Chemical-mechanical polishing on:

[Wikipedia]

[Google]

[Amazon]

Chemical mechanical polishing (CMP) or planarization is a process of smoothing surfaces with the combination of chemical and mechanical forces. It can be thought of as a hybrid of chemical etching and free

The process uses an

The process uses an

abrasive

An abrasive is a material, often a mineral, that is used to shape or finish a workpiece through rubbing which leads to part of the workpiece being worn away by friction. While finishing a material often means polishing it to gain a smooth, reflec ...

polishing.

Description

The process uses an

The process uses an abrasive

An abrasive is a material, often a mineral, that is used to shape or finish a workpiece through rubbing which leads to part of the workpiece being worn away by friction. While finishing a material often means polishing it to gain a smooth, reflec ...

and corrosive chemical slurry

A slurry is a mixture of denser solids suspended in liquid, usually water. The most common use of slurry is as a means of transporting solids or separating minerals, the liquid being a carrier that is pumped on a device such as a centrifugal p ...

(commonly a colloid

A colloid is a mixture in which one substance consisting of microscopically dispersed insoluble particles is suspended throughout another substance. Some definitions specify that the particles must be dispersed in a liquid, while others extend ...

) in conjunction with a polishing

Polishing is the process of creating a smooth and shiny surface by rubbing it or by applying a chemical treatment, leaving a clean surface with a significant specular reflection (still limited by the index of refraction of the material accordin ...

pad and retaining ring, typically of a greater diameter than the wafer. The pad and wafer are pressed together by a dynamic polishing head and held in place by a plastic retaining ring. The dynamic polishing head is rotated with different axes of rotation (i.e., not concentric

In geometry, two or more objects are said to be concentric, coaxal, or coaxial when they share the same center or axis. Circles, regular polygons and regular polyhedra, and spheres may be concentric to one another (sharing the same center p ...

). This removes material and tends to even out any irregular topography

Topography is the study of the forms and features of land surfaces. The topography of an area may refer to the land forms and features themselves, or a description or depiction in maps.

Topography is a field of geoscience and planetary sc ...

, making the wafer flat or planar. This may be necessary to set up the wafer for the formation of additional circuit elements. For example, CMP can bring the entire surface within the depth of field

The depth of field (DOF) is the distance between the nearest and the furthest objects that are in acceptably sharp focus in an image captured with a camera.

Factors affecting depth of field

For cameras that can only focus on one object dis ...

of a photolithography

In integrated circuit manufacturing, photolithography or optical lithography is a general term used for techniques that use light to produce minutely patterned thin films of suitable materials over a substrate, such as a silicon wafer, to protec ...

system, or selectively remove material based on its position. Typical depth-of-field requirements are down to Angstrom

The angstromEntry "angstrom" in the Oxford online dictionary. Retrieved on 2019-03-02 from https://en.oxforddictionaries.com/definition/angstrom.Entry "angstrom" in the Merriam-Webster online dictionary. Retrieved on 2019-03-02 from https://www.m ...

levels for the latest 22 nm technology.

