Industrial and production engineering (IPE) is an interdisciplinary engineering discipline that includes

manufacturing

Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of secondary sector of the economy. The term may refer to ...

technology,

engineering

Engineering is the use of scientific principles to design and build machines, structures, and other items, including bridges, tunnels, roads, vehicles, and buildings. The discipline of engineering encompasses a broad range of more speciali ...

sciences,

management science

Management science (or managerial science) is a wide and interdisciplinary study of solving complex problems and making strategic decisions as it pertains to institutions, corporations, governments and other types of organizational entities. It is ...

, and optimization of complex

processes

A process is a series or set of activities that interact to produce a result; it may occur once-only or be recurrent or periodic.

Things called a process include:

Business and management

*Business process, activities that produce a specific se ...

,

system

A system is a group of interacting or interrelated elements that act according to a set of rules to form a unified whole. A system, surrounded and influenced by its environment, is described by its boundaries, structure and purpose and express ...

s, or

organizations

An organization or organisation (Commonwealth English; see spelling differences), is an entity—such as a company, an institution, or an association—comprising one or more people and having a particular purpose.

The word is derived from ...

. It is concerned with the understanding and application of engineering procedures in manufacturing processes and production methods. Industrial engineering dates back all the way to the industrial revolution, initiated in 1700s by Sir

Adam Smith

Adam Smith (baptized 1723 – 17 July 1790) was a Scottish economist and philosopher who was a pioneer in the thinking of political economy and key figure during the Scottish Enlightenment. Seen by some as "The Father of Economics"——� ...

,

Henry Ford

Henry Ford (July 30, 1863 – April 7, 1947) was an American industrialist, business magnate, founder of the Ford Motor Company, and chief developer of the assembly line technique of mass production. By creating the first automobile that ...

,

Eli Whitney

Eli Whitney Jr. (December 8, 1765January 8, 1825) was an American inventor, widely known for inventing the cotton gin, one of the key inventions of the Industrial Revolution that shaped the economy of the Antebellum South.

Although Whitney hi ...

,

Frank Gilbreth and

Lilian Gilbreth,

Henry Gantt

Henry Laurence Gantt (; May 20, 1861 – November 23, 1919) was an American mechanical engineer and management consultant who is best known for his work in the development of scientific management. He created the Gantt chart in the 1910s.

Gan ...

,

F.W. Taylor, etc. After the 1970s, industrial and production engineering developed worldwide and started to widely use automation and robotics. Industrial and production engineering includes three areas:

Mechanical engineering

Mechanical engineering is the study of physical machines that may involve force and movement. It is an engineering branch that combines engineering physics and mathematics principles with materials science, to design, analyze, manufacture, ...

(where the production engineering comes from),

industrial engineering

Industrial engineering is an engineering profession that is concerned with the optimization of complex processes, systems, or organizations by developing, improving and implementing integrated systems of people, money, knowledge, information an ...

, and

management science

Management science (or managerial science) is a wide and interdisciplinary study of solving complex problems and making strategic decisions as it pertains to institutions, corporations, governments and other types of organizational entities. It is ...

.

The objective is to improve efficiency, drive up effectiveness of manufacturing, quality control, and to reduce cost while making their products more attractive and marketable. Industrial engineering is concerned with the development, improvement, and implementation of integrated systems of people, money, knowledge, information, equipment, energy, materials, as well as analysis and synthesis. The principles of IPE include mathematical, physical and

social sciences

Social science is one of the branches of science, devoted to the study of societies and the relationships among individuals within those societies. The term was formerly used to refer to the field of sociology, the original "science of so ...

and methods of engineering design to specify, predict, and evaluate the results to be obtained from the systems or processes currently in place or being developed. The target of production engineering is to complete the production process in the smoothest, most-judicious and most-economic way. Production engineering also overlaps substantially with

manufacturing engineering

Manufacturing engineering or production engineering is a branch of professional engineering that shares many common concepts and ideas with other fields of engineering such as mechanical, chemical, electrical, and industrial engineering.

Manufa ...

and

industrial engineering

Industrial engineering is an engineering profession that is concerned with the optimization of complex processes, systems, or organizations by developing, improving and implementing integrated systems of people, money, knowledge, information an ...

. The concept of production engineering is interchangeable with manufacturing engineering.

As for education, undergraduates normally start off by taking courses such as physics, mathematics (calculus, linear analysis, differential equations), computer science, and chemistry. Undergraduates will take more major specific courses like production and inventory scheduling,

process management, CAD/CAM manufacturing,

ergonomics

Human factors and ergonomics (commonly referred to as human factors) is the application of psychological and physiological principles to the engineering and design of products, processes, and systems. Four primary goals of human factors learnin ...

, etc., towards the later years of their undergraduate careers. In some parts of the world, universities will offer Bachelor's in Industrial and Production Engineering. However, most universities in the U.S. will offer them separately. Various career paths that may follow for industrial and production engineers include:

Plant Engineers,

Manufacturing Engineers,

Quality Engineers,

Process Engineers

A process is a series or set of activities that interact to produce a result; it may occur once-only or be recurrent or periodic.

Things called a process include:

Business and management

*Business process, activities that produce a specific se ...

and industrial managers,

project management

Project management is the process of leading the work of a team to achieve all project goals within the given constraints. This information is usually described in project documentation, created at the beginning of the development process. T ...

,

manufacturing

Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of secondary sector of the economy. The term may refer to ...

, production and distribution, From the various career paths people can take as an industrial and production engineer, most average a starting salary of at least $50,000.

History

Industrial Revolution

The roots of the Industrial Engineering Profession date back to the

Industrial Revolution

The Industrial Revolution was the transition to new manufacturing processes in Great Britain, continental Europe, and the United States, that occurred during the period from around 1760 to about 1820–1840. This transition included going f ...

. The technologies that helped mechanize traditional manual operations in the textile industry including the

Flying shuttle

The flying shuttle was one of the key developments in the industrialization of weaving during the early Industrial Revolution. It allowed a single weaver to weave much wider fabrics, and it could be mechanized, allowing for automatic machine l ...

, the

Spinning jenny

The spinning jenny is a multi- spindle spinning frame, and was one of the key developments in the industrialization of textile manufacturing during the early Industrial Revolution. It was invented in 1764 or 1765 by James Hargreaves in Sta ...

, and perhaps most importantly the

Steam engine

A steam engine is a heat engine that performs mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a cylinder. This pushing force can be ...

generated

Economies of scale

In microeconomics, economies of scale are the cost advantages that enterprises obtain due to their scale of operation, and are typically measured by the amount of output produced per unit of time. A decrease in cost per unit of output enables ...

that made

Mass production

Mass production, also known as flow production or continuous production, is the production of substantial amounts of standardized products in a constant flow, including and especially on assembly lines. Together with job production and ba ...

in centralized locations attractive for the first time. The concept of the production system had its genesis in the factories created by these innovations.

[Maynard & Zandin. Maynard's Industrial Engineering Handbook. McGraw Hill Professional 5th Edition. June 5, 2001. p. 1.4–1.6]

Specialization of labor

Adam Smith's concepts of

Division of Labour

The division of labour is the separation of the tasks in any economic system or organisation so that participants may specialise (specialisation). Individuals, organizations, and nations are endowed with, or acquire specialised capabilities, an ...

and the "Invisible Hand" of capitalism introduced in his treatise "

The Wealth of Nations

''An Inquiry into the Nature and Causes of the Wealth of Nations'', generally referred to by its shortened title ''The Wealth of Nations'', is the '' magnum opus'' of the Scottish economist and moral philosopher Adam Smith. First published in ...

