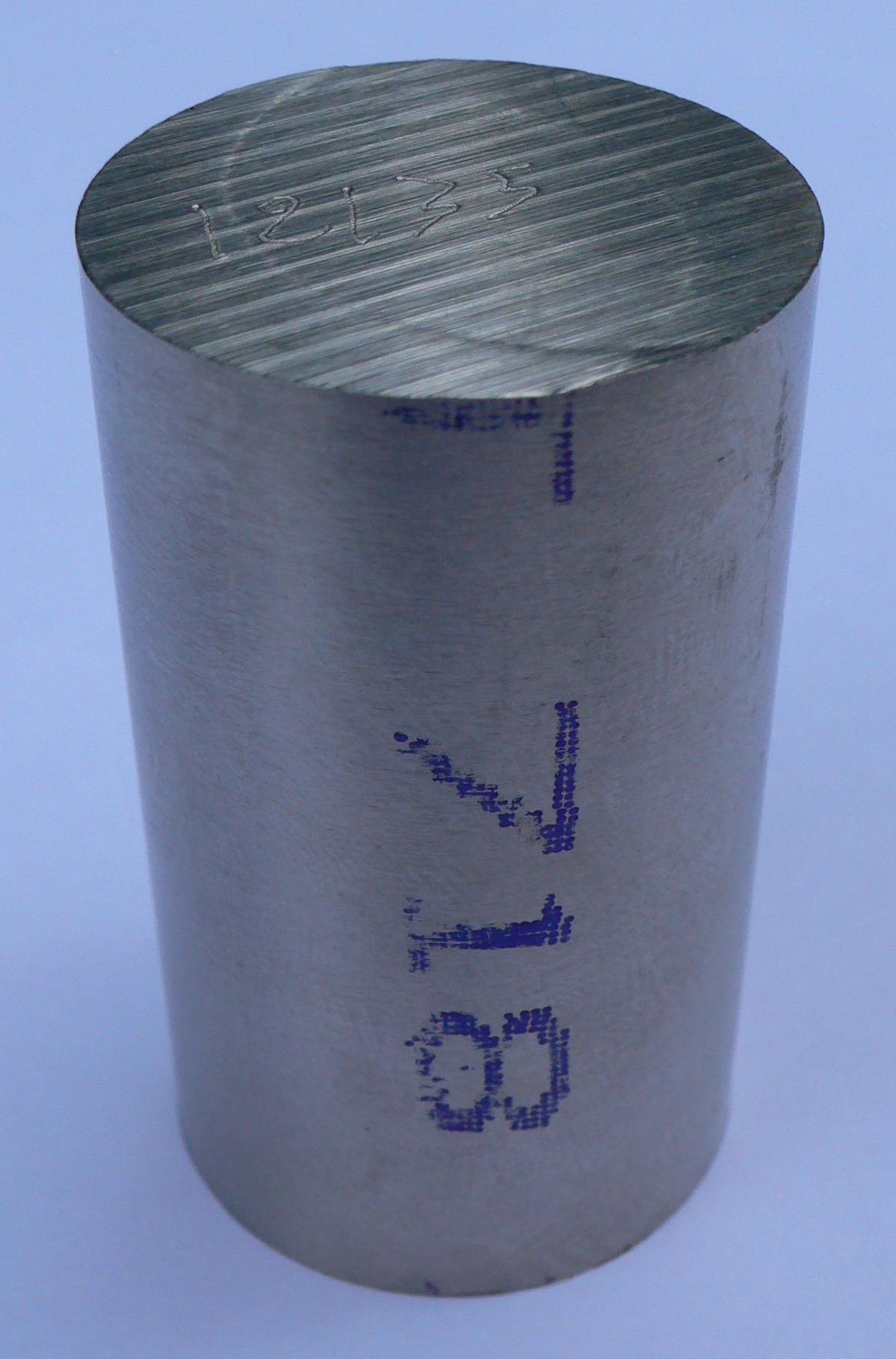

Inconel 600 on:

[Wikipedia]

[Google]

[Amazon]

Inconel is a registered trademark of Special Metals Corporation for a family of

Inconel is a registered trademark of Special Metals Corporation for a family of

Special Metals Corporation Inconel alloys are typically used in high temperature applications. Common trade names for * Inconel Alloy 625 include:

Inconel is often encountered in extreme environments. It is common in

Inconel is often encountered in extreme environments. It is common in

/ref>

Vishal Kumar Jaiswal "Experimental Investigation of Process Parameters on Inconel 925 for EDM Process by using Taguchi Method." International Journal for Scientific Research and Development 6.5 (2018): 277-282.

