Grinding Operations on:

[Wikipedia]

[Google]

[Amazon]

Grinding is a type of

Grinding is a type of

Selecting which of the following grinding operations to be used is determined by the size, shape, features and the desired production rate.

Selecting which of the following grinding operations to be used is determined by the size, shape, features and the desired production rate.

Cylindrical grinding (also called center-type grinding) is used to grind the cylindrical surfaces and shoulders of the workpiece. The workpiece is mounted on centers and rotated by a device known as a lathe dog or center driver. The abrasive wheel and the workpiece are rotated by separate motors and at different speeds. The table can be adjusted to produce tapers. The wheel head can be swiveled. The five types of cylindrical grinding are: outside diameter (OD) grinding, inside diameter (ID) grinding, plunge grinding, creep feed grinding, and centerless grinding.

A cylindrical grinder has a grinding (abrasive) wheel, two centers that hold the workpiece, and a chuck, grinding dog, or other mechanism to drive the work. Most cylindrical grinding machines include a swivel to allow the forming of tapered pieces. The wheel and workpiece move parallel to one another in both the radial and longitudinal directions. The abrasive wheel can have many shapes. Standard disk-shaped wheels can be used to create a tapered or straight workpiece geometry, while formed wheels are used to create a shaped workpiece. The process using a formed wheel creates less vibration than using a regular disk-shaped wheel.

Tolerances for cylindrical grinding are held within ± for diameter and ± for roundness. Precision work can reach tolerances as high as ± for diameter and ± for roundness.

Cylindrical grinding (also called center-type grinding) is used to grind the cylindrical surfaces and shoulders of the workpiece. The workpiece is mounted on centers and rotated by a device known as a lathe dog or center driver. The abrasive wheel and the workpiece are rotated by separate motors and at different speeds. The table can be adjusted to produce tapers. The wheel head can be swiveled. The five types of cylindrical grinding are: outside diameter (OD) grinding, inside diameter (ID) grinding, plunge grinding, creep feed grinding, and centerless grinding.

A cylindrical grinder has a grinding (abrasive) wheel, two centers that hold the workpiece, and a chuck, grinding dog, or other mechanism to drive the work. Most cylindrical grinding machines include a swivel to allow the forming of tapered pieces. The wheel and workpiece move parallel to one another in both the radial and longitudinal directions. The abrasive wheel can have many shapes. Standard disk-shaped wheels can be used to create a tapered or straight workpiece geometry, while formed wheels are used to create a shaped workpiece. The process using a formed wheel creates less vibration than using a regular disk-shaped wheel.

Tolerances for cylindrical grinding are held within ± for diameter and ± for roundness. Precision work can reach tolerances as high as ± for diameter and ± for roundness.

Centerless grinding is when the workpiece is supported by a blade instead of by centers or chucks. Two wheels are used. The larger one is used to grind the surface of the workpiece and the smaller wheel is used to regulate the axial movement of the workpiece. Types of centerless grinding include through-feed grinding, in-feed/plunge grinding, and internal centerless grinding.

Centerless grinding is when the workpiece is supported by a blade instead of by centers or chucks. Two wheels are used. The larger one is used to grind the surface of the workpiece and the smaller wheel is used to regulate the axial movement of the workpiece. Types of centerless grinding include through-feed grinding, in-feed/plunge grinding, and internal centerless grinding.

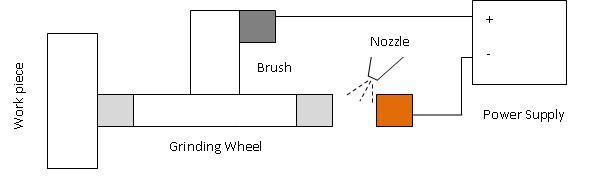

Electrolytic in-process dressing (ELID) grinding is one of the most accurate grinding methods. In this ultra precision grinding technology the grinding wheel is dressed electrochemically and in-process to maintain the accuracy of the grinding. An ELID cell consists of a metal bonded grinding wheel, a cathode electrode, a pulsed DC power supply and electrolyte. The wheel is connected to the positive terminal of the DC power supply through a carbon brush whereas the electrode is connected to the negative pole of the power supply. Usually alkaline liquids are used as both electrolytes and coolant for grinding. A nozzle is used to inject the electrolyte into the gap between wheel and electrode. The gap is usually maintained to be approximately 0.1mm to 0.3 mm. During the grinding operation one side of the wheel takes part in the grinding operation whereas the other side of the wheel is being dressed by electrochemical reaction. The dissolution of the metallic bond material is caused by the dressing which in turns results continuous protrusion of new sharp grits.

