modeling related to the topic of this issue, with the aim of widening the application of simple and effective tools related to Calphad and Metallurgy. See also "Calphad Tools for the Metallurgy of Solidification" in an ongoing issue of an Open Journal. https://www.mdpi.com/journal/metals/special_issues/Calphad_Solidification

Given a specific chemical composition, using a software for computational thermodynamics - which might be open or commercial - the calculation of the Scheil curve is possible if a thermodynamic database is available. A good point in favour of some specific commercial softwares is that the install is easy indeed and you can use it on a windows based system - for instance with students or for self training.

One should get some open, chiefly binary, databases (extension *.tdb), one could find - after registering - at Computational Phase Diagram Database (CPDDB) of the National Institute for Materials Science of Japan, NIMS https://cpddb.nims.go.jp/index_en.html. They are available - for free - and the collection is rather complete; in fact currently 507 binary systems are available in the thermodynamic data base (tdb) format.

Some wider and more specific alloy systems partly open - with tdb compatible format - are available with minor corrections for Pandat use at Matcalc https://www.matcalc.at/index.php/databases/open-databases.

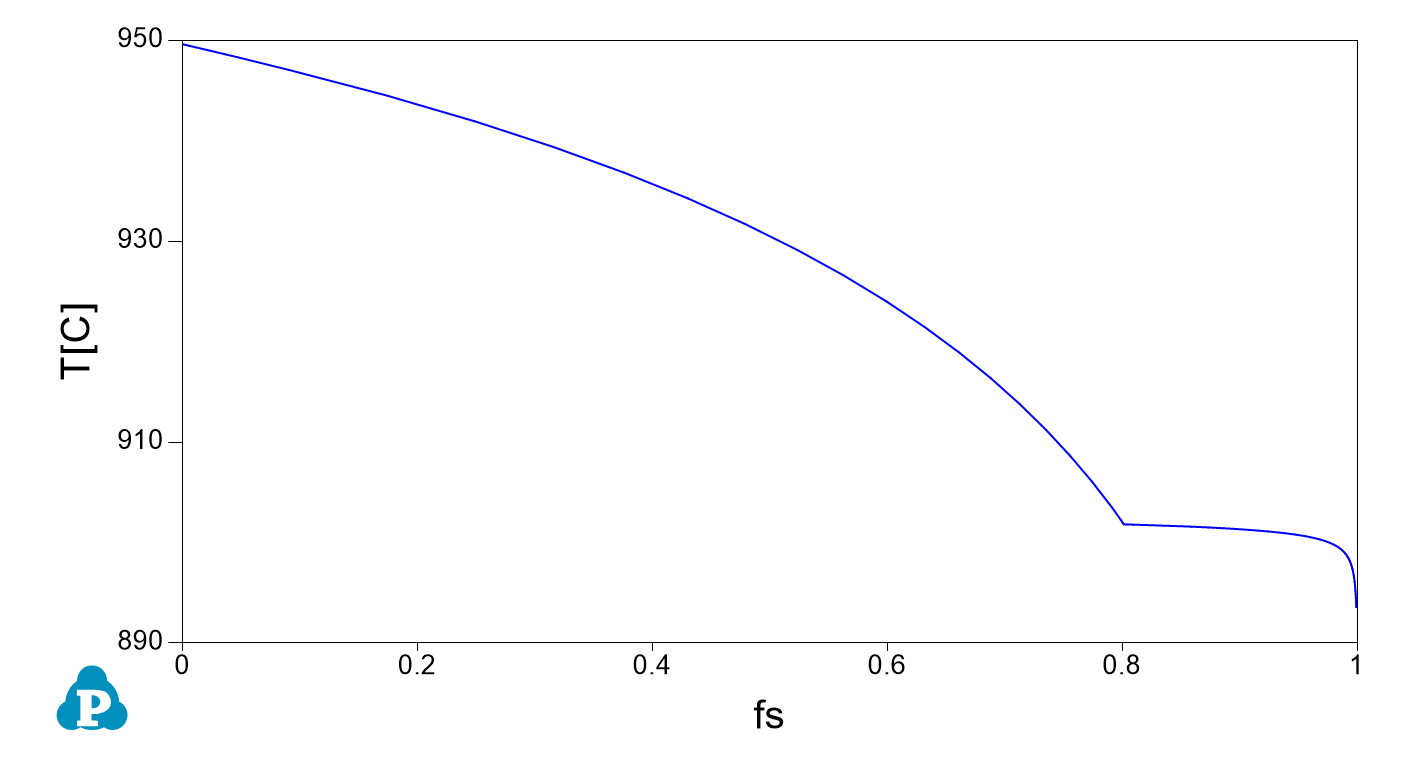

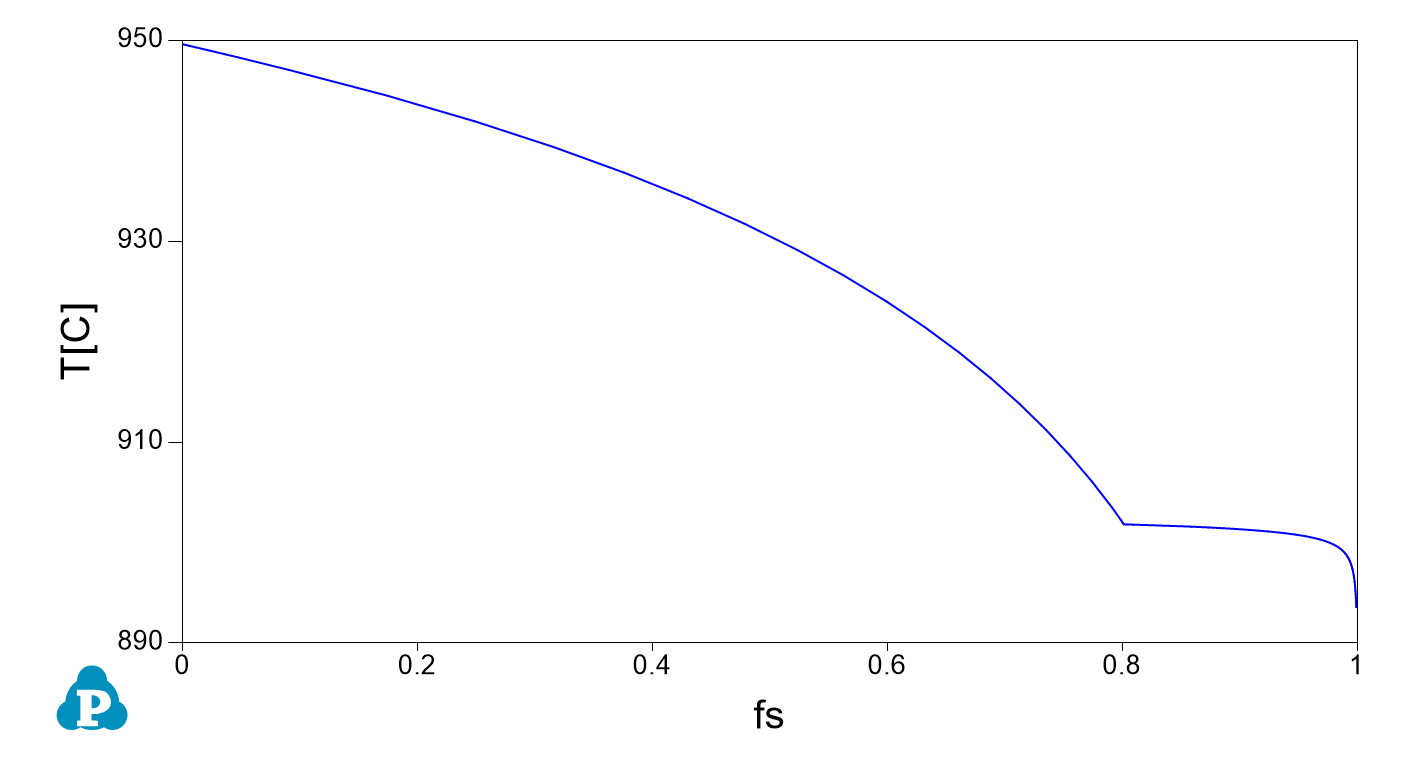

Numerical expression and numerical derivative of the Scheil curve: application to grain size on solidification and semi-solid processing

A key concept that might be used for applications is the (numerical) derivative of the solid fraction fs with temperature. A numerical example using a copper zinc alloy at composition Zn 30% in weight is proposed as an example here using the opposite sign for using both temperature and its derivative in the same graph. Kozlov and Schmid-Fetzer have calculated numerically the derivative of the Scheil curve in an open paper https://iopscience.iop.org/article/10.1088/1757-899X/27/1/012001 and applied it to the growth restriction factor Q in Al-Si-Mg-Cu alloys.

Kozlov and Schmid-Fetzer have calculated numerically the derivative of the Scheil curve in an open paper https://iopscience.iop.org/article/10.1088/1757-899X/27/1/012001 and applied it to the growth restriction factor Q in Al-Si-Mg-Cu alloys.

Application to grain size on solidification

