Glassmaking Companies Of Sweden on:

[Wikipedia]

[Google]

[Amazon]

Glass production involves two main methods – the

Glass production involves two main methods – the

The batch is fed into the

The batch is fed into the

In the "blow and blow" process, the glass is first blown through a valve in the baffle, forcing it down into the three-piece "ring mould" which is held in the "neckring arm" below the blanks, to form the "finish". The term "finish" describes the details (such as cap sealing surface, screw threads, retaining rib for a tamper-proof cap, etc.) at the open end of the container. Then compressed air is blown through the glass, which results in a hollow and partly formed container. Compressed air is then blown again at the second stage to give final shape.

Containers are made in two major stages. The first stage moulds all the details ("finish") around the opening, but the body of the container is initially made much smaller than its final size. These partly manufactured containers are called "parisons", and quite quickly, they are blow-molded into final shape.

The "rings" are sealed from below by a short plunger. After the "settleblow" finishes, the plunger retracts slightly, to allow the skin that's formed to soften. "Counterblow" air then comes up through the plunger, to create the parison. The baffle rises and the blanks open. The parison is inverted in an arc to the "mould side" by the "neckring arm", which holds the parison by the "finish".

As the neckring arm reaches the end of its arc, two mould halves close around the parison. The neckring arm opens slightly to release its grip on the "finish", then reverts to the blank side. "Final blow", applied through the "blowhead", blows the glass out, expanding into the mould, to make the final container shape.

In the "blow and blow" process, the glass is first blown through a valve in the baffle, forcing it down into the three-piece "ring mould" which is held in the "neckring arm" below the blanks, to form the "finish". The term "finish" describes the details (such as cap sealing surface, screw threads, retaining rib for a tamper-proof cap, etc.) at the open end of the container. Then compressed air is blown through the glass, which results in a hollow and partly formed container. Compressed air is then blown again at the second stage to give final shape.

Containers are made in two major stages. The first stage moulds all the details ("finish") around the opening, but the body of the container is initially made much smaller than its final size. These partly manufactured containers are called "parisons", and quite quickly, they are blow-molded into final shape.

The "rings" are sealed from below by a short plunger. After the "settleblow" finishes, the plunger retracts slightly, to allow the skin that's formed to soften. "Counterblow" air then comes up through the plunger, to create the parison. The baffle rises and the blanks open. The parison is inverted in an arc to the "mould side" by the "neckring arm", which holds the parison by the "finish".

As the neckring arm reaches the end of its arc, two mould halves close around the parison. The neckring arm opens slightly to release its grip on the "finish", then reverts to the blank side. "Final blow", applied through the "blowhead", blows the glass out, expanding into the mould, to make the final container shape.

In the ''press and blow'' process, the parison is formed by a long metal plunger which rises up and presses the glass out, in order to fill the ring and blank moulds. The process then continues as before, with the parison being transferred to the final-shape mould, and the glass being blown out into the mould.

The container is then picked up from the mould by the "take-out" mechanism, and held over the "deadplate", where air cooling helps cool down the still-soft glass. Finally, the bottles are swept onto a conveyor by the "push out paddles" that have air pockets to keep the bottles standing after landing on the "deadplate"; they're now ready for annealing.

In the ''press and blow'' process, the parison is formed by a long metal plunger which rises up and presses the glass out, in order to fill the ring and blank moulds. The process then continues as before, with the parison being transferred to the final-shape mould, and the glass being blown out into the mould.

The container is then picked up from the mould by the "take-out" mechanism, and held over the "deadplate", where air cooling helps cool down the still-soft glass. Finally, the bottles are swept onto a conveyor by the "push out paddles" that have air pockets to keep the bottles standing after landing on the "deadplate"; they're now ready for annealing.

/ref> The United States, Europe and China account for 75% of demand, with China's consumption having increased from 20% in the early 1990s to 50%. Glass container manufacture is also a geographical business; the product is heavy and large in volume, and the major raw materials (sand, soda ash and limestone) are generally readily available. Therefore production facilities need to be located close to their markets. A typical glass furnace holds hundreds of tonnes of molten glass, and so it is simply not practical to shut it down every night, or in fact in any period short of a month. Factories therefore run 24 hours a day 7 days a week. This means that there is little opportunity to either increase or decrease production rates by more than a few percent. New furnaces and forming machines cost tens of millions of dollars and require at least 18 months of planning. Given this fact, and the fact that there are usually more products than machine lines, products are sold from stock. The marketing/production challenge is therefore to predict demand both in the short 4- to 12-week term and over the 24- to 48-month-long term. Factories are generally sized to service the requirements of a city; in developed countries there is usually a factory per 1–2 million people. A typical factory will produce 1–3 million containers a day. Despite its positioning as a mature market product, glass does enjoy a high level of consumer acceptance and is perceived as a "premium" quality packaging format.