" motivated many of the technological innovators of the Industrial revolution to establish and implement factory systems. The efforts of James Watt and Matthew Boulton led to the first integrated machine manufacturing facility in the world, including the implementation of concepts such as cost control systems to reduce waste and increase productivity and the institution of skills training for craftsmen.

Charles Babbage

Charles Babbage (; 26 December 1791 – 18 October 1871) was an English polymath. A mathematician, philosopher, inventor and mechanical engineer, Babbage originated the concept of a digital programmable computer.

Babbage is considered ...

became associated with Industrial engineering because of the concepts he introduced in his book "On the Economy of Machinery and Manufacturers" which he wrote as a result of his visits to factories in England and the United States in the early 1800s. The book includes subjects such as the time required to perform a specific task, the effects of subdividing tasks into smaller and less detailed elements, and the advantages to be gained from repetitive tasks.

Interchangeable parts

Eli Whitney

Eli Whitney Jr. (December 8, 1765January 8, 1825) was an American inventor, widely known for inventing the cotton gin, one of the key inventions of the Industrial Revolution that shaped the economy of the Antebellum South.

Although Whitney hi ...

and

Simeon North proved the feasibility of the notion of

Interchangeable parts

Interchangeable parts are parts (components) that are identical for practical purposes. They are made to specifications that ensure that they are so nearly identical that they will fit into any assembly of the same type. One such part can freely r ...

in the manufacture of muskets and pistols for the US Government. Under this system, individual parts were mass-produced to tolerances to enable their use in any finished product. The result was a significant reduction in the need for skill from specialized workers, which eventually led to the industrial environment to be studied later.

Modern development

Industrial engineering

In 1960 to 1975, with the development of decision support systems in supply such as the

Material requirements planning

Material requirements planning (MRP) is a production planning, scheduling, and inventory control system used to manage manufacturing processes. Most MRP systems are software-based, but it is possible to conduct MRP by hand as well.

An MRP s ...

(MRP), people can emphasize the timing issue (inventory, production, compounding, transportation, etc.) of industrial organization. Israeli scientist Dr.

Jacob Rubinovitz

Jacob Rubinovitz (born 6 September 1947, Hebrew language, Hebrew יעקב רובינוביץ) is an Israeli scientist. He was the head of the Laboratory for robotics and Computer Integrated Manufacturing (CIM) at the Technion.

Biography

Rubino ...

installed the CMMS program developed in IAI and Control-Data (Israel) in 1976 in South Africa and worldwide.

In the seventies, with the penetration of Japanese management theories such as

Kaizen

is concept referring to business activities that continuously improve all functions and involve all employees from the CEO to the assembly line workers. ''Kaizen'' also applies to processes, such as purchasing and logistics, that cross orga ...

and

Kanban

Kanban ( Japanese: カンバン and Chinese: 看板, meaning signboard or billboard) is a scheduling system for lean manufacturing (also called just-in-time manufacturing, abbreviated JIT). Taiichi Ohno, an industrial engineer at Toyota, devel ...

, Japan realized very high levels of quality and productivity. These theories improved issues of quality, delivery time, and flexibility. Companies in the west realized the great impact of Kaizen and started implementing their own

Continuous improvement

A continual improvement process, also often called a continuous improvement process (abbreviated as CIP or CI), is an ongoing effort to improve products, services, or processes. These efforts can seek " incremental" improvement over time or "breakt ...

programs.

In the nineties, following the global industry globalization process, the emphasis was on supply chain management, and customer-oriented business process design.

Theory of constraints developed by an Israeli scientist

Eliyahu M. Goldratt

Eliyahu Moshe Goldratt (March 31, 1947 – June 11, 2011) was an Israeli business management guru. He was the originator of the Optimized Production Technique, the Theory of Constraints (TOC), the Thinking Processes, Drum-Buffer-Rope, Critical ...

(1985) is also a significant milestone in the field.

Manufacturing (production) engineering

Modern manufacturing engineering studies include all intermediate processes required for the production and integration of a product's components.Some industries, such as

semiconductor

A semiconductor is a material which has an electrical conductivity value falling between that of a conductor, such as copper, and an insulator, such as glass. Its resistivity falls as its temperature rises; metals behave in the opposite way ...

and

steel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistan ...

manufacturers use the term "fabrication" for these processes.

Automation

Automation describes a wide range of technologies that reduce human intervention in processes, namely by predetermining decision criteria, subprocess relationships, and related actions, as well as embodying those predeterminations in machines ...

is used in different processes of manufacturing such as machining and welding. Automated manufacturing refers to the application of automation to produce goods in a factory. The main advantages of automated manufacturing for the manufacturing process are realized with effective implementation of automation and include: higher consistency and quality, reduction of lead times, simplification of production, reduced handling, improved work flow, and improved worker morale.

Robotics

Robotics is an interdisciplinary branch of computer science and engineering. Robotics involves design, construction, operation, and use of robots. The goal of robotics is to design machines that can help and assist humans. Robotics integrat ...

is the application of mechatronics and automation to create robots, which are often used in manufacturing to perform tasks that are dangerous, unpleasant, or repetitive. These robots may be of any shape and size, but all are preprogrammed and interact physically with the world. To create a robot, an engineer typically employs kinematics (to determine the robot's range of motion) and mechanics (to determine the stresses within the robot). Robots are used extensively in manufacturing engineering.

Robots allow businesses to save money on labor, perform tasks that are either too dangerous or too precise for humans to perform economically, and to ensure better quality. Many companies employ assembly lines of robots, and some factories are so robotized that they can run by themselves. Outside the factory, robots have been employed in bomb disposal, space exploration, and many other fields. Robots are also sold for various residential applications.

Overview

Industrial engineering

Industrial engineering is the branch of engineering that involves figuring out how to make or do things better. Industrial engineers are concerned with reducing production costs, increasing efficiency, improving the quality of products and services, ensuring worker health and safety, protecting the environment and complying with government regulations.

The various fields and topics that industrial engineers are involved with include:

*

Manufacturing Engineering

Manufacturing engineering or production engineering is a branch of professional engineering that shares many common concepts and ideas with other fields of engineering such as mechanical, chemical, electrical, and industrial engineering.

Manufa ...

*

Engineering management

Engineering management is the application of the practice of management to the practice of engineering.

Engineering management is a career that brings together the technological problem-solving ability of engineering and the organizational, admini ...

*

Process engineering

Process engineering is the understanding and application of the fundamental principles and laws of nature that allow humans to transform raw material and energy into products that are useful to society, at an industrial level. By taking advantage ...

: design, operation, control, and optimization of chemical, physical, and biological processes.

*

Systems engineering

Systems engineering is an interdisciplinary field of engineering and engineering management that focuses on how to design, integrate, and manage complex systems over their life cycles. At its core, systems engineering utilizes systems thinki ...

: an interdisciplinary field of engineering that focuses on how to design and manage complex engineering systems over their life cycles.

*

Software engineering

Software engineering is a systematic engineering approach to software development.

A software engineer is a person who applies the principles of software engineering to design, develop, maintain, test, and evaluate computer software. The term '' ...

: an interdisciplinary field of engineering that focusing on design, development, maintenance, testing, and evaluation of the software that make computers or other devices containing software work

*

Safety engineering: an engineering discipline which assures that engineered systems provide acceptable levels of safety.

*

Data science

Data science is an interdisciplinary field that uses scientific methods, processes, algorithms and systems to extract or extrapolate knowledge and insights from noisy, structured and unstructured data, and apply knowledge from data across a br ...