Electrolytic in-process dressing (ELID) grinding is one of the most accurate grinding methods. In this ultra precision grinding technology the grinding wheel is dressed electrochemically and in-process to maintain the accuracy of the grinding. An ELID cell consists of a metal bonded grinding wheel, a cathode electrode, a pulsed DC power supply and electrolyte. The wheel is connected to the positive terminal of the DC power supply through a carbon brush whereas the electrode is connected to the negative pole of the power supply. Usually alkaline liquids are used as both electrolytes and coolant for grinding. A nozzle is used to inject the electrolyte into the gap between wheel and electrode. The gap is usually maintained to be approximately 0.1mm to 0.3 mm. During the grinding operation one side of the wheel takes part in the grinding operation whereas the other side of the wheel is being dressed by electrochemical reaction. The dissolution of the metallic bond material is caused by the dressing which in turns results continuous protrusion of new sharp grits.

T. Saleh, M. Sazedur Rahman, H.S. Lim, M. Rahman, Development and performance evaluation of an ultra precision ELID grinding machine, Journal of Materials Processing Technology, Volumes 192-193, Pages 287-291. is a specialized type of cylindrical grinding where the grinding wheel has the exact shape of the final product. The grinding wheel does not traverse the workpiece.. Internal grinding is used to grind the internal diameter of the workpiece. Tapered holes can be ground with the use of internal grinders that can swivel on the horizontal. Pre-grinding - When a new tool has been built and has been heat-treated, it is pre-ground before welding or hardfacing commences. This usually involves grinding the outside diameter (OD) slightly higher than the finish grind OD to ensure the correct finish size.

Grinding is a type of

Grinding is a type of abrasive machining

Abrasive machining is a machining process where material is removed from a workpiece using a multitude of small abrasive particles. Common examples include grinding, honing, and polishing. Abrasive processes are usually expensive, but capable of t ...

process which uses a grinding wheel

Grinding wheels contains abrasive compounds for grinding and abrasive machining operations. Such wheels are also used in grinding machines.

The wheels are generally made with composite material . This consists of coarse-particle aggregate pre ...

as cutting tool

In the context of machining, a cutting tool or cutter is typically a hardened metal tool that is used to cut, shape, and remove material from a workpiece by means of machining tools as well as abrasive tools by way of shear deformation. The majori ...

.

A wide variety of machines are used for grinding, best classified as portable or stationary:

* Portable power tool

A power tool is a tool that is actuated by an additional power source and mechanism other than the solely manual labor used with hand tools. The most common types of power tools use electric motors. Internal combustion engines and compressed ...

s such as angle grinder

An angle grinder, also known as a side grinder or disc grinder, is a handheld power tool used for grinding (abrasive cutting) and polishing. Although developed originally as tools for rigid abrasive discs, the availability of an interchangeabl ...

s, die grinder

Die grinders and rotary tools are handheld power tools used for grinding, sanding, honing, polishing, or machining material (typically metal, but also plastic or wood). All such tools are conceptually similar, with no bright dividing line be ...

s and cut-off saws

* Stationary power tool

A power tool is a tool that is actuated by an additional power source and mechanism other than the solely manual labor used with hand tools. The most common types of power tools use electric motors. Internal combustion engines and compressed ...

s such as bench grinder

A bench grinder is a benchtop type of grinding machine used to drive abrasive wheels. A pedestal grinder is a similar or larger version of grinder that is mounted on a pedestal, which may be bolted to the floor or may sit on rubber feet. These t ...

