History Of The Iron And Steel Industry In The United States on:

[Wikipedia]

[Google]

[Amazon]

The US iron and steel industry has paralleled the industry in other countries in technological developments. In the 1800s, the US switched from charcoal to

The US iron and steel industry has paralleled the industry in other countries in technological developments. In the 1800s, the US switched from charcoal to

As the only major steel maker not harmed during

As the only major steel maker not harmed during

/ref> Between 1970 and 1990, the region lost 30% of its population.

2014 Arcelormittal USA Factbook

.

Notable defunct 20th-century steel furnaces in the US

excerpt and text search

* Hogan, William T. ''Economic History of the Iron and Steel Industry in the United States '' (5 vol 1971) monumental detail * Ingham, John N. ''The Iron Barons: A Social Analysis of an American Urban Elite, 1874-1965'' (1978) * Krass, Peter. ''Carnegie'' (2002). . * Livesay, Harold C. ''Andrew Carnegie and the Rise of Big Business'', 2nd Edition (1999). . * Misa, Thomas J. ''A Nation of Steel: The Making of Modern America, 1865–1925'' (1995) Chapter 1

* Nasaw, David. ''Andrew Carnegie'' (The Penguin Press, 2006). * Paskoff, Paul F. ''Iron and Steel in the Nineteenth Century'' (Encyclopedia of American Business History and Biography) (1989) 385 pp; biographies and brief corporate histories * Rogers, Robert P. ''An Economic History of the American Steel Industry'' (2009)

excerpt and text search

* Scamehorn, H. Lee. ''Mill & Mine: The Cf&I in the Twentieth Century'' University of Nebraska Press, 1992 * Scheuerman, William. ''The Steel Crisis: The Economics and Politics of a Declining Industry'' (1986) * Seely, Bruce E., ed ''The Iron and Steel Industry in the 20th Century'' (1994) (Encyclopedia of American Business History and Biography) * Skrabec Jr, Quentin R. ''The Carnegie Boys: The Lieutenants of Andrew Carnegie that Changed America'' (McFarland, 2012). * Temin, Peter. ''Iron and Steel in Nineteenth-Century America, An Economic Inquiry'' (1964) * Wall, Joseph Frazier. ''Andrew Carnegie'' (1989). . * Warren, Kenneth, ''Big Steel: The First Century of the United States Steel Corporation, 1901–2001.'' (University of Pittsburgh Press, 2001

online review

* Warren, Kenneth. ''Bethlehem Steel: Builder and Arsenal of America'' (2010

excerpt and text search

* Warren, Kenneth. ''The American Steel Industry, 1850–1970: A Geographical Interpretation'' (1973) ({{ISBN, 0198232144) * Whaples, Robert. "Andrew Carnegie", ''EH.Net Encyclopedia of Economic and Business History'

online

* Urofsky, Melvin I. ''Big Steel and the Wilson Administration: A Study in Business-Government Relations'' (1969)

* Urofsky, Melvin I. ''Big Steel and the Wilson Administration: A Study in Business-Government Relations'' (1969) History History of the United States by topic

The US iron and steel industry has paralleled the industry in other countries in technological developments. In the 1800s, the US switched from charcoal to

The US iron and steel industry has paralleled the industry in other countries in technological developments. In the 1800s, the US switched from charcoal to coal

Coal is a combustible black or brownish-black sedimentary rock, formed as rock strata called coal seams. Coal is mostly carbon with variable amounts of other elements, chiefly hydrogen, sulfur, oxygen, and nitrogen.

Coal is formed when ...

in ore smelting, adopted the Bessemer process

The Bessemer process was the first inexpensive industrial process for the mass production of steel from molten pig iron before the development of the open hearth furnace. The key principle is removal of impurities from the iron by oxidation ...

, and saw the rise of very large integrated steel mills. In the 20th century, the US industry successively adopted the open hearth furnace

An open-hearth furnace or open hearth furnace is any of several kinds of industrial Industrial furnace, furnace in which excess carbon and other impurities are burnt out of pig iron to Steelmaking, produce steel. Because steel is difficult to ma ...

, then the basic oxygen steelmaking

Basic oxygen steelmaking (BOS, BOP, BOF, or OSM), also known as Linz-Donawitz steelmaking or the oxygen converter processBrock and Elzinga, p. 50. is a method of primary steelmaking in which carbon-rich molten pig iron is made into steel. Blowin ...

process. Since the American industry peaked in the 1940s and 1950s, the US industry has shifted to small mini-mills and specialty mills, using iron and steel scrap as feedstock, rather than iron ore.