Working principles

Physical action

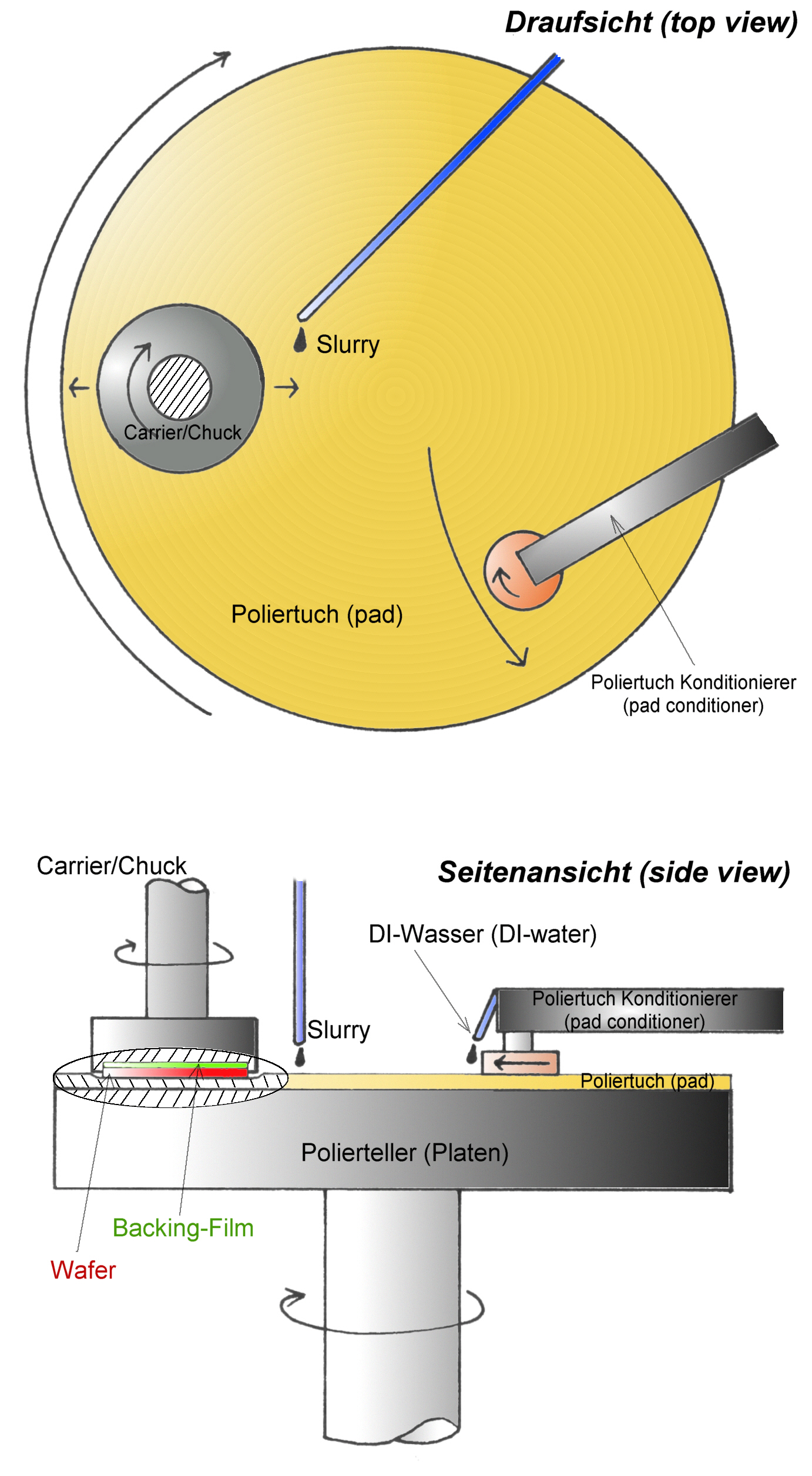

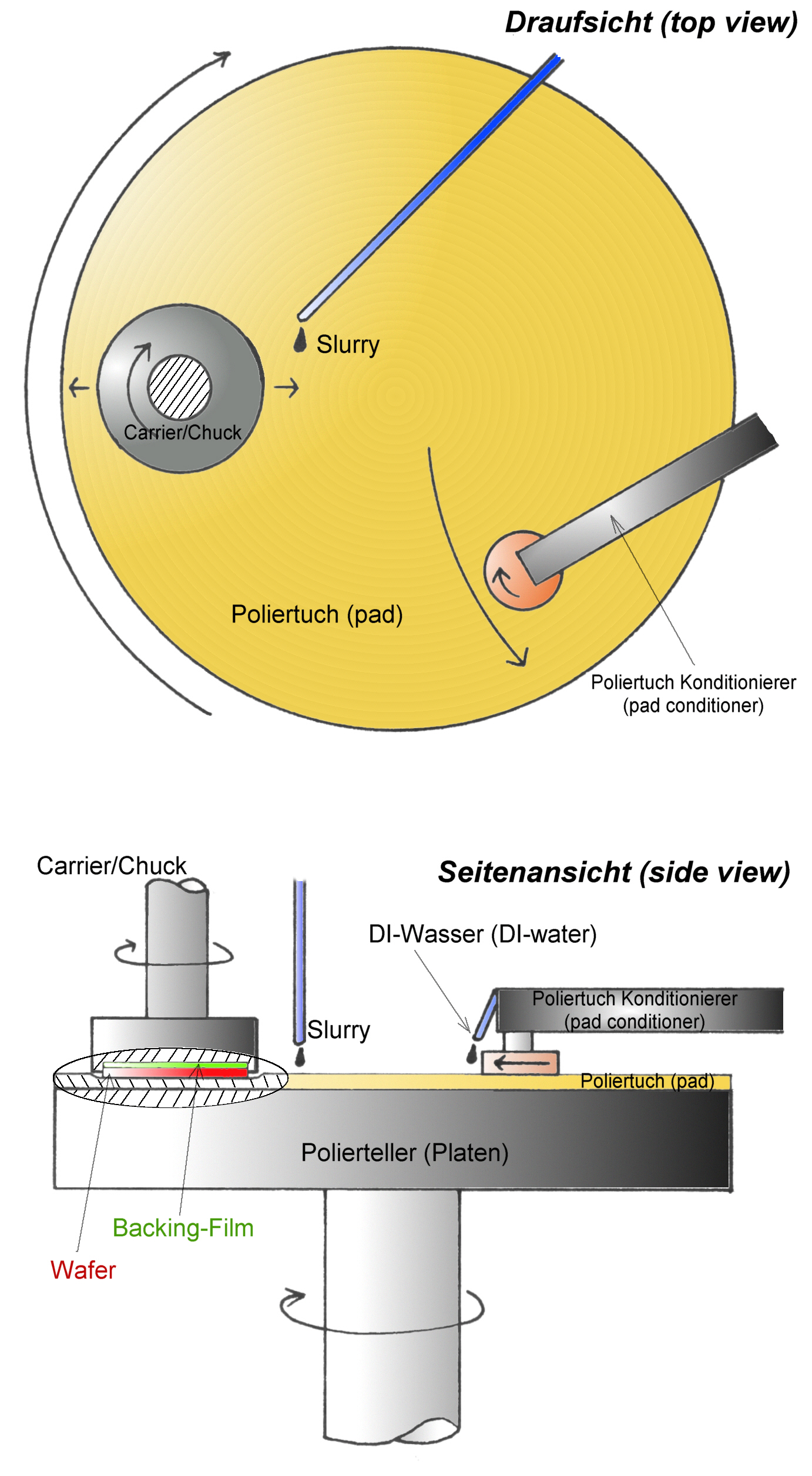

Typical CMP tools, such as the ones seen on the right, consist of rotating an extremely flat plate which is covered by a pad. The wafer that is being polished is mounted upside-down in a carrier/spindle on a backing film. The retaining ring (Figure 1) keeps the wafer in the correct horizontal position. During the process of loading and unloading the wafer onto the tool, thewafer

A wafer is a crisp, often sweet, very thin, flat, light and dry biscuit, often used to decorate ice cream, and also used as a garnish on some sweet dishes. Wafers can also be made into cookies with cream flavoring sandwiched between them. They ...

is held by vacuum by the carrier to prevent unwanted particles from building up on the wafer surface. A slurry

A slurry is a mixture of denser solids suspended in liquid, usually water. The most common use of slurry is as a means of transporting solids or separating minerals, the liquid being a carrier that is pumped on a device such as a centrifugal p ...

introduction mechanism deposits the slurry on the pad, represented by the slurry supply in Figure 1. Both the plate and the carrier are then rotated and the carrier is kept oscillating; this can be better seen in the top view of Figure 2. A downward pressure/down force is applied to the carrier, pushing it against the pad; typically the down force is an average force, but local pressure is needed for the removal mechanisms. Down force depends on the contact area which, in turn, is dependent on the structures of both the wafer and the pad. Typically the pads