Direct Ink Writing on:

[Wikipedia]

[Google]

[Amazon]

Robocasting (also known as robotic material extrusion) is an

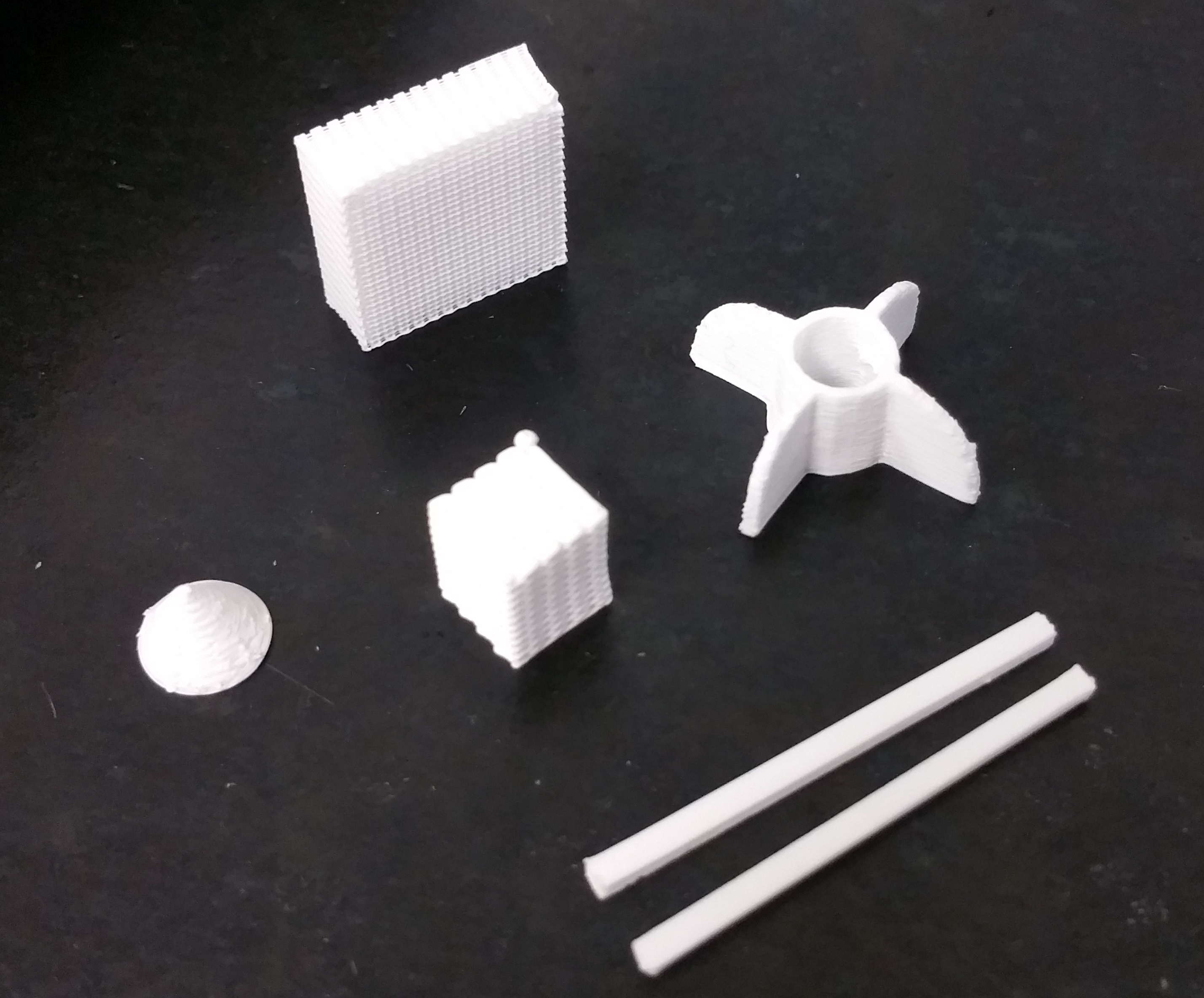

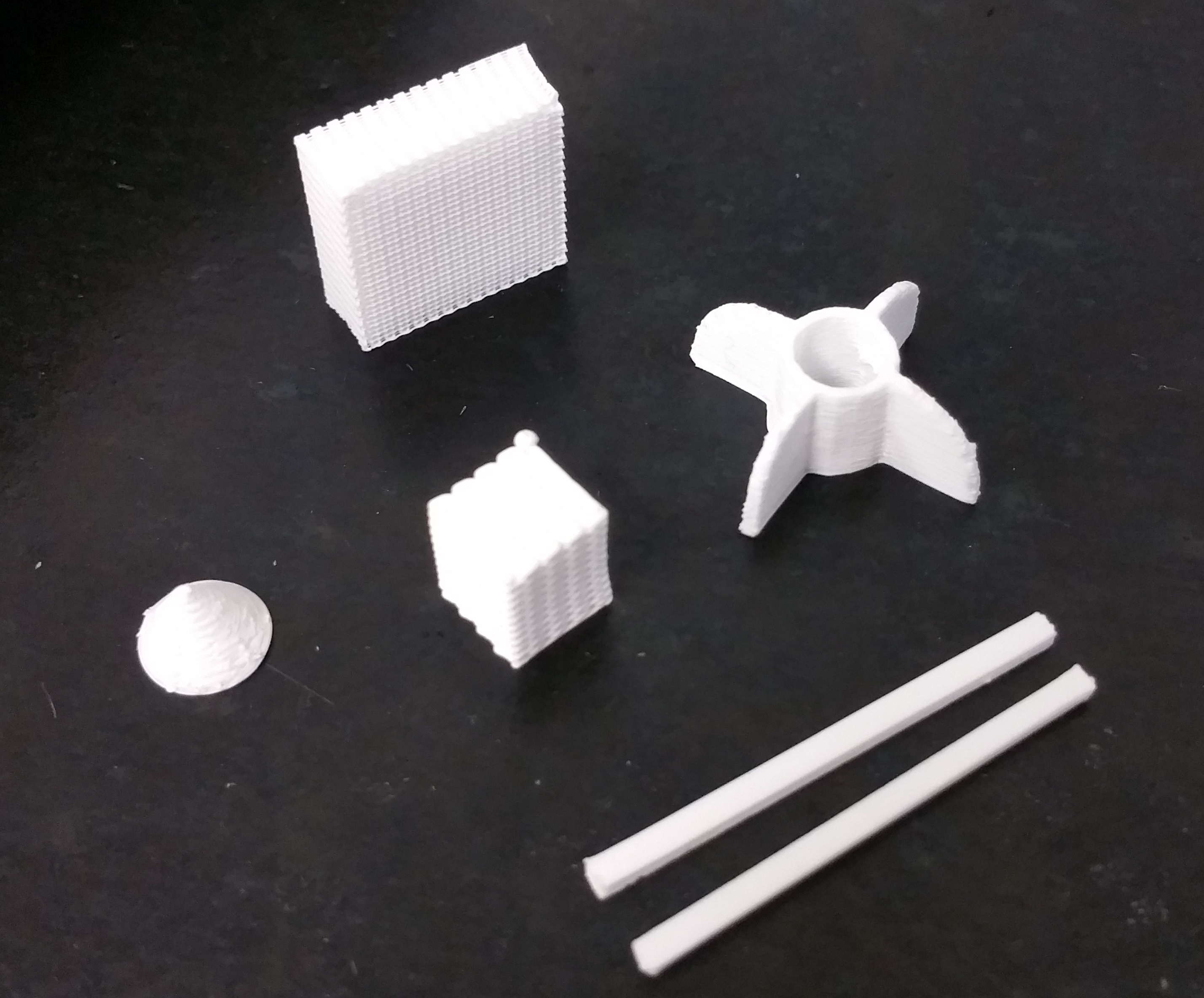

The technique can produce non-dense ceramic bodies which can be fragile and must be sintered before they can be used for most applications, analogous to a wet clay ceramic pot before being fired. A wide variety of different geometries can be formed from the technique, from solid monolithic parts to intricate microscale "scaffolds", and tailored composite materials. A heavily-researched application for robocasting is in the production of biologically compatible tissue implants. "Woodpile" stacked lattice structures can be formed quite easily which allow bone and other tissues in the human body to grow and eventually replace the transplant. With various medical scanning techniques the precise shape of the missing tissue was established and input into 3D modelling software and printed.

The technique can produce non-dense ceramic bodies which can be fragile and must be sintered before they can be used for most applications, analogous to a wet clay ceramic pot before being fired. A wide variety of different geometries can be formed from the technique, from solid monolithic parts to intricate microscale "scaffolds", and tailored composite materials. A heavily-researched application for robocasting is in the production of biologically compatible tissue implants. "Woodpile" stacked lattice structures can be formed quite easily which allow bone and other tissues in the human body to grow and eventually replace the transplant. With various medical scanning techniques the precise shape of the missing tissue was established and input into 3D modelling software and printed.

additive manufacturing

3D printing or additive manufacturing is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer co ...

technique analogous to Direct Ink Writing and other extrusion-based 3D-printing techniques in which a filament of a paste-like material is extruded

Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex c ...

from a small nozzle while the nozzle is moved across a platform. The object is thus built by printing the required shape layer by layer. The technique was first developed in the United States

The United States of America (U.S.A. or USA), commonly known as the United States (U.S. or US) or America, is a country primarily located in North America. It consists of 50 states, a federal district, five major unincorporated territori ...

in 1996 as a method to allow geometrically complex ceramic green bodies to be produced by additive manufacturing. In robocasting, a 3D CAD model is divided up into layers in a similar manner to other additive manufacturing techniques. The material (typically a ceramic slurry) is then extruded through a small nozzle as the nozzle's position is controlled, drawing out the shape of each layer of the CAD model. The material exits the nozzle in a liquid-like state but retains its shape immediately, exploiting the rheological property of shear thinning

In rheology, shear thinning is the non-Newtonian behavior of fluids whose viscosity decreases under shear strain. It is sometimes considered synonymous for pseudo-plastic behaviour, and is usually defined as excluding time-dependent effects, s ...

