Resistance Thermometer on:

[Wikipedia]

[Google]

[Amazon]

Resistance thermometers, also called resistance temperature detectors (RTDs), are

;Thin-film elements: have a sensing element that is formed by depositing a very thin layer of resistive material, normally platinum, on a ceramic substrate (

;Thin-film elements: have a sensing element that is formed by depositing a very thin layer of resistive material, normally platinum, on a ceramic substrate ( ;Wire-wound elements: can have greater accuracy, especially for wide temperature ranges. The coil diameter provides a compromise between mechanical stability and allowing expansion of the wire to minimize strain and consequential drift. The sensing wire is wrapped around an insulating mandrel or core. The winding core can be round or flat, but must be an electrical insulator. The coefficient of thermal expansion of the winding core material is matched to the sensing wire to minimize any mechanical strain. This strain on the element wire will result in a thermal measurement error. The sensing wire is connected to a larger wire, usually referred to as the element lead or wire. This wire is selected to be compatible with the sensing wire, so that the combination does not generate an emf that would distort the thermal measurement. These elements work with temperatures to 660 °C.

;Wire-wound elements: can have greater accuracy, especially for wide temperature ranges. The coil diameter provides a compromise between mechanical stability and allowing expansion of the wire to minimize strain and consequential drift. The sensing wire is wrapped around an insulating mandrel or core. The winding core can be round or flat, but must be an electrical insulator. The coefficient of thermal expansion of the winding core material is matched to the sensing wire to minimize any mechanical strain. This strain on the element wire will result in a thermal measurement error. The sensing wire is connected to a larger wire, usually referred to as the element lead or wire. This wire is selected to be compatible with the sensing wire, so that the combination does not generate an emf that would distort the thermal measurement. These elements work with temperatures to 660 °C.

;Coiled elements: have largely replaced wire-wound elements in industry. This design has a wire coil that can expand freely over temperature, held in place by some mechanical support, which lets the coil keep its shape. This “strain free” design allows the sensing wire to expand and contract free of influence from other materials; in this respect it is similar to the SPRT, the primary standard upon which

;Coiled elements: have largely replaced wire-wound elements in industry. This design has a wire coil that can expand freely over temperature, held in place by some mechanical support, which lets the coil keep its shape. This “strain free” design allows the sensing wire to expand and contract free of influence from other materials; in this respect it is similar to the SPRT, the primary standard upon which

sensor

A sensor is a device that produces an output signal for the purpose of sensing a physical phenomenon.

In the broadest definition, a sensor is a device, module, machine, or subsystem that detects events or changes in its environment and sends ...

s used to measure temperature. Many RTD elements consist of a length of fine wire wrapped around a heat-resistant ceramic or glass core but other constructions are also used. The RTD wire is a pure material, typically platinum

Platinum is a chemical element with the symbol Pt and atomic number 78. It is a dense, malleable, ductile, highly unreactive, precious, silverish-white transition metal. Its name originates from Spanish , a diminutive of "silver".

Platinu ...

(Pt), nickel

Nickel is a chemical element with symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive but large pieces are slow to ...

(Ni), or copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkis ...

(Cu). The material has an accurate resistance/temperature relationship which is used to provide an indication of temperature. As RTD elements are fragile, they are often housed in protective probes.

RTDs, which have higher accuracy and repeatability, are slowly replacing thermocouple

A thermocouple, also known as a "thermoelectrical thermometer", is an electrical device consisting of two dissimilar electrical conductors forming an electrical junction. A thermocouple produces a temperature-dependent voltage as a result of the ...

s in industrial applications below 600 ° C.

Resistance/temperature relationship of metals

Common RTD sensing elements for biomedical application constructed ofplatinum

Platinum is a chemical element with the symbol Pt and atomic number 78. It is a dense, malleable, ductile, highly unreactive, precious, silverish-white transition metal. Its name originates from Spanish , a diminutive of "silver".

