In

materials science, ceramic matrix composites (CMCs) are a subgroup of

composite material

A composite material (also called a composition material or shortened to composite, which is the common name) is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or ...

s and a subgroup of

ceramic

A ceramic is any of the various hard, brittle, heat-resistant and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcelain, ...

s. They consist of ceramic

fiber

Fiber or fibre (from la, fibra, links=no) is a natural or artificial substance that is significantly longer than it is wide. Fibers are often used in the manufacture of other materials. The strongest engineering materials often incorporate ...

s embedded in a ceramic

matrix

Matrix most commonly refers to:

* ''The Matrix'' (franchise), an American media franchise

** '' The Matrix'', a 1999 science-fiction action film

** "The Matrix", a fictional setting, a virtual reality environment, within ''The Matrix'' (franchi ...

. The fibers and the matrix both can consist of any ceramic material, whereby

carbon

Carbon () is a chemical element with the symbol C and atomic number 6. It is nonmetallic and tetravalent—its atom making four electrons available to form covalent chemical bonds. It belongs to group 14 of the periodic table. Carbon ma ...

and

carbon fiber

Carbon fiber-reinforced polymers (American English), carbon-fibre-reinforced polymers (Commonwealth English), carbon-fiber-reinforced plastics, carbon-fiber reinforced-thermoplastic (CFRP, CRP, CFRTP), also known as carbon fiber, carbon compo ...

s can also be regarded as a ceramic material.

Introduction

The motivation to develop CMCs was to overcome the problems associated with the conventional technical ceramics like

alumina,

silicon carbide

Silicon carbide (SiC), also known as carborundum (), is a hard chemical compound containing silicon and carbon. A semiconductor, it occurs in nature as the extremely rare mineral moissanite, but has been mass-produced as a powder and crystal s ...

,

aluminum nitride,

silicon nitride

Silicon nitride is a chemical compound of the elements silicon and nitrogen. is the most thermodynamically stable and commercially important of the silicon nitrides, and the term "silicon nitride" commonly refers to this specific composition. It ...

or

zirconia

Zirconium dioxide (), sometimes known as zirconia (not to be confused with zircon), is a white crystalline oxide of zirconium. Its most naturally occurring form, with a monoclinic crystalline structure, is the mineral baddeleyite. A dopant ...

– they

fracture

Fracture is the separation of an object or material into two or more pieces under the action of stress. The fracture of a solid usually occurs due to the development of certain displacement discontinuity surfaces within the solid. If a displ ...

easily under mechanical or thermo-mechanical loads because of cracks initiated by small defects or scratches. The crack resistance is very low, as in glass. To increase the crack resistance or

fracture toughness

In materials science, fracture toughness is the critical stress intensity factor of a sharp crack where propagation of the crack suddenly becomes rapid and unlimited. A component's thickness affects the constraint conditions at the tip of a ...

, particles (so-called

monocrystalline ''whiskers'' or ''platelets'') were embedded into the matrix. However, the improvement was limited, and the products have found application only in some ceramic cutting tools. So far only the integration of long multi-strand fibers has drastically increased the crack resistance,

elongation and

thermal shock resistance, and resulted in several new applications. The reinforcements used in ceramic matrix composites (CMC) serve to enhance the fracture toughness of the combined material system while still taking advantage of the inherent high strength and Young’s modulus of the ceramic matrix. The most common reinforcement embodiment is a continuous-length ceramic fiber, with an elastic modulus that is typically somewhat lower than the matrix. The functional role of this fiber is (1) to increase the CMC stress for the progress of micro-cracks through the matrix, thereby increasing the energy expended during crack propagation; and then (2) when thru-thickness cracks begin to form across the CMC at higher stress (proportional limit stress, PLS), to bridge these cracks without fracturing, thereby providing the CMC with a high ultimate tensile strength (UTS). In this way, ceramic fiber reinforcements not only increase the composite structure’s initial resistance to crack propagation but also allow the CMC to avoid abrupt brittle failure that is characteristic of monolithic ceramics. This behavior is distinct from the behavior of ceramic fibers in

polymer matrix composites (PMC) and

metal matrix composites (MMC), where the fibers typically fracture before the matrix due to the higher failure strain capabilities of these matrices.

Carbon

Carbon () is a chemical element with the symbol C and atomic number 6. It is nonmetallic and tetravalent—its atom making four electrons available to form covalent chemical bonds. It belongs to group 14 of the periodic table. Carbon ma ...

(C), special

silicon carbide

Silicon carbide (SiC), also known as carborundum (), is a hard chemical compound containing silicon and carbon. A semiconductor, it occurs in nature as the extremely rare mineral moissanite, but has been mass-produced as a powder and crystal s ...

(SiC),

alumina () and

mullite () fibers are most commonly used for CMCs. The matrix materials are usually the same, that is C, SiC, alumina and mullite. In certain ceramic systems, including SiC and

silicon nitride

Silicon nitride is a chemical compound of the elements silicon and nitrogen. is the most thermodynamically stable and commercially important of the silicon nitrides, and the term "silicon nitride" commonly refers to this specific composition. It ...

, processes of

abnormal grain growth may result in a microstructure exhibiting elongated large grains in a matrix of finer rounded grains.

AGG

Agg or AGG may refer to:

As an acronym:

* Anti-Grain Geometry, computer graphics rendering library

* Aesthetic group gymnastics, gymnastics In a group

* Abnormal grain growth, materials science phenomenon

* Art Gallery of Guelph

* AGG (programmin ...

derived microstructures exhibit toughening due to crack bridging and crack deflection by the elongated grains, which can be considered as an in-situ produced fibre reinforcement. Recently

Ultra-high-temperature ceramics (UHTCs) were investigated as ceramic matrix in a new class of CMC so-called

Ultra-high Temperature Ceramic Matrix Composites (UHTCMC) or Ultra-high Temperature Ceramic Composites (UHTCC).

Generally, CMC names include a combination of ''type of fiber/type of matrix''. For example, ''C/C'' stands for carbon-fiber-reinforced carbon (

carbon/carbon), or ''C/SiC'' for carbon-fiber-reinforced silicon carbide. Sometimes the manufacturing process is included, and a C/SiC composite manufactured with the liquid

polymer

A polymer (; Greek '' poly-'', "many" + '' -mer'', "part")

is a substance or material consisting of very large molecules called macromolecules, composed of many repeating subunits. Due to their broad spectrum of properties, both synthetic a ...

infiltration (LPI) process (see below) is abbreviated as ''LPI-C/SiC''.

The important commercially available CMCs are C/C, C/SiC, SiC/SiC and . They differ from conventional ceramics in the following properties, presented in more detail below:

*

Elongation to rupture up to 1%

*Strongly increased

fracture toughness

In materials science, fracture toughness is the critical stress intensity factor of a sharp crack where propagation of the crack suddenly becomes rapid and unlimited. A component's thickness affects the constraint conditions at the tip of a ...

*Extreme

thermal shock resistance

*Improved dynamical load capability

*

Anisotropic

Anisotropy () is the property of a material which allows it to change or assume different properties in different directions, as opposed to isotropy. It can be defined as a difference, when measured along different axes, in a material's physic ...

properties following the orientation of fibers

Manufacture

The manufacturing processes usually consist of the following three steps:

#Lay-up and fixation of the fibers, shaped like the desired component

#Infiltration of the matrix material

#Final

machining

Machining is a process in which a material (often metal) is cut to a desired final shape and size by a controlled material-removal process. The processes that have this common theme are collectively called subtractive manufacturing, which utilizes ...

and, if required, further treatments like

coating

A coating is a covering that is applied to the surface of an object, usually referred to as the substrate. The purpose of applying the coating may be decorative, functional, or both. Coatings may be applied as liquids, gases or solids e.g. Pow ...

or impregnation of the intrinsic

porosity

Porosity or void fraction is a measure of the void (i.e. "empty") spaces in a material, and is a fraction of the volume of voids over the total volume, between 0 and 1, or as a percentage between 0% and 100%. Strictly speaking, some tests measur ...