Colonial

Iron manufacture before the 19th century required charcoal, and Britain's once-vast forests could no longer supply enough charcoal for the nation's increasing need for iron. By 1700, Britain was becoming increasingly dependent on iron imported from its sometimes-adversary Sweden. Britain looked to the seemingly limitless forests of its American colonies to supply Britain with iron. British investors started an iron furnace nearPerryville, Maryland

Perryville is a town in Cecil County, Maryland, United States. The population was 4,361 at the 2010 census. The town is located near an access for Interstate 95, on the north side of the outlet of the Susquehanna River.

History

Perryville was fir ...

, which in 1718 started exporting iron back to Britain. That success prompted formation of more companies, which built numerous iron furnaces around Chesapeake Bay

The Chesapeake Bay ( ) is the largest estuary in the United States. The Bay is located in the Mid-Atlantic region and is primarily separated from the Atlantic Ocean by the Delmarva Peninsula (including the parts: the Eastern Shore of Maryland / ...

, supplied by bog iron

Bog iron is a form of impure iron deposit that develops in bogs or swamps by the chemical or biochemical oxidation

Redox (reduction–oxidation, , ) is a type of chemical reaction in which the oxidation states of substrate change. O ...

ore, which was widespread. By 1751, Virginia

Virginia, officially the Commonwealth of Virginia, is a state in the Mid-Atlantic and Southeastern regions of the United States, between the Atlantic Coast and the Appalachian Mountains. The geography and climate of the Commonwealth ar ...

and Maryland

Maryland ( ) is a state in the Mid-Atlantic region of the United States. It shares borders with Virginia, West Virginia, and the District of Columbia to its south and west; Pennsylvania to its north; and Delaware and the Atlantic Ocean to ...

were exporting 2,950 tons of pig iron to Britain each year; at the time, British iron production was about 20,000 tons per year.

While the Chesapeake Bay furnaces were established for export, iron furnaces were established in the 1700s throughout the American colonies for domestic consumption. Iron furnaces were located along rivers to supply water power. Also required were forests for charcoal, iron ore, and limestone for flux. In addition, the furnace needed to be close to a major market or close to water transport.

British business interests were split on colonial iron: manufacturers appreciated the lower prices due to colonial imports, but the British iron and steel industry objected to the competition. Parliament

In modern politics, and history, a parliament is a legislative body of government. Generally, a modern parliament has three functions: representing the electorate, making laws, and overseeing the government via hearings and inquiries. Th ...

compromised in the Iron Act

The Iron Act, also called the Importation, etc. Act 1749 (23 Geo. II c. 29), was an Act of the Parliament of Great Britain, which was one of the legislative measures introduced within the system of Trade and Navigation Acts. The Act sought to ...

of 1750, which eliminated the import duty on colonial pig iron, but barred the manufacture of steel or of iron plate in the colonies. The law was widely ignored by colonial governments.

By 1776, up to 80 iron furnaces throughout the American colonies were producing about as much iron as Britain itself. If one estimate of 30,000 tons of iron each year is accurate, then the newly formed United States was the world's third-largest iron producer, after Sweden and Russia.

Notable pre-19th-century iron furnaces in the US

Early republic

Because wood for charcoal was available throughout the eastern states, iron smelters were located close to iron ore. Although the bog iron ores mined in colonial days were widespread, the deposits were also small, and quickly exhausted. In the late 1700s the iron furnaces moved away from the bog iron ore of the coastal swamps, to larger iron ore deposits further inland. Inland locations also allowed the furnaces to be closer to sources of limestone, which was used as a flux in iron smelting. The proximity to larger ore deposits favored larger, more permanent iron smelters. Most US iron smelting before 1850 took place near iron deposits in easternPennsylvania

Pennsylvania (; ( Pennsylvania Dutch: )), officially the Commonwealth of Pennsylvania, is a state spanning the Mid-Atlantic, Northeastern, Appalachian, and Great Lakes regions of the United States. It borders Delaware to its southeast, ...

, New York, and northern New Jersey

New Jersey is a state in the Mid-Atlantic and Northeastern regions of the United States. It is bordered on the north and east by the state of New York; on the east, southeast, and south by the Atlantic Ocean; on the west by the Delaware ...

. New Jersey's principal iron ore district, at Dover, supported iron smelters beginning in 1710. The Cornwall Iron Furnace

Cornwall Iron Furnace is a designated National Historic Landmark that is administered by the Pennsylvania Historical and Museum Commission in Cornwall, Lebanon County, Pennsylvania in the United States. The furnace was a leading Pennsylvania ir ...

in Pennsylvania was established next to an iron deposit. The Adirondack iron ore district of New York also supported iron smelters.