Platinu ...

(Pt), nickel

Nickel is a chemical element with symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive but large pieces are slow to ...

(Ni), or copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkis ...

(Cu) have a repeatable resistance versus temperature relationship (''R'' vs ''T'') and operating temperature

An operating temperature is the allowable temperature range of the local ambient environment at which an electrical or mechanical device operates. The device will operate effectively within a specified temperature range which varies based on the de ...

range. The ''R'' vs ''T'' relationship is defined as the amount of resistance change of the sensor per degree of temperature change. The relative change in resistance (temperature coefficient

A temperature coefficient describes the relative change of a physical property that is associated with a given change in temperature. For a property ''R'' that changes when the temperature changes by ''dT'', the temperature coefficient α is def ...

of resistance) varies only slightly over the useful range of the sensor.

Platinum

Platinum is a chemical element with the symbol Pt and atomic number 78. It is a dense, malleable, ductile, highly unreactive, precious, silverish-white transition metal. Its name originates from Spanish , a diminutive of "silver".

Platinu ...

was proposed by Sir William Siemens as an element for a resistance temperature detector at the Bakerian lecture in 1871: it is a noble metal

A noble metal is ordinarily regarded as a metallic chemical element that is generally resistant to corrosion and is usually found in nature in its raw form. Gold, platinum, and the other platinum group metals ( ruthenium, rhodium, palladium, o ...

and has the most stable resistance–temperature relationship over the largest temperature range. Nickel

Nickel is a chemical element with symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive but large pieces are slow to ...

elements have a limited temperature range because the amount of change in resistance per degree of change in temperature becomes very non-linear at temperatures over 300 °C (572 °F). Copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkis ...

has a very linear resistance–temperature relationship; however, copper oxidizes at moderate temperatures and cannot be used over 150 °C (302 °F).

The significant characteristic of metals used as resistive elements is the linear approximation of the resistance versus temperature relationship between 0 and 100 °C. This temperature coefficient of resistance is denoted by α and is usually given in units of Ω/(Ω·°C):

:

where

: is the resistance of the sensor at 0 °C,

: is the resistance of the sensor at 100 °C.

Pure platinum

Platinum is a chemical element with the symbol Pt and atomic number 78. It is a dense, malleable, ductile, highly unreactive, precious, silverish-white transition metal. Its name originates from Spanish , a diminutive of "silver".

Platinu ...

has α = 0.003925 Ω/(Ω·°C) in the 0 to 100 °C range and is used in the construction of laboratory-grade RTDs. Conversely, two widely recognized standards for industrial RTDs IEC 60751 and ASTM E-1137 specify α = 0.00385 Ω/(Ω·°C). Before these standards were widely adopted, several different α values were used. It is still possible to find older probes that are made with platinum that have α = 0.003916 Ω/(Ω·°C) and 0.003902 Ω/(Ω·°C).

These different α values for platinum are achieved by doping – carefully introducing impurities, which become embedded in the lattice structure of the platinum and result in a different ''R'' vs. ''T'' curve and hence α value.

Calibration

To characterize the ''R'' vs ''T'' relationship of any RTD over a temperature range that represents the planned range of use, calibration must be performed at temperatures other than 0 °C and 100 °C. This is necessary to meet calibration requirements. Although RTDs are considered to be linear in operation, it must be proven that they are accurate with regard to the temperatures with which they will actually be used (see details in Comparison calibration option). Two common calibration methods are the fixed-point method and the comparison method. ;Fixed point calibration: is used for the highest-accuracy calibrations by national metrology laboratories. It uses the triple point, freezing point or melting point of pure substances such as water, zinc, tin, and argon to generate a known and repeatable temperature. These cells allow the user to reproduce actual conditions of theITS-90

The International Temperature Scale of 1990 (ITS-90) is an equipment calibration standard specified by the International Committee of Weights and Measures (CIPM) for making measurements on the Kelvin and Celsius temperature scales. It is an approx ...

temperature scale. Fixed-point calibrations provide extremely accurate calibrations (within ±0.001 °C). A common fixed-point calibration method for industrial-grade probes is the ice bath. The equipment is inexpensive, easy to use, and can accommodate several sensors at once. The ice point is designated as a secondary standard because its accuracy is ±0.005 °C (±0.009 °F), compared to ±0.001 °C (±0.0018 °F) for primary fixed points.