IJSRD

In age hardening or precipitation strengthening varieties, alloying additions of aluminum and

austenitic

Austenite, also known as gamma-phase iron (γ-Fe), is a metallic, non-magnetic allotrope of iron or a solid solution of iron with an alloying element. In plain-carbon steel, austenite exists above the critical eutectoid temperature of 1000 K ...

nickel

Nickel is a chemical element with symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive but large pieces are slow ...

-chromium

Chromium is a chemical element with the symbol Cr and atomic number 24. It is the first element in group 6. It is a steely-grey, lustrous, hard, and brittle transition metal.

Chromium metal is valued for its high corrosion resistance and h ...

-based superalloy

A superalloy, or high-performance alloy, is an alloy with the ability to operate at a high fraction of its melting point. Several key characteristics of a superalloy are excellent mechanical strength, resistance to thermal creep deformation, ...

s.

Inconel alloys are oxidation-corrosion-resistant

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engi ...

materials well suited for service in extreme environments subjected to pressure and heat. When heated, Inconel forms a thick, stable, passivating oxide layer protecting the surface from further attack. Inconel retains strength over a wide temperature range, attractive for high-temperature applications where aluminium and steel would succumb to creep as a result of thermally-induced crystal vacancies. Inconel's high-temperature strength is developed by solid solution strengthening

In metallurgy, solid solution strengthening is a type of alloying that can be used to improve the strength of a pure metal. The technique works by adding atoms of one element (the alloying element) to the crystalline lattice of another element ...

or precipitation hardening

Precipitation hardening, also called age hardening or particle hardening, is a heat treatment technique used to increase the yield strength of malleable materials, including most structural alloys of aluminium, magnesium, nickel, titanium, and so ...

, depending on the alloy.INCONEL alloy 718Special Metals Corporation Inconel alloys are typically used in high temperature applications. Common trade names for * Inconel Alloy 625 include:

Inconel 625

Inconel Alloy 625 (UNS designation N06625) is a nickel-based superalloy that possesses high strength properties and resistance to elevated temperatures. It also demonstrates remarkable protection against corrosion and oxidation. Its ability to wi ...

, Chronin 625, Altemp 625, Haynes 625, Nickelvac 625 and Nicrofer 6020.

* Inconel Alloy 600 include: NA14, N06600, BS3076, 2.4816, NiCr15Fe (FR), NiCr15Fe (EU) and NiCr15Fe8 (DE).

* Inconel 718 include: Nicrofer 5219, Superimphy 718, Haynes 718, Pyromet 718, Supermet 718, and Udimet 718.

History

The Inconel family of alloys was first developed before December 1932, when itstrademark

A trademark (also written trade mark or trade-mark) is a type of intellectual property consisting of a recognizable sign, design, or expression that identifies products or services from a particular source and distinguishes them from oth ...

was registered by the International Nickel Company of Delaware and New York. A significant early use was found in support of the development of the Whittle jet engine, during the 1940s by research teams at Henry Wiggin & Co of Hereford, England a subsidiary of the Mond Nickel Company

The Mond Nickel Company Limited was a United Kingdom of Great Britain and Ireland, United Kingdom-based List of mining companies, mining company, formed on September 20, 1900, licensed in Canada to carry on business in the province of Ontario, from ...

, which merged with Inco

Vale Canada Limited (formerly Vale Inco, CVRD Inco and Inco Limited; for corporate branding purposes simply known as "Vale" and pronounced in English) is a wholly owned subsidiary of the Brazilian mining company Vale. Vale's nickel mining and ...

in 1928. The Hereford Works and its properties including the Inconel trademark were acquired in 1998 by Special Metals Corporation.

Specific data

Composition

Inconel alloys vary widely in their compositions, but all are predominantly nickel, with chromium as the second element.Properties

Inconel alloys areoxidation

Redox (reduction–oxidation, , ) is a type of chemical reaction in which the oxidation states of substrate change. Oxidation is the loss of electrons or an increase in the oxidation state, while reduction is the gain of electrons or a ...