The movement away from charcoal in US iron smelting began in 1827, when a puddling furnace in Phoenixville, Pennsylvania

Phoenixville is a borough in Chester County, Pennsylvania, United States. It is located northwest of Philadelphia at the junction of French Creek and the Schuylkill River. It is in the Philadelphia metropolitan area. The population is 18,616 ...

started using anthracite coal. Blast furnaces continued to use only charcoal until about 1840, when coke from coal

Coal is a combustible black or brownish-black sedimentary rock, formed as rock strata called coal seams. Coal is mostly carbon with variable amounts of other elements, chiefly hydrogen, sulfur, oxygen, and nitrogen.

Coal is formed when ...

started replacing charcoal as the fuel and reducing agent. Coke has a higher crushing strength than charcoal, allowing larger smelting furnaces. Because iron and steel-making at the time consumed more coal than iron ore, the steel mills moved closer to the coal mines to minimize transportation costs. A problem of coke was that it carried impurities such as sulfur, which degraded the quality of the steel. Although coke quickly became the dominant fuel for iron-smelting, in 1884 charcoal was still used to make ten percent of iron and steel in the US. The use of cLackawanna Valley

The Lackawanna River is a U.S. Geological Survey. National Hydrography Dataset high-resolution flowline dataThe National Map, accessed August 8, 2011 tributary of the Susquehanna River in Northeastern Pennsylvania. It flows through a region of the ...

in Pennsylvania

Pennsylvania (; ( Pennsylvania Dutch: )), officially the Commonwealth of Pennsylvania, is a state spanning the Mid-Atlantic, Northeastern, Appalachian, and Great Lakes regions of the United States. It borders Delaware to its southeast, ...

was rich in anthracite coal

Coal is a combustible black or brownish-black sedimentary rock, formed as rock strata called coal seams. Coal is mostly carbon with variable amounts of other elements, chiefly hydrogen, sulfur, oxygen, and nitrogen.

Coal is formed when ...

and iron

Iron () is a chemical element with Symbol (chemistry), symbol Fe (from la, Wikt:ferrum, ferrum) and atomic number 26. It is a metal that belongs to the first transition series and group 8 element, group 8 of the periodic table. It is, Abundanc ...

deposits. Brothers George W. Scranton and Seldon T. Scranton moved to the valley in 1840 and settled in the five-house town of Slocum's Hollow (now Scranton) to establish an iron forge.Yeomans, "36 Hours: Scranton, Pa.," ''New York Times,'' November 1, 2002."The Bitter Battle," ''Time,'' October 19, 1962. The most common processes for creating blister steel

The cementation process is an obsolete technology for making steel by carburization of iron. Unlike modern steelmaking, it increased the amount of carbon in the iron. It was apparently developed before the 17th century. Derwentcote Steel Furn ...

and crucible steel

Crucible steel is steel made by melting pig iron (cast iron), iron, and sometimes steel, often along with sand, glass, ashes, and other fluxes, in a crucible. In ancient times steel and iron were impossible to melt using charcoal or coal fires ...

were slow and extremely expensive. The Scrantons instead used the new "hot blast

Hot blast refers to the preheating of air blown into a blast furnace or other metallurgical process. As this considerably reduced the fuel consumed, hot blast was one of the most important technologies developed during the Industrial Revolution. ...

method," developed in Scotland

Scotland (, ) is a Countries of the United Kingdom, country that is part of the United Kingdom. Covering the northern third of the island of Great Britain, mainland Scotland has a Anglo-Scottish border, border with England to the southeast ...

in 1828. The hot blast method solved the problem of impurities from the coke, by burning them off. The Scrantons also experimented with anthracite to make steel, rather than charcoal or bituminous coal.Lewis, "The Early History of the Lackawanna Iron and Coal Company: A Study in Technological Adaptation," ''Pennsylvania Magazine of History and Biography,'' October 1972.

The replacement of charcoal with coal in the steel-making process revolutionized the industry, and tied steelmaking to coal-mining areas. In the 1800s, making a ton of steel required a greater weight of coal than iron ore. Therefore, it was more economical to locate closer to the coal mines. Pittsburgh

Pittsburgh ( ) is a city in the Commonwealth of Pennsylvania, United States, and the county seat of Allegheny County. It is the most populous city in both Allegheny County and Western Pennsylvania, the second-most populous city in Pennsylva ...