;Comparison calibrations: is commonly used with secondary standard platinum resistance thermometers and industrial RTDs. The thermometers being calibrated are compared to calibrated thermometers by means of a bath whose temperature is uniformly stable. Unlike fixed-point calibrations, comparisons can be made at any temperature between −100 °C and 500 °C (−148 °F to 932 °F). This method might be more cost-effective, since several sensors can be calibrated simultaneously with automated equipment. These electrically heated and well-stirred baths use silicone oils and molten salts as the medium for the various calibration temperatures.

Element types

The three main categories of RTD sensors are thin-film, wire-wound, and coiled elements. While these types are the ones most widely used in industry, other more exotic shapes are used; for example,carbon

Carbon () is a chemical element with the symbol C and atomic number 6. It is nonmetallic and tetravalent

In chemistry, the valence (US spelling) or valency (British spelling) of an element is the measure of its combining capacity with o ...

resistor

A resistor is a passive two-terminal electrical component that implements electrical resistance as a circuit element. In electronic circuits, resistors are used to reduce current flow, adjust signal levels, to divide voltages, bias active el ...

s are used at ultra-low temperatures (−273 °C to −173 °C).

;Carbon resistor elements: are cheap and widely used. They have very reproducible results at low temperatures. They are the most reliable over extremely wide range of temperatures. They generally do not suffer from significant hysteresis

Hysteresis is the dependence of the state of a system on its history. For example, a magnet may have more than one possible magnetic moment in a given magnetic field, depending on how the field changed in the past. Plots of a single component of ...

or strain gauge effects.

;Strain-free elements: use a wire coil minimally supported within a sealed housing filled with an inert gas. These sensors work up to and are used in the SPRTs that define ITS-90. They consist of platinum wire loosely coiled over a support structure, so the element is free to expand and contract with temperature. They are very susceptible to shock and vibration, as the loops of platinum can sway back and forth, causing deformation.

;Thin-film elements: have a sensing element that is formed by depositing a very thin layer of resistive material, normally platinum, on a ceramic substrate (

;Thin-film elements: have a sensing element that is formed by depositing a very thin layer of resistive material, normally platinum, on a ceramic substrate (plating

Plating is a surface covering in which a metal is deposited on a conductive surface. Plating has been done for hundreds of years; it is also critical for modern technology. Plating is used to decorate objects, for corrosion inhibition, to improv ...

). This layer is usually just 10 to 100 ångströms (1 to 10 nanometers) thick. This film is then coated with an epoxy or glass that helps protect the deposited film and also acts as a strain relief for the external lead wires. Disadvantages of this type are that they are not as stable as their wire-wound or coiled counterparts. They also can only be used over a limited temperature range due to the different expansion rates of the substrate and resistive deposited giving a "strain gauge

A strain gauge (also spelled strain gage) is a device used to measure strain on an object. Invented by Edward E. Simmons and Arthur C. Ruge in 1938, the most common type of strain gauge consists of an insulating flexible backing which supports ...

" effect that can be seen in the resistive temperature coefficient. These elements work with temperatures to without further packaging, but can operate up to when suitably encapsulated in glass or ceramic. Special high-temperature RTD elements can be used up to with the right encapsulation.