.

The first and the last step are almost the same for all CMCs:

In step one, the fibers, often named rovings, are arranged and fixed using techniques used in fiber-reinforced plastic materials, such as lay-up of

fabric

Textile is an umbrella term that includes various fiber-based materials, including fibers, yarns, filaments, threads, different fabric types, etc. At first, the word "textiles" only referred to woven fabrics. However, weaving is not ...

s, filament winding,

braiding and

knot

A knot is an intentional complication in cordage which may be practical or decorative, or both. Practical knots are classified by function, including hitches, bends, loop knots, and splices: a ''hitch'' fastens a rope to another object; a ...

ting. The result of this procedure is called ''fiber-preform'' or simply ''preform''.

For the second step, five different procedures are used to fill the ceramic matrix in between the fibers of the preform:

#Deposition out of a gas mixture

#

Pyrolysis

The pyrolysis (or devolatilization) process is the thermal decomposition of materials at elevated temperatures, often in an inert atmosphere. It involves a change of chemical composition. The word is coined from the Greek-derived elements '' ...

of a pre-ceramic polymer

#

Chemical reaction

A chemical reaction is a process that leads to the chemical transformation of one set of chemical substances to another. Classically, chemical reactions encompass changes that only involve the positions of electrons in the forming and breaking ...

of elements

#

Sintering

Clinker nodules produced by sintering

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction.

Sintering happens as part of a manufacturing ...

at a relatively low temperature in the range

#

Electrophoretic deposition of a ceramic powder

Procedures one, two and three find applications with non-oxide CMCs, whereas the fourth one is used for oxide CMCs; combinations of these procedures are also practiced. The fifth procedure is not yet established in industrial processes. All procedures have sub-variations, which differ in technical details. All procedures yield a porous material.

The third and final step of

machining

Machining is a process in which a material (often metal) is cut to a desired final shape and size by a controlled material-removal process. The processes that have this common theme are collectively called subtractive manufacturing, which utilizes ...

–

grinding,

drilling

Drilling is a cutting process where a drill bit is spun to cut a hole of circular cross-section in solid materials. The drill bit is usually a rotary cutting tool, often multi-point. The bit is pressed against the work-piece and rotated at ...

,

lapping

Lapping is a machining process in which two surfaces are rubbed together with an abrasive between them, by hand movement or using a machine.

Lapping often follows other subtractive processes with more aggressive material removal as a first ste ...

or

milling – has to be done with diamond tools. CMCs can also be processed with a

water jet,

laser

A laser is a device that emits light through a process of optical amplification based on the stimulated emission of electromagnetic radiation. The word "laser" is an acronym for "light amplification by stimulated emission of radiation". The ...

, or

ultrasonic machining

Ultrasonic machining is a subtractive manufacturing process that removes material from the surface of a part through high frequency, low amplitude vibrations of a tool against the material surface in the presence of fine abrasive particles. The t ...

.

Ceramic fibers

Ceramic fibers in CMCs can have a

polycrystalline structure, as in conventional ceramics. They can also be

amorphous

In condensed matter physics and materials science, an amorphous solid (or non-crystalline solid, glassy solid) is a solid that lacks the long-range order that is characteristic of a crystal.

Etymology

The term comes from the Greek language, Gr ...

or have

inhomogeneous

Homogeneity and heterogeneity are concepts often used in the sciences and statistics relating to the uniformity of a substance or organism. A material or image that is homogeneous is uniform in composition or character (i.e. color, shape, size, ...

chemical composition

A chemical composition specifies the identity, arrangement, and ratio of the elements making up a compound.

Chemical formulas can be used to describe the relative amounts of elements present in a compound. For example, the chemical formula for ...

, which develops upon pyrolysis of organic

precursor

Precursor or Precursors may refer to:

* Precursor (religion), a forerunner, predecessor

** The Precursor, John the Baptist

Science and technology

* Precursor (bird), a hypothesized genus of fossil birds that was composed of fossilized parts of u ...

s. The high process temperatures required for making CMCs preclude the use of organic,

metallic

Metallic may be a reference to:

*Metal

*Metalloid, metal-like substance

*Metallic bonding, type of chemical bonding

*Metallicity, in astronomy the proportion of elements other than helium and hydrogen in an object

*Metallic color, a color that g ...

or

glass fibers. Only fibers stable at temperatures above can be used, such as fibers of alumina, mullite, SiC, zirconia or carbon. Amorphous SiC fibers have an elongation capability above 2% – much larger than in conventional ceramic materials (0.05 to 0.10%). The reason for this property of SiC fibers is that most of them contain additional elements like

oxygen

Oxygen is the chemical element with the symbol O and atomic number 8. It is a member of the chalcogen group in the periodic table, a highly reactive nonmetal, and an oxidizing agent that readily forms oxides with most elements ...

,

titanium

Titanium is a chemical element with the symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resistant to corrosion i ...

and/or

aluminum

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. It ha ...

yielding a

tensile strength

Ultimate tensile strength (UTS), often shortened to tensile strength (TS), ultimate strength, or F_\text within equations, is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials ...

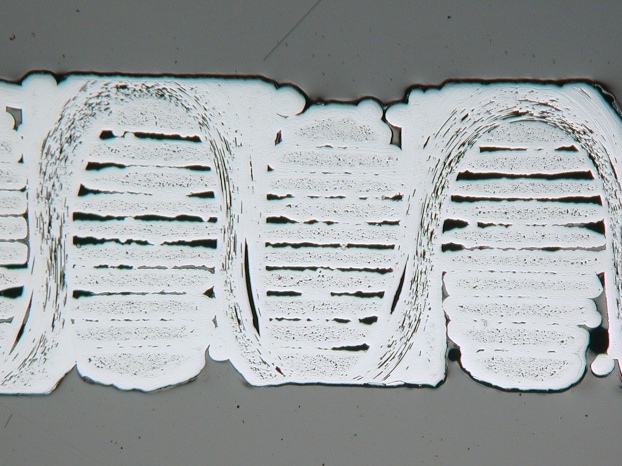

above 3 GPa. These enhanced elastic properties are required for various three-dimensional fiber arrangements (see example in figure) in

textile

Textile is an Hyponymy and hypernymy, umbrella term that includes various Fiber, fiber-based materials, including fibers, yarns, Staple (textiles)#Filament fiber, filaments, Thread (yarn), threads, different #Fabric, fabric types, etc. At f ...

fabrication, where a small bending radius is essential.

Manufacturing procedures

Matrix deposition from a gas phase

Chemical vapor deposition

Chemical vapor deposition (CVD) is a vacuum deposition method used to produce high quality, and high-performance, solid materials. The process is often used in the semiconductor industry to produce thin films.

In typical CVD, the wafer (subst ...

(CVD) is well suited for this purpose. In the presence of a fiber preform, CVD takes place in between the fibers and their individual filaments and therefore is called

chemical vapor infiltration Chemical vapour infiltration (CVI) is a ceramic engineering process whereby matrix material is infiltrated into fibrous preforms by the use of reactive gases at elevated temperature to form fiber-reinforced composites. The earliest use of CVI was th ...