have a roughness of 50 μm; contact is made by asperities (which typically are the high points on the wafer) and, as a result, the contact area is only a fraction of the wafer area. In CMP, the mechanical properties of the wafer itself must be considered too. If the wafer has a slightly bowed structure, the pressure will be greater on the edges than it would on the center, which causes non-uniform polishing. In order to compensate for the wafer bow, pressure can be applied to the wafer's backside which, in turn, will equalize the centre-edge differences. The pads used in the CMP tool should be rigid in order to uniformly polish the wafer surface. However, these rigid pads must be kept in alignment with the wafer at all times. Therefore, real pads are often just stacks of soft and hard materials that conform to wafer topography to some extent. Generally, these pads are made from porous polymeric materials with a pore size between 30-50 μm, and because they are consumed in the process, they must be regularly reconditioned. In most cases the pads are very much proprietary, and are usually referred to by their trademark names rather than their chemical or other properties.

Chemical action

Chemical mechanical polishing or planarization is a process of smoothing surfaces with the combination of chemical and mechanical forces. It can be thought of as a hybrid of chemical etching and freeabrasive

An abrasive is a material, often a mineral, that is used to shape or finish a workpiece through rubbing which leads to part of the workpiece being worn away by friction. While finishing a material often means polishing it to gain a smooth, reflec ...

polishing.

