Relief Valves on:

[Wikipedia]

[Google]

[Amazon]

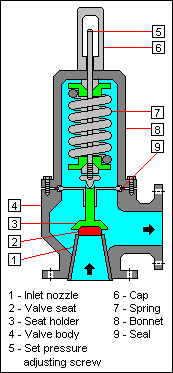

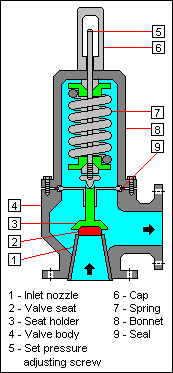

A relief valve or pressure relief valve (PRV) is a type of safety valve used to control or limit the pressure in a system; pressure might otherwise build up and create a process upset, instrument or equipment failure, or fire. The pressure is relieved by allowing the pressurized fluid to flow from an auxiliary passage out of the system. The relief valve is designed or set to open at a predetermined set pressure to protect

A relief valve or pressure relief valve (PRV) is a type of safety valve used to control or limit the pressure in a system; pressure might otherwise build up and create a process upset, instrument or equipment failure, or fire. The pressure is relieved by allowing the pressurized fluid to flow from an auxiliary passage out of the system. The relief valve is designed or set to open at a predetermined set pressure to protect

PED 97/23/EC

Pressure Equipment Directive – European Union. {{DEFAULTSORT:Relief Valve Piping Pressure vessels Safety valves ru:Сбросной клапан (сантехника)

A relief valve or pressure relief valve (PRV) is a type of safety valve used to control or limit the pressure in a system; pressure might otherwise build up and create a process upset, instrument or equipment failure, or fire. The pressure is relieved by allowing the pressurized fluid to flow from an auxiliary passage out of the system. The relief valve is designed or set to open at a predetermined set pressure to protect

A relief valve or pressure relief valve (PRV) is a type of safety valve used to control or limit the pressure in a system; pressure might otherwise build up and create a process upset, instrument or equipment failure, or fire. The pressure is relieved by allowing the pressurized fluid to flow from an auxiliary passage out of the system. The relief valve is designed or set to open at a predetermined set pressure to protect pressure vessel

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure.

Construction methods and materials may be chosen to suit the pressure application, and will depend on the size o ...

s and other equipment from being subjected to pressures that exceed their design limits. When the set pressure is exceeded, the relief valve becomes the " path of least resistance" as the valve is forced open and a portion of the fluid is diverted through the auxiliary route. In systems containing flammable fluids, the diverted fluid (liquid, gas or liquid-gas mixture) is either recaptured by a low pressure, high-flow vapor recovery system or is routed through a piping system known as a ''flare header'' or ''relief header'' to a central, elevated gas flare where it is burned, releasing naked combustion gases into the atmosphere. In non-hazardous systems, the fluid is often discharged to the atmosphere by a suitable discharge pipework designed to prevent rainwater ingress which can affect the set lift pressure, and positioned not to cause a hazard to personnel. As the fluid is diverted, the pressure inside the vessel will stop rising. Once it reaches the valve's reseating pressure, the valve will close. The ''blowdown'' is usually stated as a percentage of set pressure and refers to how much the pressure needs to drop before the valve reseats. The blowdown can vary roughly 2–20%, and some valves have adjustable blowdowns.

In high-pressure gas systems, it is recommended that the outlet of the relief valve is in the open air. In systems where the outlet is connected to piping, the opening of a relief valve will give a pressure build-up in the piping system downstream of the relief valve. This often means that the relief valve will not re-seat once the set pressure is reached. For these systems often so-called "differential" relief valves are used. This means that the pressure is only working on an area that is much smaller than the area of the opening of the valve. If the valve is opened the pressure has to decrease enormously before the valve closes and also the outlet pressure of the valve can easily keep the valve open. Another consideration is that if other relief valves are connected to the outlet pipe system, they may open as the pressure in the exhaust pipe system increases. This may cause undesired operation.