: the science of exploring, manipulating, analyzing, and visualizing data to derive useful insights and conclusions

*

Machine learning

Machine learning (ML) is a field of inquiry devoted to understanding and building methods that 'learn', that is, methods that leverage data to improve performance on some set of tasks. It is seen as a part of artificial intelligence.

Machine ...

: the automation of learning from data using models and algorithms

*

Analytics

Analytics is the systematic computational analysis of data or statistics. It is used for the discovery, interpretation, and communication of meaningful patterns in data. It also entails applying data patterns toward effective decision-making. It ...

and

Data Mining: the discovery, interpretation, and extraction of patterns and insights from large quantities of data

*

Cost engineering Cost engineering is "the engineering practice devoted to the management of project cost, involving such activities as estimating, cost control, cost forecasting, investment appraisal and risk analysis". "Cost Engineers budget, plan and monitor inve ...

: practice devoted to the management of project cost, involving such activities as cost- and control- estimating, which is cost control and cost forecasting, investment appraisal, and risk analysis.

*

Value engineering

Value engineering (VE) is a systematic analysis of the functions of various components and materials to lower the cost of goods, products and services with a tolerable loss of performance or functionality. Value, as defined, ...

: a systematic method to improve the "value" of goods or products and services by using an examination of function.

*

Predetermined motion time system A predetermined motion time system (PMTS) is frequently used to perform Labor Minute Costing in order to set piece-rates, wage-rates and/or incentives in labor (labour) oriented industries by quantifying the amount of time required to perform specif ...

: a technique to quantify time required for repetitive tasks.

*

Quality engineering

Quality engineering is the discipline of engineering concerned with the principles and practice of product and service quality assurance and control. In software development, it is the management, development, operation and maintenance of IT sys ...

: a way of preventing mistakes or defects in manufactured products and avoiding problems when delivering solutions or services to customers.

*

Project management

Project management is the process of leading the work of a team to achieve all project goals within the given constraints. This information is usually described in project documentation, created at the beginning of the development process. T ...

: is the process and activity of planning, organizing, motivating, and controlling resources, procedures and protocols to achieve specific goals in scientific or daily problems.

*

Supply chain management

In commerce, supply chain management (SCM) is the management of the flow of goods and services including all processes that transform raw materials into final products between businesses and locations. This can include the movement and st ...

: the management of the flow of goods. It includes the movement and storage of raw materials, work-in-process inventory, and finished goods from point of origin to point of consumption.

*

Ergonomics

Human factors and ergonomics (commonly referred to as human factors) is the application of psychological and physiological principles to the engineering and design of products, processes, and systems. Four primary goals of human factors learnin ...

: the practice of designing products, systems or processes to take proper account of the interaction between them and the people that use them.

*

Operations research

Operations research ( en-GB, operational research) (U.S. Air Force Specialty Code: Operations Analysis), often shortened to the initialism OR, is a discipline that deals with the development and application of analytical methods to improve decis ...

, also known as

management science

Management science (or managerial science) is a wide and interdisciplinary study of solving complex problems and making strategic decisions as it pertains to institutions, corporations, governments and other types of organizational entities. It is ...

: discipline that deals with the application of advanced analytical methods to help make better decisions

*

Operations management: an area of management concerned with overseeing, designing, and controlling the process of production and redesigning business operations in the production of goods or services.

*

Job design: the specification of contents, methods and relationship of jobs in order to satisfy technological and organizational requirements as well as the social and personal requirements of the job holder.

*

Financial engineering: the application of technical methods, especially from mathematical finance and computational finance, in the practice of finance

*

Industrial plant configuration: sizing of necessary infrastructure used in support and maintenance of a given facility.

*

Facility management

Facility management or facilities management (FM) is a professional management discipline focused on the efficient and effective delivery of logistics and other support services related to real property and buildings. It encompasses multiple disc ...

: an interdisciplinary field devoted to the coordination of space, infrastructure, people and organization

*

Engineering design process

The engineering design process is a common series of steps that engineers use in creating functional products and processes. The process is highly iterative - parts of the process often need to be repeated many times before another can be entere ...

: formulation of a plan to help an engineer build a product with a specified performance goal.

*

Logistics

Logistics is generally the detailed organization and implementation of a complex operation. In a general business sense, logistics manages the flow of goods between the point of origin and the point of consumption to meet the requirements of ...

: the management of the flow of goods between the point of origin and the point of consumption in order to meet some requirements, of customers or corporations.

*

Accounting

Accounting, also known as accountancy, is the measurement, processing, and communication of financial and non financial information about economic entities such as businesses and corporations. Accounting, which has been called the "languag ...

: the measurement, processing and communication of financial information about economic entities

*

Capital projects: the management of activities in capital projects involves the flow of resources, or inputs, as they are transformed into outputs.

Many of the tools and principles of industrial engineering can be applied to the configuration of work activities within a project. The application of industrial engineering and operations management concepts and techniques to the execution of projects has been thus referred to as Project Production Management.

[ Traditionally, a major aspect of industrial engineering was planning the layouts of factories and designing assembly lines and other manufacturing paradigms. And now, in ]lean manufacturing

Lean manufacturing is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. It is closely related to another concept called just-in-time manufacturing (J ...

systems, industrial engineers work to eliminate wastes of time, money, materials, energy, and other resources.

Examples of where industrial engineering might be used include flow process charting, process mapping, designing an assembly workstation, strategizing for various operational logistics, consulting as an efficiency expert, developing a new financial algorithm or loan system for a bank, streamlining operation and emergency room location or usage in a hospital, planning complex distribution schemes for materials or products (referred to as supply-chain management

In commerce, supply chain management (SCM) is the management of the flow of goods and services including all processes that transform raw materials into final products between businesses and locations. This can include the movement and stor ...

), and shortening lines (or queues) at a bank, hospital, or a theme park.

Modern industrial engineers typically use predetermined motion time system A predetermined motion time system (PMTS) is frequently used to perform Labor Minute Costing in order to set piece-rates, wage-rates and/or incentives in labor (labour) oriented industries by quantifying the amount of time required to perform specif ...

, computer simulation

Computer simulation is the process of mathematical modelling, performed on a computer, which is designed to predict the behaviour of, or the outcome of, a real-world or physical system. The reliability of some mathematical models can be deter ...

(especially discrete event simulation

A discrete-event simulation (DES) models the operation of a system as a ( discrete) sequence of events in time. Each event occurs at a particular instant in time and marks a change of state in the system. Between consecutive events, no change in t ...

), along with extensive mathematical tools for modeling, such as mathematical optimization

Mathematical optimization (alternatively spelled ''optimisation'') or mathematical programming is the selection of a best element, with regard to some criterion, from some set of available alternatives. It is generally divided into two subfi ...

and queueing theory

Queueing theory is the mathematical study of waiting lines, or queues. A queueing model is constructed so that queue lengths and waiting time can be predicted. Queueing theory is generally considered a branch of operations research because the ...

, and computational methods for system analysis, evaluation, and optimization. Industrial engineers also use the tools of data science

Data science is an interdisciplinary field that uses scientific methods, processes, algorithms and systems to extract or extrapolate knowledge and insights from noisy, structured and unstructured data, and apply knowledge from data across a br ...

and machine learning

Machine learning (ML) is a field of inquiry devoted to understanding and building methods that 'learn', that is, methods that leverage data to improve performance on some set of tasks. It is seen as a part of artificial intelligence.

