Hydraulic Turbines on:

[Wikipedia]

[Google]

[Amazon]

A water turbine is a rotary machine that converts kinetic energy and

A water turbine is a rotary machine that converts kinetic energy and

Water wheels have been used for hundreds of years for industrial power. Their main shortcoming is size, which limits the flow rate and

Water wheels have been used for hundreds of years for industrial power. Their main shortcoming is size, which limits the flow rate and

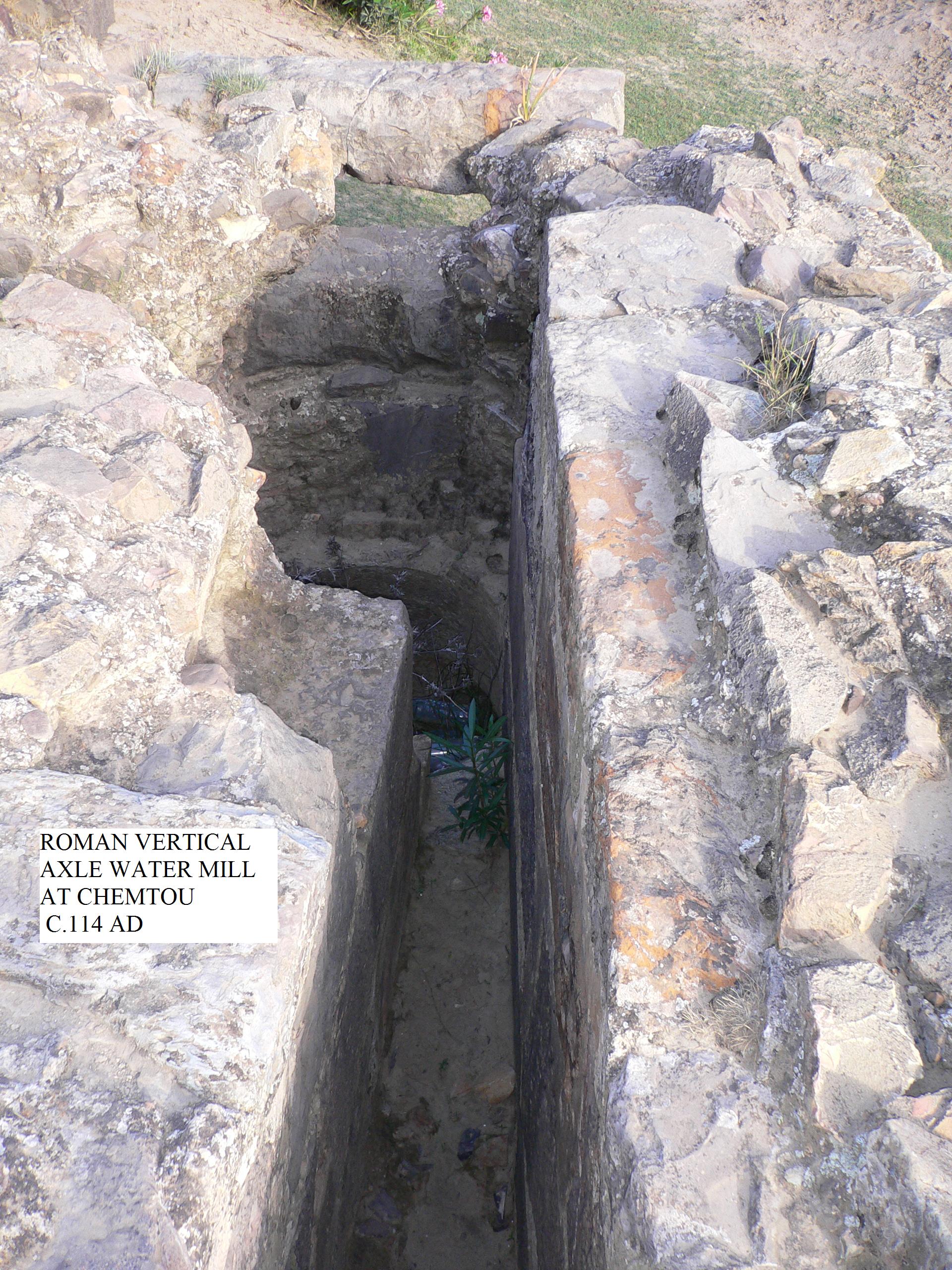

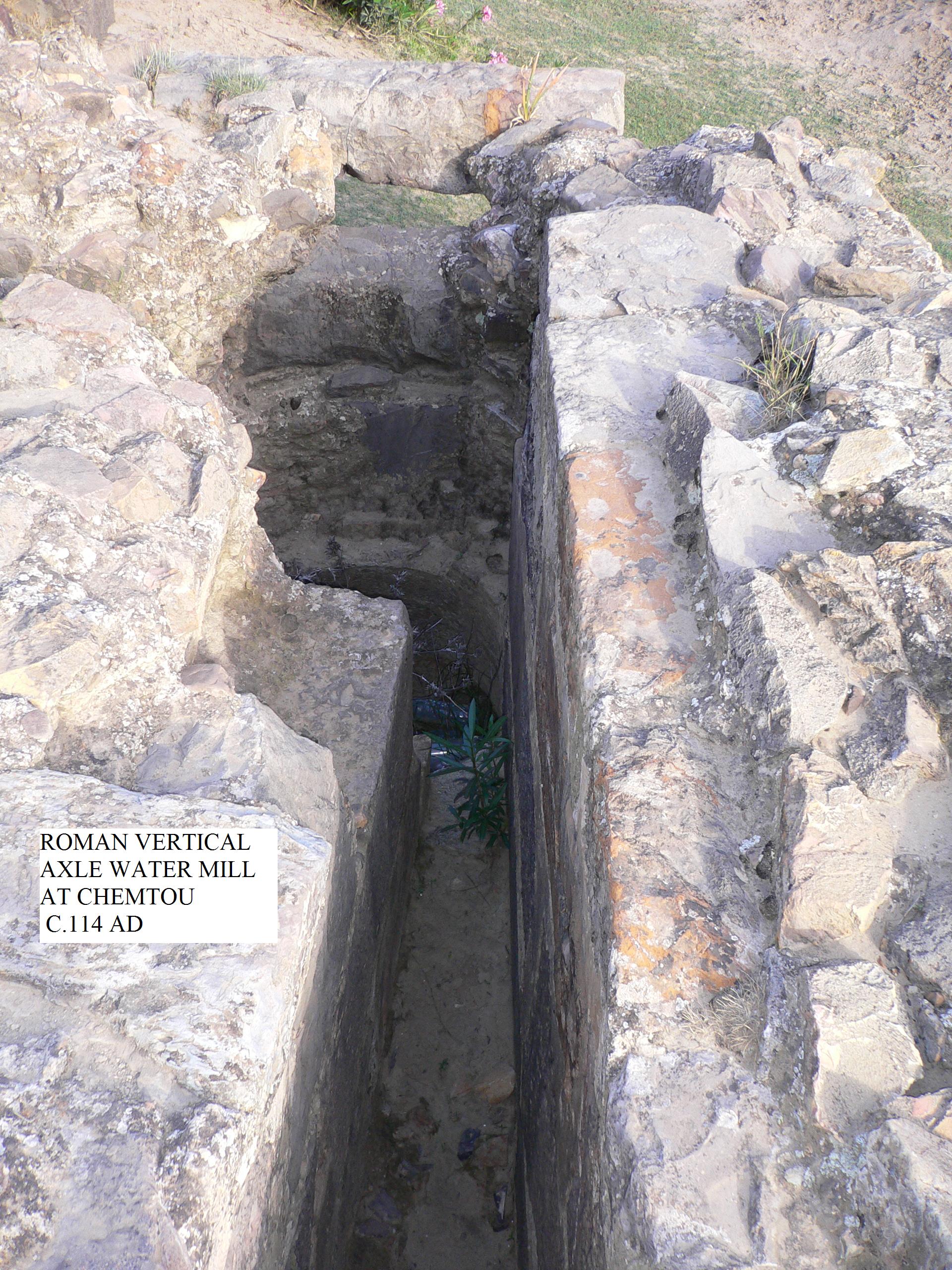

The earliest known water turbines date to the Roman Empire. Two helix-turbine mill sites of almost identical design were found at Chemtou and

The earliest known water turbines date to the Roman Empire. Two helix-turbine mill sites of almost identical design were found at Chemtou and

All common water machines until the late 19th century (including water wheels) were basically reaction machines; water ''pressure'' head acted on the machine and produced work. A reaction turbine needs to fully contain the water during energy transfer.

In 1866, California millwright Samuel Knight invented a machine that took the impulse system to a new level. Inspired by the high pressure jet systems used in hydraulic mining in the gold fields, Knight developed a bucketed wheel which captured the energy of a free jet, which had converted a high head (hundreds of vertical feet in a pipe or penstock) of water to kinetic energy. This is called an impulse or tangential turbine. The water's velocity, roughly twice the velocity of the bucket periphery, does a U-turn in the bucket and drops out of the runner at low velocity.

In 1879,

All common water machines until the late 19th century (including water wheels) were basically reaction machines; water ''pressure'' head acted on the machine and produced work. A reaction turbine needs to fully contain the water during energy transfer.

In 1866, California millwright Samuel Knight invented a machine that took the impulse system to a new level. Inspired by the high pressure jet systems used in hydraulic mining in the gold fields, Knight developed a bucketed wheel which captured the energy of a free jet, which had converted a high head (hundreds of vertical feet in a pipe or penstock) of water to kinetic energy. This is called an impulse or tangential turbine. The water's velocity, roughly twice the velocity of the bucket periphery, does a U-turn in the bucket and drops out of the runner at low velocity.