- and corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engi ...

-resistant materials well suited for service in extreme environments subjected to high mechanical loads. When heated, Inconel forms a thick and stable passivating oxide layer protecting the surface from further attack. Inconel retains strength over a wide temperature range, attractive for high-temperature applications where aluminium

Aluminium (aluminum in AmE, American and CanE, Canadian English) is a chemical element with the Symbol (chemistry), symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately o ...

and steel would succumb to creep as a result of thermally induced crystal vacancies (see Arrhenius equation

In physical chemistry, the Arrhenius equation is a formula for the temperature dependence of reaction rates. The equation was proposed by Svante Arrhenius in 1889, based on the work of Dutch chemist Jacobus Henricus van 't Hoff who had noted in 18 ...

). Inconel's high temperature strength is developed by solid solution strengthening

In metallurgy, solid solution strengthening is a type of alloying that can be used to improve the strength of a pure metal. The technique works by adding atoms of one element (the alloying element) to the crystalline lattice of another element ...

or precipitation strengthening

Precipitation hardening, also called age hardening or particle hardening, is a heat treatment technique used to increase the yield strength of malleable materials, including most structural alloys of aluminium, magnesium, nickel, titanium, and so ...

, depending on the alloy. In age-hardening or precipitation-strengthening varieties, small amounts of niobium

Niobium is a chemical element with chemical symbol Nb (formerly columbium, Cb) and atomic number 41. It is a light grey, crystalline, and ductile transition metal. Pure niobium has a Mohs hardness rating similar to pure titanium, and it ha ...

combine with nickel

Nickel is a chemical element with symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive but large pieces are slow ...

to form the intermetallic

An intermetallic (also called an intermetallic compound, intermetallic alloy, ordered intermetallic alloy, and a long-range-ordered alloy) is a type of metallic alloy that forms an ordered solid-state compound between two or more metallic elem ...

compound Ni3Nb or gamma double prime (γ″). Gamma prime forms small cubic crystals that inhibit slip and creep effectively at elevated temperatures. The formation of gamma-prime crystals increases over time, especially after three hours of a heat exposure of , and continues to grow after 72 hours of exposure.

Machining

Inconel is a difficult metal to shape and to machine using traditionalcold forming

In metallurgy, cold forming or cold working is any metalworking process in which metal is shaped below its recrystallization temperature, usually at the ambient temperature. Such processes are contrasted with hot working techniques like hot ro ...

techniques due to rapid work hardening

In materials science, work hardening, also known as strain hardening, is the strengthening of a metal or polymer by plastic deformation. Work hardening may be desirable, undesirable, or inconsequential, depending on the context.

This strength ...

. After the first machining pass, work hardening tends to plastically deform either the workpiece or the tool on subsequent passes. For this reason, age-hardened Inconels such as 718 are typically machined using an aggressive but slow cut with a hard tool, minimizing the number of passes required. Alternatively, the majority of the machining can be performed with the workpiece in a "solutionized" form, with only the final steps being performed after age hardening. However some claim that Inconel can be machined extremely quickly with very fast spindle speeds using a multifluted ceramic tool with small depth of cut at high feed rates as this causes localised heating and softening in front of the flute.

External threads

Thread may refer to:

Objects

* Thread (yarn), a kind of thin yarn used for sewing

** Thread (unit of measurement), a cotton yarn measure

* Screw thread, a helical ridge on a cylindrical fastener

Arts and entertainment

* ''Thread'' (film), 2016 ...

are machined using a lathe

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to ...

to "single-point" the threads or by rolling the threads in the solution treated condition (for hardenable alloys) using a screw machine. Inconel 718 can also be roll-threaded after full aging by using induction heat

Induction heating is the process of heating electrically conductive materials, namely metals or semi-conductors, by electromagnetic induction, through heat transfer passing through an induction coil that creates an electromagnetic field within th ...

to without increasing the grain size. Holes with internal threads are made by threadmilling. Internal threads can also be formed using a sinker electrical discharge machining

Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal

fabrication process whereby a desired shape is obtained by using electrical discharges (sparks). Material i ...

(EDM).

More often than machining, water-jet or laser grinding is a preferred and economical method for forming nickel alloy components to shape and finish. Due to the hardness of the abrasives used, the grinding wheels are not as affected by the material work hardening and remain sharp and durable.