Float glass is a sheet of

Float glass is a sheet of

Glass production involves two main methods – the

Glass production involves two main methods – the float glass

Float glass is a sheet of glass made by floating molten glass on a bed of molten metal, typically tin, although lead and other various low- melting-point alloys were used in the past. This method gives the sheet uniform thickness and very flat sur ...

process that produces sheet glass, and glassblowing

Glassblowing is a glassforming technique that involves inflating molten glass into a bubble (or parison) with the aid of a Blowpipe (tool), blowpipe (or blow tube). A person who blows glass is called a ''glassblower'', ''glassmith'', or ''gaffer'' ...

that produces bottles and other containers. It has been done in a variety of ways during the history of glass

The history of glass-making dates back to at least 3,600 years ago in Mesopotamia. However, some writers claim that they may have been producing copies of glass objects from ancient Egypt, Egypt. Other archaeological evidence suggests that the fi ...

.

Glass container production

Broadly, modern glass container factories are three-part operations: the "batch house", the "hot end", and the "cold end". The batch house handles the raw materials; the hot end handles the manufacture proper—the forehearth, forming machines, and annealing ovens; and the cold end handles the product-inspection and packaging equipment.Batch processing system (batch house)

Batch processing is one of the initial steps of the glass-making process. The batch house simply houses the raw materials in large silos (fed by truck or railcar), and holds anywhere from 1–5 days of material. Some batch systems include material processing such as raw material screening/sieve, drying, or pre-heating (i.e.cullet

Glass recycling is the processing of waste glass into usable products. Glass that is crushed or imploded and ready to be remelted is called cullet. There are two types of cullet: internal and external. Internal cullet is composed of defective p ...

). Whether automated or manual, the batch house measures, assembles, mixes, and delivers the glass raw material recipe (batch) via an array of chutes, conveyors, and scales to the furnace. The batch enters the furnace at the "dog house" or "batch charger". Different glass types, colors, desired quality, raw material purity/availability, and furnace design will affect the batch recipe.

Hot end

The hot end of a glassworks is where the molten glass is manufactured into glass products. The batch enters the furnace, then passes to the forming process, internal treatment, and annealing. The following table lists commonviscosity

The viscosity of a fluid is a measure of its resistance to deformation at a given rate. For liquids, it corresponds to the informal concept of "thickness": for example, syrup has a higher viscosity than water.

Viscosity quantifies the inte ...

fixpoints, applicable to large-scale glass production and experimental glass melting in the laboratory:Werner Vogel: "Glass Chemistry"; Springer-Verlag Berlin and Heidelberg GmbH & Co. K; 2nd revised edition (November 1994),

Furnace

The batch is fed into the

The batch is fed into the furnace

A furnace is a structure in which heat is produced with the help of combustion.

Furnace may also refer to:

Appliances Buildings

* Furnace (central heating): a furnace , or a heater or boiler , used to generate heat for buildings

* Boiler, used t ...

at a slow, controlled rate by the batch processing system. The furnaces are natural gas

Natural gas (also called fossil gas or simply gas) is a naturally occurring mixture of gaseous hydrocarbons consisting primarily of methane in addition to various smaller amounts of other higher alkanes. Low levels of trace gases like carbo ...

- or fuel oil

Fuel oil is any of various fractions obtained from the distillation of petroleum (crude oil). Such oils include distillates (the lighter fractions) and residues (the heavier fractions). Fuel oils include heavy fuel oil, marine fuel oil (MFO), bun ...

-fired, and operate at temperatures up to . The temperature is limited only by the quality of the furnace’s superstructure material and by the glass composition. Types of furnaces used in container glass making include "end-port" (end-fired), "side-port", and "oxy-fuel". Typically, furnace size is classified by metric tons per day (MTPD) production capability.