In 1879,

Turbine selection is based on the available water head, and less so on the available flow rate. In general, impulse turbines are used for high head sites, and reaction turbines are used for

Turbine selection is based on the available water head, and less so on the available flow rate. In general, impulse turbines are used for high head sites, and reaction turbines are used for

A wicket gate, or guide vane, is a component of water turbines to control the flow of water that enters the turbine. A series of small openings of the wicket gates surround the turbine. When the wicket gates are opened wider, more water will flow into the turbine runner which results in higher power output. The control of wicket gate opening and closing will allow the output energy generated by the turbines to be controlled to match the desired output energy levels.

A wicket gate, or guide vane, is a component of water turbines to control the flow of water that enters the turbine. A series of small openings of the wicket gates surround the turbine. When the wicket gates are opened wider, more water will flow into the turbine runner which results in higher power output. The control of wicket gate opening and closing will allow the output energy generated by the turbines to be controlled to match the desired output energy levels.

Turbines are designed to run for decades with very little maintenance of the main elements; overhaul intervals are on the order of several years. Maintenance of the runners and parts exposed to water include removal, inspection, and repair of worn parts.

Normal wear and tear includes pitting corrosion from

Turbines are designed to run for decades with very little maintenance of the main elements; overhaul intervals are on the order of several years. Maintenance of the runners and parts exposed to water include removal, inspection, and repair of worn parts.

Normal wear and tear includes pitting corrosion from

''Turbine Repair (Facilities Instructions, Standards & Techniques, Volume 2-5)''

(1.5 MB pdf).