. It is distinct from fused deposition modelling

Fused filament fabrication (FFF), also known as fused deposition modeling (with the trademarked acronym FDM), or called ''filament freeform fabrication'', is a 3D printing process that uses a continuous filament of a thermoplastic material. Filam ...

as it does not rely on the solidification or drying to retain its shape after extrusion.

Process

Robocasting begins with a software process. One method is importing an STL file and slicing that shape into layers of similar thickness to the nozzle diameter. The part is produced by extruding a continuous filament of material in the shape required to fill the first layer. Next, either the stage is moved down or the nozzle is moved up and the next layer is deposited in the required pattern. This is repeated until the 3D part is complete. Numerically controlled mechanisms are typically used to move the nozzle in a calculated tool-path generated by acomputer-aided manufacturing

Computer-aided manufacturing (CAM) also known as computer-aided modeling or computer-aided machining is the use of software to control machine tools in the manufacturing of work pieces. This is not the only definition for CAM, but it is the most ...

(CAM) software package. Stepper motors

A stepper is a device used in the manufacture of integrated circuits (ICs) that is similar in operation to a slide projector or a photographic enlarger. ''Stepper'' is short for step-and-repeat camera. Steppers are an essential part of the comp ...

or servo motors

A servomotor (or servo motor) is a rotary actuator or linear actuator that allows for precise control of angular or linear position, velocity and acceleration. It consists of a suitable motor coupled to a sensor for position feedback. It also ...

are usually employed to move the nozzle with precision as fine as nanometers.

The part is typically very fragile and soft at this point. Drying, debinding and sintering

Clinker nodules produced by sintering

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction.

Sintering happens as part of a manufacturing ...

usually follow to give the part the desired mechanical properties.

Depending on the material composition, printing speed and printing environment, robocasting can typically deal with moderate overhangs and large spanning regions many times the filament diameter in length, where the structure is unsupported from below. This allows intricate periodic 3D scaffolds to be printed with ease, a capability which is not possessed by other additive manufacturing techniques. These parts have shown extensive promise in fields of photonic crystals

A photonic crystal is an optical nanostructure in which the refractive index changes periodically. This affects the propagation of light in the same way that the structure of natural crystals gives rise to X-ray diffraction and that the atomic ...

, bone transplants, catalyst supports, and filters. Furthermore, supporting structures can also be printed from a "fugitive material" which is easily removed. This allows almost any shape to be printed in any orientation.

Applications

The technique can produce non-dense ceramic bodies which can be fragile and must be sintered before they can be used for most applications, analogous to a wet clay ceramic pot before being fired. A wide variety of different geometries can be formed from the technique, from solid monolithic parts to intricate microscale "scaffolds", and tailored composite materials. A heavily-researched application for robocasting is in the production of biologically compatible tissue implants. "Woodpile" stacked lattice structures can be formed quite easily which allow bone and other tissues in the human body to grow and eventually replace the transplant. With various medical scanning techniques the precise shape of the missing tissue was established and input into 3D modelling software and printed.

The technique can produce non-dense ceramic bodies which can be fragile and must be sintered before they can be used for most applications, analogous to a wet clay ceramic pot before being fired. A wide variety of different geometries can be formed from the technique, from solid monolithic parts to intricate microscale "scaffolds", and tailored composite materials. A heavily-researched application for robocasting is in the production of biologically compatible tissue implants. "Woodpile" stacked lattice structures can be formed quite easily which allow bone and other tissues in the human body to grow and eventually replace the transplant. With various medical scanning techniques the precise shape of the missing tissue was established and input into 3D modelling software and printed. Calcium phosphate

The term calcium phosphate refers to a family of materials and minerals containing calcium ions (Ca2+) together with inorganic phosphate anions. Some so-called calcium phosphates contain oxide and hydroxide as well. Calcium phosphates are whi ...

glasses and hydroxyapatite have been extensively explored as candidate materials due to their biocompatibility and structural similarity to bone.

Other potential applications include the production of specific high surface area structures, such as catalyst beds or fuel cell electrolytes. Advanced metal matrix- and ceramic matrix- load bearing composites can be formed by infiltrating woodpile bodies with molten glasses, alloys or slurries.

Robocasting has also been used to deposit polymer and sol-gel inks through much finer nozzle diameters (less than 2 μm) than is possible with ceramic inks.

References

External links

* {{emerging technologies, topics=yes, robotics=yes, manufacture=yes, materials=yes Ceramic engineering 3D printing processes Articles containing video clips 1996 introductions American inventions 1996 establishments in the United States