In some cases, a so-called ''bypass valve'' acts as a relief valve by being used to return all or part of the fluid discharged by a pump

A pump is a device that moves fluids (liquids or gases), or sometimes slurries, by mechanical action, typically converted from electrical energy into hydraulic energy. Pumps can be classified into three major groups according to the method they u ...

or gas compressor back to either a storage reservoir or the inlet of the pump or gas compressor. This is done to protect the pump or gas compressor and any associated equipment from excessive pressure. The bypass valve and bypass path can be internal (an integral part of the pump or compressor) or external (installed as a component in the fluid path). Many fire engines have such relief valves to prevent the overpressurization of fire hoses

A fire hose (or firehose) is a high-pressure hose that carries water or other fire retardant (such as Firefighting foam, foam) to a fire to extinguish it. Outdoors, it attaches either to a Firefighting apparatus, fire engine, fire hydrant, or a ...

.

In other cases, equipment must be protected against being subjected to an internal vacuum (i.e., low pressure) that is lower than the equipment can withstand. In such cases, ''vacuum relief valves'' are used to open at a predetermined low-pressure limit and to admit air or an inert gas into the equipment to control the amount of vacuum.

Technical terms

In the petroleum refining, petrochemical andchemical manufacturing

The chemical industry comprises the companies that produce industrial chemicals. Central to the modern world economy, it converts raw materials (oil, natural gas, air, water, metals, and minerals) into more than 70,000 different products. The pla ...

, natural gas processing

Natural-gas processing is a range of industrial processes designed to purify raw natural gas by removing impurities, contaminants and higher molecular mass hydrocarbons to produce what is known as ''pipeline quality'' dry natural gas. Natural gas ...

and power generation

Electricity generation is the process of generating electric power from sources of primary energy. For utilities in the electric power industry, it is the stage prior to its delivery ( transmission, distribution, etc.) to end users or its stor ...

industries, the term relief valve is associated with the terms pressure relief valve (PRV), pressure safety valve (PSV) and safety valve:

* Pressure relief valve (PRV) or Pressure Release valve (PRV) or pressure safety valve (PSV): The difference is that PSVs have a manual lever to activate the valve in case of emergency. Most PRVs are spring operated. At lower pressures some use a diaphragm in place of a spring. The oldest PRV designs use a weight to seal the valve.

* Set pressure: When the system pressure increases to this value, the PRV opens. The accuracy of the set pressure may follow guidelines set by the American Society of Mechanical Engineers

The American Society of Mechanical Engineers (ASME) is an American professional association that, in its own words, "promotes the art, science, and practice of multidisciplinary engineering and allied sciences around the globe" via "continuing ...

(ASME).

* Relief valve (RV): A valve is used on a liquid service, which opens proportionally as the increasing pressure overcomes the spring pressure.

* Safety valve (SV): Used in gas service. Most SVs are full lift or snap-acting, in that they pop completely open.

* Safety relief valve (SRV): A relief valve that can be used for gas or liquid service. However, the set pressure will usually only be accurate for one type of fluid at a time.

* Pilot-operated relief valve

Like other pressure relief valves (PRV), pilot-operated relief valves (PORV) are used for emergency relief during overpressure events (e.g., a tank gets too hot and the expanding fluid increases the pressure to dangerous levels). PORV are also c ...

(POSRV, PORV, POPRV): A device that relieves by remote command from a pilot valve which is connected to the upstream system pressure.

* Low-pressure safety valve (LPSV): An automatic system that relieves by the static pressure of a gas. The relieving pressure is small and near the atmospheric pressure.

* Vacuum pressure safety valve (VPSV): An automatic system that relieves by the static pressure of a gas. The relieving pressure is small, negative, and near the atmospheric pressure.

* Low and vacuum pressure safety valve (LVPSV): An automatic system that relieves by the static pressure of a gas. The relieving pressure is small, negative, or positive, and near the atmospheric pressure.