;Wire-wound elements: can have greater accuracy, especially for wide temperature ranges. The coil diameter provides a compromise between mechanical stability and allowing expansion of the wire to minimize strain and consequential drift. The sensing wire is wrapped around an insulating mandrel or core. The winding core can be round or flat, but must be an electrical insulator. The coefficient of thermal expansion of the winding core material is matched to the sensing wire to minimize any mechanical strain. This strain on the element wire will result in a thermal measurement error. The sensing wire is connected to a larger wire, usually referred to as the element lead or wire. This wire is selected to be compatible with the sensing wire, so that the combination does not generate an emf that would distort the thermal measurement. These elements work with temperatures to 660 °C.

;Wire-wound elements: can have greater accuracy, especially for wide temperature ranges. The coil diameter provides a compromise between mechanical stability and allowing expansion of the wire to minimize strain and consequential drift. The sensing wire is wrapped around an insulating mandrel or core. The winding core can be round or flat, but must be an electrical insulator. The coefficient of thermal expansion of the winding core material is matched to the sensing wire to minimize any mechanical strain. This strain on the element wire will result in a thermal measurement error. The sensing wire is connected to a larger wire, usually referred to as the element lead or wire. This wire is selected to be compatible with the sensing wire, so that the combination does not generate an emf that would distort the thermal measurement. These elements work with temperatures to 660 °C.

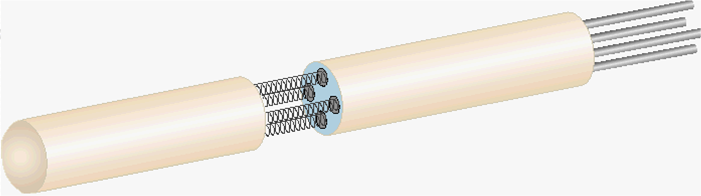

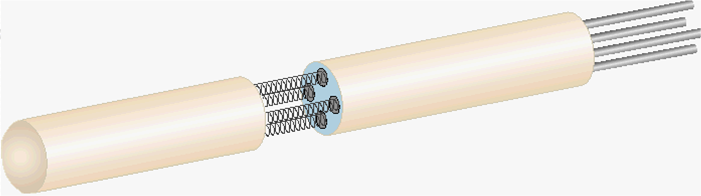

;Coiled elements: have largely replaced wire-wound elements in industry. This design has a wire coil that can expand freely over temperature, held in place by some mechanical support, which lets the coil keep its shape. This “strain free” design allows the sensing wire to expand and contract free of influence from other materials; in this respect it is similar to the SPRT, the primary standard upon which

;Coiled elements: have largely replaced wire-wound elements in industry. This design has a wire coil that can expand freely over temperature, held in place by some mechanical support, which lets the coil keep its shape. This “strain free” design allows the sensing wire to expand and contract free of influence from other materials; in this respect it is similar to the SPRT, the primary standard upon which ITS-90

The International Temperature Scale of 1990 (ITS-90) is an equipment calibration standard specified by the International Committee of Weights and Measures (CIPM) for making measurements on the Kelvin and Celsius temperature scales. It is an approx ...

is based, while providing the durability necessary for industrial use. The basis of the sensing element is a small coil of platinum sensing wire. This coil resembles a filament in an incandescent light bulb. The housing or mandrel is a hard fired ceramic oxide tube with equally spaced bores that run transverse to the axes. The coil is inserted in the bores of the mandrel and then packed with a very finely ground ceramic powder. This permits the sensing wire to move, while still remaining in good thermal contact with the process. These elements work with temperatures to 850 °C.

The current international standard that specifies tolerance and the temperature-to-electrical resistance relationship for platinum resistance thermometers (PRTs) is IEC 60751:2008; ASTM E1137 is also used in the United States. By far the most common devices used in industry have a nominal resistance of 100 ohms at 0 °C and are called Pt100 sensors ("Pt" is the symbol for platinum, "100" for the resistance in ohms at 0 °C). It is also possible to get Pt1000 sensors, where 1000 is for the resistance in ohms at 0 °C. The sensitivity of a standard 100 Ω sensor is a nominal 0.385 Ω/°C. RTDs with a sensitivity of 0.375 and 0.392 Ω/°C, as well as a variety of others, are also available.