(CVI). One example is the manufacture of C/C composites: a C-fiber preform is exposed to a mixture of

argon

Argon is a chemical element with the symbol Ar and atomic number 18. It is in group 18 of the periodic table and is a noble gas. Argon is the third-most abundant gas in Earth's atmosphere, at 0.934% (9340 ppmv). It is more than twice a ...

and a hydrocarbon gas (

methane

Methane ( , ) is a chemical compound with the chemical formula (one carbon atom bonded to four hydrogen atoms). It is a group-14 hydride, the simplest alkane, and the main constituent of natural gas. The relative abundance of methane ...

,

propane

Propane () is a three-carbon alkane with the molecular formula . It is a gas at standard temperature and pressure, but compressible to a transportable liquid. A by-product of natural gas processing and petroleum refining, it is commonly used as ...

, etc.) at a pressure of around or below 100 kPa and a temperature above 1000 °C. The gas decomposes depositing carbon on and between the fibers. Another example is the deposition of silicon carbide, which is usually conducted from a mixture of

hydrogen

Hydrogen is the chemical element with the symbol H and atomic number 1. Hydrogen is the lightest element. At standard conditions hydrogen is a gas of diatomic molecules having the formula . It is colorless, odorless, tasteless, non-to ...

and methyl-

trichlorosilane (MTS, ; it is also common in

silicone

A silicone or polysiloxane is a polymer made up of siloxane (−R2Si−O−SiR2−, where R = organic group). They are typically colorless oils or rubber-like substances. Silicones are used in sealants, adhesives, lubricants, medicine, cookin ...

production). Under defined condition this gas mixture deposits fine and crystalline silicon carbide on the hot surface within the preform.

This CVI procedure leaves a body with a porosity of about 10–15%, as access of reactants to the interior of the preform is increasingly blocked by deposition on the exterior.

Matrix forming via pyrolysis of C- and Si-containing polymers

Hydrocarbon

In organic chemistry, a hydrocarbon is an organic compound consisting entirely of hydrogen and carbon. Hydrocarbons are examples of group 14 hydrides. Hydrocarbons are generally colourless and hydrophobic, and their odors are usually weak or ...

polymers shrink during

pyrolysis

The pyrolysis (or devolatilization) process is the thermal decomposition of materials at elevated temperatures, often in an inert atmosphere. It involves a change of chemical composition. The word is coined from the Greek-derived elements '' ...

, and upon

outgassing

Outgassing (sometimes called offgassing, particularly when in reference to indoor air quality) is the release of a gas that was dissolved, trapped, frozen, or absorbed in some material. Outgassing can include sublimation and evaporation (which ...

form carbon with an amorphous, glass-like structure, which by additional heat treatment can be changed to a more

graphite

Graphite () is a crystalline form of the element carbon. It consists of stacked layers of graphene. Graphite occurs naturally and is the most stable form of carbon under standard conditions. Synthetic and natural graphite are consumed on la ...

-like structure. Other special polymers, known as

preceramic polymers where some carbon atoms are replaced by silicon atoms, the so-called polycarbo

silane

Silane is an inorganic compound with chemical formula, . It is a colourless, pyrophoric, toxic gas with a sharp, repulsive smell, somewhat similar to that of acetic acid. Silane is of practical interest as a precursor to elemental silicon. Sila ...

s, yield amorphous silicon carbide of more or less

stoichiometric composition. A large variety of such

silicon carbide

Silicon carbide (SiC), also known as carborundum (), is a hard chemical compound containing silicon and carbon. A semiconductor, it occurs in nature as the extremely rare mineral moissanite, but has been mass-produced as a powder and crystal s ...

,

silicon oxycarbide, silicon carbonitride and silicon oxynitride

precursors

Precursor or Precursors may refer to:

*Precursor (religion), a forerunner, predecessor

** The Precursor, John the Baptist

Science and technology

* Precursor (bird), a hypothesized genus of fossil birds that was composed of fossilized parts of unr ...

already exist and more

preceramic polymers for the fabrication of

polymer derived ceramics Polymer derived ceramics (PDCs) are ceramic materials formed by the pyrolysis of preceramic polymers, usually under inert atmosphere.

The compositions of PDCs most commonly include silicon carbide (SiC), silicon oxycarbide (SiOxCy), silicon nitri ...

are being developed.

[Wang X. et al]

Additive manufacturing of ceramics from preceramic polymers:

A versatile stereolithographic approach assisted by thiol-ene click chemistry, ''Additive Manufacturing 2019, volume 27 pages 80-90'' To manufacture a CMC material, the fiber preform is infiltrated with the chosen polymer. Subsequent

curing and pyrolysis yield a highly porous matrix, which is undesirable for most applications. Further cycles of polymer infiltration and pyrolysis are performed until the final and desired quality is achieved. Usually, five to eight cycles are necessary.

The process is called ''liquid polymer infiltration'' (LPI), or ''polymer infiltration and pyrolysis'' (PIP). Here also a porosity of about 15% is common due to the shrinking of the polymer. The porosity is reduced after every cycle.

Matrix forming via chemical reaction

With this method, one material located between the fibers reacts with a second material to form the ceramic matrix. Some conventional ceramics are also manufactured by

chemical reaction

A chemical reaction is a process that leads to the chemical transformation of one set of chemical substances to another. Classically, chemical reactions encompass changes that only involve the positions of electrons in the forming and breaking ...

s. For example, reaction-bonded

silicon nitride

Silicon nitride is a chemical compound of the elements silicon and nitrogen. is the most thermodynamically stable and commercially important of the silicon nitrides, and the term "silicon nitride" commonly refers to this specific composition. It ...

(RBSN) is produced through the reaction of silicon powder with nitrogen, and porous carbon reacts with silicon to form

reaction bonded silicon carbide, a silicon carbide which contains inclusions of a silicon phase. An example of CMC manufacture, which was introduced for the production of ceramic

brake discs, is the reaction of

silicon

Silicon is a chemical element with the symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic luster, and is a tetravalent metalloid and semiconductor. It is a member of group 14 in the periodic ...

with a porous preform of C/C. The process temperature is above , that is above the

melting point

The melting point (or, rarely, liquefaction point) of a substance is the temperature at which it changes state from solid to liquid. At the melting point the solid and liquid phase exist in equilibrium. The melting point of a substance depen ...

of silicon, and the process conditions are controlled such that the carbon fibers of the C/C-preform almost completely retain their mechanical properties. This process is called ''liquid silicon infiltration'' (LSI). Sometimes, and because of its starting point with C/C, the material is abbreviated as ''C/C-SiC''. The material produced in this process has a very low porosity of about 3%.

Matrix forming via sintering

This process is used to manufacture oxide fiber/oxide matrix CMC materials. Since most ceramic fibers cannot withstand the normal

sintering

Clinker nodules produced by sintering

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction.

Sintering happens as part of a manufacturing ...

temperatures of above , special

precursor

Precursor or Precursors may refer to:

* Precursor (religion), a forerunner, predecessor

** The Precursor, John the Baptist

Science and technology

* Precursor (bird), a hypothesized genus of fossil birds that was composed of fossilized parts of u ...

liquids are used to infiltrate the preform of oxide fibers. These precursors allow sintering, that is ceramic-forming processes, at temperatures of 1000–1200 °C. They are, for example, based on mixtures of alumina powder with the liquids tetra-ethyl-ortho

silicate

In chemistry, a silicate is any member of a family of polyatomic anions consisting of silicon and oxygen, usually with the general formula , where . The family includes orthosilicate (), metasilicate (), and pyrosilicate (, ). The name is a ...

(as Si donor) and aluminium-

butyl

In organic chemistry, butyl is a four- carbon alkyl radical or substituent group with general chemical formula , derived from either of the two isomers (''n''-butane and isobutane) of butane.