, Pennsylvania

Pennsylvania (; ( Pennsylvania Dutch: )), officially the Commonwealth of Pennsylvania, is a state spanning the Mid-Atlantic, Northeastern, Appalachian, and Great Lakes regions of the United States. It borders Delaware to its southeast, ...

, surrounded by large coal deposits and at the junction of three navigable rivers, was an ideal location for steelmaking.

Notable early 19th-century iron furnaces in the US

Rapid growth, 1856-1940

In 1856, EnglishmanHenry Bessemer

Sir Henry Bessemer (19 January 1813 – 15 March 1898) was an English inventor, whose steel-making process would become the most important technique for making steel in the nineteenth century for almost one hundred years from 1856 to 1950. H ...

invented the Bessemer process

The Bessemer process was the first inexpensive industrial process for the mass production of steel from molten pig iron before the development of the open hearth furnace. The key principle is removal of impurities from the iron by oxidation ...

, which allowed for mass production of steel from molten pig iron, reducing the cost of making steel by more than 50%. The first American steel mill to use the process was constructed in 1865 in Troy, New York

Troy is a city in the U.S. state of New York and the county seat of Rensselaer County. The city is located on the western edge of Rensselaer County and on the eastern bank of the Hudson River. Troy has close ties to the nearby cities of Albany ...

. In 1875, the largest-yet steel mill, Edgar Thomson Steel Works The Edgar Thomson Steel Works is a steel mill in the Pittsburgh area communities of Braddock and North Braddock, Pennsylvania, United States. It has been active since 1875. It is currently owned by U.S. Steel and is known as Mon Valley Works – ...

in the Pittsburgh area, was built to use the Bessemer process, financed by industrialist Andrew Carnegie

Andrew Carnegie (, ; November 25, 1835August 11, 1919) was a Scottish-American industrialist and philanthropist. Carnegie led the expansion of the American steel industry in the late 19th century and became one of the richest Americans i ...

.

The tremendous iron ore deposits around Lake Superior

Lake Superior in central North America is the largest freshwater lake in the world by surface areaThe Caspian Sea is the largest lake, but is saline, not freshwater. and the third-largest by volume, holding 10% of the world's surface fresh wa ...

were located far from coal deposits, and so were shipped to ports on the southern Great Lakes

The Great Lakes, also called the Great Lakes of North America, are a series of large interconnected freshwater lakes in the mid-east region of North America that connect to the Atlantic Ocean via the Saint Lawrence River. There are five lak ...

that were closer to the coal mines of Pennsylvania

Pennsylvania (; ( Pennsylvania Dutch: )), officially the Commonwealth of Pennsylvania, is a state spanning the Mid-Atlantic, Northeastern, Appalachian, and Great Lakes regions of the United States. It borders Delaware to its southeast, ...

, Ohio

Ohio () is a state in the Midwestern region of the United States. Of the fifty U.S. states, it is the 34th-largest by area, and with a population of nearly 11.8 million, is the seventh-most populous and tenth-most densely populated. The sta ...

, Indiana

Indiana () is a U.S. state in the Midwestern United States. It is the 38th-largest by area and the 17th-most populous of the 50 States. Its capital and largest city is Indianapolis. Indiana was admitted to the United States as the 19th s ...

, and Illinois

Illinois ( ) is a state in the Midwestern United States. Its largest metropolitan areas include the Chicago metropolitan area, and the Metro East section, of Greater St. Louis. Other smaller metropolitan areas include, Peoria and Rockf ...

. Large integrated steel mills were built in Chicago

(''City in a Garden''); I Will

, image_map =

, map_caption = Interactive Map of Chicago

, coordinates =

, coordinates_footnotes =

, subdivision_type = Country

, subdivision_name ...

, Detroit

Detroit ( , ; , ) is the largest city in the U.S. state of Michigan. It is also the largest U.S. city on the United States–Canada border, and the seat of government of Wayne County. The City of Detroit had a population of 639,111 at t ...

, Gary, Indiana

Gary is a city in Lake County, Indiana, United States. The city has been historically dominated by major industrial activity and is home to U.S. Steel's Gary Works, the largest steel mill complex in North America. Gary is located along the sou ...

, Cleveland

Cleveland ( ), officially the City of Cleveland, is a city in the U.S. state of Ohio and the county seat of Cuyahoga County. Located in the northeastern part of the state, it is situated along the southern shore of Lake Erie, across the U.S. ...

, and Buffalo, New York

Buffalo is the second-largest city in the U.S. state of New York (behind only New York City) and the seat of Erie County. It is at the eastern end of Lake Erie, at the head of the Niagara River, and is across the Canadian border from Sou ...

