Microchannel (microtechnology) on:

[Wikipedia]

[Google]

[Amazon]

Microchannel in

Microchannel in

Microchannel in

Microchannel in microtechnology

Microtechnology is technology whose features have dimensions of the order of one micrometre (one millionth of a metre, or 10−6 metre, or 1μm). It focuses on physical and chemical processes as well as the production or manipulation of structures ...

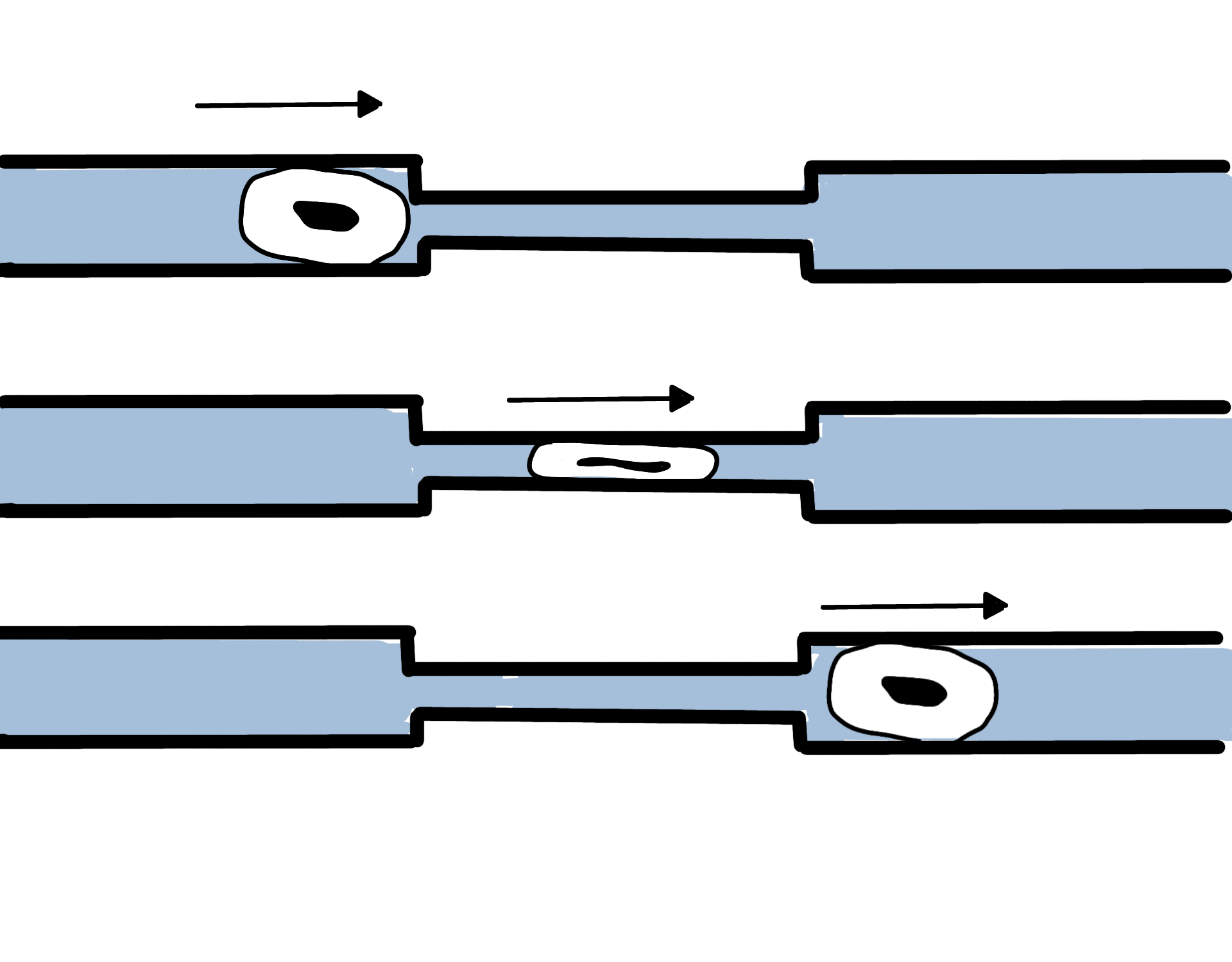

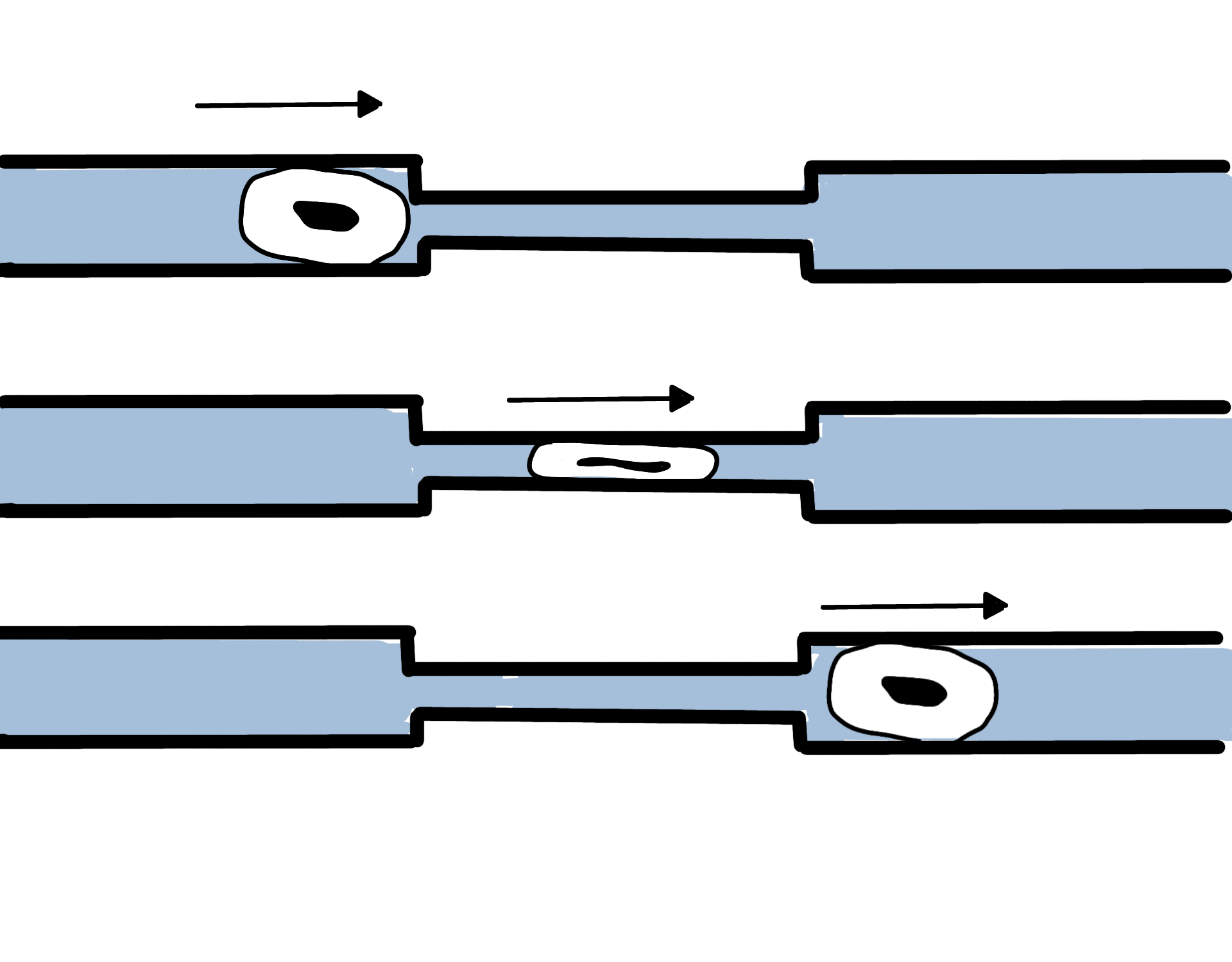

is a channel with a hydraulic diameter

The hydraulic diameter, , is a commonly used term when handling flow in non-circular tubes and channels. Using this term, one can calculate many things in the same way as for a round tube. When the cross-section is uniform along the tube or channe ...

below 1 mm, usually 1–99 μm. Microchannels are used in fluid control (see Microfluidics

Microfluidics refers to a system that manipulates a small amount of fluids (10−9 to 10−18 liters) using small channels with sizes of ten to hundreds of micrometres. It is a multidisciplinary field that involves molecular analysis, molecular bi ...

), heat transfer (see Micro heat exchanger) and cell migration

Cell migration is a central process in the development and maintenance of multicellular organisms. Tissue formation during embryogenesis, embryonic development, wound healing and immune system, immune responses all require the orchestrated movemen ...

observation. They are more efficient than their 'macro' counterparts, because of a high surface-area to volume ratio yet pose a multitude of challenges due to their small size.

Materials