Usage in semiconductor fabrication

Before about 1990 CMP was viewed as too "dirty" to be included in high-precision fabrication processes, since abrasion tends to create particles and the abrasives themselves are not without impurities. Since that time, theintegrated circuit

An integrated circuit or monolithic integrated circuit (also referred to as an IC, a chip, or a microchip) is a set of electronic circuits on one small flat piece (or "chip") of semiconductor material, usually silicon. Large numbers of tiny ...

industry has moved from aluminum

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. It ha ...

to copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pink ...

conductors. This required the development of an ''additive patterning'' process, which relies on the unique abilities of CMP to remove material in a planar and uniform fashion and to stop repeatably at the interface between copper and oxide insulating layers (see Copper interconnects

In semiconductor technology, copper interconnects are interconnects made of copper. They are used in silicon integrated circuits (ICs) to reduce propagation delays and power consumption. Since copper is a better conductor than aluminium, ICs usin ...

for details). Adoption of this process has made CMP processing much more widespread. In addition to aluminum and copper, CMP processes have been developed for polishing tungsten, silicon dioxide, and (recently) carbon nanotubes.Awano,Y.: (2006), "Carbon Nanotube (CNT) Via Interconnect Technologies: Low temperature CVD growth and chemical mechanical planarization for vertically aligned CNTs". ''Proc. 2006 ICPT'', 10

Limitations

There are currently several limitations of CMP that appear during the polishing process requiring optimization of a new technology. In particular, an improvement in wafer metrology is required. In addition, it was discovered that the CMP process has several potential defects including stress cracking, delaminating at weak interfaces, and corrosive attacks fromslurry

A slurry is a mixture of denser solids suspended in liquid, usually water. The most common use of slurry is as a means of transporting solids or separating minerals, the liquid being a carrier that is pumped on a device such as a centrifugal p ...

chemicals. The oxide polishing process, which is the oldest and most used in today's industry, has one problem: a lack of end points requires blind polishing, making it hard to determine when the desired amount of material has been removed or the desired degree of planarization has been obtained. If the oxide layer has not been sufficiently thinned and/or the desired degree of planarity has not been achieved during this process, then (theoretically) the wafer can be repolished, but in a practical sense this is unattractive in production and is to be avoided if at all possible. If the oxide thickness is too thin or too non-uniform, then the wafer must be reworked, an even less attractive process and one that is likely to fail. Obviously, this method is time-consuming and costly since technicians have to be more attentive while performing this process.

Application

Shallow trench isolation

Shallow trench isolation (STI), also known as box isolation technique, is an integrated circuit feature which prevents electric current leakage between adjacent semiconductor device components. STI is generally used on CMOS process technology ...

(STI), a process used to fabricate semiconductor devices, is a technique used to enhance the isolation between devices and active areas. Moreover, STI has a higher degree of planarity making it essential in photolithographic

In integrated circuit manufacturing, photolithography or optical lithography is a general term used for techniques that use light to produce minutely patterned thin films of suitable materials over a substrate, such as a silicon wafer, to protect ...

applications, depth of focus budget by decreasing minimum line width. To planarize shallow trenches, a common method should be used such as the combination of resist etching-back (REB) and chemical mechanical polishing (CMP). This process comes in a sequence pattern as follows. First, the isolation trench pattern is transferred to the silicon wafer. Oxide is deposited on the wafer in the shape of trenches. A photo mask, composed of silicon nitride

Silicon nitride is a chemical compound of the elements silicon and nitrogen. is the most thermodynamically stable and commercially important of the silicon nitrides, and the term "silicon nitride" commonly refers to this specific composition. It ...

, is patterned on the top of this sacrificial oxide. A second layer is added to the wafer to create a planar surface. After that, the silicon is thermally oxidized, so the oxide grows in regions where there is no Si3N4 and the growth is between 0.5 and 1.0 μm thick. Since the oxidizing species such as water or oxygen are unable to diffuse through the mask, the nitride prevents the oxidation. Next, the etching process is used to etch the wafer and leave a small amount of oxide in the active areas. In the end, CMP is used to polish the SiO2 overburden with an oxide on the active area.

See also

*Etching (microfabrication)

Etching is used in microfabrication to chemically remove layers from the surface of a wafer during manufacturing. Etching is a critically important process module, and every wafer undergoes many etching steps before it is complete.

For many etch ...

*RCA clean

The RCA clean is a standard set of wafer cleaning steps which need to be performed before high-temperature processing steps ( oxidation, diffusion, CVD) of silicon wafers in semiconductor manufacturing.

Werner Kern developed the basic procedure ...

References

Books

*Silicon processing for the VLSI Era — Vol. IV ''Deep-submicron Process Technology'' — S Wolf, 2002, {{ISBN, 978-0-9616721-7-1, Chapter 8 "Chemical mechanical polishing" pp. 313–432External links

* "CMP, chemical mechanical planarization, polishing equipment", by Crystec Technology Trading GmbH obtained from: http://www.crystec.com/alpovere.htm * "Chemical Mechanical Planarization", by Dr. Wang Zengfeng, Dr. Yin Ling, Ng Sum Huan, and Teo Phaik Luan obtained from: http://maltiel-consulting.com/CMP-Chemical-mechanical_planarization_maltiel_semiconductor.pdf Semiconductor device fabrication