The isomer ''n''-butane can connect in two ways, gi ...

ate (as Al donor), which yield a mullite matrix. Other techniques, such as

sol–gel process chemistry, are also used. CMCs obtained with this process usually have a high porosity of about 20%.

Matrix formed via electrophoresis

In the

electrophoretic process, electrically charged particles dispersed in a special liquid are transported through an

electric field

An electric field (sometimes E-field) is the physical field that surrounds electrically charged particles and exerts force on all other charged particles in the field, either attracting or repelling them. It also refers to the physical field ...

into the preform, which has the opposite electrical charge polarity. This process is under development, and is not yet used industrially. Some remaining porosity must be expected here, too.

Properties

Mechanical properties

Basic mechanism of mechanical properties

The high fracture toughness or crack resistance mentioned above is a result of the following mechanism: under load the ceramic matrix cracks, like any ceramic material, at an elongation of about 0.05%. In CMCs the embedded fibers bridge these cracks (see picture). This mechanism works only when the matrix can slide along the fibers, which means that there must be a weak bond between the fibers and matrix. A strong bond would require a very high elongation capability of the fiber bridging the crack and would result in a brittle fracture, as with conventional ceramics. The production of CMC material with high crack resistance requires a step to weaken this bond between the fibers and matrix. This is achieved by depositing a thin layer of pyrolytic carbon or boron nitride on the fibers, which weakens the bond at the fiber/matrix interface, leading to the

fiber pull-out

Fiber pull-out is one of the failure mechanisms in fiber-reinforced composite materials. Other forms of failure include delamination, intralaminar matrix cracking, longitudinal matrix splitting, fiber/matrix debonding, and fiber fracture. The ca ...

at crack surfaces, as shown in the

SEM picture at the top of this article. In oxide-CMCs, the high porosity of the matrix is sufficient to establish a weak bond.

Properties under tensile and bending loads, crack resistance

The influence and quality of the fiber interface can be evaluated through mechanical properties. Measurements of the crack resistance were performed with notched specimens (see figure) in so-called single-edge-notch-bend (SENB) tests. In

fracture mechanics

Fracture mechanics is the field of mechanics concerned with the study of the propagation of cracks in materials. It uses methods of analytical solid mechanics to calculate the driving force on a crack and those of experimental solid mechanics ...

, the measured data (force, geometry and crack surface) are normalized to yield the so-called

stress intensity factor (SIF), K

Ic. Because of the complex crack surface (see figure at the top of this article) the real crack surface area can not be determined for CMC materials. The measurements, therefore, use the initial notch as the crack surface, yielding the ''formal SIF'' shown in the figure. This requires identical geometry for comparing different samples. The area under these curves thus gives a relative indication of the energy required to drive the crack tip through the sample (force times path length gives energy). The maxima indicate the load level necessary to propagate the crack through the sample. Compared to the sample of conventional SiSiC ceramic, two observations can be made:

*All tested CMC materials need up to several orders of magnitude more energy to propagate the crack through the material.

*The force required for crack propagation varies between different types of CMCs.

In the table, CVI, LPI, and LSI denote the manufacturing process of the C/SiC-material. Data on the oxide CMC and SiSiC are taken from manufacturer datasheets. The tensile strength of SiSiC and were calculated from measurements of elongation to fracture and

Young's modulus

Young's modulus E, the Young modulus, or the modulus of elasticity in tension or compression (i.e., negative tension), is a mechanical property that measures the tensile or compressive stiffness of a solid material when the force is applied ...

, since generally only bending strength data are available for those ceramics. Averaged values are given in the table, and significant differences, even within one manufacturing route, are possible.

Tensile tests of CMCs usually show nonlinear stress-strain curves, which look as if the material deforms plastically. It is called ''quasi-

plastic

Plastics are a wide range of synthetic or semi-synthetic materials that use polymers as a main ingredient. Their plasticity makes it possible for plastics to be moulded, extruded or pressed into solid objects of various shapes. This adapta ...

'', because the effect is caused by the microcracks, which are formed and bridged with increasing load. Since the

Young's modulus

Young's modulus E, the Young modulus, or the modulus of elasticity in tension or compression (i.e., negative tension), is a mechanical property that measures the tensile or compressive stiffness of a solid material when the force is applied ...

of the load-carrying fibers is generally lower than that of the matrix, the slope of the curve decreases with increasing load.

Curves from bending tests look similar to those of the crack resistance measurements shown above.

The following features are essential in evaluating bending and tensile data of CMCs:

*CMC materials with a low matrix content (down to zero) have a high

tensile strength

Ultimate tensile strength (UTS), often shortened to tensile strength (TS), ultimate strength, or F_\text within equations, is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials ...

(close to the tensile strength of the fiber), but low

bending strength

Flexural strength, also known as modulus of rupture, or bend strength, or transverse rupture strength is a material property, defined as the stress in a material just before it yields in a flexure test. The transverse bending test is most frequ ...

.

*CMC materials with a low fiber content (down to zero) have a high bending strength (close to the strength of the monolithic ceramic), but no elongation beyond 0.05% under tensile load.

The primary quality criterion for CMCs is crack resistance behavior or fracture toughness.

= High Temperature Creep Properties

=

Although CMCs are able to operate at very high temperatures,

creep deformation still occur around 1000 °C, in the range of certain high-temperature applications. Creep acts on either the matrix or fiber depending on the creep mismatch ratio (CMR) between the effective fiber strain rate and effective matrix strain rate. The component with the smaller strain rate bears the load and is susceptible to creep.

The three main creep stages are governed by the creep mismatch ratio. During primary creep,

internal stresses are transferred allowing the CMR to approach unity, as well as the secondary creep stage. The tertiary creep stage, where failure occurs, can be governed by fiber creep, where failure occurs due to fiber fracture, or matrix creep, which lead to matrix cracking. Usually, matrix creep strength is worse than the fiber, so the fiber bears the load. However, matrix cracking can still occur with weak fiber regions, resulting in

oxidation

Redox (reduction–oxidation, , ) is a type of chemical reaction in which the oxidation states of substrate change. Oxidation is the loss of electrons or an increase in the oxidation state, while reduction is the gain of electrons or ...

in oxidizing atmospheres, weakening the material. Increasing temperature, applied stress, and defect densities lead to greater creep deformation and earlier failure.

A

rule of mixtures may be applied to find the strain rate of the composite given the strain rates of the constituents. For particulates, a simple sum of the product of the cross-sectional area fraction and creep response of each constituent can determine the composite’s total creep response. For fibers, a sum of the constituents’ creep response divided by the cross-sectional area fraction determines the total creep response.

Particulates:

Fibers:

where

is the creep response and

is the constituent cross sectional area fraction.

Other mechanical properties

In many CMC components the fibers are arranged as 2-dimensional (2D) stacked

plain

In geography, a plain is a flat expanse of land that generally does not change much in elevation, and is primarily treeless. Plains occur as lowlands along valleys or at the base of mountains, as coastal plains, and as plateaus or uplands ...

or

satin weave fabric

Textile is an umbrella term that includes various fiber-based materials, including fibers, yarns, filaments, threads, different fabric types, etc. At first, the word "textiles" only referred to woven fabrics. However, weaving is not ...

s. Thus the resulting material is

anisotropic

Anisotropy () is the property of a material which allows it to change or assume different properties in different directions, as opposed to isotropy. It can be defined as a difference, when measured along different axes, in a material's physic ...

or, more specifically,

orthotropic. A crack between the layers is not bridged by fibers. Therefore, the interlaminar

shear strength

In engineering, shear strength is the strength of a material or component against the type of yield or structural failure when the material or component fails in shear. A shear load is a force that tends to produce a sliding failure on a materi ...

