Forrester effect on:

[Wikipedia]

[Google]

[Amazon]

The bullwhip effect is a

The bullwhip effect is a

''The Economist'', 31 January 2002 Research indicates a fluctuation in point-of-sale demand of five percent will be interpreted by supply chain participants as a change in demand of up to forty percent. Much like cracking a

Because

Because

What the “beer game” can teach about supply chain challenges

segment from the Jun 29, 2021 episode of

The bullwhip effect is a

The bullwhip effect is a supply chain

In commerce, a supply chain is a network of facilities that procure raw materials, transform them into intermediate goods and then final products to customers through a distribution system. It refers to the network of organizations, people, acti ...

phenomenon where orders to suppliers tend to have a larger variability than sales to buyers, which results in an amplified demand variability upstream. In part, this results in increasing swings in inventory in response to shifts in consumer demand as one moves further up the supply chain. The concept first appeared in Jay Forrester

Jay Wright Forrester (July 14, 1918 – November 16, 2016) was a pioneering American computer engineer and systems scientist. He is credited with being one of the inventors of magnetic core memory, the predominant form of random-access computer ...

's ''Industrial Dynamics'' (1961) and thus it is also known as the Forrester effect. It has been described as “the observed propensity for material orders to be more variable than demand signals and for this variability to increase the further upstream a company is in a supply chain”.

Science at Stanford University

Stanford University, officially Leland Stanford Junior University, is a private research university in Stanford, California. The campus occupies , among the largest in the United States, and enrolls over 17,000 students. Stanford is consider ...

helped incorporate the concept into supply chain vernacular using a story about Volvo

The Volvo Group ( sv, Volvokoncernen; legally Aktiebolaget Volvo, shortened to AB Volvo, stylized as VOLVO) is a Swedish multinational manufacturing corporation headquartered in Gothenburg. While its core activity is the production, distributio ...