Forming process

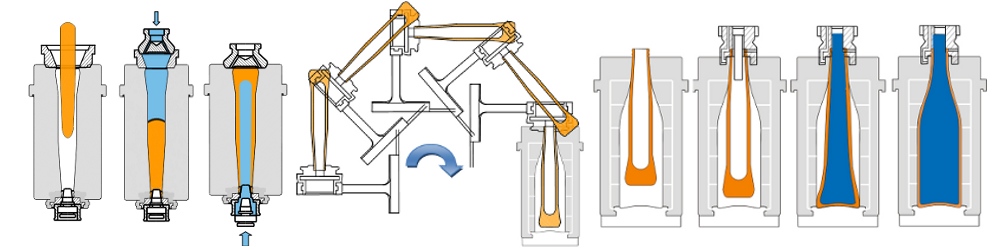

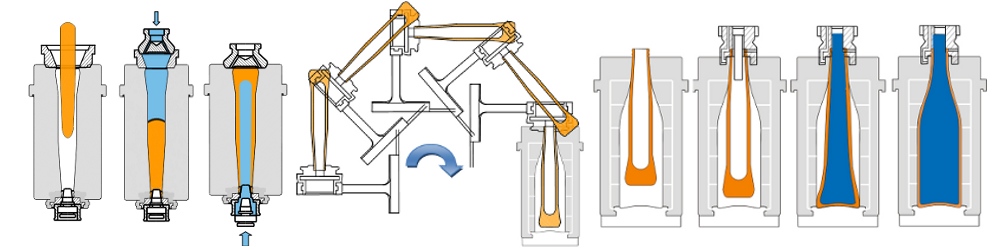

There are currently two primary methods of making glass containers: the "blow and blow" method for narrow-neck containers only, and the "press and blow" method used for jars and tapered narrow-neck containers. In both methods, a stream of molten glass at its plastic temperature () is cut with a shearing blade to form a solid cylinder of glass, called a "gob". The gob is of predetermined weight just sufficient to make a bottle. Both processes start with the gob falling, by gravity, and guided, through troughs and chutes, into the blank moulds, two halves of which are clamped shut and then sealed by the "baffle" from above. In the "blow and blow" process, the glass is first blown through a valve in the baffle, forcing it down into the three-piece "ring mould" which is held in the "neckring arm" below the blanks, to form the "finish". The term "finish" describes the details (such as cap sealing surface, screw threads, retaining rib for a tamper-proof cap, etc.) at the open end of the container. Then compressed air is blown through the glass, which results in a hollow and partly formed container. Compressed air is then blown again at the second stage to give final shape.

Containers are made in two major stages. The first stage moulds all the details ("finish") around the opening, but the body of the container is initially made much smaller than its final size. These partly manufactured containers are called "parisons", and quite quickly, they are blow-molded into final shape.

The "rings" are sealed from below by a short plunger. After the "settleblow" finishes, the plunger retracts slightly, to allow the skin that's formed to soften. "Counterblow" air then comes up through the plunger, to create the parison. The baffle rises and the blanks open. The parison is inverted in an arc to the "mould side" by the "neckring arm", which holds the parison by the "finish".

As the neckring arm reaches the end of its arc, two mould halves close around the parison. The neckring arm opens slightly to release its grip on the "finish", then reverts to the blank side. "Final blow", applied through the "blowhead", blows the glass out, expanding into the mould, to make the final container shape.

In the "blow and blow" process, the glass is first blown through a valve in the baffle, forcing it down into the three-piece "ring mould" which is held in the "neckring arm" below the blanks, to form the "finish". The term "finish" describes the details (such as cap sealing surface, screw threads, retaining rib for a tamper-proof cap, etc.) at the open end of the container. Then compressed air is blown through the glass, which results in a hollow and partly formed container. Compressed air is then blown again at the second stage to give final shape.

Containers are made in two major stages. The first stage moulds all the details ("finish") around the opening, but the body of the container is initially made much smaller than its final size. These partly manufactured containers are called "parisons", and quite quickly, they are blow-molded into final shape.

The "rings" are sealed from below by a short plunger. After the "settleblow" finishes, the plunger retracts slightly, to allow the skin that's formed to soften. "Counterblow" air then comes up through the plunger, to create the parison. The baffle rises and the blanks open. The parison is inverted in an arc to the "mould side" by the "neckring arm", which holds the parison by the "finish".