s and cut-off saws

* Stationary hydro- or hand-powered sharpening stones

Milling practice is a large and diverse area of manufacturing

Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of secondary sector of the economy. The term may refer to a ...

and toolmaking. It can produce very fine finishes and very accurate dimensions; yet in mass production contexts, it can also rough out large volumes of metal quite rapidly. It is usually better suited to the machining of very hard materials than is "regular" machining (that is, cutting larger chips with cutting tools such as tool bits or milling cutter

Milling cutters are cutting tools typically used in milling machines or machining centres to perform milling operations (and occasionally in other machine tools). They remove material by their movement within the machine (e.g., a ball nose mill) ...

s), and until recent decades it was the only practical way to machine such materials as hardened steels. Compared to "regular" machining, it is usually better suited to taking very shallow cuts, such as reducing a shaft's diameter by half a thousandth of an inch

A thousandth of an inch is a derived unit of length in a system of units using inches. Equal to of an inch, a thousandth is commonly called a thou (used for both singular and plural) or particularly in North America a mil (plural mils).

The w ...

or 12.7 μm

The micrometre ( international spelling as used by the International Bureau of Weights and Measures; SI symbol: μm) or micrometer (American spelling), also commonly known as a micron, is a unit of length in the International System of Unit ...

.

Grinding is a subset of cutting, as grinding is a true metal-cutting process. Each grain of abrasive functions as a microscopic single-point cutting edge (although of high negative rake angle

Rake angle is a parameter used in various cutting and machining processes, describing the angle of the cutting face relative to the work. There are three types of rake angles: ''positive'', ''zero'' or ''neutral'', and ''negative''.

* Positive ...

), and shears a tiny chip that is analogous to what would conventionally be called a "cut" chip (turning, milling, drilling, tapping, etc.) . However, among people who work in the machining fields, the term ''cutting'' is often understood to refer to the macroscopic cutting operations, and ''grinding'' is often mentally categorized as a "separate" process. This is why the terms are usually used separately in shop-floor practice.

Lapping

Lapping is a machining process in which two surfaces are rubbed together with an abrasive between them, by hand movement or using a machine.

Lapping often follows other subtractive processes with more aggressive material removal as a first ste ...

and sanding

upright=1.35, Sheets of sandpaper with different grit sizes (40 (coarse), 80, 150, 240, 600 (fine)).

Sandpaper and glasspaper are names used for a type of coated abrasive that consists of sheets of paper or cloth with abrasive material glued ...

are subsets of grinding.Processes

Creep-feed grinding

Creep-feed grinding (CFG) was a grinding process which was invented in Germany in the late 1950s by Edmund and Gerhard Lang. Normal grinding is used primarily to finish surfaces. But CFG is used for high rates of material removal, competing with milling and turning as a manufacturing process choice. CFG has grinding depth up to 6 mm (0.236 inches) and workpiece speed is low. Surfaces with a softer-grade resin bond are used to keep workpiece temperature low and an improved surface finish up to 1.6 μm Rmax. CFG can take 117 s to remove of material. Precision grinding would take more than 200 s to do the same. CFG has the disadvantage of a wheel that is constantly degrading, requires high spindle power (), and is limited in the length of part it can machine. To address the problem of wheel sharpness, continuous-dress creep-feed grinding (CDCF) was developed in 1970s. The wheel is dressed constantly during machining in CDCF process and keeps the wheel in a state of specified sharpness. It takes only 17 s to remove of material, a huge gain in productivity. 38 hp (28 kW) spindle power is required, with a low to conventional spindle speeds. The limit on part length was erased. High-efficiency deep grinding (HEDG) is another type of grinding. This process uses plated superabrasive wheels. These wheels never need dressing and last longer than other wheels. This reduces capital equipment investment costs. HEDG can be used on long part lengths and removes material at a rate of in 83 s. HEDG requires high spindle power and high spindle speeds. Peel grinding, patented under the name of Quickpoint in 1985 by Erwin Junker Maschinenfabrik, GmbH in Nordrach, Germany, uses a thin superabrasive grinding disk oriented almost parallel to a cylindrical workpiece and operates somewhat like a lathe turning tool. Ultra-high speed grinding (UHSG) can run at speeds higher than 40,000 fpm (200 m/s), taking 41 s to remove of material, but is still in the research and development (R&D) stage. It also requires high spindle power and high spindle speeds.Cylindrical grinding