Joining

Welding of some Inconel alloys (especially the gamma prime precipitation hardened family; e.g., Waspalloy and X-750) can be difficult due to cracking and microstructural segregation of alloying elements in theheat-affected zone

In fusion welding, the heat-affected zone (HAZ) is the area of base material, either a metal or a thermoplastic, which is not melted but has had its microstructure and properties altered by welding or heat intensive cutting operations. The heat ...

. However, several alloys such as 625 and 718 have been designed to overcome these problems. The most common welding methods are gas tungsten arc welding

Gas tungsten arc welding (GTAW), also known as tungsten inert gas (TIG) welding, is an arc welding process that uses a non-consumable tungsten electrode to produce the weld. The weld area and electrode are protected from oxidation or other atmo ...

and electron-beam welding.

Uses

Inconel is often encountered in extreme environments. It is common in

Inconel is often encountered in extreme environments. It is common in gas turbine

A gas turbine, also called a combustion turbine, is a type of continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part (known as the gas generator or core) and are, in the directio ...

blades, seals, and combustors, as well as turbocharger

In an internal combustion engine, a turbocharger (often called a turbo) is a forced induction device that is powered by the flow of exhaust gases. It uses this energy to compress the intake gas, forcing more air into the engine in order to pr ...

rotors and seals, electric submersible well pump motor shafts, high temperature fasteners, chemical processing and pressure vessel

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure.

Construction methods and materials may be chosen to suit the pressure application, and will depend on the size o ...

s, heat exchanger

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct conta ...

tubing, steam generators and core components in nuclear pressurized water reactors, natural gas processing

Natural-gas processing is a range of industrial processes designed to purify raw natural gas by removing impurities, contaminants and higher molecular mass hydrocarbons to produce what is known as ''pipeline quality'' dry natural gas. Natural gas ...

with contaminants such as H2S and CO2, firearm sound suppressor

A silencer, also known as a sound suppressor, suppressor, or sound moderator, is a muzzle device that reduces the acoustic intensity of the muzzle report (sound of a gunshot) and muzzle rise when a gun ( firearm or air gun) is discharged, ...

blast baffles, and Formula One

Formula One (also known as Formula 1 or F1) is the highest class of international racing for open-wheel single-seater formula racing cars sanctioned by the Fédération Internationale de l'Automobile (FIA). The World Drivers' Championship ...

, NASCAR

The National Association for Stock Car Auto Racing, LLC (NASCAR) is an American auto racing sanctioning and operating company that is best known for stock car racing. The privately owned company was founded by Bill France Sr. in 1948, and h ...

, NHRA

The National Hot Rod Association (NHRA) is a drag racing governing body, which sets rules in drag racing and hosts events all over the United States and Canada. With over 40,000 drivers in its rosters, the NHRA claims to be the largest motorspo ...

, and APR, LLC exhaust systems. It is also used in the turbo system of the 3rd generation Mazda RX7, and the exhaust systems of high powered Wankel engine

The Wankel engine (, ) is a type of internal combustion engine using an eccentric rotary design to convert pressure into rotating motion. It was invented by German engineer Felix Wankel, and designed by German engineer Hanns-Dieter Paschke. ...

d Norton motorcycles where exhaust temperatures reach more than . Inconel is increasingly used in the boilers of waste incinerators. The Joint European Torus

The Joint European Torus, or JET, is an operational magnetically confined plasma physics experiment, located at Culham Centre for Fusion Energy in Oxfordshire, UK. Based on a tokamak design, the fusion research facility is a joint European p ...

and DIII-D tokamaks' vacuum vessels are made of Inconel. Inconel 718 is commonly used for cryogenic

In physics, cryogenics is the production and behaviour of materials at very low temperatures.

The 13th IIR International Congress of Refrigeration (held in Washington DC in 1971) endorsed a universal definition of “cryogenics” and “cr ...

storage tanks, downhole shafts, wellhead parts, and in the aerospace industry -- where it has become a prime candidate material for constructing heat resistant turbines.