Introductory turbine math

European Union publication, Layman's hydropower handbook,12 MB pdf

"Selecting Hydraulic Reaction Turbines", US Bureau of Reclamation publication, 48 MB pdf

"Laboratory for hydraulic machines", Lausanne (Switzerland)

{{Authority control Articles containing video clips

A water turbine is a rotary machine that converts kinetic energy and

A water turbine is a rotary machine that converts kinetic energy and potential energy

In physics, potential energy is the energy held by an object because of its position relative to other objects, stresses within itself, its electric charge, or other factors.

Common types of potential energy include the gravitational potentia ...

of water into mechanical work.

Water turbines were developed in the 19th century and were widely used for industrial power prior to electrical grid

An electrical grid is an interconnected network for electricity delivery from producers to consumers. Electrical grids vary in size and can cover whole countries or continents. It consists of:Kaplan, S. M. (2009). Smart Grid. Electrical Power ...

s. Now, they are mostly used for electric power generation.

Water turbines are mostly found in dams to generate electric power from water potential energy.

History

Water wheels have been used for hundreds of years for industrial power. Their main shortcoming is size, which limits the flow rate and

Water wheels have been used for hundreds of years for industrial power. Their main shortcoming is size, which limits the flow rate and head

A head is the part of an organism which usually includes the ears, brain, forehead, cheeks, chin, eyes, nose, and mouth, each of which aid in various sensory functions such as sight, hearing, smell, and taste. Some very simple animals may ...

that can be harnessed.

The migration from water wheels to modern turbines took about one hundred years. Development occurred during the Industrial revolution, using scientific principles and methods. They also made extensive use of new materials and manufacturing methods developed at the time.

Swirl

The word turbine was introduced by the French engineer Claude Burdin in the early 19th century and is derived from the Greek word "τύρβη" for "whirling" or a "vortex". The main difference between early water turbines and water wheels is a swirl component of the water which passes energy to a spinning rotor. This additional component of motion allowed the turbine to be smaller than a water wheel of the same power. They could process more water by spinning faster and could harness much greater heads. (Later, impulse turbines were developed which didn't use swirl.)Timeline

The earliest known water turbines date to the Roman Empire. Two helix-turbine mill sites of almost identical design were found at Chemtou and

The earliest known water turbines date to the Roman Empire. Two helix-turbine mill sites of almost identical design were found at Chemtou and Testour

Testour ( ar, تستور ') is a small town located in the north of Tunisia. The town is perched on the hills of Medjerda Valley, south-west of Medjez-el-Bab, the crossroads between Tunis, Béja, and the north of Tunisia. It was known during th ...

, modern-day Tunisia, dating to the late 3rd or early 4th century AD. The horizontal water wheel with angled blades was installed at the bottom of a water-filled, circular shaft. The water from the mill-race entered the pit tangentially, creating a swirling water column which made the fully submerged wheel act like a true turbine.; ;

Fausto Veranzio in his book ''Machinae Novae'' (1595) described a vertical axis mill with a rotor similar to that of a Francis turbine

The Francis turbine is a type of water turbine. It is an inward-flow reaction turbine that combines radial and axial flow concepts. Francis turbines are the most common water turbine in use today, and can achieve over 95% efficiency.

The proces ...

.

Johann Segner developed a reactive water turbine (Segner wheel

The Segner wheel or Segner turbine is a type of water turbine invented by Johann Andreas Segner in the 18th century. It uses the same principle as Hero's aeolipile.

The device is placed in a suitable hole in the ground (or at the slope of a hill ...

) in the mid-18th century in Kingdom of Hungary. It had a horizontal axis and was a precursor to modern water turbines. It is a very simple machine that is still produced today for use in small hydro sites. Segner worked with Euler

Leonhard Euler ( , ; 15 April 170718 September 1783) was a Swiss mathematician, physicist, astronomer, geographer, logician and engineer who founded the studies of graph theory and topology and made pioneering and influential discoveries in ma ...

on some of the early mathematical theories of turbine design. In the 18th century, a Dr. Robert Barker invented a similar reaction hydraulic turbine that became popular as a lecture-hall demonstration. The only known surviving example of this type of engine used in power production, dating from 1851, is found at Hacienda Buena Vista in Ponce, Puerto Rico.R. Sackett, p. 16.

In 1820, Jean-Victor Poncelet developed an inward-flow turbine.

In 1826, Benoît Fourneyron developed an outward-flow turbine. This was an efficient machine (~80%) that sent water through a runner with blades curved in one dimension. The stationary outlet also had curved guides.

In 1844, Uriah A. Boyden

Uriah Atherton Boyden (February 17, 1804 – October 17, 1879) was an American civil and mechanical engineer and inventor from Foxborough, Massachusetts best known for the development of a water turbine, that later became known as the Boyden ...

developed an outward flow turbine that improved on the performance of the Fourneyron turbine. Its runner shape was similar to that of a Francis turbine

The Francis turbine is a type of water turbine. It is an inward-flow reaction turbine that combines radial and axial flow concepts. Francis turbines are the most common water turbine in use today, and can achieve over 95% efficiency.

The proces ...

.

In 1849, James B. Francis

James Bicheno Francis (May 18, 1815 – September 18, 1892) was a British-American civil engineer, who invented the Francis turbine.

Early years

James Francis was born in South Leigh, near Witney, Oxfordshire, in England, United Kingdom. ...

improved the inward flow reaction turbine to over 90% efficiency. He also conducted sophisticated tests and developed engineering methods for water turbine design. The Francis turbine

The Francis turbine is a type of water turbine. It is an inward-flow reaction turbine that combines radial and axial flow concepts. Francis turbines are the most common water turbine in use today, and can achieve over 95% efficiency.