, to handle the Lake Superior ore.

Cleveland's first blast furnace was built in 1859. In 1860, the steel mill employed 374 workers. By 1880, Cleveland was a major steel producer, with ten steel mills and 3,000 steelworkers.

The city of Gary, Indiana

Gary is a city in Lake County, Indiana, United States. The city has been historically dominated by major industrial activity and is home to U.S. Steel's Gary Works, the largest steel mill complex in North America. Gary is located along the sou ...

was founded in 1906 by United States Steel Corporation

United States Steel Corporation, more commonly known as U.S. Steel, is an American integrated steel producer headquartered in Pittsburgh, Pennsylvania, with production operations primarily in the United States of America and in several countries ...

to serve the Gary Works

The Gary Works is a major steel mill in Gary, Indiana

Gary is a city in Lake County, Indiana, United States. The city has been historically dominated by major industrial activity and is home to U.S. Steel's Gary Works, the largest steel ...

.

The Lackawanna Steel Company

The Lackawanna Steel Company was an American steel manufacturing company that existed as an independent company from 1840 to 1922, and as a subsidiary of the Bethlehem Steel company from 1922 to 1983. Founded by the Scranton family, it was once t ...

built a large integrated steel works near Buffalo, which began producing steel from Lake Superior ore in 1903. The company had made steel in Scranton, Pennsylvania

Scranton is a city in the Commonwealth of Pennsylvania, United States, and the county seat of Lackawanna County. With a population of 76,328 as of the 2020 U.S. census, Scranton is the largest city in Northeastern Pennsylvania, the Wyoming V ...

since 1840, but moved to provide easier access to iron ore, and in an unsuccessful attempt to avoid labor troubles.

Birmingham, Alabama

Birmingham ( ) is a city in the north central region of the U.S. state of Alabama. Birmingham is the seat of Jefferson County, Alabama's most populous county. As of the 2021 census estimates, Birmingham had a population of 197,575, down 1% fr ...

became a major steel producer in the late 1800s, using locally mined coal and iron ore. The iron ore was mined from the Red Mountain Formation of Silurian age.

Notable defunct late 19th-century iron and steel furnaces in the US

World War II and after

As the only major steel maker not harmed during

As the only major steel maker not harmed during World War II

World War II or the Second World War, often abbreviated as WWII or WW2, was a world war that lasted from 1939 to 1945. It involved the vast majority of the world's countries—including all of the great powers—forming two opposing ...