Function

Resistance thermometers are constructed in a number of forms and offer greater stability,accuracy

Accuracy and precision are two measures of ''observational error''.

''Accuracy'' is how close a given set of measurements ( observations or readings) are to their ''true value'', while ''precision'' is how close the measurements are to each oth ...

and repeatability in some cases than thermocouples. While thermocouples use the Seebeck effect

The thermoelectric effect is the direct conversion of temperature differences to electric voltage and vice versa via a thermocouple. A thermoelectric device creates a voltage when there is a different temperature on each side. Conversely, when ...

to generate a voltage, resistance thermometers use electrical resistance

The electrical resistance of an object is a measure of its opposition to the flow of electric current. Its reciprocal quantity is , measuring the ease with which an electric current passes. Electrical resistance shares some conceptual parallels ...

and require a power source to operate. The resistance ideally varies nearly linear

Linearity is the property of a mathematical relationship (''function'') that can be graphically represented as a straight line. Linearity is closely related to '' proportionality''. Examples in physics include rectilinear motion, the linear r ...

ly with temperature per the Callendar–Van Dusen equation.

The platinum detecting wire needs to be kept free of contamination to remain stable. A platinum wire or film is supported on a former in such a way that it gets minimal differential expansion or other strains from its former, yet is reasonably resistant to vibration. RTD assemblies made from iron or copper are also used in some applications. Commercial platinum grades exhibit a temperature coefficient

A temperature coefficient describes the relative change of a physical property that is associated with a given change in temperature. For a property ''R'' that changes when the temperature changes by ''dT'', the temperature coefficient α is def ...

of resistance 0.00385/°C (0.385%/°C) (European Fundamental Interval). The sensor is usually made to have a resistance of 100 Ω at 0 °C. This is defined in BS EN 60751:1996 (taken from IEC 60751:1995). The American Fundamental Interval is 0.00392/°C, based on using a purer grade of platinum than the European standard. The American standard is from the Scientific Apparatus Manufacturers Association (SAMA), who are no longer in this standards field. As a result, the "American standard" is hardly the standard even in the US.

Lead-wire resistance can also be a factor; adopting three- and four-wire, instead of two-wire, connections can eliminate connection-lead resistance effects from measurements (see below); three-wire connection is sufficient for most purposes and is an almost universal industrial practice. Four-wire connections are used for the most precise applications.

Advantages and limitations

The advantages of platinum resistance thermometers include: * High accuracy * Low drift * Wide operating range * Suitability for precision applications. Limitations: RTDs in industrial applications are rarely used above 660 °C. At temperatures above 660 °C it becomes increasingly difficult to prevent the platinum from becoming contaminated by impurities from the metal sheath of the thermometer. This is why laboratory standard thermometers replace the metal sheath with a glass construction. At very low temperatures, say below −270 °C (3 K), because there are very fewphonon

In physics, a phonon is a collective excitation in a periodic, Elasticity (physics), elastic arrangement of atoms or molecules in condensed matter physics, condensed matter, specifically in solids and some liquids. A type of quasiparticle, a phon ...

s, the resistance of an RTD is mainly determined by impurities and boundary scattering and thus basically independent of temperature. As a result, the sensitivity of the RTD is essentially zero and therefore not useful.

Compared to thermistor

A thermistor is a type of resistor whose resistance is strongly dependent on temperature, more so than in standard resistors. The word thermistor is a portmanteau of ''thermal'' and ''resistor''.

Thermistors are divided based on their conduction ...

s, platinum RTDs are less sensitive to small temperature changes and have a slower response time. However, thermistors have a smaller temperature range and stability.