Machine ...

in their work owing to the strong relatedness of these disciplines with the field and the similar technical background required of industrial engineers (including a strong foundation in probability theory

Probability theory is the branch of mathematics concerned with probability. Although there are several different probability interpretations, probability theory treats the concept in a rigorous mathematical manner by expressing it through a set ...

, linear algebra

Linear algebra is the branch of mathematics concerning linear equations such as:

:a_1x_1+\cdots +a_nx_n=b,

linear maps such as:

:(x_1, \ldots, x_n) \mapsto a_1x_1+\cdots +a_nx_n,

and their representations in vector spaces and through matrice ...

, and statistics

Statistics (from German: '' Statistik'', "description of a state, a country") is the discipline that concerns the collection, organization, analysis, interpretation, and presentation of data. In applying statistics to a scientific, indust ...

, as well as having coding skills).

Manufacturing (production) engineering

Manufacturing Engineering is based on core industrial engineering

Industrial engineering is an engineering profession that is concerned with the optimization of complex processes, systems, or organizations by developing, improving and implementing integrated systems of people, money, knowledge, information an ...

and mechanical engineering

Mechanical engineering is the study of physical machines that may involve force and movement. It is an engineering branch that combines engineering physics and mathematics principles with materials science, to design, analyze, manufacture, ...

skills, adding important elements from mechatronics, commerce, economics and business management. This field also deals with the integration of different facilities and systems for producing quality products (with optimal expenditure) by applying the principles of physics and the results of manufacturing systems studies, such as the following:

* Craft

A craft or trade is a pastime or an occupation that requires particular skills and knowledge of skilled work. In a historical sense, particularly the Middle Ages and earlier, the term is usually applied to people occupied in small scale pr ...

or Guild

A guild ( ) is an association of artisans and merchants who oversee the practice of their craft/trade in a particular area. The earliest types of guild formed as organizations of tradesmen belonging to a professional association. They sometim ...

* Putting-out system

The putting-out system is a means of subcontracting work. Historically, it was also known as the workshop system and the domestic system. In putting-out, work is contracted by a central agent to subcontractors who complete the project via remote w ...

* British factory system

The factory system is a method of manufacturing using machinery and division of labor. Because of the high capital cost of machinery and factory buildings, factories are typically privately owned by wealthy individuals or corporations who emplo ...

* American system of manufacturing

The American system of manufacturing was a set of manufacturing methods that evolved in the 19th century. The two notable features were the extensive use of interchangeable parts and mechanization for production, which resulted in more efficient ...

* Soviet collectivism in manufacturing

* Mass production

Mass production, also known as flow production or continuous production, is the production of substantial amounts of standardized products in a constant flow, including and especially on assembly lines. Together with job production and ba ...

* Computer integrated manufacturing

Computer-integrated manufacturing (CIM) is the manufacturing approach of using computers to control the entire production process. This integration allows individual processes to exchange information with each part. Manufacturing can be faster a ...

* Computer-aided technologies in manufacturing

* Just in time manufacturing

* Lean manufacturing

Lean manufacturing is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. It is closely related to another concept called just-in-time manufacturing (J ...

* Flexible manufacturing

A flexible manufacturing system (FMS) is a manufacturing system in which there is some amount of flexibility that allows the system to react in case of changes, whether predicted or unpredicted.

This flexibility is generally considered to fall i ...

* Mass customization

In marketing, manufacturing, call centre operations, and management, mass customization makes use of flexible computer-aided systems to produce custom output. Such systems combine the low unit costs of mass production processes with the flexibili ...

* Agile manufacturing

Agile may refer to:

* Agile, an entity that possesses agility

Project management

* Agile software development, a development method

* Agile construction, iterative and incremental construction method

* Agile learning, the application of increme ...

* Rapid manufacturing

3D printing or additive manufacturing is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer ...

* Prefabrication

Prefabrication is the practice of assembling components of a structure in a factory or other manufacturing site, and transporting complete assemblies or sub-assemblies to the construction site where the structure is to be located. The term is ...

* Ownership

Ownership is the state or fact of legal possession and control over property, which may be any asset, tangible or intangible. Ownership can involve multiple rights, collectively referred to as title, which may be separated and held by different ...

* Fabrication

Fabrication may refer to:

* Manufacturing, specifically the crafting of individual parts as a solo product or as part of a larger combined product.

Processes in arts, crafts and manufacturing

* Semiconductor device fabrication, the process used ...

* Publication

To publish is to make content available to the general public.[Berne Conve ...](_blank)

Manufacturing engineers develop and create physical artifacts, production processes, and technology. It is a very broad area which includes the design and development of products. Manufacturing engineering is considered to be a sub-discipline of

Manufacturing engineers develop and create physical artifacts, production processes, and technology. It is a very broad area which includes the design and development of products. Manufacturing engineering is considered to be a sub-discipline of industrial engineering

Industrial engineering is an engineering profession that is concerned with the optimization of complex processes, systems, or organizations by developing, improving and implementing integrated systems of people, money, knowledge, information an ...

/systems engineering

Systems engineering is an interdisciplinary field of engineering and engineering management that focuses on how to design, integrate, and manage complex systems over their life cycles. At its core, systems engineering utilizes systems thinki ...

and has very strong overlaps with mechanical engineering

Mechanical engineering is the study of physical machines that may involve force and movement. It is an engineering branch that combines engineering physics and mathematics principles with materials science, to design, analyze, manufacture, ...

. Manufacturing engineers' success or failure directly impacts the advancement of technology and the spread of innovation. This field of manufacturing engineering emerged from tool and die discipline in the early 20th century. It expanded greatly from the 1960s when industrialized countries introduced factories with:

1. Numerical control

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer. A CNC machine processes ...

machine tools and automated systems of production.

2. Advanced statistical methods of quality control

Quality control (QC) is a process by which entities review the quality of all factors involved in production. ISO 9000 defines quality control as "a part of quality management focused on fulfilling quality requirements".

This approach place ...

: These factories were pioneered by the American electrical engineer William Edwards Deming

William Edwards Deming (October 14, 1900 – December 20, 1993) was an American engineer, statistician, professor, author, lecturer, and management consultant. Educated initially as an electrical engineer and later specializing in mathematica ...

, who was initially ignored by his home country. The same methods of quality control later turned Japanese factories into world leaders in cost-effectiveness and production quality.

3. Industrial robots

An industrial robot is a robot system used for manufacturing. Industrial robots are automated, programmable and capable of movement on three or more axes.

Typical applications of robots include welding, painting, assembly, disassembly, pic ...

on the factory floor, introduced in the late 1970s: These computer-controlled welding

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. Welding is distinct from lower temperature techniques such as b ...

arms and grippers could perform simple tasks such as attaching a car door quickly and flawlessly 24 hours a day. This cut costs and improved production speed.

Education

Industrial engineering

Undergraduate curriculum

In the United States the undergraduate degree earned is the Bachelor of Science (B.S.) or Bachelor of Science and Engineering (B.S.E.) in Industrial Engineering (IE). Variations of the title include Industrial & Operations Engineering (IOE), and Industrial & Systems Engineering (ISE). The typical curriculum includes a broad math and science foundation spanning chemistry

Chemistry is the scientific study of the properties and behavior of matter. It is a natural science that covers the elements that make up matter to the compounds made of atoms, molecules and ions: their composition, structure, proper ...

, physics

Physics is the natural science that studies matter, its fundamental constituents, its motion and behavior through space and time, and the related entities of energy and force. "Physical science is that department of knowledge which ...