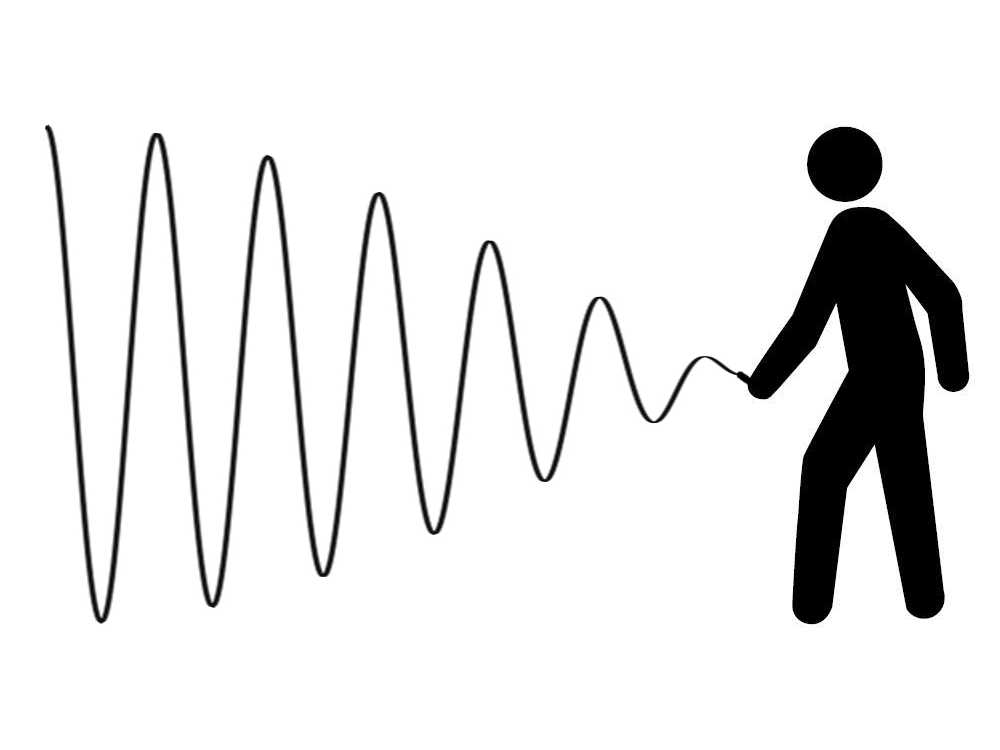

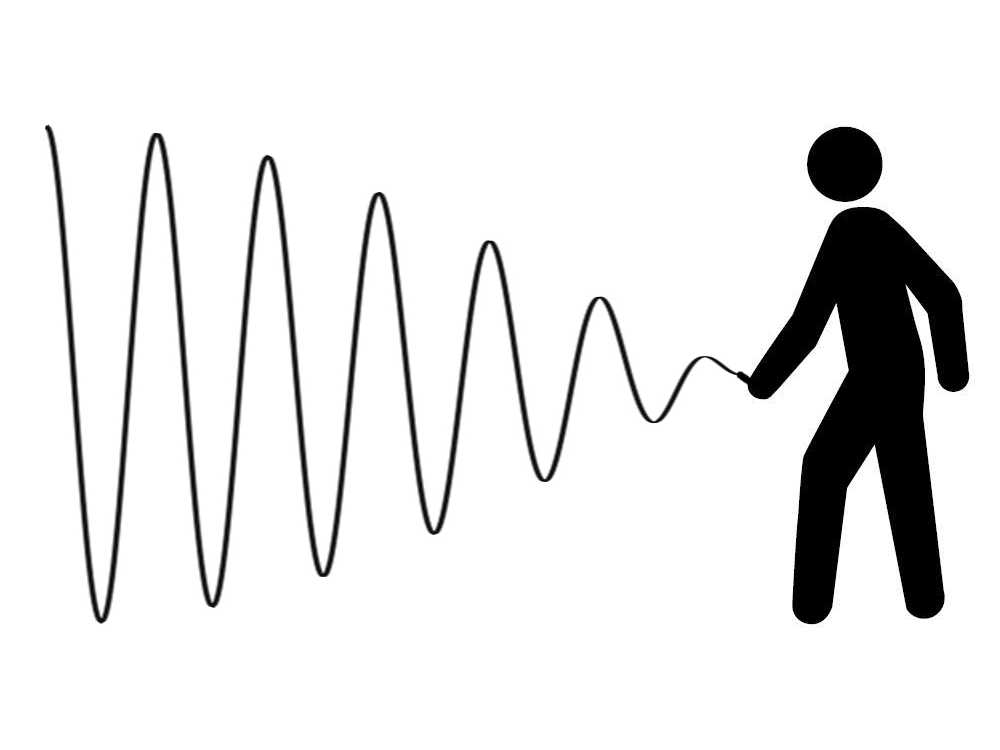

. Suffering a glut in green cars, sales and marketing developed a program to sell the excess inventory. While successful in generating the desired market pull, manufacturing did not know about the promotional plans. Instead, they read the increase in sales as an indication of growing demand for green cars and ramped up production.Chain reaction: Managing a supply chain is becoming a bit like rocket science''The Economist'', 31 January 2002 Research indicates a fluctuation in point-of-sale demand of five percent will be interpreted by supply chain participants as a change in demand of up to forty percent. Much like cracking a

whip

A whip is a tool or weapon designed to strike humans or other animals to exert control through pain compliance or fear of pain. They can also be used without inflicting pain, for audiovisual cues, such as in equestrianism. They are generally e ...

, a small flick of the wrist - a shift in point of sale demand - can cause a large motion at the end of the whip - manufacturers' responses.