RTDs vs thermocouples

The two most common ways of measuring temperatures for industrial applications are with resistance temperature detectors (RTDs) and thermocouples. The choice between them is typically determined by four factors. ;Temperature: If process temperatures are between , an industrial RTD is the preferred option.Thermocouple

A thermocouple, also known as a "thermoelectrical thermometer", is an electrical device consisting of two dissimilar electrical conductors forming an electrical junction. A thermocouple produces a temperature-dependent voltage as a result of the ...

s have a range of , so for temperatures above it is the contact temperature measurement device commonly found in physics laboratories.

;Response time: If the process requires a very fast response to temperature changes (fractions of a second as opposed to seconds), then a thermocouple is the best choice. Time response is measured by immersing the sensor in water moving at with a 63.2% step change.

;Size: A standard RTD sheath is in diameter; sheath diameters for thermocouples can be less than .

;Accuracy and stability requirements: If a tolerance of 2 °C is acceptable and the highest level of repeatability is not required, a thermocouple will serve. RTDs are capable of higher accuracy and can maintain stability for many years, while thermocouples can drift within the first few hours of use.

Construction

These elements nearly always require insulated leads attached. PVC,silicone rubber Silicone rubber is an elastomer (rubber-like material) composed of silicone—itself a polymer—containing silicon together with carbon, hydrogen, and oxygen. Silicone rubbers are widely used in industry, and there are multiple formulations ...

or PTFE

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene that has numerous applications. It is one of the best-known and widely applied PFAS. The commonly known brand name of PTFE-based composition is Teflon by Chemour ...

insulators are used at temperatures below about 250 °C. Above this, glass fibre or ceramic are used. The measuring point, and usually most of the leads, require a housing or protective sleeve, often made of a metal alloy that is chemically inert to the process being monitored. Selecting and designing protection sheaths can require more care than the actual sensor, as the sheath must withstand chemical or physical attack and provide convenient attachment points.

The RTD construction design may be enhanced to handle shock and vibration by including compacted magnesium oxide (MgO) powder inside the sheath. MgO is used to isolate the conductors from the external sheath and from each other. MgO is used due to its dielectric constant, rounded grain structure, high-temperature capability, and its chemical inertness.

Wiring configurations

Two-wire configuration

The simplest resistance-thermometer configuration uses two wires. It is only used when high accuracy is not required, as the resistance of the connecting wires is added to that of the sensor, leading to errors of measurement. This configuration allows use of 100 meters of cable. This applies equally to balanced bridge and fixed bridge system. For a balanced bridge usual setting is with R2 = R1, and R3 around the middle of the range of the RTD. So for example, if we are going to measure between , RTD resistance will range from 100 Ω to 138.5 Ω. We would choose R3 = 120 Ω. In that way we get a small measured voltage in the bridge.Three-wire configuration

In order to minimize the effects of the lead resistances, a three-wire configuration can be used. The suggested setting for the configuration shown, is with R1 = R2, and R3 around the middle of the range of the RTD. Looking at theWheatstone bridge

A Wheatstone bridge is an electrical circuit used to measure an unknown electrical resistance by balancing two legs of a bridge circuit, one leg of which includes the unknown component. The primary benefit of the circuit is its ability to provid ...

circuit shown, the voltage drop on the lower left hand side is V_rtd + V_lead, and on the lower right hand side is V_R3 + V_lead, therefore the bridge voltage (V_b) is the difference, V_rtd - V_R3. The voltage drop due to the lead resistance has been cancelled out. This always applies if R1=R2, and R1, R2 >> RTD, R3. R1 and R2 can serve the use of limiting the current through the RTD, for example for a PT100, limiting to 1mA, and 5V, would suggest a limiting resistance of approximately R1 = R2 = 5/0.001 = 5,000 Ohms.