, mechanics (i.e., statics, kinematics, and dynamics), materials science, computer science, electronics/circuits, engineering design, and the standard range of engineering mathematics (i.e. calculus

Calculus, originally called infinitesimal calculus or "the calculus of infinitesimals", is the mathematics, mathematical study of continuous change, in the same way that geometry is the study of shape, and algebra is the study of generalizati ...

, linear algebra

Linear algebra is the branch of mathematics concerning linear equations such as:

:a_1x_1+\cdots +a_nx_n=b,

linear maps such as:

:(x_1, \ldots, x_n) \mapsto a_1x_1+\cdots +a_nx_n,

and their representations in vector spaces and through matrice ...

, differential equations

In mathematics, a differential equation is an equation that relates one or more unknown functions and their derivatives. In applications, the functions generally represent physical quantities, the derivatives represent their rates of change, an ...

, statistics

Statistics (from German: '' Statistik'', "description of a state, a country") is the discipline that concerns the collection, organization, analysis, interpretation, and presentation of data. In applying statistics to a scientific, indust ...

). For any engineering undergraduate program to be accredited, regardless of concentration, it must cover a largely similar span of such foundational work – which also overlaps heavily with the content tested on one or more engineering licensure exams in most jurisdictions.

The coursework specific to IE entails specialized courses in aeas such as optimization

Mathematical optimization (alternatively spelled ''optimisation'') or mathematical programming is the selection of a best element, with regard to some criterion, from some set of available alternatives. It is generally divided into two subfi ...

, applied probability

Applied probability is the application of probability theory to statistical problems and other scientific and engineering domains.

Scope

Much research involving probability is done under the auspices of applied probability. However, while such res ...

, stochastic

Stochastic (, ) refers to the property of being well described by a random probability distribution. Although stochasticity and randomness are distinct in that the former refers to a modeling approach and the latter refers to phenomena themselv ...

modeling, design of experiments

The design of experiments (DOE, DOX, or experimental design) is the design of any task that aims to describe and explain the variation of information under conditions that are hypothesized to reflect the variation. The term is generally associ ...

, statistical process control

Statistical process control (SPC) or statistical quality control (SQC) is the application of statistical methods to monitor and control the quality of a production process. This helps to ensure that the process operates efficiently, producing ...

, simulation

A simulation is the imitation of the operation of a real-world process or system over time. Simulations require the use of Conceptual model, models; the model represents the key characteristics or behaviors of the selected system or proc ...

, manufacturing engineering

Manufacturing engineering or production engineering is a branch of professional engineering that shares many common concepts and ideas with other fields of engineering such as mechanical, chemical, electrical, and industrial engineering.

Manufa ...

, ergonomics

Human factors and ergonomics (commonly referred to as human factors) is the application of psychological and physiological principles to the engineering and design of products, processes, and systems. Four primary goals of human factors learnin ...

/ safety engineering, and engineering economics

''For the application of engineering economics in the practice of civil engineering see Engineering economics (Civil Engineering).''

Engineering economics, previously known as engineering economy, is a subset of economics concerned with the us ...

. Industrial engineering elective courses typically cover more specialized topics in areas such as manufacturing

Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of secondary sector of the economy. The term may refer to ...

, supply chains

In commerce, a supply chain is a network of facilities that procure raw materials, transform them into intermediate goods and then final products to customers through a distribution system. It refers to the network of organizations, people, activ ...

and logistics

Logistics is generally the detailed organization and implementation of a complex operation. In a general business sense, logistics manages the flow of goods between the point of origin and the point of consumption to meet the requirements of ...

, analytics

Analytics is the systematic computational analysis of data or statistics. It is used for the discovery, interpretation, and communication of meaningful patterns in data. It also entails applying data patterns toward effective decision-making. It ...

and machine learning

Machine learning (ML) is a field of inquiry devoted to understanding and building methods that 'learn', that is, methods that leverage data to improve performance on some set of tasks. It is seen as a part of artificial intelligence.

Machine ...

, production systems, human factors

Human factors and ergonomics (commonly referred to as human factors) is the application of psychological and physiological principles to the engineering and design of products, processes, and systems. Four primary goals of human factors learnin ...

and industrial design

Industrial design is a process of design applied to physical products that are to be manufactured by mass production. It is the creative act of determining and defining a product's form and features, which takes place in advance of the manufactu ...

, and service system

A service system (or customer service system, CSS) is a configuration of technology and organizational networks designed to deliver services that satisfy the needs, wants, or aspirations of customers. "Service system" is a term used in the serv ...

s.

Certain business schools may offer programs with some overlapping relevance to IE, but the engineering programs are distinguished by a much more intensely quantitative focus, required engineering science electives, and the core math and science courses required of all engineering programs.

Graduate curriculum

The usual graduate degree earned is the Master of Science (MS) or Master of Science and Engineering (MSE) in Industrial Engineering or various alternative related concentration titles. Typical MS curricula may cover:

* Operations research

Operations research ( en-GB, operational research) (U.S. Air Force Specialty Code: Operations Analysis), often shortened to the initialism OR, is a discipline that deals with the development and application of analytical methods to improve decis ...

and optimization

Mathematical optimization (alternatively spelled ''optimisation'') or mathematical programming is the selection of a best element, with regard to some criterion, from some set of available alternatives. It is generally divided into two subfi ...

techniques

* Engineering economics

''For the application of engineering economics in the practice of civil engineering see Engineering economics (Civil Engineering).''

Engineering economics, previously known as engineering economy, is a subset of economics concerned with the us ...

* Supply chain management

In commerce, supply chain management (SCM) is the management of the flow of goods and services including all processes that transform raw materials into final products between businesses and locations. This can include the movement and st ...

and logistics

Logistics is generally the detailed organization and implementation of a complex operation. In a general business sense, logistics manages the flow of goods between the point of origin and the point of consumption to meet the requirements of ...

* Systems simulation

Computers are used to generate numeric models for the purpose of describing or displaying complex interaction among multiple variables within a system. The complexity of the system arises from the stochastic (probabilistic) nature of the events, ...

and stochastic

Stochastic (, ) refers to the property of being well described by a random probability distribution. Although stochasticity and randomness are distinct in that the former refers to a modeling approach and the latter refers to phenomena themselv ...

processes

* Analytics

Analytics is the systematic computational analysis of data or statistics. It is used for the discovery, interpretation, and communication of meaningful patterns in data. It also entails applying data patterns toward effective decision-making. It ...

and machine learning

Machine learning (ML) is a field of inquiry devoted to understanding and building methods that 'learn', that is, methods that leverage data to improve performance on some set of tasks. It is seen as a part of artificial intelligence.

Machine ...

* Manufacturing systems/manufacturing engineering

Manufacturing engineering or production engineering is a branch of professional engineering that shares many common concepts and ideas with other fields of engineering such as mechanical, chemical, electrical, and industrial engineering.

Manufa ...

* Human factors engineering and ergonomics ( safety engineering)

* Production planning and control

Production planning is the planning of production and manufacturing modules in a company or industry. It utilizes the resource allocation of activities of employees, materials and production capacity, in order to serve different customers.Fargher ...

* System analysis and techniques

* Management science

Management science (or managerial science) is a wide and interdisciplinary study of solving complex problems and making strategic decisions as it pertains to institutions, corporations, governments and other types of organizational entities. It is ...

s

* Computer-aided manufacturing

Computer-aided manufacturing (CAM) also known as computer-aided modeling or computer-aided machining is the use of software to control machine tools in the manufacturing of work pieces. This is not the only definition for CAM, but it is the most ...