The proces ...

, named for him, is the first modern water turbine. It is still the most widely used water turbine in the world today. The Francis turbine is also called a radial flow turbine, since water flows from the outer circumference towards the centre of runner.

Inward flow water turbines have a better mechanical arrangement and all modern reaction water turbines are of this design. As the water swirls inward, it accelerates, and transfers energy to the runner. Water pressure decreases to atmospheric, or in some cases subatmospheric, as the water passes through the turbine blades and loses energy.

In 1876, John B. McCormick

John Buchanan McCormick (November 4, 1834 – August 21, 1924) was an American mechanical engineer who invented the first modern mixed flow water turbine, the "Hercules", as well variants including the Holyoke-McCormick, and Achilles turbines. Mc ...

, building on Francis's designs, demonstrated the first modern mixed-flow turbine with the development of the Hercules turbine, initially manufactured by the Holyoke Machine Company and subsequently improved upon by engineers in Germany and the United States. The design effectively combined the inward flow principles of the Francis design with the downward discharge of the Jonval turbine, with flow inward at the inlet, axial through the wheel's body, and slightly outward at the outlet. Initially performing optimally at 90% efficiency at lower speeds, this design would see many improvements in the subsequent decades in derivatives under names like "Victor", "Risdon", "Samson" and "New American," ushering in a new era of American turbine engineering.

Water turbines, particularly in the Americas, would largely become standardized with the establishment of the Holyoke Testing Flume

The Holyoke Testing Flume was a hydraulic testing laboratory and apparatus in Holyoke, Massachusetts, operated by the Holyoke Water Power Company from 1870 to 1932, and used to test the performance of water turbine designs, completing 3,176 tests ...

, described as the first modern hydraulic laboratory in the United States by Robert E. Horton

Robert Elmer Horton (May 18, 1875 – April 22, 1945) was an American hydrologist, geomorphologist, civil engineer, and soil scientist, considered by many to be the father of modern American hydrology. An eponymous medal is awarded by the Ameri ...

and Clemens Herschel, the latter of which would serve as its chief engineer for a time. Initially created in 1872 by James B. Emerson

James is a common English language surname and given name:

*James (name), the typically masculine first name James

* James (surname), various people with the last name James

James or James City may also refer to:

People

* King James (disambiguat ...

from the testing flumes of Lowell, after 1880 the Holyoke, Massachusetts

Holyoke is a city in Hampden County, Massachusetts, United States, that lies between the western bank of the Connecticut River and the Mount Tom Range. As of the 2020 census, the city had a population of 38,238. Located north of Springfield ...

hydraulic laboratory was standardized by Herschel, who used it to develop the Venturi meter, the first accurate means of measuring large flows, to properly measure water power efficiency by different turbine models. While skepticism of certain weir calculations were held by European hydrologists, the facility allowed for standard efficiency testing among major manufacturers through 1932, by which time more modern facilities and methods had proliferated.

Around 1890, the modern fluid bearing was invented, now universally used to support heavy water turbine spindles. As of 2002, fluid bearings appear to have a mean time between failures of more than 1300 years.

Around 1913, Viktor Kaplan created the Kaplan turbine, a propeller-type machine. It was an evolution of the Francis turbine and revolutionized the ability to develop low-head hydro sites.

New concept

All common water machines until the late 19th century (including water wheels) were basically reaction machines; water ''pressure'' head acted on the machine and produced work. A reaction turbine needs to fully contain the water during energy transfer.