Aerospace

*TheSpace Shuttle

The Space Shuttle is a retired, partially reusable low Earth orbital spacecraft system operated from 1981 to 2011 by the U.S. National Aeronautics and Space Administration (NASA) as part of the Space Shuttle program. Its official program na ...

used four Inconel studs to secure the solid rocket boosters to the launch platform, eight total studs supported the entire weight of the ready to fly Shuttle system. Eight frangible nut

The frangible nut is a component used in many industries, but most commonly by NASA, to sever mechanical connections. It is, by definition, an explosively-splittable nut. The bolt remains intact while the nut itself is split into two or more par ...

s are encased on the outside of the solid rocket boosters, at launch explosives separated the nuts releasing the Shuttle from its launch platform.

*North American Aviation

North American Aviation (NAA) was a major American aerospace manufacturer that designed and built several notable aircraft and spacecraft. Its products included: the T-6 Texan trainer, the P-51 Mustang fighter, the B-25 Mitchell bomber, the ...

constructed the skin of the North American X-15

The North American X-15 is a hypersonic rocket-powered aircraft. It was operated by the United States Air Force and the National Aeronautics and Space Administration as part of the X-plane series of experimental aircraft. The X-15 set spe ...

Rocket-powered aircraft

A rocket-powered aircraft or rocket plane is an aircraft that uses a rocket engine for propulsion, sometimes in addition to airbreathing jet engines. Rocket planes can achieve much higher speeds than similarly sized jet aircraft, but typicall ...

out of Inconel X/750 alloy.

*Rocketdyne

Rocketdyne was an American rocket engine design and production company headquartered in Canoga Park, California, Canoga Park, in the western San Fernando Valley of suburban Los Angeles, California, Los Angeles, in southern California.

The Rocke ...

used Inconel X-750 for the thrust chamber of the F-1 rocket engine used in the first stage of the Saturn V

Saturn V is a retired American super heavy-lift launch vehicle developed by NASA under the Apollo program for human exploration of the Moon. The rocket was human-rated, with three stages, and powered with liquid fuel. It was flown from 1 ...

booster.

*SpaceX

Space Exploration Technologies Corp. (SpaceX) is an American spacecraft manufacturer, launcher, and a satellite communications corporation headquartered in Hawthorne, California. It was founded in 2002 by Elon Musk with the stated goal of ...

uses inconel (Inconel 718) in the engine manifold of their Merlin

Merlin ( cy, Myrddin, kw, Marzhin, br, Merzhin) is a mythical figure prominently featured in the legend of King Arthur and best known as a mage, with several other main roles. His usual depiction, based on an amalgamation of historic and le ...

engine which powers the Falcon 9

Falcon 9 is a partially reusable medium lift launch vehicle that can carry cargo and crew into Earth orbit, produced by American aerospace company SpaceX.

The rocket has two stages. The first (booster) stage carries the second stage and pa ...

launch vehicle

A launch vehicle or carrier rocket is a rocket designed to carry a payload (spacecraft or satellites) from the Earth's surface to outer space. Most launch vehicles operate from a launch pads, supported by a launch control center and syste ...

.>

*In a first for 3D printing

3D printing or additive manufacturing is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer ...

, the SpaceX SuperDraco

SuperDraco is a hypergolic propellant rocket engine designed and built by SpaceX. It is part of the SpaceX Draco family of rocket engines. A redundant array of eight SuperDraco engines provides fault-tolerant propulsion for use as a launch escap ...

rocket engine

A rocket engine uses stored rocket propellants as the reaction mass for forming a high-speed propulsive Jet (fluid), jet of fluid, usually high-temperature gas. Rocket engines are reaction engines, producing thrust by ejecting mass rearward, i ...

that provides launch escape system

A launch escape system (LES) or launch abort system (LAS) is a crew-safety system connected to a space capsule that can be used to quickly separate the capsule from its launch vehicle in case of an emergency requiring the abort of the launch, suc ...

for the Dragon V2

Dragon 2 is a class of partially reusable spacecraft developed and manufactured by American aerospace manufacturer SpaceX, primarily for flights to the International Space Station (ISS). SpaceX has also launched private missions such as Insp ...

crew-carrying space capsule

A space capsule is an often-crewed spacecraft that uses a blunt-body reentry capsule to reenter the Earth's atmosphere without wings. Capsules are distinguished from other satellites primarily by the ability to survive reentry and return a paylo ...

is fully printed. In particular, the engine combustion chamber is printed of Inconel using a process of direct metal laser sintering

Selective laser sintering (SLS) is an additive manufacturing (AM) technique that uses a laser as the power and heat source to sinter powdered material (typically nylon or polyamide), aiming the laser automatically at points in space defined by ...