Different types of materials are required for the different uses of microchannels. These are the three main categories.Polymeric and glass substrates

Polymethyl methacrylate (PMMA) is used as a solution to a wide range of microfluidic devices due to its low cost and easier fabricating methods. Silicon elastomers can be used for situations in which elasticity and deformation is necessary.Metallic substrates

Metallic substrates are often chosen for their advantageous metallic properties, such as withstanding high temperatures and transferring heat faster. They can be subject tocorrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engine ...

.

Semiconductors, ceramics and composites

Ceramic materials allow for high-temperature operation in comparison to metallic substrates and enable operation in harsh chemical environments in which metals cannot be used.History

The concept of the microchannel was proposed for the first time by researchers Tuckerman and Pease of Stanford Electronics Laboratories in 1981. They suggested an effective method for designing microchannels in the laminar and fully developed flow.Common uses

Microchannels are extensively used in the pharmaceuticals, and biochemical industries due to short diffusion distances, higher interfacial area, and higher heat/mass transfer rates.Jaiswal, P., Kumar, U., Biswas, K. G.(2021) Liquid-Liquid Flow through Micro Dimensional Reactors: A Review on Hydrodynamics, Mass Transfer, and Reaction Kinetics. Exp. Comput. Multiph. Flow 2021. https://doi.org/10.1007/s42757-020-0092-0See also

* Micro process engineering * MicroreactorSources