* Lean Six Sigma

* Financial engineering

* Facilities design and work-space design

* Quality engineering

Quality engineering is the discipline of engineering concerned with the principles and practice of product and service quality assurance and control. In software development, it is the management, development, operation and maintenance of IT sys ...

* Reliability engineering

Reliability engineering is a sub-discipline of systems engineering that emphasizes the ability of equipment to function without failure. Reliability describes the ability of a system or component to function under stated conditions for a specifie ...

and life testing

* Statistical process control

Statistical process control (SPC) or statistical quality control (SQC) is the application of statistical methods to monitor and control the quality of a production process. This helps to ensure that the process operates efficiently, producing ...

or quality control

Quality control (QC) is a process by which entities review the quality of all factors involved in production. ISO 9000 defines quality control as "a part of quality management focused on fulfilling quality requirements".

This approach place ...

* Time and motion study

A time and motion study (or time-motion study) is a business efficiency technique combining the Time Study work of Frederick Winslow Taylor with the Motion Study work of Frank and Lillian Gilbreth (the same couple as is best known through the biog ...

* Predetermined motion time system A predetermined motion time system (PMTS) is frequently used to perform Labor Minute Costing in order to set piece-rates, wage-rates and/or incentives in labor (labour) oriented industries by quantifying the amount of time required to perform specif ...

and computer use for IE

* Operations management

* Project management

Project management is the process of leading the work of a team to achieve all project goals within the given constraints. This information is usually described in project documentation, created at the beginning of the development process. T ...

* Productivity

Productivity is the efficiency of production of goods or services expressed by some measure. Measurements of productivity are often expressed as a ratio of an aggregate output to a single input or an aggregate input used in a production proces ...

improvement

* Materials management

* Robotics

Robotics is an interdisciplinary branch of computer science and engineering. Robotics involves design, construction, operation, and use of robots. The goal of robotics is to design machines that can help and assist humans. Robotics integrat ...

* Product Development

In business and engineering, new product development (NPD) covers the complete process of bringing a new product to market, renewing an existing product or introducing a product in a new market. A central aspect of NPD is product design, along w ...

* System dynamics

System dynamics (SD) is an approach to understanding the nonlinear behaviour of complex systems over time using stocks, flows, internal feedback loops, table functions and time delays.

Overview

System dynamics is a methodology and mathematica ...

and policy planning

Manufacturing (production) engineering

Degree certification programs

Manufacturing engineers possess an associate's or bachelor's degree in engineering with a major in manufacturing engineering. The length of study for such a degree is usually two to five years followed by five more years of professional practice to qualify as a professional engineer. Working as a manufacturing engineering technologist involves a more applications-oriented qualification path.

Academic degrees for manufacturing engineers are usually the Associate or Bachelor of Engineering, Eor Eng and the Associate or Bachelor of Science, Sor Sc For manufacturing technologists the required degrees are Associate or Bachelor of Technology .TECHor Associate or Bachelor of Applied Science ASc ASC may refer to:

Educational institutions

* Anglican Schools Commission, Australia

* Andres Soriano Colleges of Bislig, located in Surigao del Sur, Philippines

* Agnes Scott College, Decatur, Georgia

Organizations Australia

* Australian Singi ...

in Manufacturing, depending upon the university. Master's degrees in engineering manufacturing include Master of Engineering Eor Engin Manufacturing, Master of Science .Scin Manufacturing Management, Master of Science .Scin Industrial and Production Management, and Master of Science .Scas well as Master of Engineering Ein Design, which is a subdiscipline of manufacturing. Doctoral hDor Englevel courses in manufacturing are also available depending on the university.

The undergraduate degree curriculum generally includes courses in physics, mathematics, computer science, project management, and specific topics in mechanical and manufacturing engineering. Initially such topics cover most, if not all, of the subdisciplines of manufacturing engineering. Students then choose to specialize in one or more sub disciplines towards the end of their degree work.

Specific to Industrial Engineers, people will see courses covering ergonomics, scheduling, inventory management, forecasting, product development, and in general courses that focus on optimization. Most colleges breakdown the large sections of industrial engineering into Healthcare, Ergonomics, Product Development, or Consulting sectors. This allows for the student to get a good grasp on each of the varying sub-sectors so they know what area they are most interested about pursuing a career in.

Undergraduate curriculum

The Foundational Curriculum for a bachelor's degree of Manufacturing Engineering or Production Engineering includes below mentioned Syllabus. This Syllabus is closely related to Industrial Engineering and Mechanical Engineering. But it Differs by Placing more Emphasis on Manufacturing Science or Production Science. It includes following:

* Mathematics (Calculus, Differential Equations, Statistics and Linear Algebra)

* Mechanics (Statics & Dynamics)

* Solid Mechanics

* Fluid Mechanics

* Materials Science

* Strength of Materials

* Fluid Dynamics

* Hydraulics

* Pneumatics

* HVAC (Heating, Ventilation & Air Conditioning)

* Heat Transfer

* Applied Thermodynamics

* Energy conversion

Energy transformation, also known as energy conversion, is the process of changing energy from one form to another. In physics, energy is a quantity that provides the capacity to perform work or moving, (e.g. Lifting an object) or provides heat ...

* Instrumentation and Measurement

* Engineering Drawing (Drafting) & Engineering Design

* Engineering Graphics

* Mechanism Design including Kinematics and Dynamics

* Manufacturing Processes

* Mechatronics

Mechatronics engineering also called mechatronics, is an interdisciplinary branch of engineering that focuses on the integration of mechanical, electrical and electronic engineering systems, and also includes a combination of robotics, electronics, ...

* Circuit analysis

A network, in the context of electrical engineering and electronics, is a collection of interconnected components. Network analysis is the process of finding the voltages across, and the currents through, all network components. There are many ...

* Lean manufacturing

Lean manufacturing is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. It is closely related to another concept called just-in-time manufacturing (J ...

* Automation

* Reverse Engineering

* Quality Control

* CAD (Computer aided Design which includes Solid Modelling) and CAM (Computer aided Manufacturing)

A degree in Manufacturing Engineering versus Mechanical Engineering will typically differ only by a few specialized classes. Mechanical Engineering degree focuses more on the Product Design Process and on Complex Products which requires more Mathematics Expertise.

Manufacturing engineering certification

Professional engineering license

A Professional Engineer

Regulation and licensure in engineering is established by various jurisdictions of the world to encourage life, public welfare, safety, well-being, then environment and other interests of the general public and to define the licensure process thro ...

, PE, is a licensed engineer who is permitted to offer professional services to the public. Professional Engineers may prepare, sign, seal, and submit engineering plans to the public. Before a candidate can become a professional engineer, they will need to receive a bachelor's degree from an ABET

The ABET (incorporated as the Accreditation Board for Engineering and Technology, Inc.) is a non-governmental organization that accredits post-secondary education programs in applied and natural sciences, computing, engineering and engineering ...

recognized university in the US, take and pass the Fundamentals of Engineering exam to become an "engineer-in-training", and work four years under the supervision of a professional engineer. After those tasks are complete the candidate will be able to take the PE exam. Upon receiving a passing score on the test, the candidate will receive their PE License .

Society of Manufacturing Engineers (SME) certifications (USA)

The SME (society) administers qualifications specifically for the manufacturing industry. These are not degree level qualifications and are not recognized at the professional engineering level. The SME offers two certifications for Manufacturing engineers: Certified Manufacturing Technologist Certificate (CMfgT) and Certified Manufacturing Engineer (CMfgE).