, and operates at very high temperature and a chamber pressure

Within firearms, chamber pressure is the pressure exerted by a cartridge case's outside walls on the inside of a firearm's chamber when the cartridge is fired. The SI unit for chamber pressure is the megapascal (MPa), while the American SAAMI uses ...

of .

* SpaceX cast the Raptor rocket engine manifolds from SX300, later SX500, which are monocrystal nickel alloy (improvement over older Inconel alloys).''SpaceX Casting Raptor Engine Parts from Supersteel Alloys'' Feb 2019/ref>

Automotive

* Tesla is now claiming to use Inconel in place of steel in the main battery pack contactor of its Model S so that it remains springy under the heat of heavy current. Tesla claims that this allows these upgraded vehicles to safely increase the maximum pack output from 1300 to 1500ampere

The ampere (, ; symbol: A), often Clipping (morphology), shortened to amp,SI supports only the use of symbols and deprecates the use of abbreviations for units. is the unit of electric current in the International System of Units (SI). One amp ...

s, allowing for an increase in power output (acceleration) Tesla refers to as "Ludicrous Mode

The Tesla Model S is a battery-powered liftback car serving as the flagship model of Tesla, Inc. The Model S features a dual-motor, all-wheel drive layout, although earlier versions of the Model S featured a rear-motor and rear-wheel drive la ...

".

*Ford Motor Company

Ford Motor Company (commonly known as Ford) is an American multinational automobile manufacturer headquartered in Dearborn, Michigan, United States. It was founded by Henry Ford and incorporated on June 16, 1903. The company sells automobiles ...

is using Inconel to make the turbine wheel in the turbocharger of its EcoBlue

EcoBlue is the marketing name for a range of Diesel engines from Ford Motor Company. The EcoBlue engines were developed under the codename "Panther" by Ford engineering teams in the U.K. and Germany, and are expected to succeed the Duratorq diesel ...

diesel engines introduced in 2016.

*The exhaust valves on NHRA Top Fuel and Funny Car drag racing engines are often made of Inconel. Inconel is also used in the manufacture of exhaust valves in high performance aftermarket turbo and Supercharged Mazda Miata engine builds (see Flyin' Miata).

*Ford Australia

Ford Motor Company of Australia Limited (known by its trading name Ford Australia) is the Australian subsidiary of United States-based automaker Ford Motor Company. It was founded in Geelong, Victoria, in 1925 as an outpost of Ford Motor Comp ...

used Inconel valves in their turbocharged Barra

Barra (; gd, Barraigh or ; sco, Barra) is an island in the Outer Hebrides, Scotland, and the second southernmost inhabited island there, after the adjacent island of Vatersay to which it is connected by a short causeway. The island is nam ...

engines. These valves have been proven very reliable, holding in excess of 1900 horsepower.

* BMW has since used Inconel in the exhaust manifold of its high performance luxury car, the BMW M5 E34 with the S38 engine, withstanding higher temperatures and reducing backpressure.

* Jaguar Cars has fit, in their Jaguar F-Type

The Jaguar F-Type (X152) is a series of two-door, two-seater grand tourers manufactured by British car manufacturer Jaguar Land Rover under their Jaguar Cars marque since 2013. The car's JLR D6a platform is based on a shortened version of the ...

SVR high performance sports car, a new lightweight Inconel titanium exhaust system as standard which withstands higher peak temperatures, reduces backpressure and eliminates of mass from the vehicle.

*DeLorean Motor Company

The DeLorean Motor Company (DMC) was an American automobile manufacturer formed by automobile industry executive John DeLorean in 1975. It is remembered for the one model it produced—the stainless steel DeLorean sports car featuring gul ...

offers Inconel replacements for failure prone OE trailing arm bolts on the DMC-12. Failure of these bolts can result in loss of the vehicle.

Rolled Inconel was frequently used as the recording medium by engraving in black box

In science, computing, and engineering, a black box is a system which can be viewed in terms of its inputs and outputs (or transfer characteristics), without any knowledge of its internal workings. Its implementation is "opaque" (black). The te ...

recorders on aircraft.