Causes

Because

Because customer

In sales, commerce, and economics, a customer (sometimes known as a client, buyer, or purchaser) is the recipient of a good, service, product or an idea - obtained from a seller, vendor, or supplier via a financial transaction or exchange for ...

demand is rarely perfectly stable, business

Business is the practice of making one's living or making money by producing or Trade, buying and selling Product (business), products (such as goods and Service (economics), services). It is also "any activity or enterprise entered into for pr ...

es must forecast demand to properly position inventory and other resources. Forecasts are based on statistics, and they are rarely perfectly accurate. Because forecast errors are given, companies often carry an inventory

Inventory (American English) or stock (British English) refers to the goods and materials that a business holds for the ultimate goal of resale, production or utilisation.

Inventory management is a discipline primarily about specifying the shap ...

buffer called "safety stock

Safety stock is a term used by logistics, logisticians to describe a level of extra stock that is maintained to mitigate risk of stockouts (shortfall in raw material or packaging) caused by uncertainties in supply and demand. Adequate safety stock ...

".

Moving up the supply chain

In commerce, a supply chain is a network of facilities that procure raw materials, transform them into intermediate goods and then final products to customers through a distribution system. It refers to the network of organizations, people, acti ...

from end-consumer to raw material

A raw material, also known as a feedstock, unprocessed material, or primary commodity, is a basic material that is used to produce goods, finished goods, energy, or intermediate materials that are feedstock for future finished products. As feedst ...

s supplier, each supply chain participant has greater observed variation in demand and thus greater need for safety stock

Safety stock is a term used by logistics, logisticians to describe a level of extra stock that is maintained to mitigate risk of stockouts (shortfall in raw material or packaging) caused by uncertainties in supply and demand. Adequate safety stock ...

. In periods of rising demand, down-stream participants increase orders. In periods of falling demand, orders fall or stop, thereby not reducing inventory. The effect is that variations are amplified as one moves upstream in the supply chain (further from the customer). This sequence of events is well simulated by the beer distribution game

The beer distribution game (also known as the beer game) is an educational game that is used to experience typical coordination problems of a supply chain process. It reflects a role-play simulation where several participants play with each othe ...

which was developed by MIT Sloan School of Management

The MIT Sloan School of Management (MIT Sloan or Sloan) is the business school of the Massachusetts Institute of Technology, a private university in Cambridge, Massachusetts.

MIT Sloan offers bachelor's, master's, and doctoral degree programs, ...

in the 1960s.

* Disorganisation

* Lack of communication

* Free return policies

* Order batching

* Price variations

* Demand information

* Simply human greed and exaggeration

The causes can further be divided into behavioral

Behavior (American English) or behaviour (British English) is the range of actions and mannerisms made by individuals, organisms, systems or artificial entities in some environment. These systems can include other systems or organisms as well ...

and operational

An operational definition specifies concrete, replicable procedures designed to represent a construct. In the words of American psychologist S.S. Stevens (1935), "An operation is the performance which we execute in order to make known a concept." F ...

causes.

Behavioral causes

The first theories focusing onto the bullwhip effect were mainly focusing on the irrational behavior of the human in the supply chain, highlighting them as the main cause of the bullwhip effect. Since the 90’s, the studies evolved, placing the supply chain’s misfunctioning at the heart of their studies abandoning the human factors. Previous control-theoretic models have identified as causes the tradeoff between stationary and dynamic performance as well as the use of independent controllers. In accordance with Dellaert et al. (2017), one of the main behavioral causes that contribute to the bullwhip effect is the under-estimation of the pipeline. In addition, the complementary bias, over-estimation of the pipeline, also has a negative effect under such conditions. Nevertheless, it has been shown that when the demand stream is stationary, the system is relatively robust to this bias. In such situations, it has been found that biased policies (both under-estimating and over-estimating the pipeline) perform just as well as unbiased policies. Some others behavioral causes can be highlighted: * Misuse of base-stock policies * Mis-perceptions of feedback and time delays. In 1979, Buffa and Miller highlighted that in their example. If a retailer sees a permanent drop of 10% of the demand on day 1, he will not place a new order until day 10. That way, the wholesaler is going to notice the 10% drop at day 10 and will place his order on day 20. The longer the supply chain is, the bigger this delay will be and the player at the end of the supply chain will discover the decline of the demand after several weeks. * Panic ordering reactions after unmet demand * Perceived risk of other players'bounded rationality

Bounded rationality is the idea that rationality is limited when individuals make decisions, and under these limitations, rational individuals will select a decision that is satisfactory rather than optimal.