Cylindrical grinding (also called center-type grinding) is used to grind the cylindrical surfaces and shoulders of the workpiece. The workpiece is mounted on centers and rotated by a device known as a lathe dog or center driver. The abrasive wheel and the workpiece are rotated by separate motors and at different speeds. The table can be adjusted to produce tapers. The wheel head can be swiveled. The five types of cylindrical grinding are: outside diameter (OD) grinding, inside diameter (ID) grinding, plunge grinding, creep feed grinding, and centerless grinding.

A cylindrical grinder has a grinding (abrasive) wheel, two centers that hold the workpiece, and a chuck, grinding dog, or other mechanism to drive the work. Most cylindrical grinding machines include a swivel to allow the forming of tapered pieces. The wheel and workpiece move parallel to one another in both the radial and longitudinal directions. The abrasive wheel can have many shapes. Standard disk-shaped wheels can be used to create a tapered or straight workpiece geometry, while formed wheels are used to create a shaped workpiece. The process using a formed wheel creates less vibration than using a regular disk-shaped wheel.

Tolerances for cylindrical grinding are held within ± for diameter and ± for roundness. Precision work can reach tolerances as high as ± for diameter and ± for roundness.

Cylindrical grinding (also called center-type grinding) is used to grind the cylindrical surfaces and shoulders of the workpiece. The workpiece is mounted on centers and rotated by a device known as a lathe dog or center driver. The abrasive wheel and the workpiece are rotated by separate motors and at different speeds. The table can be adjusted to produce tapers. The wheel head can be swiveled. The five types of cylindrical grinding are: outside diameter (OD) grinding, inside diameter (ID) grinding, plunge grinding, creep feed grinding, and centerless grinding.

A cylindrical grinder has a grinding (abrasive) wheel, two centers that hold the workpiece, and a chuck, grinding dog, or other mechanism to drive the work. Most cylindrical grinding machines include a swivel to allow the forming of tapered pieces. The wheel and workpiece move parallel to one another in both the radial and longitudinal directions. The abrasive wheel can have many shapes. Standard disk-shaped wheels can be used to create a tapered or straight workpiece geometry, while formed wheels are used to create a shaped workpiece. The process using a formed wheel creates less vibration than using a regular disk-shaped wheel.

Tolerances for cylindrical grinding are held within ± for diameter and ± for roundness. Precision work can reach tolerances as high as ± for diameter and ± for roundness. Surface finish

Surface finish, also known as surface texture or surface topography, is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness.. It comprises the small, local deviations of a surface from the p ...

es can range from to , with typical finishes ranging from .

Surface grinding

''Surface grinding'' uses a rotating abrasive wheel to remove material, creating a flat surface. The tolerances that are normally achieved with grinding are ± for grinding a flat material and ± for a parallel surface. The surface grinder is composed of an abrasive wheel, a workholding device known as a chuck, either electromagnetic or vacuum, and a reciprocating table. Grinding is commonly used oncast iron

Cast iron is a class of iron– carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impu ...

and various types of steel. These materials lend themselves to grinding because they can be held by the magnetic chuck commonly used on grinding machines and do not melt into the cutting wheel, clogging it and preventing it from cutting. Materials that are less commonly ground are aluminum

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. It h ...

, stainless steel, brass

Brass is an alloy of copper (Cu) and zinc (Zn), in proportions which can be varied to achieve different mechanical, electrical, and chemical properties. It is a substitutional alloy: atoms of the two constituents may replace each other wit ...