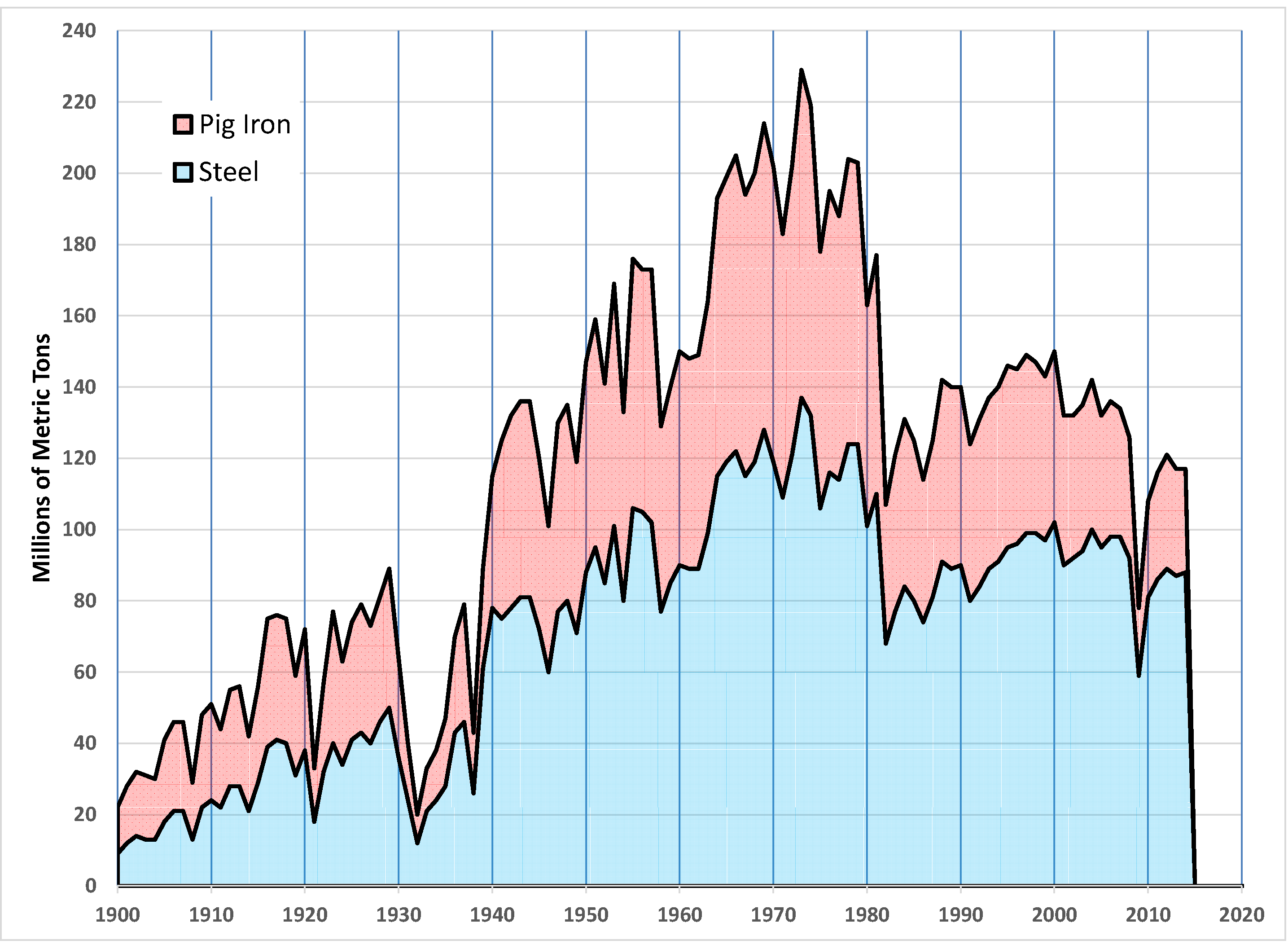

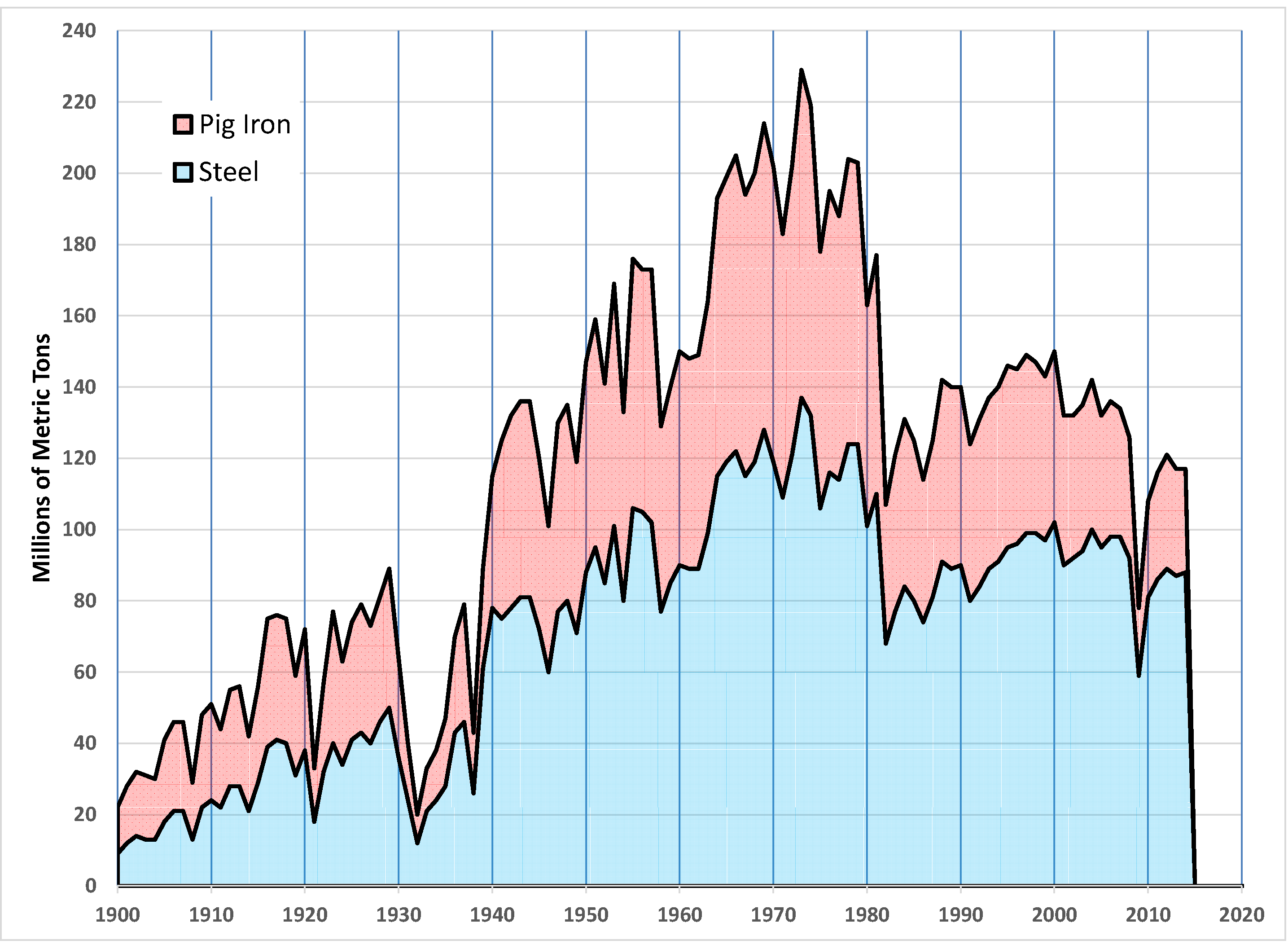

, the United States iron and steel industry reached its maximum world importance during and just after World War II. In 1945, the US produced 67% of the world's pig iron, and 72% of the steel. By comparison, 2014 percentages were 2.4% of the pig iron, and 5.3% of the steel production.

Although US iron and steel output continued to grow overall through the 1950s and 1960s, the world steel industry grew much faster, and the US share of world production shrank. In the 1960s, the US became a major importer of steel, mostly from Japan.

Contraction: 1979-1984

US production of iron and steel peaked in 1973, when the US industry produced a combined total of 229 million metric tons of iron and steel. But US iron and steel production dropped drastically during the recession of the late 1970s and early 1980s. From a combined iron and steel production of 203 million tons in 1979, US output fell almost in half, to 107 million tons in 1982. Some steel companies declared bankruptcy, and many permanently closed steelmaking plants. By 1989, US combined iron and steel production recovered to 142 million tons, a much lower level than in the 1960s and 1970s. The causes of the sudden decline are disputed. Among the many causes alleged have been: dumping of foreign imports below cost, high labor costs, poor management, unfavorable tax policies, and costs of environmental controls. One recent study found that hypotheses based on declining domestic production (such as foreign imports displacing domestic product) cannot explain the magnitude of the decline in employment, as shipments of domestic steel products in 2005 were similar to the level of the early 1960s, whereas employment in the domestic sector had plummeted by approximately 75% over the same time period. Instead, the majority of the losses could be accounted for by rising productivity, principally through technological efficiencies and the shift from traditional steel plants tomini mill