Limitations include the difficulty of ...

. Following the logic of the example of Buffa and Miller, after several weeks of producing at the classical rate, the producer will receive the information of the demand drop. As the drop was 10%, during the delay of the information’s circulation the producer had a surplus of 11% per day, accumulated since day 1. He is thus more inclined to cut more than the necessary production.

Human factors

Human factors and ergonomics (commonly referred to as human factors) is the application of psychological and physiological principles to the engineering and design of products, processes, and systems. Four primary goals of human factors learnin ...

influencing the behavior in supply chains are largely unexplored. However, studies suggest that people with increased need for safety and security seem to perform worse than risk-takers in a simulated supply chain environment. People with high self-efficacy

In psychology, self-efficacy is an individual's belief in their capacity to act in the ways necessary to reach specific goals. The concept was originally proposed by the psychologist Albert Bandura.

Self-efficacy affects every area of human endea ...

experience less trouble handling the bullwhip-effect in the supply chain.

Operational causes

A seminal Lee et. al (1997) study found that the bullwhip effect did not solely result from irrational decision making: it found that under some circumstances it is rational for a firm to order with greater variability than variability of demand, i.e., distort demand and cause the bullwhip effect. They established a list of four major factors which cause the bullwhip effect: demand signal processing, rationing game, order batching, and price variations. This list has become a standard and is used as a framework to identify bullwhip effect. *Demand forecast updating is accomplished individually by all members of a supply chain. When a player of the chain is ordering, he will automatically add to the stock he needs a safety stock to answer to an unexpected event. When the first player supplier is going to order to its own supplier, he will also add a safety stock, based on the total order of the first player. The more player there is in the chain, the safety stock will be made, resulting in an artificial raise of the demand. *Order batching. In order to minimize the cost and to simplify the logistics of a firm, most of the company prefers to accumulate the demand before doing the order. That way, they can benefit from a bigger sale on their order (economy of scale) and they have possibility to order a full truck or container which reduce greatly the transport cost. The more centralized are the orders, the more erratic the demand chart will be, it create an artificial variability in the demand, and it can influence the neighbors’ industries which is likely to increase the bullwhip effect. *Price fluctuations as a result of inflationary factors, quantity discounts, or sales tend to stimulate customers to buy larger quantities than they require. The game of sales and discount push, in the case where the sales economy is higher than the stocking expenses, the firm to buy greater amount that what they need. This increase the variability by having spikes of demand and then a flatten line the time that the exceeding stock is sold by the customer. It leads to more uncertainty by the different players and a prediction of the moment when the demand will increase. All this is leading to the bullwhip effect. If it can appear as easy to counter by stopping the important sales, a competitor would take the place by offering better prices. *Rationing and gaming is when a retailer tries to limit order quantities by providing only a percentage of the order placed by the buyer. As the buyer knows that the retailer is delivering only a fraction of the order placed, he attempts to “game” the system by making an upward adjustment to the order quantity. Rationing and gaming generate inconsistencies in the ordering information that is being received. Other operational causes include: * Dependent demand processing ** Forecast errors ** Adjustment of inventory control parameters with each demand observation *Lead time

A lead time is the latency between the initiation and completion of a process. For example, the lead time between the placement of an order and delivery of new cars by a given manufacturer might be between 2 weeks and 6 months, depending on vari ...

variability (forecast error during replenishment lead time)