As the neckring arm reaches the end of its arc, two mould halves close around the parison. The neckring arm opens slightly to release its grip on the "finish", then reverts to the blank side. "Final blow", applied through the "blowhead", blows the glass out, expanding into the mould, to make the final container shape.

In the ''press and blow'' process, the parison is formed by a long metal plunger which rises up and presses the glass out, in order to fill the ring and blank moulds. The process then continues as before, with the parison being transferred to the final-shape mould, and the glass being blown out into the mould.

The container is then picked up from the mould by the "take-out" mechanism, and held over the "deadplate", where air cooling helps cool down the still-soft glass. Finally, the bottles are swept onto a conveyor by the "push out paddles" that have air pockets to keep the bottles standing after landing on the "deadplate"; they're now ready for annealing.

In the ''press and blow'' process, the parison is formed by a long metal plunger which rises up and presses the glass out, in order to fill the ring and blank moulds. The process then continues as before, with the parison being transferred to the final-shape mould, and the glass being blown out into the mould.

The container is then picked up from the mould by the "take-out" mechanism, and held over the "deadplate", where air cooling helps cool down the still-soft glass. Finally, the bottles are swept onto a conveyor by the "push out paddles" that have air pockets to keep the bottles standing after landing on the "deadplate"; they're now ready for annealing.

Forming machines

The forming machines hold and move the parts that form the container. The machine consists of 19 basic mechanisms in operation to form a bottle and generally powered bycompressed air

Compressed air is air kept under a pressure that is greater than atmospheric pressure. Compressed air is an important medium for transfer of energy in industrial processes, and is used for power tools such as air hammers, drills, wrenches, and o ...

(high pressure – 3.2 bar and low pressure – 2.8 bar), the mechanisms are electronically timed to coordinate all movements of the mechanisms. The most widely used forming machine arrangement is the ''individual section'' machine (or IS machine). This machine has a bank of 5–20 identical sections, each of which contains one complete set of mechanisms to make containers. The sections are in a row, and the gobs feed into each section via a moving chute, called the ''gob distributor''. Sections make either one, two, three or four containers simultaneously (referred to as "single", "double", "triple" and "quad" gob). In the case of multiple gobs, the "shears" cut the gobs simultaneously, and they fall into the blank moulds in parallel.

Forming machines are largely powered by compressed air

Compressed air is air kept under a pressure that is greater than atmospheric pressure. Compressed air is an important medium for transfer of energy in industrial processes, and is used for power tools such as air hammers, drills, wrenches, and o ...

and a typical glass works will have several large compressor

A compressor is a mechanical device that increases the pressure of a gas by reducing its volume. An air compressor is a specific type of gas compressor.

Compressors are similar to pumps: both increase the pressure on a fluid and both can transp ...

s (totaling 30k–60k cfm) to provide the necessary compressed air. However in recent times servo drives have been implemented in the machines which achieve a better digital control of the forming process. It is one step to initialize industries 2.0 in this branch.

Furnaces, compressors, and forming machines generate large quantities of waste heat

Waste heat is heat that is produced by a machine, or other process that uses energy, as a byproduct of doing work. All such processes give off some waste heat as a fundamental result of the laws of thermodynamics. Waste heat has lower utility ...

which are generally cooled by water. Hot glass which is not used in the forming machine is diverted and this diverted glass (called "cullet") is generally cooled by water, and sometimes even processed and crushed in a water bath arrangement. Often cooling requirements are shared over banks of cooling towers arranged to allow for backup during maintenance.

Internal treatment

After the forming process, some containers—particularly those intended for alcoholic spirits—undergo a treatment to improve the chemical resistance of the inside, called "internal treatment" ordealkalization Dealkalization is a process of surface modification applicable to glasses containing alkali ions, wherein a thin surface layer is created that has a lower concentration of alkali ions than is present in the underlying, bulk glass. This change in s ...

. This is usually accomplished through the injection of a sulfur- or fluorine-containing gas mixture into bottles at high temperatures. The gas is typically delivered to the container either in the air used in the forming process (that is, during the final blow of the container), or through a nozzle directing a stream of the gas into the mouth of the bottle after forming. The treatment renders the container more resistant to alkali extraction, which can cause increases in product pH, and in some cases container degradation.