(ILS) and the strength perpendicular to the 2D fiber orientation are low for these materials.

Delamination

Delamination is a mode of failure where a material fractures into layers. A variety of materials including laminate composites and concrete can fail by delamination. Processing can create layers in materials such as steel formed by rolling a ...

can occur easily under certain mechanical loads. Three-dimensional fiber structures can improve this situation (see micrograph above).

The

compressive strength

In mechanics, compressive strength or compression strength is the capacity of a material or structure to withstand loads tending to reduce size (as opposed to tensile strength which withstands loads tending to elongate). In other words, compres ...

s shown in the table are lower than those of conventional ceramics, where values above 2000 MPa are common; this is a result of porosity.

The composite structure allows high dynamical loads. In the so-called low-

cycle-fatigue (LCF) or high-cycle-fatigue (HCF) tests the material experiences cyclic loads under tensile and compressive (LCF) or only tensile (HCF) load. The higher the initial stress the shorter the lifetime and the smaller the number of cycles to rupture. With an initial load of 80% of the strength, a SiC/SiC sample survived about 8 million cycles (see figure).

The

Poisson's ratio shows an anomaly when measured perpendicular to the plane of the fabric because interlaminar cracks increase the sample thickness.

Thermal and electrical properties

The thermal and electrical properties of the composite are a result of its constituents, namely fibers, matrix, and pores as well as their composition. The orientation of the fibers yields anisotropic data. Oxide CMCs are very good

electrical insulator

An electrical insulator is a material in which electric current does not flow freely. The atoms of the insulator have tightly bound electrons which cannot readily move. Other materials—semiconductors and conductors—conduct electric current ...

s, and because of their high porosity, their

thermal insulation

Thermal insulation is the reduction of heat transfer (i.e., the transfer of thermal energy between objects of differing temperature) between objects in thermal contact or in range of radiative influence. Thermal insulation can be achieved with ...

is much better than that of conventional oxide ceramics.

The use of carbon fibers increases the

electrical conductivity

Electrical resistivity (also called specific electrical resistance or volume resistivity) is a fundamental property of a material that measures how strongly it resists electric current. A low resistivity indicates a material that readily allows ...

, provided the fibers contact each other and the voltage source. The silicon carbide matrix is a good thermal conductor. Electrically, it is a

semiconductor

A semiconductor is a material which has an electrical conductivity value falling between that of a conductor, such as copper, and an insulator, such as glass. Its resistivity falls as its temperature rises; metals behave in the opposite way ...

, and its

resistance therefore decreases with increasing temperature. Compared to (poly)crystalline SiC, the amorphous SiC fibers are relatively poor conductors of heat and electricity.

Comments for the table: (p) and (v) refer to data parallel and vertical to fiber orientation of the 2D-fiber structure, respectively. LSI material has the highest

thermal conductivity

The thermal conductivity of a material is a measure of its ability to conduct heat. It is commonly denoted by k, \lambda, or \kappa.

Heat transfer occurs at a lower rate in materials of low thermal conductivity than in materials of high thermal ...

because of its low porosity – an advantage when using it for brake discs. These data are subject to scatter depending on details of the manufacturing processes.

Conventional ceramics are very sensitive to

thermal stress because of their high Young's modulus and low elongation capability. Temperature differences and low

thermal conductivity

The thermal conductivity of a material is a measure of its ability to conduct heat. It is commonly denoted by k, \lambda, or \kappa.

Heat transfer occurs at a lower rate in materials of low thermal conductivity than in materials of high thermal ...

create locally different elongations, which together with the high Young's modulus generate high stress. This results in cracks, rupture, and brittle failure. In CMCs, the fibers bridge the cracks, and the components show no macroscopic damage, even if the matrix has cracked locally. The application of CMCs in brake disks demonstrates the effectiveness of ceramic composite materials under extreme thermal shock conditions.

Corrosion properties

Data on the

corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engi ...

behaviour of CMCs are scarce except for

oxidation

Redox (reduction–oxidation, , ) is a type of chemical reaction in which the oxidation states of substrate change. Oxidation is the loss of electrons or an increase in the oxidation state, while reduction is the gain of electrons or ...

at temperatures above 1000 °C. These properties are determined by the constituents, namely the fibers and matrix. Ceramic materials, in general, are very stable to corrosion. The broad spectrum of manufacturing techniques with different sintering additives, mixtures, glass phases, and porosities are crucial for the results of corrosion tests. Less

impurities

In chemistry and materials science, impurities are chemical substances inside a confined amount of liquid, gas, or solid, which differ from the chemical composition of the material or compound. Firstly, a pure chemical should appear thermodynami ...

and exact

stoichiometry

Stoichiometry refers to the relationship between the quantities of reactants and products before, during, and following chemical reactions.

Stoichiometry is founded on the law of conservation of mass where the total mass of the reactants equ ...

lead to less corrosion. Amorphous structures and non-ceramic chemicals frequently used as sintering aids are starting points of corrosive attack.

;Alumina

Pure alumina shows excellent corrosion resistance against most chemicals. Amorphous glass and silica

phases at the grain boundaries determine the speed of corrosion in concentrated

acid

In computer science, ACID ( atomicity, consistency, isolation, durability) is a set of properties of database transactions intended to guarantee data validity despite errors, power failures, and other mishaps. In the context of databases, a se ...

s and

bases and result in

creep

Creep, Creeps or CREEP may refer to:

People

* Creep, a creepy person

Politics

* Committee for the Re-Election of the President (CRP), mockingly abbreviated as CREEP, an fundraising organization for Richard Nixon's 1972 re-election campaign

Art ...

at high temperatures. These characteristics limit the use of alumina. For molten metals, alumina is used only with gold and platinum.

;Alumina fibers

These fibers demonstrate corrosion properties similar to alumina, but commercially available fibers are not very pure and therefore less resistant. Because of creep at temperatures above 1000 °C, there are only a few applications for oxide CMCs.

;Carbon

The most significant corrosion of carbon occurs in the presence of

oxygen

Oxygen is the chemical element with the symbol O and atomic number 8. It is a member of the chalcogen group in the periodic table, a highly reactive nonmetal, and an oxidizing agent that readily forms oxides with most elements ...

above about . It burns to form

carbon dioxide

Carbon dioxide ( chemical formula ) is a chemical compound made up of molecules that each have one carbon atom covalently double bonded to two oxygen atoms. It is found in the gas state at room temperature. In the air, carbon dioxide is t ...

and/or

carbon monoxide

Carbon monoxide ( chemical formula CO) is a colorless, poisonous, odorless, tasteless, flammable gas that is slightly less dense than air. Carbon monoxide consists of one carbon atom and one oxygen atom connected by a triple bond. It is the simpl ...

. It also oxidizes in strong oxidizing agents like concentrated

nitric acid

Nitric acid is the inorganic compound with the formula . It is a highly corrosive mineral acid. The compound is colorless, but older samples tend to be yellow cast due to decomposition into oxides of nitrogen. Most commercially available ni ...

. In molten metals, it dissolves and forms metal

carbide

In chemistry, a carbide usually describes a compound composed of carbon and a metal. In metallurgy, carbiding or carburizing is the process for producing carbide coatings on a metal piece.

Interstitial / Metallic carbides

The carbides of t ...

s. Carbon fibers do not differ from carbon in their corrosion behavior.