* Pressure vacuum release valve (PVRV): A combination of vacuum pressure and a relief valve in one housing. Used on storage tanks for liquids to prevent implosion or overpressure.

* Snap acting: The opposite of modulating, refers to a valve that "pops" open. It snaps into a full lift in milliseconds. Usually accomplished with a skirt on the disc so that the fluid passing the seat suddenly affects a larger area and creates more lifting force.

* Modulating: Opens in proportion to the overpressure.

Legal and code requirements in industry

In most countries, industries are legally required to protect pressure vessels and other equipment by using relief valves. Also in most countries, equipment design codes such as those provided by theAmerican Society of Mechanical Engineers

The American Society of Mechanical Engineers (ASME) is an American professional association that, in its own words, "promotes the art, science, and practice of multidisciplinary engineering and allied sciences around the globe" via "continuing ...

(ASME), American Petroleum Institute (API) and other organizations like ISO (ISO 4126) must be complied with and those codes include design standards for relief valves.

The main standards, laws, or directives are:

* ''AD Merkblatt'' (German)

* American Petroleum Institute (API); Standards 520, 521, 526, and 2000

* American Society of Mechanical Engineers

The American Society of Mechanical Engineers (ASME) is an American professional association that, in its own words, "promotes the art, science, and practice of multidisciplinary engineering and allied sciences around the globe" via "continuing ...

(ASME); Boiler & Pressure Vessel Code, Section VIII Division 1 and Section I

* American Water Works Association (AWWA), storage tank

Storage tanks are containers that hold liquids, compressed gases (gas tank; or in U.S.A "pressure vessel", which is not typically labeled or regulated as a storage tank) or mediums used for the short- or long-term storage of heat or cold. The t ...

s

* EN 764-7; European Standard based on pressure Equipment Directive 97/23/EC

* Eurocode EN 1993-4-2, storage tanks.

* International Organization for Standardization; ISO 4126

* Pressure Systems Safety Regulations 2000 (PSSR); UK

DIERS

Formed in 1977, the Design Institute for Emergency Relief Systems was a consortium of 29 companies under the auspices of the American Institute of Chemical Engineers ( AIChE) that developed methods for the design of emergency relief systems to handle runaway reactions. Its purpose was to develop the technology and methods needed for sizing pressure relief systems for chemical reactors, particularly those in which exothermic reactions are carried out. Such reactions include many classes of industrially important processes including polymerizations, nitrations, diazotizations, sulphonations, epoxidations, aminations, esterifications, neutralizations, and many others. Pressure relief systems can be difficult to design, not least because what is expelled can be gas/vapor, liquid, or a mixture of the two – just as with a can of carbonated drink when it is suddenly opened. For chemical reactions, it requires extensive knowledge of both chemical reaction hazards and fluid flow. DIERS investigated the two-phase vapor-liquid onset/disengagement dynamics and the hydrodynamics of emergency relief systems with extensive experimental and analysis work. Of particular interest to DIERS were the prediction of two-phase flow venting and the applicability of various sizing methods for two-phase vapor-liquid flashing flow. DIERS became a user's group in 1985. European DIERS Users’ Group (EDUG) is a group of mainly European industrialists, consultants and academics who use the DIERS technology. The EDUG started in the late 1980s and has an annual meeting. A summary of many of key aspects of the DIERS technology has been published in the UK by the HSE.See also

* Blowoff valve * Rupture disc * Safety valve *Surge control

Surge control is the use of different techniques and equipment in a hydraulic system to prevent any excessive gain in pressure (also known as a pressure surge) that would cause the hydraulic process pressure to exceed the maximum working pressure ...

References

External links

*PED 97/23/EC

Pressure Equipment Directive – European Union. {{DEFAULTSORT:Relief Valve Piping Pressure vessels Safety valves ru:Сбросной клапан (сантехника)