Annealing

As glass cools, it shrinks and solidifies. Uneven cooling may make glass more susceptible to fracture due to internal stresses: the surface cools first, then as the interior cools and contracts it creates tension. Even cooling is achieved by annealing. An annealing oven (known in the industry as a lehr) heats the container to about , then cools it, depending on the glass thickness, over a 20 – 60 minute period.Cold end

The role of the cold end of glass container production is to complete the final tasks in the manufacturing process: spray on a polyethylene coating for abrasion resistance and increased lubricity, inspect the containers for defects, label the containers, and package the containers for shipment.Coatings

Glass containers typically receive two surface coatings, one at the ''hot end'', just before annealing and one at the ''cold end'' just after annealing. At the ''hot end'' a very thin layer oftin(IV) oxide

Tin(IV) oxide, also known as stannic oxide, is the inorganic compound with the formula SnO2. The mineral form of SnO2 is called cassiterite, and this is the main ore of tin. With many other names, this oxide of tin is an important material in tin ...

is applied either using a safe organic compound or inorganic stannic chloride

Tin(IV) chloride, also known as tin tetrachloride or stannic chloride, is an inorganic compound with the formula Sn Cl4. It is a colorless hygroscopic liquid, which fumes on contact with air. It is used as a precursor to other tin compounds. It ...

. Tin based systems are not the only ones used, although the most popular. Titanium tetrachloride

Titanium tetrachloride is the inorganic compound with the formula . It is an important intermediate in the production of titanium metal and the pigment titanium dioxide. is a volatile liquid. Upon contact with humid air, it forms thick clouds o ...

or organo titanates can also be used. In all cases the coating renders the surface of the glass more adhesive to the cold end coating. At the cold end a layer of typically, polyethylene

Polyethylene or polythene (abbreviated PE; IUPAC name polyethene or poly(methylene)) is the most commonly produced plastic. It is a polymer, primarily used for packaging ( plastic bags, plastic films, geomembranes and containers including bo ...

wax

Waxes are a diverse class of organic compounds that are lipophilic, malleable solids near ambient temperatures. They include higher alkanes and lipids, typically with melting points above about 40 °C (104 °F), melting to giv ...

, is applied via a water based emulsion

An emulsion is a mixture of two or more liquids that are normally immiscible (unmixable or unblendable) owing to liquid-liquid phase separation. Emulsions are part of a more general class of two-phase systems of matter called colloids. Althoug ...

. This makes the glass slippery, protecting it from scratching and stopping containers from sticking together when they are moved on a conveyor

A conveyor system is a common piece of mechanical handling equipment that moves materials from one location to another. Conveyors are especially useful in applications involving the transport of heavy or bulky materials. Conveyor systems allow ...

. The resultant invisible combined coating gives a virtually unscratchable surface to the glass. Due to reduction of in-service surface damage, the coatings often are described as strengtheners, however a more correct definition might be strength-retaining coatings.

Inspection equipment

Glass containers are 100% inspected; automatic machines, or sometimes persons, inspect every container for a variety of faults. Typical faults include small cracks in the glass called "checks" and foreign inclusions called "stones" which are pieces of therefractory

In materials science, a refractory material or refractory is a material that is resistant to decomposition by heat, pressure, or chemical attack, and retains strength and form at high temperatures. Refractories are polycrystalline, polyphase, ...

brick lining of the melting furnace that break off and fall into the pool of molten glass, or more commonly oversized silica granules (sand) that have failed to melt and which subsequently are included in the final product. These are especially important to select out due to the fact that they can impart a destructive element to the final glass product. For example, since these materials can withstand large amounts of thermal energy, they can cause the glass product to sustain thermal shock resulting in explosive destruction when heated. Other defects include bubbles in the glass called "blisters" and excessively thin walls. Another defect common in glass manufacturing is referred to as a "tear". In the "press and blow" forming, if a plunger and mould are out of alignment, or heated to an incorrect temperature, the glass will stick to either item and become torn. In addition to rejecting faulty containers, inspection equipment gathers statistical information and relays it to the forming machine operators in the hot end. Computer systems collect fault information and trace it to the mould that produced the container. This is done by reading the mould number on the container, which is encoded (as a numeral, or a binary code of dots) on the container by the mould that made it. Operators carry out a range of checks manually on samples of containers, usually visual and dimensional checks.