;Silicon carbide

Pure silicon carbide is one of the most corrosion-resistant materials. Only strong bases, oxygen above about , and molten metals react with it to form carbides and

silicides. The reaction with oxygen forms and , whereby a surface layer of slows down subsequent oxidation (''

passive oxidation''). Temperatures above about and a low

partial pressure

In a mixture of gases, each constituent gas has a partial pressure which is the notional pressure of that constituent gas as if it alone occupied the entire volume of the original mixture at the same temperature. The total pressure of an ideal g ...

of oxygen result in so-called ''active oxidation'', in which CO, and gaseous SiO are formed causing rapid loss of SiC. If the SiC matrix is produced other than by CVI, corrosion-resistance is not as good. This is a consequence of porosity in the amorphous LPI, and residual silicon in the LSI-matrix.

;Silicon carbide fibers

Silicon carbide fibers are produced via pyrolysis of organic polymers, and therefore their corrosion properties are similar to those of the silicon carbide found in LPI-matrices. These fibers are thus more sensitive to bases and oxidizing media than pure silicon carbide.

Applications

CMC materials overcome the major disadvantages of conventional technical ceramics, namely brittle failure and low fracture toughness, and limited thermal shock resistance. Therefore, their applications are in fields requiring reliability at high-temperatures (beyond the capability of metals) and resistance to corrosion and wear. These include:

*

Heat shield

In thermodynamics, heat is defined as the form of energy crossing the boundary of a thermodynamic system by virtue of a temperature difference across the boundary. A thermodynamic system does not ''contain'' heat. Nevertheless, the term is al ...

systems for

space vehicles, which are needed during the

re-entry phase, where high temperatures,

thermal shock conditions and heavy vibration loads take place.

*Components for high-temperature

gas turbine

A gas turbine, also called a combustion turbine, is a type of continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part (known as the gas generator or core) and are, in the directio ...

s such as

combustion chamber

A combustion chamber is part of an internal combustion engine in which the fuel/air mix is burned. For steam engines, the term has also been used for an extension of the firebox which is used to allow a more complete combustion process.

Intern ...

s,

stator vanes,

exhaust mixer

In aviation, exhaust mixer is a feature of many turbofan engines, where the bypass (cold/slow) air is mixed with the core (hot/fast) exhaust gases, before exhausting to atmospheric pressure through a common (mixed flow) propelling nozzle.

Benefi ...

s and

turbine blades.

*Components for

burners

Burning Man is an event focused on community, art, self-expression, and self-reliance held annually in the western United States. The name of the event comes from its culminating ceremony: the symbolic burning of a large wooden effigy, referre ...

,

flame holders, and hot gas ducts, where the use of oxide CMCs has found its way.

*

Brake disks and brake system components, which experience extreme thermal shock (greater than throwing a glowing part of any material into water).

*Components for

slide bearings under heavy loads requiring high corrosion and wear resistance.

In addition to the foregoing, CMCs can be used in applications which employ conventional ceramics or in which metal components have limited

lifetimes due to corrosion or high temperatures.

Developments for applications in space

During the re-entry phase of space vehicles, the heat shield system is exposed to temperatures above for a few minutes. Only ceramic materials can survive such conditions without significant damage, and among ceramics, only CMCs can adequately handle thermal shocks. The development of CMC-based heat shield systems promises the following advantages:

*Reduced weight

*Higher load-carrying capacity of the system

*Reusability for several re-entries

*Better steering during the re-entry phase with CMC flap systems

In these applications, the high temperatures preclude the use of oxide fiber CMCs, because under the expected loads the creep would be too high. Amorphous silicon carbide fibers lose their strength due to re-

crystallization

Crystallization is the process by which solid forms, where the atoms or molecules are highly organized into a structure known as a crystal. Some ways by which crystals form are precipitating from a solution, freezing, or more rarely deposi ...

at temperatures above . Therefore, carbon fibers in a silicon carbide matrix (C/SiC) are used in development programs for these applications. The European program HERMES of

ESA, started in the 1980s and for financial reasons abandoned in 1992, has produced first results. Several follow-up programs focused on the development, manufacture, and qualification of nose cap, leading edges and steering flaps for the

NASA X-38 space vehicle.

This development program has qualified the use of C/SiC bolts and nuts and the bearing system of the flaps. The latter were ground-tested at the DLR in Stuttgart, Germany, under expected conditions of the re-entry phase: , 4

tonne

The tonne ( or ; symbol: t) is a unit of mass equal to 1000 kilograms. It is a non-SI unit accepted for use with SI. It is also referred to as a metric ton to distinguish it from the non-metric units of the short ton ( United State ...

s load, oxygen partial pressure similar to re-entry conditions, and simultaneous bearing movements of four cycles per second. A total of five re-entry phases were simulated. Design and manufacture of the two steering flaps and its bearings, screws and nuts was performed by

MT Aerospace in Augsburg, Germany based on the

CVI CVI may refer to:

Ancient history & culture

*106 (number), 106 in Roman numerals

*Cvi, a verbal formation in classical Sanskrit connected with the Devi and Vrkis feminines

Geography

*Cape Verde Islands, UNDP code

Medical conditions

*Stroke ...

-process for the production of carbon fiber reinforced silicon carbide (see manufacturing procedures above).

Furthermore, oxidation protection systems were developed and qualified to prevent burnout of the carbon fibers. After mounting of the flaps, mechanical ground tests were performed successfully by NASA in Houston, Texas, US. The next test – a real re-entry of the unmanned vehicle X-38 – was canceled for financial reasons. One of the

Space Shuttle

The Space Shuttle is a retired, partially reusable low Earth orbital spacecraft system operated from 1981 to 2011 by the U.S. National Aeronautics and Space Administration (NASA) as part of the Space Shuttle program. Its official program n ...

s would have brought the vehicle into orbit, from where it would have returned to the Earth.

These qualifications were promising for only this application. The high-temperature load lasts only around 20 minutes per re-entry, and for reusability, only about 30 cycles would be sufficient. For industrial applications in a hot gas environment, though, several hundred cycles of thermal loads and up to many thousands of hours of lifetime are required.

The

Intermediate eXperimental Vehicle (IXV), a project initiated by

ESA in 2009, is Europe's first lifting body reentry vehicle. Developed by

Thales Alenia Space

Thales Alenia Space () is a Franco-Italian aerospace manufacturer. A joint venture between the French technology corporation Thales Group (67%) and Italian defense conglomerate Leonardo (33%), the company is the largest satellite manufactur ...

, the IXV is scheduled to make its first flight in 2014 on the fourth

Vega

Vega is the brightest star in the northern constellation of Lyra. It has the Bayer designation α Lyrae, which is Latinised to Alpha Lyrae and abbreviated Alpha Lyr or α Lyr. This star is relatively close at only from the Sun, a ...

mission (VV04) over the Gulf of Guinea. More than 40 European companies contributed to its construction. The thermal protection system for the underside of the vehicle, comprising the nose, leading edges and lower surface of the wing, were designed and made by

Herakles using a ceramic matrix composite (CMC), carbon/silicon-carbide (C/SiC), in this case based on the liquid silicon infilration (LSI) process (see manufacturing procedures above). These components should have been functioned as the vehicle's heat shield during its atmospheric reentry.

The

European Commission

The European Commission (EC) is the executive of the European Union (EU). It operates as a cabinet government, with 27 members of the Commission (informally known as "Commissioners") headed by a President. It includes an administrative body ...

funded a research project, C3HARME, under the NMP-19-2015 call of

(H2020) in 2016 for the design, development, production, and testing of a new class of

Ultra-high-temperature ceramic matrix composites (UHTCMC) reinforced with silicon carbide fibers and

carbon fibers

Carbon fibers or carbon fibres (alternatively CF, graphite fiber or graphite fibre) are fibers about in diameter and composed mostly of carbon atoms. Carbon fibers have several advantages: high stiffness, high tensile strength, high stren ...

suitable for applications in severe aerospace environments such as propulsion and

Thermal protection systems (TPSs).