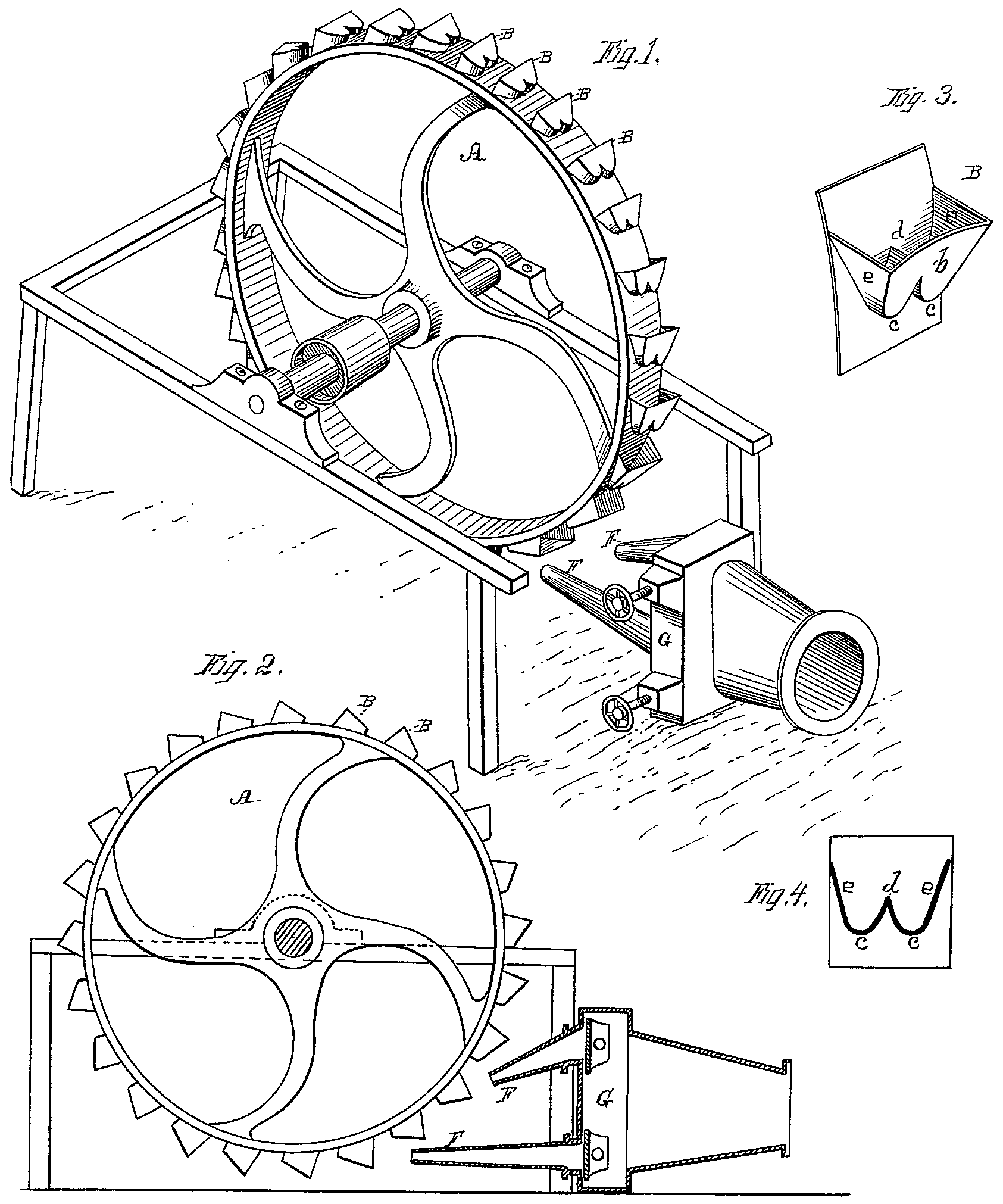

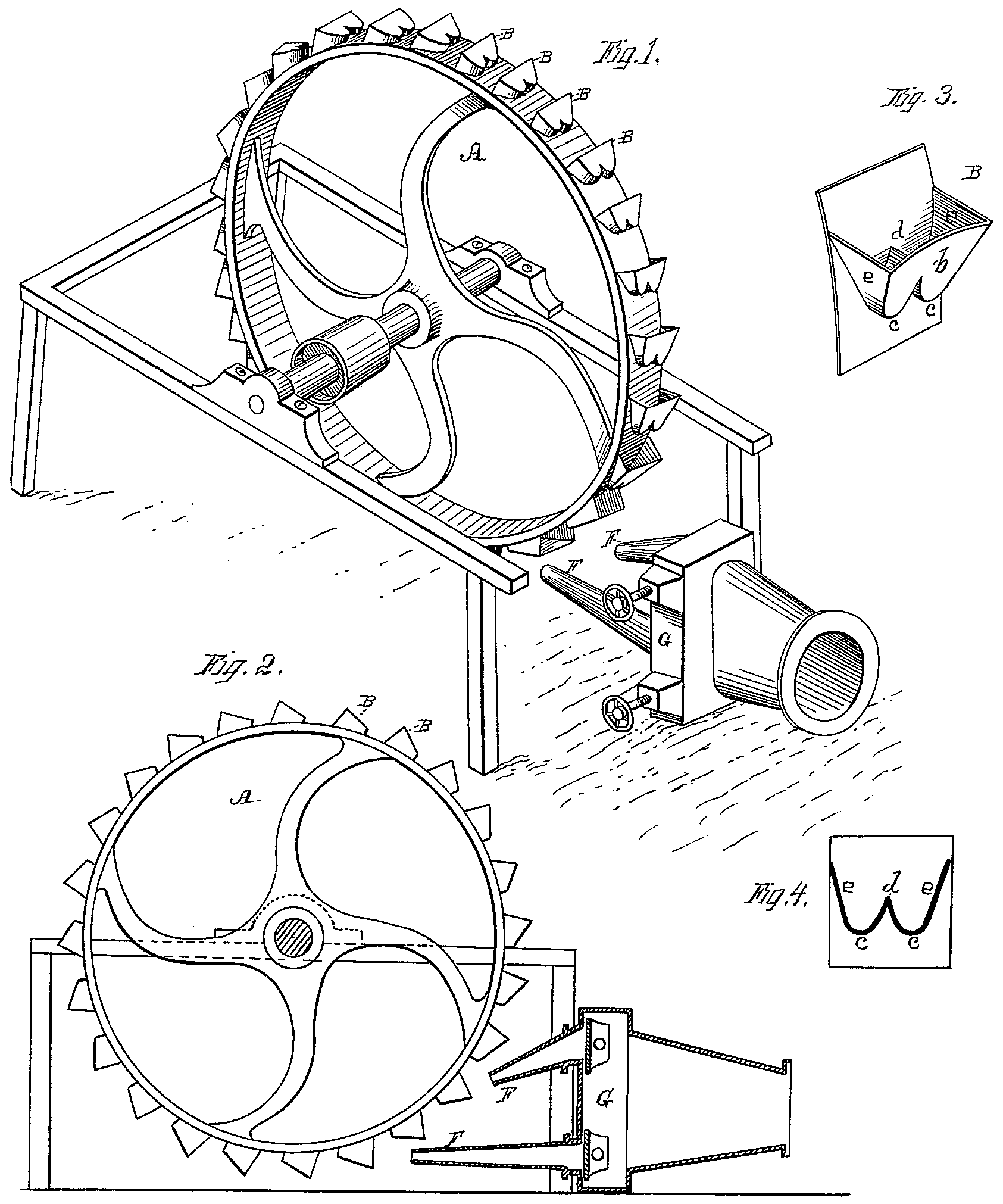

In 1866, California millwright Samuel Knight invented a machine that took the impulse system to a new level. Inspired by the high pressure jet systems used in hydraulic mining in the gold fields, Knight developed a bucketed wheel which captured the energy of a free jet, which had converted a high head (hundreds of vertical feet in a pipe or penstock) of water to kinetic energy. This is called an impulse or tangential turbine. The water's velocity, roughly twice the velocity of the bucket periphery, does a U-turn in the bucket and drops out of the runner at low velocity.