Secondary processing

Sometimes container factories will offer services such as "labelling". Several labelling technologies are available. Unique to glass is the ''Applied Ceramic Labelling'' process (ACL). This isscreen-printing

Screen printing is a printing technique where a mesh is used to transfer ink (or dye) onto a substrate, except in areas made impermeable to the ink by a blocking stencil. A blade or squeegee is moved across the screen to fill the open mesh ...

of the decoration onto the container with a vitreous enamel

Vitreous enamel, also called porcelain enamel, is a material made by fusing powdered glass to a substrate by firing, usually between . The powder melts, flows, and then hardens to a smooth, durable vitreous coating. The word comes from the Lati ...

paint, which is then baked on. An example of this is the original Coca-Cola

Coca-Cola, or Coke, is a carbonated soft drink manufactured by the Coca-Cola Company. Originally marketed as a temperance drink and intended as a patent medicine, it was invented in the late 19th century by John Stith Pemberton in Atlanta ...

bottle.

Packaging

Glass containers are packaged in various ways. Popular in Europe are bulkpallet

A pallet (also called a skid) is a flat transport structure, which supports goods in a stable fashion while being lifted by a forklift, a pallet jack, a front loader, a jacking device, or an erect crane. A pallet is the structural foundat ...

s with between 1000 and 4000 containers each. This is carried out by automatic machines (palletisers) which arrange and stack containers separated by layer sheets. Other possibilities include boxes and even hand-sewn sacks. Once packed, the new "stock units" are labelled, warehoused, and ultimately shipped.

Marketing

Glass container manufacture in the developed world is a mature market business. World demand for flat glass was approximately 52 million tonnes in 2009.zbindendesign/ref> The United States, Europe and China account for 75% of demand, with China's consumption having increased from 20% in the early 1990s to 50%. Glass container manufacture is also a geographical business; the product is heavy and large in volume, and the major raw materials (sand, soda ash and limestone) are generally readily available. Therefore production facilities need to be located close to their markets. A typical glass furnace holds hundreds of tonnes of molten glass, and so it is simply not practical to shut it down every night, or in fact in any period short of a month. Factories therefore run 24 hours a day 7 days a week. This means that there is little opportunity to either increase or decrease production rates by more than a few percent. New furnaces and forming machines cost tens of millions of dollars and require at least 18 months of planning. Given this fact, and the fact that there are usually more products than machine lines, products are sold from stock. The marketing/production challenge is therefore to predict demand both in the short 4- to 12-week term and over the 24- to 48-month-long term. Factories are generally sized to service the requirements of a city; in developed countries there is usually a factory per 1–2 million people. A typical factory will produce 1–3 million containers a day. Despite its positioning as a mature market product, glass does enjoy a high level of consumer acceptance and is perceived as a "premium" quality packaging format.

Lifecycle impact

Glass containers are whollyrecyclable

Recycling is the process of converting waste materials into new materials and objects. The recovery of energy from waste materials is often included in this concept. The recyclability of a material depends on its ability to reacquire the p ...

and the glass industries in many countries have a policy, sometimes required by government regulations, of maintaining a high price on cullet to ensure high return rates. Return rates of 95% are not uncommon in the Nordic countries (Sweden, Norway, Denmark and Finland). Return rates of less than 50% are usual in other countries.

Of course glass containers can also be reused, and in developing countries this is common, however the environmental impact of washing containers as against remelting them is uncertain. Factors to consider here are the chemicals and fresh water used in the washing, and the fact that a single-use container can be made much lighter, using less than half the glass (and therefore energy content) of a multiuse container. Also, a significant factor in the developed world's consideration of reuse are producer concerns over the risk and consequential product liability

Product liability is the area of law in which manufacturers, distributors, suppliers, retailers, and others who make products available to the public are held responsible for the injuries those products cause. Although the word "product" has br ...

of using a component (the reused container) of unknown and unqualified safety.

How glass containers compare to other packaging types (plastic

Plastics are a wide range of synthetic or semi-synthetic materials that use polymers as a main ingredient. Their plasticity makes it possible for plastics to be moulded, extruded or pressed into solid objects of various shapes. This adaptab ...

, cardboard

Cardboard is a generic term for heavy paper-based products. The construction can range from a thick paper known as paperboard to corrugated fiberboard which is made of multiple plies of material. Natural cardboards can range from grey to light b ...

, aluminium

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. I ...

) is hard to say; conclusive lifecycle studies are yet to be produced.