A steel mill or steelworks is an industrial plant for the manufacture of steel. It may be an integrated steel works carrying out all steps of steelmaking from smelting iron ore to rolled product, but may also be a plant where steel semi-fini ...

s.

Cleveland had nine integrated steel mills in the 1970s. US Steel closed one mill in 1979, then shut down its six remaining Cleveland mills in 1984. Cleveland's two remaining steel producers, Republic Steel

Republic Steel is an American steel manufacturer that was once the country's third largest steel producer. It was founded as the Republic Iron and Steel Company in Youngstown, Ohio in 1899. After rising to prominence during the early 20th Centu ...

and Jones & Laughlin, merged to form LTV Steel in June 1984. LTV Steel declared bankruptcy in 2000. The operation, on both sides of the Cuyahoga River, is Cleveland's last remaining integrated steel mill, now owned by Cleveland Cliffs.

In the Pittsburgh region, mill closures led to a regional unemployment rate that peaked at 17.1% in January 1983, with local unemployment rates as high as 27.1% in Beaver County.In desperate 1983, there was nowhere for Pittsburgh's economy to go but up/ref> Between 1970 and 1990, the region lost 30% of its population.

Transformation

The number of integrated steel mills has continued to decline, and in 2014, only 11 integrated mills were operating in the US. Most of the steel produced has been by the growing number of mini-mills, also called specialty mills, which in 2014 numbered 113. In 1981, mini-mills produced an estimated 15% of US steel. Since 2002, steel produced by electric arc furnace, the process used by the mini-mills, has produced more than half the steel made in the US. Many companies operating integrated mills also have mini-mills. A number of bankruptcies and acquisitions between 2000 and 2014 reversed the trend of industry fragmentation. In 2000, the top three steelmakers (Nucor

Nucor Corporation is an American producer of steel and related products based in Charlotte, North Carolina. It is the largest steel producer in the United States, the largest "mini-mill" steelmaker (i.e. it uses electric arc furnaces to melt s ...

