Kværner Process on:

[Wikipedia]

[Google]

[Amazon]

The Kværner process or the Kværner carbon black and hydrogen process (CB&H) is a method of producing

The

The C_\mathitH_\mathit -> + \frac H2

In comparison to other reformation methods such as

carbon black

Carbon black (subtypes are acetylene black, channel black, furnace black, lamp black and thermal black) is a material produced by the incomplete combustion of coal and coal tar, vegetable matter, or petroleum products, including fuel oil, fluid ...

and hydrogen gas

Hydrogen is the chemical element with the symbol H and atomic number 1. Hydrogen is the lightest element. At standard conditions hydrogen is a gas of diatomic molecules having the formula . It is colorless, odorless, tasteless, non-toxic, a ...

from hydrocarbons

In organic chemistry, a hydrocarbon is an organic compound consisting entirely of hydrogen and carbon. Hydrocarbons are examples of group 14 hydrides. Hydrocarbons are generally colourless and hydrophobic, and their odors are usually weak or e ...

such as methane

Methane ( , ) is a chemical compound with the chemical formula (one carbon atom bonded to four hydrogen atoms). It is a group-14 hydride, the simplest alkane, and the main constituent of natural gas. The relative abundance of methane on Ea ...

, natural gas

Natural gas (also called fossil gas or simply gas) is a naturally occurring mixture of gaseous hydrocarbons consisting primarily of methane in addition to various smaller amounts of other higher alkanes. Low levels of trace gases like carbo ...

and biogas

Biogas is a mixture of gases, primarily consisting of methane, carbon dioxide and hydrogen sulphide, produced from raw materials such as agricultural waste, manure, municipal waste, plant material, sewage, green waste and food waste. It is a ...

with no greenhouse gas pollution. The process was developed in the 1980s by the Norwegian engineering firm Kværner

Kværner was a Norwegian engineering and construction services company that existed between 1853 and 2005. In 2004, it was amalgamated to the newly formed subsidiary of Aker ASA - Aker Kværner, which was renamed Aker Solutions on 3 April 2008 ...

, and was first commercially exploited in 1999. Further refinement enabled the methane pyrolysis

The pyrolysis (or devolatilization) process is the thermal decomposition of materials at elevated temperatures, often in an inert atmosphere. It involves a change of chemical composition. The word is coined from the Greek-derived elements ''pyr ...

process for implementation at high-volume and low-cost.

Description

endothermic reaction

In thermochemistry, an endothermic process () is any thermodynamic process with an increase in the enthalpy (or internal energy ) of the system.Oxtoby, D. W; Gillis, H.P., Butler, L. J. (2015).''Principle of Modern Chemistry'', Brooks Cole. p ...

separates (i.e. decomposes) hydrocarbons into carbon and hydrogen in a plasma burner at around 1600 °C. The resulting components, carbon particles and hydrogen, are present as a mixture in form of an aerosol.

:steam reforming

Steam reforming or steam methane reforming (SMR) is a method for producing syngas (hydrogen and carbon monoxide) by reaction of hydrocarbons with water. Commonly natural gas is the feedstock. The main purpose of this technology is hydrogen product ...

and partial oxidation Partial oxidation (POX) is a type of chemical reaction. It occurs when a substoichiometric fuel-air mixture is partially combusted in a reformer, creating a hydrogen-rich syngas which can then be put to further use, for example in a fuel cell. A d ...

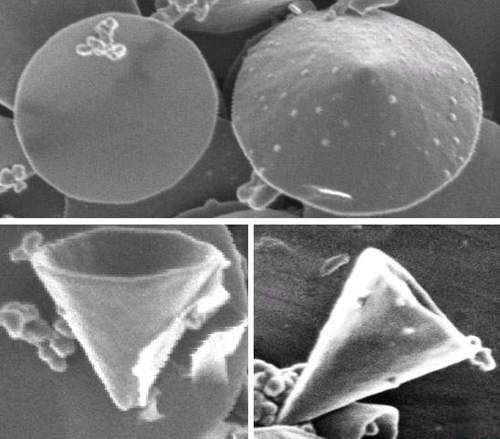

that have carbon dioxide as a by-product, there is no by-product in the Kværner process. The natural gas is efficiently and completely transformed into pure carbon and hydrogen and does not release carbon dioxide into the atmosphere. After separating the mixture, the carbon particles can be used for instance as activated carbon, graphite or industrial soot, special kinds of carbon such as carbon discs and carbon cones (see SEM image). The carbon is obtained as black powdery solid matter and forms a technical product which may be used e.g. as filler in the rubber industry, as pigment soot for inks and paints or as raw material for electrical components. The hydrogen may be discharged for the chemical industry or may be used for generating electricity.

Of the available energy of the feed, approximately 48% is contained in the hydrogen, 40% is contained in activated carbon and 10% in superheated steam.

Plasma variation

A variation of this process usingplasma arc waste disposal

Plasma gasification is an extreme thermal process using plasma which converts organic matter into a syngas (synthesis gas) which is primarily made up of hydrogen and carbon monoxide. A plasma torch powered by an electric arc is used to ionize g ...

was presented in 2009. Methane and natural gas is converted to hydrogen, heat and carbon using a plasma converter.

See also

*Hydrogen production

Hydrogen production is the family of industrial methods for generating hydrogen gas. As of 2020, the majority of hydrogen (∼95%) is produced from fossil fuels by steam reforming of natural gas and other light hydrocarbons, partial oxidation of ...

* Methane pyrolysis

The pyrolysis (or devolatilization) process is the thermal decomposition of materials at elevated temperatures, often in an inert atmosphere. It involves a change of chemical composition. The word is coined from the Greek-derived elements ''pyr ...

* '' Renewable energy''

* Electric arc

An electric arc, or arc discharge, is an electrical breakdown of a gas that produces a prolonged electrical discharge. The current through a normally nonconductive medium such as air produces a plasma; the plasma may produce visible light. An ...

References