Four-wire configuration

The four-wire resistance configuration increases the accuracy of measurement of resistance.Four-terminal sensing

Four-terminal sensing (4T sensing), 4-wire sensing, or 4-point probes method is an electrical impedance measuring technique that uses separate pairs of current-carrying and voltage-sensing electrodes to make more accurate measurements than the si ...

eliminates voltage drop in the measuring leads as a contribution to error. To increase accuracy further, any residual thermoelectric voltages generated by different wire types or screwed connections are eliminated by reversal of the direction of the 1 mA current and the leads to the DVM (digital voltmeter). The thermoelectric voltages will be produced in one direction only. By averaging the reversed measurements, the thermoelectric error voltages are cancelled out.

Classifications of RTDs

The highest-accuracy of all PRTs are the ''Ultra Precise Platinum Resistance Thermometers'' (UPRTs). This accuracy is achieved at the expense of durability and cost. The UPRT elements are wound from reference-grade platinum wire. Internal lead wires are usually made from platinum, while internal supports are made from quartz or fused silica. The sheaths are usually made from quartz or sometimesInconel

Inconel is a registered trademark of Special Metals Corporation for a family of austenitic nickel-chromium-based superalloys.

Inconel alloys are oxidation-corrosion-resistant materials well suited for service in extreme environments subjected t ...

, depending on temperature range. Larger-diameter platinum wire is used, which drives up the cost and results in a lower resistance for the probe (typically 25.5 Ω). UPRTs have a wide temperature range (−200 °C to 1000 °C) and are approximately accurate to ±0.001 °C over the temperature range. UPRTs are only appropriate for laboratory use.

Another classification of laboratory PRTs is ''Standard Platinum Resistance Thermometers'' (Standard SPRTs). They are constructed like the UPRT, but the materials are more cost-effective. SPRTs commonly use reference-grade, high-purity smaller-diameter platinum wire, metal sheaths and ceramic type insulators. Internal lead wires are usually a nickel-based alloy. Standard PRTs are more limited in temperature range (−200 °C to 500 °C) and are approximately accurate to ±0.03 °C over the temperature range.

''Industrial PRTs'' are designed to withstand industrial environments. They can be almost as durable as a thermocouple. Depending on the application, industrial PRTs can use thin-film or coil-wound elements. The internal lead wires can range from PTFE-insulated stranded nickel-plated copper to silver wire, depending on the sensor size and application. Sheath material is typically stainless steel; higher-temperature applications may demand Inconel. Other materials are used for specialized applications.

History

The application of the tendency ofelectrical conductor

In physics and electrical engineering, a conductor is an object or type of material that allows the flow of charge (electric current) in one or more directions. Materials made of metal are common electrical conductors. Electric current is gener ...

s to increase their electrical resistance

The electrical resistance of an object is a measure of its opposition to the flow of electric current. Its reciprocal quantity is , measuring the ease with which an electric current passes. Electrical resistance shares some conceptual parallels ...

with rising temperature was first described by Sir William Siemens

Sir Carl Wilhelm Siemens (4 April 1823 – 19 November 1883), anglicised to Charles William Siemens, was a German-British electrical engineer and businessman.

Biography

Siemens was born in the village of Lenthe, today part of Gehrden, near Ha ...

at the Bakerian Lecture of 1871 before the Royal Society

The Royal Society, formally The Royal Society of London for Improving Natural Knowledge, is a learned society and the United Kingdom's national academy of sciences. The society fulfils a number of roles: promoting science and its benefits, re ...

of Great Britain

Great Britain is an island in the North Atlantic Ocean off the northwest coast of continental Europe. With an area of , it is the largest of the British Isles, the largest European island and the ninth-largest island in the world. It is ...

. The necessary methods of construction were established by Callendar Callendar is a title of Scottish nobility and a surname. It may refer to:

* Earl of Callendar

** Callendar House, Falkirk

* Guy Stewart Callendar (1898 – 1964), English steam engineer and inventor and son of Hugh Longbourne Callendar

** Callendar ...

, Griffiths, Holborn and Wein between 1885 and 1900.