, and plastic

Plastics are a wide range of synthetic or semi-synthetic materials that use polymers as a main ingredient. Their plasticity makes it possible for plastics to be moulded, extruded or pressed into solid objects of various shapes. This adaptab ...

s. These all tend to clog the cutting wheel more than steel and cast iron, but with special techniques it is possible to grind them.

Others

Electrochemical grinding

Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive grinding wheel, an electrolyte fluid, and a positively charged workpiece. Materials removed from the workpiece stay ...

is a type of grinding in which a positively charged workpiece in a conductive fluid is eroded by a negatively charged grinding wheel. The pieces from the workpiece are dissolved into the conductive fluid.

T. Saleh, M. Sazedur Rahman, H.S. Lim, M. Rahman, Development and performance evaluation of an ultra precision ELID grinding machine, Journal of Materials Processing Technology, Volumes 192-193, Pages 287-291. is a specialized type of cylindrical grinding where the grinding wheel has the exact shape of the final product. The grinding wheel does not traverse the workpiece.. Internal grinding is used to grind the internal diameter of the workpiece. Tapered holes can be ground with the use of internal grinders that can swivel on the horizontal. Pre-grinding - When a new tool has been built and has been heat-treated, it is pre-ground before welding or hardfacing commences. This usually involves grinding the outside diameter (OD) slightly higher than the finish grind OD to ensure the correct finish size.

Grinding wheel

A grinding wheel is an expendable wheel used for various grinding and abrasive machining operations. It is generally made from a matrix of coarse abrasive particles pressed and bonded together to form a solid, circular shape, various profiles and cross sections are available depending on the intended usage for the wheel. Grinding wheels may also be made from a solid steel or aluminium disc with particles bonded to the surface.Lubrication

The use of fluids in a grinding process is often necessary to cool and lubricate the wheel and workpiece as well as remove the chips produced in the grinding process. The most common grinding fluids are water-soluble chemical fluids, water-soluble oils, synthetic oils, and petroleum-based oils. It is imperative that the fluid be applied directly to the cutting area to prevent the fluid being blown away from the piece due to rapid rotation of the wheel.The workpiece

Workholding methods

The workpiece is manually clamped to a lathe dog, powered by the faceplate, that holds the piece in between two centers and rotates the piece. The piece and the grinding wheel rotate in opposite directions and small bits of the piece are removed as it passes along the grinding wheel. In some instances special drive centers may be used to allow the edges to be ground. The workholding method affects the production time as it changes set up times.Workpiece materials

Typical workpiece materials include aluminum, brass, plastics, cast iron, mild steel, and stainless steel. Aluminum, brass and plastics can have poor to fair machinability characteristics for cylindrical grinding. Cast Iron and mild steel have very good characteristics for cylindrical grinding. Stainless steel is very difficult to grind due to its toughness and ability to work harden, but can be worked with the right grade of grinding wheels.Workpiece geometry

The final shape of a workpiece is the mirror image of the grinding wheel, with cylindrical wheels creating cylindrical pieces and formed wheels creating formed pieces. Typical sizes on workpieces range from 0.75 in to 20 in (18 mm to 1 m) and 0.80 in to 75 in (2 cm to 4 m) in length, although pieces from 0.25 in to 60 in (6 mm to 1.5 m) in diameter and 0.30 in to 100 in (8 mm to 2.5 m) in length can be ground. Resulting shapes can be straight cylinders, straight-edged conical shapes, or even crankshafts for engines that experience relatively low torque.Effects on workpiece materials

Chemical property changes include an increased susceptibility to corrosion because of high surface stress. Mechanical properties will change due to stresses put on the part during finishing. High grinding temperatures may cause a thin Martensite, martensitic layer to form on the part, which will lead to reduced material strength from microcracks. Physical property changes include the possible loss of magnetic properties onferromagnetic

Ferromagnetism is a property of certain materials (such as iron) which results in a large observed magnetic permeability, and in many cases a large magnetic coercivity allowing the material to form a permanent magnet. Ferromagnetic materials ...

materials.

See also

References

Bibliography

* {{DEFAULTSORT:Grinding (Abrasive Cutting) Grinding and lapping Sharpening