Developments for gas turbine components

The use of CMCs in gas turbines permit higher turbine inlet temperatures, which improves engine efficiency. Because of the complex shape of stator vanes and turbine blades, the development was first focused on the combustion chamber. In the US, a combustor made of SiC/SiC with a special SiC fiber of enhanced high-temperature stability was successfully tested for 15,000 hours. SiC oxidation was substantially reduced by the use of an oxidation protection coating consisting of several layers of oxides.

The engine collaboration between

General Electric

General Electric Company (GE) is an American multinational conglomerate founded in 1892, and incorporated in New York state and headquartered in Boston. The company operated in sectors including healthcare, aviation, power, renewable ene ...

and

Rolls-Royce studied the use of CMC stator vanes in the hot section of the F136

turbofan

The turbofan or fanjet is a type of airbreathing jet engine that is widely used in aircraft engine, aircraft propulsion. The word "turbofan" is a portmanteau of "turbine" and "fan": the ''turbo'' portion refers to a gas turbine engine which ac ...

engine, an engine which failed to beat the Pratt and Whitney F-135 for use in the

Joint Strike Fighter. The engine joint venture,

CFM International

CFM International is a 50/50 Franco-American joint venture between GE Aviation and Safran Aircraft Engines (formerly known as Snecma). It was formed to build and support the CFM56 series of turbofan engines. The company is the world’s lead ...

is using CMCs to manufacture the high-temperature turbine shrouds. General Electric is using CMCs in combustor liners, nozzles, and the high-temperature turbine shroud for its upcoming GE9X engine.

CMC parts are also being studied for stationary applications in both the cold and hot sections of the engines since stresses imposed on rotating parts would require further development effort. Generally, development continues of CMCs for use in turbines to reduce technical issues and cost reduction.

After in investment and 20 years of

research and development

Research and development (R&D or R+D), known in Europe as research and technological development (RTD), is the set of innovative activities undertaken by corporations or governments in developing new services or products, and improving existi ...

, by 2020

GE Aviation

GE Aviation, a subsidiary of General Electric, is headquartered in Evendale, Ohio, outside Cincinnati. GE Aviation is among the top aircraft engine suppliers, and offers engines for the majority of commercial aircraft. GE Aviation is part of t ...

aims to produce per year up to of CMC

prepreg

Pre-preg is a composite material made from "pre-impregnated" fibers and a ''partially cured'' polymer matrix, such as epoxy or phenolic resin, or even thermoplastic mixed with liquid rubbers or resins. The fibers often take the form of a weave an ...

and 10 t of

silicon carbide

Silicon carbide (SiC), also known as carborundum (), is a hard chemical compound containing silicon and carbon. A semiconductor, it occurs in nature as the extremely rare mineral moissanite, but has been mass-produced as a powder and crystal s ...

fiber.

Chemical vapor deposition

Chemical vapor deposition (CVD) is a vacuum deposition method used to produce high quality, and high-performance, solid materials. The process is often used in the semiconductor industry to produce thin films.

In typical CVD, the wafer (subst ...

can apply

coating

A coating is a covering that is applied to the surface of an object, usually referred to as the substrate. The purpose of applying the coating may be decorative, functional, or both. Coatings may be applied as liquids, gases or solids e.g. Pow ...

s on a laid-able fiber tape in large quantities and GE managed to

infiltrate and

cast parts with very high silicon densities, higher than 90% for

cyclic fatigue environments, thanks to thermal processing.

Environmental Barrier Coatings (EBCs) provide a barrier to the CMCs to reduce the amount of oxygen and other corrosive substances from diffusing through the surface of CMC components.

''Design Requirements for EBCs:''

* Relative coefficient match with CMC component to reduce probability of cracking

* Low volatility to minimize stead-induced corrosion/recession

* Resistant to molten ingested particulate

* High temperature capability

* Phase stability at high temperatures

* Chemical Compatibility with the CMC and additional layers

* High Hardness and toughness to protect against Foreign Object Damage (FOD) and erosion

Typically when coating with an EBC a bond coat is required to support good adhesion to the CMC component. NASA has developed a slurry based EBC which starts with a mullite-based coating before being layered with an additional 2-3 layers. In order for EBCs to actively protect the CMC surface, sintering aids must be added to the slurry coat to create a dense coating that will block the penetration of oxygen, gaseous, and molten deposits from the engine. Sintering creates a densified coating and enhances bonding and performance of the coating.

Currently, research is being done to combat common failure modes such as delamination, erosion, and cracking caused by steam or molten deposits. Delamination and cracking due to molten deposits are typically caused by the reaction with the EBC creating an unexpected microstructure leading to CTE mismatch and low toughness in that phase. Steam degradation is caused by the volatilization of the thermally grown oxide layer between the EBC and the ceramic. The steam produced from this leads to a rapid recession of SiC, i.e. degradation of the EBC. The success of EBCs are imperative to the overall success of CMC components in the gas flow of the turbine in jet engines.

''Overall benefits of EBCs:''

* Extends the life of CMC components allowing for overall cost savings in jet engine production

* Improves Oxidation Resistance of CMC components

* Provides greater oxidation resistance to CMC components exposed to gaseous compounds from the jet engine

Application of oxide CMC in burner and hot gas ducts

Oxygen-containing gas at temperatures above is rather corrosive for metal and silicon carbide components. Such components, which are not exposed to high mechanical stress, can be made of oxide CMCs, which can withstand temperatures up to . The gallery below shows the

flame holder of a

crispbread bakery

A bakery is an establishment that produces and sells flour-based food baked in an oven such as bread, cookies, cakes, donuts, pastries, and pies. Some retail bakeries are also categorized as cafés, serving coffee and tea to customers who w ...

as tested after for 15,000 hours, which subsequently operated for a total of more than 20,000 hours.

Flaps and ventilators circulating hot, oxygen-containing gases can be fabricated in the same shape as their metal equivalents. The lifetime for these oxide CMC components is several times longer than for metals, which often deform. A further example is an oxide CMC lifting gate for a sintering furnace, which has survived more than 260,000 opening cycles.

Application in brake disk

Carbon/carbon (C/C) materials have found their way into the

disc brake

A disc brake is a type of brake that uses the calipers to squeeze pairs of pads against a disc or a "rotor" to create friction. This action slows the rotation of a shaft, such as a vehicle axle, either to reduce its rotational speed or to h ...

s of

racing cars and

airplane

An airplane or aeroplane (informally plane) is a fixed-wing aircraft that is propelled forward by thrust from a jet engine, propeller, or rocket engine. Airplanes come in a variety of sizes, shapes, and wing configurations. The broad ...

s, and C/SiC brake disks manufactured by the LSI process were qualified and are commercially available for

sports car

A sports car is a car designed with an emphasis on dynamic performance, such as handling, acceleration, top speed, the thrill of driving and racing capability. Sports cars originated in Europe in the early 1900s and are currently produced by ...

s. The advantages of these C/SiC disks are:

*Very little wear, resulting in lifetime use for a car with a normal driving load of , is forecast by manufacturers.

*No

fading

In wireless communications, fading is variation of the attenuation of a signal with various variables. These variables include time, geographical position, and radio frequency. Fading is often modeled as a random process. A fading channel is ...

is experienced, even under high load.

*No surface

humidity

Humidity is the concentration of water vapor present in the air. Water vapor, the gaseous state of water, is generally invisible to the human eye. Humidity indicates the likelihood for precipitation, dew, or fog to be present.

Humidity dep ...

effect on the friction coefficient shows up, as in C/C brake disks.

*The corrosion resistance, for example to the road salt, is much better than for metal disks.

*The disk mass is only 40% of a metal disk. This translates into less unsprung and rotating mass.