The Space Shuttle

The Space Shuttle is a retired, partially reusable low Earth orbital spacecraft system operated from 1981 to 2011 by the U.S. National Aeronautics and Space Administration (NASA) as part of the Space Shuttle program. Its official program na ...

made extensive use of platinum resistance thermometers. The only in-flight shutdown of a Space Shuttle Main Engine

The Aerojet Rocketdyne RS-25, also known as the Space Shuttle Main Engine (SSME), is a liquid-fuel cryogenic rocket engine that was used on NASA's Space Shuttle and is currently used on the Space Launch System (SLS).

Designed and manufacture ...

— mission STS-51F — was caused by multiple failures of RTDs which had become brittle and unreliable due to multiple heat-and-cool cycles. (The failures of the sensors falsely suggested that a fuel pump was critically overheating, and the engine was automatically shut down.) Following the engine failure incident, the RTDs were replaced with thermocouples

A thermocouple, also known as a "thermoelectrical thermometer", is an electrical device consisting of two dissimilar electrical conductors forming an electrical junction. A thermocouple produces a temperature-dependent voltage as a result of the ...

.

In 1871 Carl Wilhelm Siemens

Sir Carl Wilhelm Siemens (4 April 1823 – 19 November 1883), anglicised to Charles William Siemens, was a German-British electrical engineer and businessman.

Biography

Siemens was born in the village of Lenthe, today part of Gehrden, near Han ...

invented the Platinum Resistance Temperature Detector and presented a three-term interpolation formula. Siemens’ RTD rapidly fell out of favour due to the instability of the temperature reading. Hugh Longbourne Callendar developed the first commercially successful platinum RTD in 1885.

A 1971 paper by Eriksson, Keuther, and Glatzel identified six noble metal alloys (63Pt37Rh, 37Pd63Rh, 26Pt74Ir, 10Pd90Ir, 34Pt66Au, 14Pd86Au) with approximately linear resistance temperature characteristics. The alloy 63Pt37Rh is similar to the readily available 70Pt30Rh alloy wire used in thermocouples.

Standard resistance thermometer data

Temperature sensors are usually supplied with thin-film elements. The resistance elements are rated in accordance with BS EN 60751:2008 as: Resistance-thermometer elements functioning up to 1000 °C can be supplied. The relation between temperature and resistance is given by the Callendar-Van Dusen equation: : : Here is the resistance at temperature ''T'', is the resistance at 0 °C, and the constants (for an α = 0.00385 platinum RTD) are: : : : Since the ''B'' and ''C'' coefficients are relatively small, the resistance changes almost linearly with the temperature. For positive temperature, solution of the quadratic equation yields the following relationship between temperature and resistance: : Then for a four-wire configuration with a 1 mA precision current source the relationship between temperature and measured voltage is :Temperature-dependent resistances for various popular resistance thermometers

See also

*Thermowell

Thermowells are cylindrical fittings used to protect temperature sensors installed in industrial processes. A thermowell consists of a tube closed at one end and mounted in the process stream. A temperature sensor such as a thermometer, thermocoup ...

* Thermistor

A thermistor is a type of resistor whose resistance is strongly dependent on temperature, more so than in standard resistors. The word thermistor is a portmanteau of ''thermal'' and ''resistor''.

Thermistors are divided based on their conduction ...

* Thermostat

A thermostat is a regulating device component which senses the temperature of a physical system and performs actions so that the system's temperature is maintained near a desired setpoint.

Thermostats are used in any device or system tha ...

* Thermocouple

A thermocouple, also known as a "thermoelectrical thermometer", is an electrical device consisting of two dissimilar electrical conductors forming an electrical junction. A thermocouple produces a temperature-dependent voltage as a result of the ...

Notes

References

{{DEFAULTSORT:Resistance Thermometer Sensors Resistive components Thermometers