, US Steel

United States Steel Corporation, more commonly known as U.S. Steel, is an American integrated steel producer headquartered in Pittsburgh, Pennsylvania, with production operations primarily in the United States of America and in several countries ...

, and Bethlehem Steel

The Bethlehem Steel Corporation was an American steelmaking company headquartered in Bethlehem, Pennsylvania. For most of the 20th century, it was one of the world's largest steel producing and shipbuilding companies. At the height of its succe ...

) had 28% of the steelmaking capacity, and the top ten had 58%. By 2014, the top three (Nucor, ArcelorMittal, and US Steel) accounted for 56% of the steel capacity, and the top ten 87%..

See also

*Iron and steel industry in the United States

In 2022, the United States was the world’s third-largest producer of raw steel (after China and India), and the sixth-largest producer of pig iron. The industry produced 29 million metric tons of pig iron and 88 million tons of steel. Most iron ...

* Iron mining in the United States

Iron mining in the United States produced 48 million metric tons of iron ore in 2019. Iron ore was the third-highest-value metal mined in the United States, after gold and copper. Iron ore was mined from nine active mines and three reclamation ope ...

* History of the steel industry (1850-1970)

* History of the steel industry (1970-present)

* 2002 United States steel tariff

On March 5, 2002, U.S. President George W. Bush placed tariffs on imported steel. The tariffs took effect March 20 and were lifted by Bush on December 4, 2003. Research shows that the tariffs were a net positive, reviving many previously shuttered ...

References

Further reading

* Hoerr, John P. ''And the Wolf Finally Came: The Decline of the American Steel Industry'' (1988excerpt and text search

* Hogan, William T. ''Economic History of the Iron and Steel Industry in the United States '' (5 vol 1971) monumental detail * Ingham, John N. ''The Iron Barons: A Social Analysis of an American Urban Elite, 1874-1965'' (1978) * Krass, Peter. ''Carnegie'' (2002). . * Livesay, Harold C. ''Andrew Carnegie and the Rise of Big Business'', 2nd Edition (1999). . * Misa, Thomas J. ''A Nation of Steel: The Making of Modern America, 1865–1925'' (1995) Chapter 1

* Nasaw, David. ''Andrew Carnegie'' (The Penguin Press, 2006). * Paskoff, Paul F. ''Iron and Steel in the Nineteenth Century'' (Encyclopedia of American Business History and Biography) (1989) 385 pp; biographies and brief corporate histories * Rogers, Robert P. ''An Economic History of the American Steel Industry'' (2009)

excerpt and text search

* Scamehorn, H. Lee. ''Mill & Mine: The Cf&I in the Twentieth Century'' University of Nebraska Press, 1992 * Scheuerman, William. ''The Steel Crisis: The Economics and Politics of a Declining Industry'' (1986) * Seely, Bruce E., ed ''The Iron and Steel Industry in the 20th Century'' (1994) (Encyclopedia of American Business History and Biography) * Skrabec Jr, Quentin R. ''The Carnegie Boys: The Lieutenants of Andrew Carnegie that Changed America'' (McFarland, 2012). * Temin, Peter. ''Iron and Steel in Nineteenth-Century America, An Economic Inquiry'' (1964) * Wall, Joseph Frazier. ''Andrew Carnegie'' (1989). . * Warren, Kenneth, ''Big Steel: The First Century of the United States Steel Corporation, 1901–2001.'' (University of Pittsburgh Press, 2001

online review

* Warren, Kenneth. ''Bethlehem Steel: Builder and Arsenal of America'' (2010

excerpt and text search

* Warren, Kenneth. ''The American Steel Industry, 1850–1970: A Geographical Interpretation'' (1973) ({{ISBN, 0198232144) * Whaples, Robert. "Andrew Carnegie", ''EH.Net Encyclopedia of Economic and Business History'

online

* Urofsky, Melvin I. ''Big Steel and the Wilson Administration: A Study in Business-Government Relations'' (1969)

U.S. Labor

* Brody, David. ''Labor in Crisis: The Steel Strike of 1919'' (1965) * Mary Margaret Fonow; ''Union Women: Forging Feminism in the United Steelworkers of America'' (University of Minnesota Press, 2003)* Urofsky, Melvin I. ''Big Steel and the Wilson Administration: A Study in Business-Government Relations'' (1969) History History of the United States by topic