* Lot-sizing/order synchronization

** Consolidation of demands

** Transaction motive

** Quantity discounts

* Trade promotion and forward buying

* Anticipation of shortages

** Allocation rule of suppliers

** Shortage gaming

** Lean and JIT style management of inventories and a chase production strategy

Consequences

In addition to greater safety stocks, the described effect can lead to either inefficient production or excessive inventory, as each producer needs to fulfill the demand of its customers in the supply chain. This also leads to a low utilization of the distribution channel. In spite of having safety stocks there is still the hazard of stock-outs which result in poor customer service and lost sales. In addition to the (financially) hard measurable consequences of poor customer services and the damage to public image and loyalty, an organization has to cope with the ramifications of failed fulfillment which may include contractual penalties. Moreover, repeated hiring and dismissal of employees to manage the demand variability induces further costs due to training and possible lay-offs. The impact of the bullwhip effect has been especially acute at the beginning stages of the COVID-19pandemic

A pandemic () is an epidemic of an infectious disease that has spread across a large region, for instance multiple continents or worldwide, affecting a substantial number of individuals. A widespread endemic (epidemiology), endemic disease wi ...

, when sudden spikes in demand for everything from medical supplies such as masks or ventilators to consumer items such as toilet paper or eggs created feedback loops of panic buying, hoarding, and rationing.

Countermeasures

Information sharing across the supply chain is an effective strategy to mitigate the bullwhip effect. For example, it has been successfully implemented inWal-Mart

Walmart Inc. (; formerly Wal-Mart Stores, Inc.) is an American multinational retail corporation that operates a chain of hypermarkets (also called supercenters), discount department stores, and grocery stores from the United States, headquarter ...

's distribution system. Individual Wal-Mart stores transmit point-of-sale

The point of sale (POS) or point of purchase (POP) is the time and place at which a retail transaction is completed. At the point of sale, the merchant calculates the amount owed by the customer, indicates that amount, may prepare an invoice f ...

(POS) data from the cash register

A cash register, sometimes called a till or automated money handling system, is a mechanical or electronic device for registering and calculating transactions at a point of sale. It is usually attached to a drawer for storing cash and other v ...

back to corporate headquarters several times a day. This demand information is used to queue shipments from the Wal-Mart distribution center to the store and from the supplier to the Wal-Mart distribution center. The result is near-perfect visibility of customer demand and inventory movement throughout the supply chain. Better information leads to better inventory positioning and lower costs throughout the supply chain.

Another recommended strategy to limit the bullwhip effect is order smoothing. Previous research has demonstrated that order smoothing and the bullwhip effect are concurrent in industry. It has been proved that order smoothing is beneficial for the system's performance when the demand is stationary. However, its impact is limited to the worst-case order amplification when the demand is unpredictable. Having said that, dynamic analysis reveals that order smoothing can degrade performance in the presence of demand shocks. The opposite bias (i.e., over-reaction to mismatches), on the other hand, degrades the stationary performance but can increase dynamic performance; controlled over-reaction can aid the system reach its new goals quickly. The system, nevertheless, is considerably sensitive to that behaviour; extreme over-reaction significantly reduces performance. Overall, unbiased policies offer in general good results under a large range of demand types. Although these policies do not result in the best performance under certain criteria. It is always possible to find a biased policy that outperforms an unbiased policy for any one performance metric.

Methods intended to reduce uncertainty, variability, and lead time:

* Vendor-managed inventory

Vendor-managed inventory (VMI) is an inventory management practice in which a supplier of goods, usually the manufacturer, is responsible for optimizing the inventory held by a distributor.

In traditional inventory management, a retailer (sometim ...

(VMI)

* Just in time replenishment (JIT)

* Demand-driven MRP

* Strategic partnership

* Information sharing

* Smooth the flow of products

** Coordinate with retailers to spread deliveries evenly

** Reduce minimum batch sizes

** Smaller and more frequent replenishments

* Eliminate pathological incentives

** Every day low price policy

** Restrict returns and order cancellations

** Order allocation based on past sales instead of current size in case of shortage

See also

*Beer distribution game

The beer distribution game (also known as the beer game) is an educational game that is used to experience typical coordination problems of a supply chain process. It reflects a role-play simulation where several participants play with each othe ...