In 1879,

All common water machines until the late 19th century (including water wheels) were basically reaction machines; water ''pressure'' head acted on the machine and produced work. A reaction turbine needs to fully contain the water during energy transfer.

In 1866, California millwright Samuel Knight invented a machine that took the impulse system to a new level. Inspired by the high pressure jet systems used in hydraulic mining in the gold fields, Knight developed a bucketed wheel which captured the energy of a free jet, which had converted a high head (hundreds of vertical feet in a pipe or penstock) of water to kinetic energy. This is called an impulse or tangential turbine. The water's velocity, roughly twice the velocity of the bucket periphery, does a U-turn in the bucket and drops out of the runner at low velocity.

In 1879, Lester Pelton

Lester Allan Pelton (September 5, 1829 – March 14, 1908) was an American inventor who contributed significantly to the development of hydroelectricity and hydropower in the American Old West as well as world-wide. In the late 1870s, he invent ...

, experimenting with a Knight Wheel, developed a Pelton wheel (double bucket design), which exhausted the water to the side, eliminating some energy loss of the Knight wheel which exhausted some water back against the center of the wheel. In about 1895, William Doble improved on Pelton's half-cylindrical bucket form with an elliptical bucket that included a cut in it to allow the jet a cleaner bucket entry. This is the modern form of the Pelton turbine which today achieves up to 92% efficiency. Pelton had been quite an effective promoter of his design and although Doble took over the Pelton company he did not change the name to Doble because it had brand name recognition.

Turgo and cross-flow turbines were later impulse designs.

Theory of operation

Flowing water is directed on to the blades of a turbine runner, creating a force on the blades. Since the runner is spinning, the force acts through a distance (force acting through a distance is the definition of work). In this way, energy is transferred from the water flow to the turbine. Water turbines are divided into two groups: reaction turbines and impulse turbines. The precise shape of water turbine blades is a function of the supply pressure of water, and the type of impeller selected.Reaction turbines

Reaction turbines are acted on by water, which changes pressure as it moves through the turbine and gives up its energy. They must be encased to contain the water pressure (or suction), or they must be fully submerged in the water flow. Newton's third law describes the transfer of energy for reaction turbines. Most water turbines in use are reaction turbines and are used in low (<) and medium () head applications. In reaction turbine pressure drop occurs in both fixed and moving blades. It is largely used in dam and large power plantsImpulse turbines

Impulse turbines change the velocity of a water jet. The jet pushes on the turbine's curved blades which changes the direction of the flow. The resulting change in momentum ( impulse) causes a force on the turbine blades. Since the turbine is spinning, the force acts through a distance (work) and the diverted water flow is left with diminished energy. An impulse turbine is one in which the pressure of the fluid flowing over the rotor blades is constant and all the work output is due to the change in kinetic energy of the fluid. Prior to hitting the turbine blades, the water's pressure (potential energy

In physics, potential energy is the energy held by an object because of its position relative to other objects, stresses within itself, its electric charge, or other factors.

Common types of potential energy include the gravitational potentia ...

) is converted to kinetic energy by a nozzle

A nozzle is a device designed to control the direction or characteristics of a fluid flow (specially to increase velocity) as it exits (or enters) an enclosed chamber or pipe.

A nozzle is often a pipe or tube of varying cross sectional area, a ...

and focused on the turbine. No pressure change occurs at the turbine blades, and the turbine doesn't require a housing for operation.

Newton's second law describes the transfer of energy for impulse turbines.

Impulse turbines are often used in very high (>300m/1000 ft) head applications.

Power

The power available in a stream is; where: * power (J/s or watts) * turbine efficiency * density of fluid (kg/m3) * acceleration of gravity (9.81 m/s2) * head (m). For still water, this is the difference in height between the inlet and outlet surfaces. Moving water has an additional component added to account for the kinetic energy of the flow. The total head equals the ''pressure head'' plus ''velocity head''. *= flow rate (m3/s)Pumped-storage hydroelectricity

Some water turbines are designed for pumped-storage hydroelectricity. They can reverse flow and operate as apump

A pump is a device that moves fluids (liquids or gases), or sometimes slurries, by mechanical action, typically converted from electrical energy into hydraulic energy. Pumps can be classified into three major groups according to the method they u ...

to fill a high reservoir during off-peak electrical hours, and then revert to a water turbine for power generation during peak electrical demand. This type of turbine is usually a Deriaz or Francis turbine

The Francis turbine is a type of water turbine. It is an inward-flow reaction turbine that combines radial and axial flow concepts. Francis turbines are the most common water turbine in use today, and can achieve over 95% efficiency.

The proces ...

in design.

This type of system is used in El Hierro, one of the Canary Islands: "When wind production exceeds demand, excess energy will pump water from a lower reservoir at the bottom of a volcanic cone to an upper reservoir at the top of the volcano 700 meters above sea level. The lower reservoir stores 150,000 cubic meters of water. The stored water acts as a battery. The maximum storage capacity is 270 MWh. When demand rises and there is not enough wind power, the water will be released to four hydroelectric turbines with a total capacity of 11 MW."