Float glass process

Float glass is a sheet of

Float glass is a sheet of glass

Glass is a non-crystalline, often transparent, amorphous solid that has widespread practical, technological, and decorative use in, for example, window panes, tableware, and optics. Glass is most often formed by rapid cooling (quenching) of ...

made by floating molten glass on a bed of molten metal, typically tin

Tin is a chemical element with the symbol Sn (from la, stannum) and atomic number 50. Tin is a silvery-coloured metal.

Tin is soft enough to be cut with little force and a bar of tin can be bent by hand with little effort. When bent, t ...

, although lead

Lead is a chemical element with the symbol Pb (from the Latin ) and atomic number 82. It is a heavy metal that is denser than most common materials. Lead is soft and malleable, and also has a relatively low melting point. When freshly cu ...

and various low melting point

The melting point (or, rarely, liquefaction point) of a substance is the temperature at which it changes state from solid to liquid. At the melting point the solid and liquid phase exist in equilibrium. The melting point of a substance depends ...

alloys were used in the past. This method gives the sheet uniform thickness and very flat surfaces. Modern window

A window is an opening in a wall, door, roof, or vehicle that allows the exchange of light and may also allow the passage of sound and sometimes air. Modern windows are usually glazed or covered in some other transparent or translucent materia ...

s are made from float glass. Most float glass is soda–lime glass

Soda–lime glass, also called soda–lime–silica glass, is the most prevalent type of glass, used for windowpanes and glass containers (bottles and jars) for beverages, food, and some commodity items. Some glass bakeware is made of soda-lime ...

, but relatively minor quantities of special borosilicate

Borosilicate glass is a type of glass with silica and boron trioxide as the main glass-forming constituents. Borosilicate glasses are known for having very low coefficients of thermal expansion (≈3 × 10−6 K−1 at 20 °C), ma ...

and flat panel display

A flat-panel display (FPD) is an electronic display used to display visual content such as text or images. It is present in consumer, medical, transportation, and industrial equipment.

Flat-panel displays are thin, lightweight, provide better li ...

glass are also produced using the float glass process. The float glass process is also known as the Pilkington process, named after the British glass manufacturer Pilkington

Pilkington is a Japanese-owned glass-manufacturing company which is based in Lathom, Lancashire, United Kingdom. In the UK it includes several legal entities and is a subsidiary of Japanese company NSG Group.

Prior to its acquisition by NSG i ...

, who pioneered the technique (invented by Sir Alastair Pilkington

Sir Lionel Alexander Bethune Pilkington (7 January 1920 – 5 May 1995), known as Sir Alastair Pilkington, was a British engineer and businessman who invented and perfected the float glass process for commercial manufacturing of plate glass.

E ...

) in the 1950s.

Environmental impacts

Local impacts

As with all highly concentrated industries, glassworks suffer from moderately high local environmental impacts. Compounding this is that because they are mature market businesses, they often have been located on the same site for a long time and this has resulted in residential encroachment. The main impacts on residential housing and cities are noise, fresh water use, water pollution,NOx

In atmospheric chemistry, is shorthand for nitric oxide () and nitrogen dioxide (), the nitrogen oxides that are most relevant for air pollution.

These gases contribute to the formation of smog and acid rain, as well as affecting tropos ...

and SOx air pollution, and dust.

Noise is created by the forming machines. Operated by compressed air, they can produce noise levels of up to 106 dBA. How this noise is carried into the local neighborhood depends heavily on the layout of the factory. Another factor in noise production is truck movements. A typical factory will process 600 T of material a day. This means that some 600 T of raw material has to come onto the site and the same off the site again as finished product.

Water is used to cool the furnace, compressor and unused molten glass. Water use in factories varies widely; it can be as little as one tonne water used per melted tonne of glass. Of the one tonne, roughly half is evaporated to provide cooling, the rest forms a wastewater stream.

Most factories use water containing an emulsified

An emulsion is a mixture of two or more liquids that are normally immiscible (unmixable or unblendable) owing to liquid-liquid phase separation. Emulsions are part of a more general class of two-phase systems of matter called colloids. Although ...

oil to cool and lubricate the ''gob'' cutting ''shear blades''. This oil-laden water mixes with the water outflow stream, thus polluting it. Factories usually have some kind of water processing equipment that removes this emulsified oil to various degrees of effectiveness.