*Forrester effect mapping

The Forrester effect map is a business technique used to analyse the disturbance on the supply chain of reorder activity.

The tool is one of the seven Value Stream Mapping tools as defined by Hines and Rich.

Forrester's research, (''Industrial ...

*PID controller

A proportional–integral–derivative controller (PID controller or three-term controller) is a control loop mechanism employing feedback that is widely used in industrial control systems and a variety of other applications requiring continuou ...

*Supply chain management

In commerce, supply chain management (SCM) is the management of the flow of goods and services including all processes that transform raw materials into final products between businesses and locations. This can include the movement and stor ...

*Damping ratio

Damping is an influence within or upon an oscillatory system that has the effect of reducing or preventing its oscillation. In physical systems, damping is produced by processes that dissipate the energy stored in the oscillation. Examples inc ...

References

* * *Literature

*Bray, Robert L., and Haim Mendelson. "Information transmission and the bullwhip effect: An empirical investigation." Management Science 58.5 (2012): 860–875. *Buffa Elwood S and Jeffrey G Miller. 1979. ''Production-Inventory Systems : Planning and Control''. 3d ed. Homewood Ill: Richard D. Irwin. *Cannella S., and Ciancimino E. (2010). On the bullwhip avoidance phase: supply chain collaboration and order smoothing. International Journal of Production Research, 48 (22), 6739-6776 *Chen, Y. F., Z. Drezner, J. K. Ryan and D. Simchi-Levi (2000), Quantifying the Bullwhip Effect in a Simple Supply Chain: The Impact of Forecasting, Lead Times and Information. Management Science, 46, 436–443. *Chen, Y. F., J. K. Ryan and D. Simchi-Levi (2000), The Impact of Exponential Smoothing Forecasts on the Bullwhip Effect. Naval Research Logistics, 47, 269–286. *Chen, Y. F., Z. Drezner, J. K. Ryan and D. Simchi-Levi (1998), The Bullwhip Effect: Managerial Insights on the Impact of Forecasting and Information on Variability in a Supply Chain. Quantitative Models for *Disney, S.M., and Towill, D.R. (2003). On the bullwhip and inventory variance produced by an ordering policy. Omega, the International Journal of Management Science, 31 (3), 157–167. *Lee, H.L., Padmanabhan, V., and Whang, S. (1997). Information distortion in a supply chain: the bullwhip effect. Management Science, 43 (4), 546–558. *Lee, H.L. (2010). Taming the bullwhip. Journal of Supply Chain Management 46 (1), pp. 7–7. *Supply Chain Management, S. Tayur, R. Ganeshan and M. Magazine, eds., Kluwer, pp. 417–439. *Selwyn, B. (2008) Bringing Social Relations Back In: (re)Conceptualising the 'Bullwhip Effect' in global commodity chains. International Journal of Management Concepts and Philosophy, 3 (2)156-175. *Tempelmeier, H. (2006). Inventory Management in Supply Networks—Problems, Models, Solutions, Norderstedt:Books on Demand. {{ISBN, 3-8334-5373-7.External links

What the “beer game” can teach about supply chain challenges

segment from the Jun 29, 2021 episode of

Marketplace

A marketplace or market place is a location where people regularly gather for the purchase and sale of provisions, livestock, and other goods. In different parts of the world, a marketplace may be described as a '' souk'' (from the Arabic), ' ...

with Professor Willy Shih of the Harvard Business School

Harvard Business School (HBS) is the graduate business school of Harvard University, a private research university in Boston, Massachusetts. It is consistently ranked among the top business schools in the world and offers a large full-time MBA p ...

interviewed by Kai Ryssdal

Kai Ryssdal (; born October 8, 1963) is an American radio journalist and the host of ''Marketplace'', a business program that airs weekdays on U.S. public radio stations. He also co-hosts the spinoff podcast ''Make Me Smart'' with Kimberly Adams. ...

Distribution (marketing)

Demand response

Supply chain management

Consumer behaviour