Efficiency

Large modern water turbines operate at mechanical efficiencies greater than 90%.Types of water turbines

Reaction turbines

* VLH turbine *Francis turbine

The Francis turbine is a type of water turbine. It is an inward-flow reaction turbine that combines radial and axial flow concepts. Francis turbines are the most common water turbine in use today, and can achieve over 95% efficiency.

The proces ...

* Kaplan turbine

* Tyson turbine

*Deriaz turbine

The Deriaz turbine, presented by engineer Paul Deriaz, was the first diagonal hydraulic pump-turbine to be designed. In contrast to most hydraulic machines, the flow in a Deriaz turbine does not follow a full axial nor radial direction but is a di ...

* Gorlov helical turbine

Impulse turbine

* Water wheel * Pelton wheel * Turgo turbine * Cross-flow turbine (also known as the Bánki-Michell turbine, or Ossberger turbine) * Jonval turbine * Reverse overshot water-wheel * Screw turbine * Barkh TurbineDesign and application

Turbine selection is based on the available water head, and less so on the available flow rate. In general, impulse turbines are used for high head sites, and reaction turbines are used for

Turbine selection is based on the available water head, and less so on the available flow rate. In general, impulse turbines are used for high head sites, and reaction turbines are used for low head

Low Head is a rural residential locality in the local government area (LGA) of George Town Council, George Town in the Launceston LGA Region, Launceston LGA region of Tasmania. The locality is about north of the town of George Town, Tasmania, G ...

sites. Kaplan turbines with adjustable blade pitch are well-adapted to wide ranges of flow or head conditions, since their peak efficiency can be achieved over a wide range of flow conditions.

Small turbines (mostly under 10 MW) may have horizontal shafts, and even fairly large bulb-type turbines up to 100 MW or so may be horizontal. Very large Francis and Kaplan machines usually have vertical shafts because this makes best use of the available head, and makes installation of a generator more economical. Pelton wheels may be either vertical or horizontal shaft machines because the size of the machine is so much less than the available head. Some impulse turbines use multiple jets per runner to balance shaft thrust. This also allows for the use of a smaller turbine runner, which can decrease costs and mechanical losses.

Typical range of heads

• Water wheel

• Screw turbine

• VLH turbine

• Kaplan turbine

•

• Pelton wheel

• Turgo turbine

0.2 < ''H'' < 4 (''H'' = head in m)

1 < ''H'' < 10

1.5 < ''H'' < 4.5

2 < ''H'' < 70

10 < ''H'' < 300

80 < ''H'' < 1600

50 < ''H'' < 250

• Screw turbine

• VLH turbine

• Kaplan turbine

•

Francis turbine

The Francis turbine is a type of water turbine. It is an inward-flow reaction turbine that combines radial and axial flow concepts. Francis turbines are the most common water turbine in use today, and can achieve over 95% efficiency.

The proces ...

• Pelton wheel

• Turgo turbine

0.2 < ''H'' < 4 (''H'' = head in m)

1 < ''H'' < 10

1.5 < ''H'' < 4.5

2 < ''H'' < 70

10 < ''H'' < 300

80 < ''H'' < 1600

50 < ''H'' < 250

Specific speed

The specific speed of a turbine characterizes the turbine's shape in a way that is not related to its size. This allows a new turbine design to be scaled from an existing design of known performance. The specific speed is also the main criteria for matching a specific hydro site with the correct turbine type. The specific speed is the speed with which the turbine turns for a particular discharge Q, with unit head and thereby is able to produce unit power.Affinity laws

Affinity laws allow the output of a turbine to be predicted based on model tests. A miniature replica of a proposed design, about one foot (0.3 m) in diameter, can be tested and the laboratory measurements applied to the final application with high confidence. Affinity laws are derived by requiringsimilitude

Similitude is a concept applicable to the testing of engineering models. A model is said to have similitude with the real application if the two share geometric similarity, kinematic similarity and dynamic similarity. ''Similarity'' and ''simili ...

between the test model and the application.

Flow through the turbine is controlled either by a large valve or by wicket gates arranged around the outside of the turbine runner. Differential head and flow can be plotted for a number of different values of gate opening, producing a hill diagram used to show the efficiency of the turbine at varying conditions.

Runaway speed

The runaway speed of a water turbine is its speed at full flow, and no shaft load. The turbine will be designed to survive the mechanical forces of this speed. The manufacturer will supply the runaway speed rating.Control systems

Different designs of governors have been used since the mid-18th century to control the speeds of the water turbines. A variety of flyball systems, or first-generation governors, were used during the first 100 years of water turbine speed controls. In early flyball systems, the flyball component countered by a spring acted directly to the valve of the turbine or the wicket gate to control the amount of water that enters the turbines. Newer systems with mechanical governors started around 1880. An early mechanical governor is aservomechanism

In control engineering a servomechanism, usually shortened to servo, is an automatic device that uses error-sensing negative feedback to correct the action of a mechanism. On displacement-controlled applications, it usually includes a built-in ...

that comprises a series of gears that use the turbine's speed to drive the flyball and turbine's power to drive the control mechanism. The mechanical governors were continued to be enhanced in power amplification through the use of gears and the dynamic behavior. By 1930, the mechanical governors had many parameters that could be set on the feedback system for precise controls. In the later part of the twentieth century, electronic governors and digital systems started to replace the mechanical governors. In the electronic governors, also known as second-generation governors, the flyball was replaced by rotational speed sensor

A sensor is a device that produces an output signal for the purpose of sensing a physical phenomenon.

In the broadest definition, a sensor is a device, module, machine, or subsystem that detects events or changes in its environment and sends ...

but the controls were still done through analog

Analog or analogue may refer to:

Computing and electronics

* Analog signal, in which information is encoded in a continuous variable

** Analog device, an apparatus that operates on analog signals

*** Analog electronics, circuits which use analo ...

systems. In the modern systems, also known as third-generation governors, the controls are performed digitally by algorithms that are programmed to the computer of the governor.