This - Calphad calculated value of numerical derivative - Q has some interesting applications in the field of metal solidification. In fact, Q reflects the phase diagram of the alloy system and its reciprocal has been found to have a relationship with grain size d on solidification, which empirically has been found in some cases to be linear: where a and b are constants, as illustrated with some examples from the literature for Mg and Al alloys. Before Calphad use, Q values were calculated from the conventional relationship: Q=m*c0(k−1) where m is the slope of the liquidus, c0 is the solute concentration, and k is the equilibrium distribution coefficient. More recently some other possible correlation of Q with grain size d have been found, for instance: where B is a constant independent of alloy composition.Application to solidification cracking

In recent publications, prof. Sindo Kou has proposed an approach to evaluate susceptibility to solidification cracking; this approach is based on a similar approach where a quantity, , which has the dimensions of a temperature is proposed as an index of the cracking susceptibility. Again one could exploit Scheil based solidification curves to link this index to the slope of the (Scheil) solidification curve: ∂T/(∂(fS)^1/2)= ∂T/(∂(fS)*(∂(fS)^1/2)/∂(fS))= (1/2)∂T/∂(fS)*(fS)^1/2=Application to semi-solid processing

Last but not least prof. E.J.Zoqui has summarized in his work the approach proposed by several researchers in the criteria for semi-solid processing, which involves the stability of the solid phase fs with the temperature; to process semisolid alloys the sensitivity to variation of solid fraction with temperature should be minimal: in one direction it could evolve to a difficult to deform solid, on the other to a liquid which may be difficult to shape without proper moulding. It turns out that we can express this criterion again by evaluating the slope of the solidification curve, in fact ∂(fS)/∂T should be less than a certain threshold, which is commonly accepted in the scientific and technical literature to be below 0.03 1/K. Mathematically this may be expressed by an inequation , ∂(fS)/∂T < 0.03 (1/K) - where K stands for Kelvin degrees - could be equally assumed for a rough estimate of the two main semi-solid casting processing: both rheocasting ( 0.3References

External links

* * * * * * {{cite web, title= Solidification Simulation by Scheil Model and Lever Rule , date= 3 March 2021 , url= https://computherm.com/solidification-simulation-by-scheil-model-and-lever-rule , accessdate=26 September 2021 Metallurgy Differential equations