The weight reduction improves shock absorber response, road-holding comfort, agility, fuel economy, and thus driving comfort.

The SiC-matrix of LSI has a very low porosity, which protects the carbon fibers quite well. Brake disks do not experience temperatures above for more than a few hours in their lifetime. Oxidation is therefore not a problem in this application. The reduction of manufacturing costs will decide the success of this application for middle-class cars.

Application in slide bearings

Conventional SiC, or sometimes the less expensive

SiSiC, have been used successfully for more than 25 years in

slide or journal bearings of

pump

A pump is a device that moves fluids (liquids or gases), or sometimes slurries, by mechanical action, typically converted from electrical energy into hydraulic energy. Pumps can be classified into three major groups according to the method they ...

s. The pumped liquid itself provides the

lubricant

A lubricant (sometimes shortened to lube) is a substance that helps to reduce friction between surfaces in mutual contact, which ultimately reduces the heat generated when the surfaces move. It may also have the function of transmitting forces, t ...

for the bearing. Very good corrosion resistance against practically all kinds of media, and very low wear and low

friction coefficients are the basis of this success. These bearings consist of a static bearing, shrink-fitted in its metallic environment, and a rotating shaft sleeve, mounted on the shaft. Under compressive stress, the ceramic static bearing has a low risk of failure, but a SiC shaft sleeve does not have this situation and must, therefore, have a large wall thickness and/or be specially designed. In large pumps with shafts in diameter, the risk of failure is higher due to the changing requirements on the pump performance – for example, load changes during operation. The introduction of SiC/SiC as a shaft sleeve material has proven to be very successful. Test rig experiments showed an almost triple specific load capability of the bearing system with a shaft sleeve made of SiC/SiC, sintered SiC as static bearing, and water at as lubricant.

[K. Gaffal, A.-K. Usbeck, W. Prechtl: ''Neue Werkstoffe ermöglichen innovative Pumpenkonzepte für die Speisewasserförderung in Kesselanlagen''. VDI-Berichte Nr. 1331, VDI-Verlag, Düsseldorf, 1997, p. 275] The specific load capacity of a bearing is usually given in

W/mm

2 and calculated as a product of the load (MPa), the surface speed of the bearing (m/s) and friction coefficient; it is equal to the power loss of the bearing system due to friction.

This slide bearing concept, namely SiC/SiC shaft sleeve and SiC bearing, has been used since 1994 in applications such as in the

boiler feedwater pumps of

power station

A power station, also referred to as a power plant and sometimes generating station or generating plant, is an industrial facility for the generation of electric power. Power stations are generally connected to an electrical grid.

Many ...

s,

which pump several thousand cubic meters of hot water to a level of , and in tubular casing pumps for

water works or seawater

desalination

Desalination is a process that takes away mineral components from saline water. More generally, desalination refers to the removal of salts and minerals from a target substance, as in soil desalination, which is an issue for agriculture. Salt ...

plants, pumping up to to a level of around .

This bearing system has been tested in pumps for

liquid oxygen

Liquid oxygen—abbreviated LOx, LOX or Lox in the aerospace, submarine and gas industries—is the liquid form of molecular oxygen. It was used as the oxidizer in the first liquid-fueled rocket invented in 1926 by Robert H. Goddard, an app ...

, for example in oxygen

turbopump

A turbopump is a propellant pump with two main components: a rotodynamic pump and a driving gas turbine, usually both mounted on the same shaft, or sometimes geared together. They were initially developed in Germany in the early 1940s. The purpo ...

s for thrust engines of space rockets, with the following results. SiC and SiC/SiC are compatible with liquid oxygen. In an auto-

ignition

Ignition may refer to:

Science and technology

* Firelighting, the human act of creating a fire for warmth, cooking and other uses

* Combustion, an exothermic chemical reaction between a fuel and an oxidant

* Fusion ignition, the point at which a ...

test according to the French standard NF 28-763, no auto-ignition was observed with powdered SiC/SiC in 20 bar pure oxygen at temperatures up to . Tests have shown that the friction coefficient is half, and wear one-fiftieth of standard metals used in this environment. A hydrostatic bearing system (see picture) has survived several hours at a speed up to 10,000 revolutions per minute, various loads, and 50 cycles of start/stop transients without any significant traces of wear.

Other applications and developments

*Thrust control flaps for military

jet engine

A jet engine is a type of reaction engine discharging a fast-moving jet (fluid), jet of heated gas (usually air) that generates thrust by jet propulsion. While this broad definition can include Rocket engine, rocket, Pump-jet, water jet, and ...

s

*Components for

fusion and

fission reactors

*Friction systems for various applications

*Nuclear applications

*heat treatment, high temperature, soldering fixtures

[J. Demmel, U. Nägele (ed.): "CFC. The perfect material for new heat treatment fixtures". European Carbon Conference 1998. Science and technology of carbon. Vol.2. Strasbourg. pp. 741-742]

References

Further reading

*

*

*

* {{cite book , title=Ceramic Matrix Composites: Materials, Modeling and Technology , publisher=Wiley , location=Hoboken , editor1-first=N. P. , editor1-last=Bansal , editor2-first=J. , editor2-last=Lamon , name-list-style=amp , date=2015 , isbn=978-1-118-23116-6

Ceramic materials

Composite materials

In materials science, ceramic matrix composites (CMCs) are a subgroup of

In materials science, ceramic matrix composites (CMCs) are a subgroup of

The influence and quality of the fiber interface can be evaluated through mechanical properties. Measurements of the crack resistance were performed with notched specimens (see figure) in so-called single-edge-notch-bend (SENB) tests. In

The influence and quality of the fiber interface can be evaluated through mechanical properties. Measurements of the crack resistance were performed with notched specimens (see figure) in so-called single-edge-notch-bend (SENB) tests. In  Tensile tests of CMCs usually show nonlinear stress-strain curves, which look as if the material deforms plastically. It is called ''quasi-

Tensile tests of CMCs usually show nonlinear stress-strain curves, which look as if the material deforms plastically. It is called ''quasi- The composite structure allows high dynamical loads. In the so-called low- cycle-fatigue (LCF) or high-cycle-fatigue (HCF) tests the material experiences cyclic loads under tensile and compressive (LCF) or only tensile (HCF) load. The higher the initial stress the shorter the lifetime and the smaller the number of cycles to rupture. With an initial load of 80% of the strength, a SiC/SiC sample survived about 8 million cycles (see figure).

The Poisson's ratio shows an anomaly when measured perpendicular to the plane of the fabric because interlaminar cracks increase the sample thickness.

The composite structure allows high dynamical loads. In the so-called low- cycle-fatigue (LCF) or high-cycle-fatigue (HCF) tests the material experiences cyclic loads under tensile and compressive (LCF) or only tensile (HCF) load. The higher the initial stress the shorter the lifetime and the smaller the number of cycles to rupture. With an initial load of 80% of the strength, a SiC/SiC sample survived about 8 million cycles (see figure).

The Poisson's ratio shows an anomaly when measured perpendicular to the plane of the fabric because interlaminar cracks increase the sample thickness.

In these applications, the high temperatures preclude the use of oxide fiber CMCs, because under the expected loads the creep would be too high. Amorphous silicon carbide fibers lose their strength due to re-

In these applications, the high temperatures preclude the use of oxide fiber CMCs, because under the expected loads the creep would be too high. Amorphous silicon carbide fibers lose their strength due to re- Conventional SiC, or sometimes the less expensive SiSiC, have been used successfully for more than 25 years in slide or journal bearings of

Conventional SiC, or sometimes the less expensive SiSiC, have been used successfully for more than 25 years in slide or journal bearings of