Wicket gate

A wicket gate, or guide vane, is a component of water turbines to control the flow of water that enters the turbine. A series of small openings of the wicket gates surround the turbine. When the wicket gates are opened wider, more water will flow into the turbine runner which results in higher power output. The control of wicket gate opening and closing will allow the output energy generated by the turbines to be controlled to match the desired output energy levels.

A wicket gate, or guide vane, is a component of water turbines to control the flow of water that enters the turbine. A series of small openings of the wicket gates surround the turbine. When the wicket gates are opened wider, more water will flow into the turbine runner which results in higher power output. The control of wicket gate opening and closing will allow the output energy generated by the turbines to be controlled to match the desired output energy levels.

Turbine blade materials

Given that the turbine blades in a water turbine are constantly exposed to water and dynamic forces, they need to have high corrosion resistance and strength. The most common material used in overlays on carbon steel runners in water turbines are austenitic steel alloys that have 17% to 20% chromium to increase stability of the film which improves aqueous corrosion resistance. The chromium content in these steel alloys exceed the minimum of 12% chromium required to exhibit some atmospheric corrosion resistance. Having a higher chromium concentration in the steel alloys allows for a much longer lifespan of the turbine blades. Currently, the blades are made of martensitic stainless steels which have high strength compared to austenitic stainless steels by a factor of 2. Besides corrosion resistance and strength as the criteria for material selection, weld-ability and density of the turbine blade. Greater weld-ability allows for easier repair of the turbine blades. This also allows for higher weld quality which results in a better repair. Selecting a material with low density is important to achieve higher efficiency because the lighter blades rotate more easily. The most common material used in Kaplan Turbine blades are stainless steel alloys (SS). The martensitic stainless steel alloys have high strength, thinner sections than standard carbon steel, and reduced mass that enhances the hydrodynamic flow conditions and efficiency of the water turbine. The SS(13Cr-4Ni) has been shown to have improved erosion resistance at all angles of attack through the process of laser peening. It is important to minimize erosion in order to maintain high efficiencies because erosion negatively impacts the hydraulic profile of the blades which reduces the relative ease to rotate.Maintenance

cavitation

Cavitation is a phenomenon in which the static pressure of a liquid reduces to below the liquid's vapour pressure, leading to the formation of small vapor-filled cavities in the liquid. When subjected to higher pressure, these cavities, cal ...

, fatigue cracking

In materials science, fatigue is the initiation and propagation of cracks in a material due to cyclic loading. Once a fatigue crack has initiated, it grows a small amount with each loading cycle, typically producing striations on some parts of ...

, and abrasion from suspended solids in the water. Steel elements are repaired by welding, usually with stainless steel

Stainless steel is an alloy of iron that is resistant to rusting and corrosion. It contains at least 11% chromium and may contain elements such as carbon, other nonmetals and metals to obtain other desired properties. Stainless steel's corros ...

rods. Damaged areas are cut or ground out, then welded back up to their original or an improved profile. Old turbine runners may have a significant amount of stainless steel added this way by the end of their lifetime. Elaborate welding procedures may be used to achieve the highest quality repairs.

Other elements requiring inspection and repair during overhauls include bearings, packing box and shaft sleeves, servomotors, cooling systems for the bearings and generator coils, seal rings, wicket gate linkage elements and all surfaces.United States Department of the Interior Bureau of Reclamation; Duncan, William (revised April 1989)''Turbine Repair (Facilities Instructions, Standards & Techniques, Volume 2-5)''

(1.5 MB pdf).

Environmental impact

Water turbines are generally considered a clean power producer, as the turbine causes essentially no change to the water. They use a renewable energy source and are designed to operate for decades. They produce significant amounts of the world's electrical supply. Historically there have also been negative consequences, mostly associated with the dams normally required for power production. Dams alter the natural ecology of rivers, potentially killing fish, stopping migrations, and disrupting peoples' livelihoods. For example, Native American tribes in the Pacific Northwest had livelihoods built around salmon fishing, but aggressive dam-building destroyed their way of life. Dams also cause less obvious, but potentially serious consequences, including increased evaporation of water (especially in arid regions), buildup of silt behind the dam, and changes to water temperature and flow patterns. In the United States, it is now illegal to block the migration of fish, for example thewhite sturgeon

White sturgeon (''Acipenser transmontanus'') is a species of sturgeon in the family Acipenseridae of the order Acipenseriformes. They are an anadromous fish species ranging in the Eastern Pacific; from the Gulf of Alaska to Monterey, California ...

in North America

North America is a continent in the Northern Hemisphere and almost entirely within the Western Hemisphere. It is bordered to the north by the Arctic Ocean, to the east by the Atlantic Ocean, to the southeast by South America and the Car ...

, so fish ladders must be provided by dam builders.

See also

* Archimedes' screw * HydroelectricityReferences

Notes

*Robert Sackett, Preservationist, PRSHPO (Original 1990 draft). Arleen Pabon, Certifying Official and State Historic Preservation Officer, State Historic Preservation Office, San Juan, Puerto Rico. September 9, 1994. In National Register of Historic Places Registration Form—Hacienda Buena Vista. United States Department of the Interior. National Park Service. (Washington, D.C.)Sources

* * *External links

Introductory turbine math

European Union publication, Layman's hydropower handbook,12 MB pdf

"Selecting Hydraulic Reaction Turbines", US Bureau of Reclamation publication, 48 MB pdf

"Laboratory for hydraulic machines", Lausanne (Switzerland)

{{Authority control Articles containing video clips