Certified manufacturing technologist

Qualified candidates for the Certified Manufacturing Technologist Certificate (CMfgT) must pass a three-hour, 130-question multiple-choice exam. The exam covers math, manufacturing processes, manufacturing management, automation, and related subjects. A score of 60% or higher must be achieved to pass the exam. Additionally, a candidate must have at least four years of combined education and manufacturing-related work experience. The CMfgT certification must be renewed every three years in order to stay certified.

Certified manufacturing engineer

Certified Manufacturing Engineer (CMfgE) is an engineering qualification administered by the Society of Manufacturing Engineers, Dearborn, Michigan, USA. Candidates qualifying for a Certified Manufacturing Engineer credential must pass a four-hour, 180 question multiple-choice exam which covers more in-depth topics than does the CMfgT exam. A score of 60% or higher must be achieved to pass the exam. CMfgE candidates must also have eight years of combined education and manufacturing-related work experience, with a minimum of four years of work experience. The CMfgT certification must be renewed every three years in order to stay certified.

Research

Industrial engineering

Human factors

The human factors

Human factors and ergonomics (commonly referred to as human factors) is the application of psychological and physiological principles to the engineering and design of products, processes, and systems. Four primary goals of human factors learnin ...

area specializes in exploring how systems fit the people who must operate them, determining the roles of people with the systems, and selecting those people who can best fit particular roles within these systems. Students who focus on Human Factors will be able to work with a multidisciplinary team of faculty with strengths in understanding cognitive behavior as it relates to automation, air and ground transportation, medical studies, and space exploration.

Production systems

The production systems area develops new solutions in areas such as engineering design, supply chain management (e.g. supply chain system design, error recovery

In information theory and coding theory with applications in computer science and telecommunication, error detection and correction (EDAC) or error control are techniques that enable reliable delivery of digital data over unreliable communic ...

, large scale systems), manufacturing (e.g. system design, planning and scheduling), and medicine (e.g. disease diagnosis, discovery of medical knowledge). Students who focus on production systems will be able to work on topics related to computational intelligence theories for applications in industry, healthcare, and service organizations.

Reliability systems

The objective of the reliability systems area is to provide students with advanced data analysis and decision making techniques that will improve quality and reliability of complex systems. Students who focus on system reliability and uncertainty will be able to work on areas related to contemporary reliability systems including integration of quality and reliability, simultaneous life cycle design for manufacturing systems, decision theory in quality and reliability engineering, condition-based maintenance and degradation modeling, discrete event simulation and decision analysis.

Wind power management

The Wind Power Management Program aims at meeting the emerging needs for graduating professionals involved in design, operations, and management of wind farm

A wind farm or wind park, also called a wind power station or wind power plant, is a group of wind turbines in the same location used to produce electricity. Wind farms vary in size from a small number of turbines to several hundred wind turb ...

s deployed in massive numbers all over the country. The graduates will be able to fully understand the system and management issues of wind farms and their interactions with alternative and conventional power generation systems.

Production (manufacturing) engineering

Flexible manufacturing systems

A

A flexible manufacturing system

A flexible manufacturing system (FMS) is a manufacturing system in which there is some amount of flexibility that allows the system to react in case of changes, whether predicted or unpredicted.

This flexibility is generally considered to fall ...

(FMS) is a manufacturing system in which there is some amount of flexibility that allows the system to react to changes, whether predicted or unpredicted. This flexibility is generally considered to fall into two categories, both of which have numerous subcategories. The first category, machine flexibility, covers the system's ability to be changed to produce new product types and the ability to change the order of operations executed on a part. The second category, called routing flexibility, consists of the ability to use multiple machines to perform the same operation on a part, as well as the system's ability to absorb large-scale changes, such as in volume, capacity, or capability.

Most FMS systems comprise three main systems. The work machines, which are often automated CNC machines, are connected by a material handling system to optimize parts flow, and to a central control computer, which controls material movements and machine flow. The main advantages of an FMS is its high flexibility in managing manufacturing resources like time and effort in order to manufacture a new product. The best application of an FMS is found in the production of small sets of products from a mass production.

Computer integrated manufacturing

Computer-integrated manufacturing (CIM) in engineering is a method of manufacturing in which the entire production process is controlled by computer. Traditionally separated process methods are joined through a computer by CIM. This integration allows the processes to exchange information and to initiate actions. Through this integration, manufacturing can be faster and less error-prone, although the main advantage is the ability to create automated manufacturing processes. Typically CIM relies on closed-loop control processes based on real-time input from sensors. It is also known as flexible design and manufacturing.

Friction stir welding

Friction stir welding was discovered in 1991 by The Welding Institute (TWI). This innovative steady state (non-fusion) welding technique joins previously un-weldable materials, including several

Friction stir welding was discovered in 1991 by The Welding Institute (TWI). This innovative steady state (non-fusion) welding technique joins previously un-weldable materials, including several aluminum alloys

An aluminium alloy (or aluminum alloy; see spelling differences) is an alloy in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin, nickel and zinc. There are two pr ...

. It may play an important role in the future construction of airplanes, potentially replacing rivets. Current uses of this technology to date include: welding the seams of the aluminum main space shuttle external tank, the Orion Crew Vehicle test article, Boeing Delta II and Delta IV Expendable Launch Vehicles and the SpaceX Falcon 1 rocket; armor plating for amphibious assault ships; and welding the wings and fuselage panels of the new Eclipse 500 aircraft from Eclipse Aviation, among an increasingly growing range of uses.

Employment

Industrial engineering

The total number of engineers employed in the US in 2015 was roughly 1.6 million. Of these, 272,470 were industrial engineers (16.92%), the third most popular engineering specialty. The median salaries by experience level are $62,000 with 0–5 years experience, $75,000 with 5–10 years experience, and $81,000 with 10–20 years experience. The average starting salaries were $55,067 with a bachelor's degree, $77,364 with a master's degree, and $100,759 with a doctorate degree. This places industrial engineering at 7th of 15 among engineering bachelor's degrees, 3rd of 10 among master's degrees, and 2nd of 7 among doctorate degrees in average annual salary. The median annual income of industrial engineers in the U.S. workforce is $83,470.

Production (manufacturing) engineering

Manufacturing engineering is just one facet of the engineering industry. Manufacturing engineers enjoy improving the production process from start to finish. They have the ability to keep the whole production process in mind as they focus on a particular portion of the process. Successful students in manufacturing engineering degree programs are inspired by the notion of starting with a natural resource, such as a block of wood, and ending with a usable, valuable product, such as a desk, produced efficiently and economically.

Manufacturing engineers are closely connected with engineering and industrial design efforts. Examples of major companies that employ manufacturing engineers in the United States include General Motors Corporation

The General Motors Company (GM) is an American multinational automotive manufacturing company headquartered in Detroit, Michigan, United States. It is the largest automaker in the United States and was the largest in the world for 77 years bef ...

, Ford Motor Company, Chrysler

Stellantis North America (officially FCA US and formerly Chrysler ()) is one of the " Big Three" automobile manufacturers in the United States, headquartered in Auburn Hills, Michigan. It is the American subsidiary of the multinational automotiv ...

, Boeing

The Boeing Company () is an American multinational corporation that designs, manufactures, and sells airplanes, rotorcraft, rockets, satellites, telecommunications equipment, and missiles worldwide. The company also provides leasing and ...