Alternatives to the use of Inconel in chemical applications such as scrubbers, columns, reactors, and pipes are Hastelloy

Haynes International, Inc., headquartered in Kokomo, Indiana, is one of the largest producers of corrosion-resistant and high-temperature alloys. In addition to Kokomo, Haynes has manufacturing facilities in Arcadia, Louisiana, and Mountain Hom ...

, perfluoroalkoxy

Perfluoroalkoxy alkanes (PFA) are fluoropolymers. They are copolymers of tetrafluoroethylene (C2F4) and perfluoroethers (C2F3ORf, where Rf is a perfluorinated group such as trifluoromethyl (CF3)). The properties of these polymers are similar ...

(PFA) lined carbon steel or fiber reinforced plastic.

Inconel alloys

Alloy

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductilit ...

s of inconel include:

* Inconel 188: Readily fabricated for commercial gas turbine and aerospace applications.

* Inconel 230: Alloy 230 Plate & Sheet mainly used by the power, aerospace, chemical processing and industrial heating industries.

* Inconel 600: Solid solution strengthened

* Inconel 601:

* Inconel 617: Solid solution strengthened (nickel-chromium-cobalt-molybdenum), high-temperature strength, corrosion and oxidation resistant, high workability and weldability. Incorporated in ASME Boiler and Pressure Vessel Code

The American Society of Mechanical Engineers (ASME) is an American professional association that, in its own words, "promotes the art, science, and practice of multidisciplinary engineering and allied sciences around the globe" via "continuing ...

for high temperature nuclear applications such as molten salt reactor

A molten salt reactor (MSR) is a class of nuclear fission reactor in which the primary nuclear reactor coolant and/or the fuel is a molten salt mixture. Only two MSRs have ever operated, both research reactors in the United States. The 1950's ...

s April, 2020.

* Inconel 625: Acid resistant, good weldability. The LCF version is typically used in bellows.

* Inconel 690: Low cobalt content for nuclear applications, and low resistivity

* Inconel 713C: Precipitation hardenable nickel-chromium base cast alloy

* Inconel 718: Gamma double prime strengthened with good weldability

* Inconel X-750: Commonly used for gas turbine components, including blades, seals and rotors.

* Inconel 751: Increased aluminium content for improved rupture strength in the 1600 °F range

* Inconel 792: Increased aluminium content for improved high temperature corrosion resistant properties, used especially in gas turbines

* Inconel 907

* Inconel 909

* Inconel 706

* Inconel 939: Gamma prime strengthened to increase weldability.

* Inconel 925: Inconel 925 is a nonstabilized austenitic stainless steel with low carbon content.IJSRD

titanium

Titanium is a chemical element with the Symbol (chemistry), symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resista ...

combine with nickel to form the intermetallic compound or gamma prime (γ′). Gamma prime forms small cubic crystals that inhibit slip and creep effectively at elevated temperatures.

See also

*Hastelloy

Haynes International, Inc., headquartered in Kokomo, Indiana, is one of the largest producers of corrosion-resistant and high-temperature alloys. In addition to Kokomo, Haynes has manufacturing facilities in Arcadia, Louisiana, and Mountain Hom ...

* Incoloy

Incoloy refers to a range of superalloys now produced by the Special Metals Corporation (SMC) group of companies and created with a trademark by the Inco company in 1952. Originally Inco protected these alloys by patent. In 2000, the SMC publishe ...

* Monel

Monel is a group of alloys of nickel (from 52 to 67%) and copper, with small amounts of iron, manganese, carbon, and silicon. Monel is not a cupronickel alloy because it has less than 60% copper.

Stronger than pure nickel, Monel alloys are res ...

* Nimonic Nimonic is a registered trademark of Special Metals Corporation that refers to a family of nickel-based high-temperature low creep superalloys. Nimonic alloys typically consist of more than 50% nickel and 20% chromium with additives such as titan ...

* Stellite

Stellite is a range of cobalt-chromium alloys designed for wear resistance. The alloys may also contain tungsten or molybdenum and a small, but important, amount of carbon.

History

Stellite is a trademarked name of Kennametal Inc. Prior to tha ...

References

{{reflist, 35em Metals Nickel–chromium alloys Refractory metals Superalloys Aerospace materials Nickel alloys Chromium alloys