Nitrogen oxide Nitrogen oxide may refer to a binary compound of oxygen and nitrogen, or a mixture of such compounds:

Charge-neutral

*Nitric oxide (NO), nitrogen(II) oxide, or nitrogen monoxide

*Nitrogen dioxide (), nitrogen(IV) oxide

* Nitrogen trioxide (), or n ...

s are a natural product of the burning of gas in air and are produced in large quantities by gas-fired furnaces. Some factories in cities with particular air pollution problems will mitigate this by using liquid oxygen

Liquid oxygen—abbreviated LOx, LOX or Lox in the aerospace, submarine and gas industries—is the liquid form of molecular oxygen. It was used as the oxidizer in the first liquid-fueled rocket invented in 1926 by Robert H. Goddard, an applica ...

, however the logic of this given the cost in carbon of (1) not using regenerators and (2) having to liquefy and transport oxygen is highly questionable. Sulfur oxide

Sulfur oxide refers to many types of sulfur and oxygen containing compounds such as SO, SO2, SO3, S7O2, S6O2, S2O2, etc.

Sulfur oxide (SO''x'') refers to one or more of the following:

* Lower sulfur oxides (S''n''O, S7O2 and S6O2)

* Sulfur monox ...

s are produced as a result of the glass melting process. Manipulating the batch formula can effect some limited mitigation of this; alternatively exhaust plume scrubbing can be used.

The raw materials for glass-making are all dusty material and are delivered either as a powder or as a fine-grained material. Systems for controlling dusty materials tend to be difficult to maintain, and given the large amounts of material moved each day, only a small amount has to escape for there to be a dust problem. ''Cullet'' (broken or waste glass) is also moved about in a glass factory and tends to produce fine glass particles when shovelled or broken.

See also

*Mirrors

A mirror or looking glass is an object that Reflection (physics), reflects an image. Light that bounces off a mirror will show an image of whatever is in front of it, when focused through the lens of the eye or a camera. Mirrors reverse the ...

*Blow moulding

Blow molding (or moulding) is a manufacturing process for forming hollow plastic parts. It is also used for forming glass bottles or other hollow shapes.

In general, there are three main types of blow molding: extrusion blow molding, injection ...

*Borosilicate glass

Borosilicate glass is a type of glass with silica and boron trioxide as the main glass-forming constituents. Borosilicate glasses are known for having very low coefficients of thermal expansion (≈3 × 10−6 K−1 at 20 °C), ma ...

*Boston round (bottle)

A Boston round bottle, or Winchester bottle, is a strong, heavy bottle commonly used in the drug and chemical industries. It is often made of amber (brown) glass (to filter out UV light) but can also be made of plastics.

History

The "Wincheste ...

* Drinkware

*Float glass

Float glass is a sheet of glass made by floating molten glass on a bed of molten metal, typically tin, although lead and other various low- melting-point alloys were used in the past. This method gives the sheet uniform thickness and very flat sur ...

*Glass disease

Glass disease, also referred to as sick glass or glass illness, is a degradation process of glass that can result in weeping, crizzling, spalling, cracking and fragmentation.

Glass disease is caused by an inherent instability in the chemical com ...

*History of glass

The history of glass-making dates back to at least 3,600 years ago in Mesopotamia. However, some writers claim that they may have been producing copies of glass objects from ancient Egypt, Egypt. Other archaeological evidence suggests that the fi ...

*Irving Wightman Colburn

Irving Wightman Colburn (16 May 1861 – 4 September 1917) was an American inventor and manufacturer.

In 1898, Colburn applied for a patent for a "Glass Working Machine" that could make hollow-bodied glass containers like bottles. The paten ...

*Packaging and labelling

Packaging is the science, art and technology of enclosing or protecting products for distribution, storage, sale, and use. Packaging also refers to the process of designing, evaluating, and producing packages. Packaging can be described as a co ...

*Wine bottle

A wine bottle is a bottle, generally a glass bottle, that is used for holding wine. Some wines are fermented in the bottle while others are bottled only after fermentation. Recently the bottle has become a standard unit of volume to describe sal ...

*Cage cup

A cage cup, also ''vas diatretum'', plural ''diatreta'', or "reticulated cup" is a type of luxury late Roman glass vessel, found from roughly the 4th century, and "the pinnacle of Roman achievements in glass-making". ''Diatreta'' consist of a ...

References

External links

{{Authority control Containers