, Gates Corporation

Gates Industrial Corporation plc, based in Denver, Colorado, is a manufacturer of power transmission belts and fluid power products, which are used in diverse industrial and automotive applications. The company employs over 14,000 and has sales ...

and Pfizer

Pfizer Inc. ( ) is an American multinational pharmaceutical and biotechnology corporation headquartered on 42nd Street in Manhattan, New York City. The company was established in 1849 in New York by two German entrepreneurs, Charles Pfize ...

. Examples in Europe include Airbus

Airbus SE (; ; ; ) is a European multinational aerospace corporation. Airbus designs, manufactures and sells civil and military aerospace products worldwide and manufactures aircraft throughout the world. The company has three divisions: '' ...

, Daimler, BMW, Fiat

Fiat Automobiles S.p.A. (, , ; originally FIAT, it, Fabbrica Italiana Automobili di Torino, lit=Italian Automobiles Factory of Turin) is an Italian automobile manufacturer, formerly part of Fiat Chrysler Automobiles, and since 2021 a subsidiar ...

, Navistar International

Navistar, Inc is an American holding company created in 1986 as the successor to International Harvester. Navistar operates as the owner of International-branded trucks and diesel engines. The company also produces buses under the IC Bus ...

, and Michelin Tyre.

Related industries

Industries where industrial and production engineers are generally employed include:

* Aerospace industry

Aerospace is a term used to collectively refer to the atmosphere and outer space. Aerospace activity is very diverse, with a multitude of commercial, industrial and military applications. Aerospace engineering consists of aeronautics and astron ...

* Automotive industry

The automotive industry comprises a wide range of companies and organizations involved in the design, development, manufacturing, marketing, and selling of motor vehicles. It is one of the world's largest industries by revenue (from 16 % ...

* Chemical industry

The chemical industry comprises the companies that produce industrial chemicals. Central to the modern world economy, it converts raw materials ( oil, natural gas, air, water, metals, and minerals) into more than 70,000 different products. ...

* Computer industry

A computer is a machine that can be programmed to carry out sequences of arithmetic or logical operations ( computation) automatically. Modern digital electronic computers can perform generic sets of operations known as programs. These progr ...

* Electronics industry

The electronics industry is the economic sector that produces electronic devices. It emerged in the 20th century and is today one of the largest global industries. Contemporary society uses a vast array of electronic devices built-in automated or ...

* Food processing industry

Food processing is the transformation of agricultural products into food, or of one form of food into other forms. Food processing includes many forms of processing foods, from grinding grain to make raw flour to home cooking to complex indus ...

* Garment industry

* Pharmaceutical industry

The pharmaceutical industry discovers, develops, produces, and markets drugs or pharmaceutical drugs for use as medications to be administered to patients (or self-administered), with the aim to cure them, vaccinate them, or alleviate symptoms. ...

* Plastic packaging

Plastic containers are containers made exclusively or partially of plastic. Plastic containers are ubiquitous either as single-use or reuseable/durable plastic cups, plastic bottles, plastic bags, foam food containers, Tupperware, plastic tubes, ...

* Pulp and paper industry

The pulp and paper industry comprises companies that use wood as raw material and produce Pulp (paper), pulp, paper, paperboard and other cellulose-based products.

Manufacturing process

The pulp is fed to a paper machine where it is formed as ...

* Toy industry

Modern tools

Many manufacturing companies, especially those in industrialized nations, have begun to incorporate

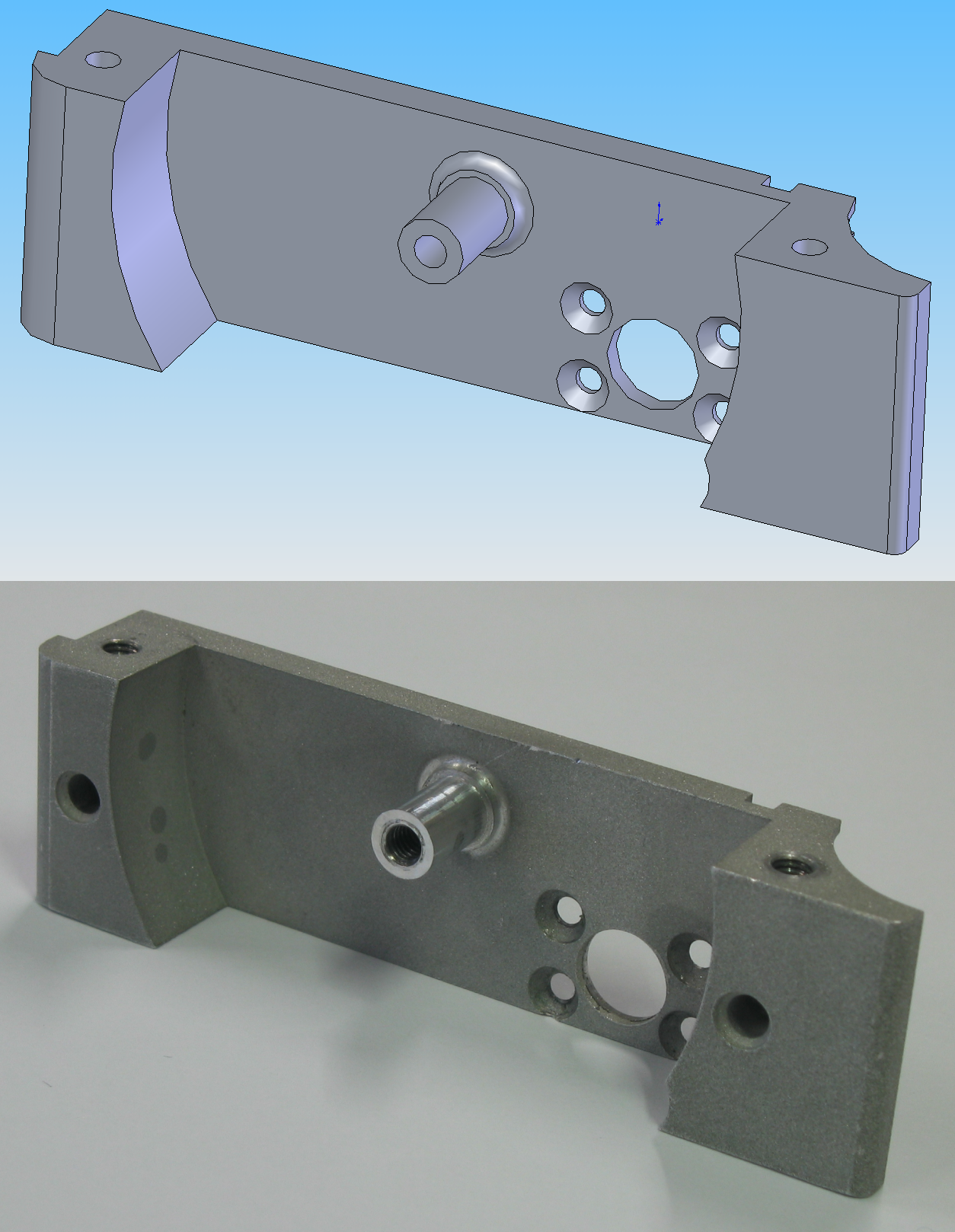

Many manufacturing companies, especially those in industrialized nations, have begun to incorporate computer-aided engineering

Computer-aided engineering (CAE) is the broad usage of computer software to aid in engineering analysis tasks. It includes , , , durability and optimization. It is included with computer-aided design (CAD) and computer-aided manufacturing (CAM) ...

(CAE) programs, such as SolidWorks

SolidWorks is a solid modeling computer-aided design (CAD) and computer-aided engineering (CAE) application published by Dassault Systèmes.