Ceramic knife on:

[Wikipedia]

[Google]

[Amazon]

A ceramic knife is a

Zirconium oxide is used due to its polymorphism. It exists in three phases:

Zirconium oxide is used due to its polymorphism. It exists in three phases:

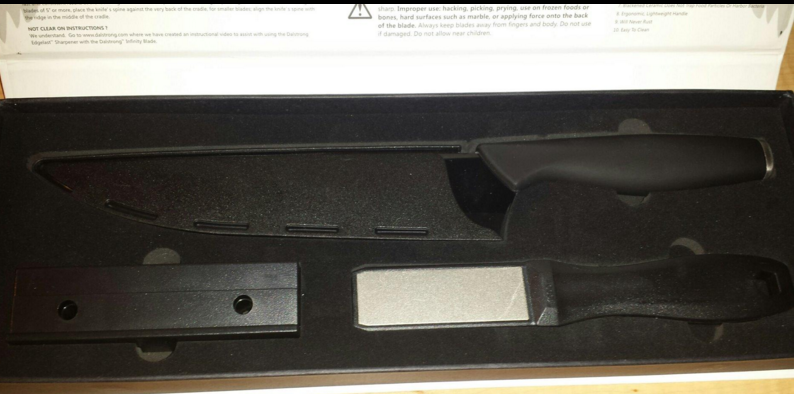

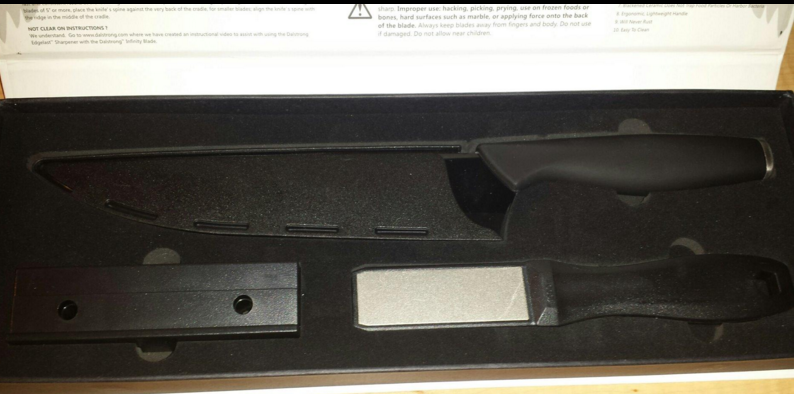

Ceramic knives are substantially harder than steel knives, will not corrode in harsh environments, are non-magnetic, and do not conduct electricity at room temperature. Because of their resistance to strong acid and caustic substances, and their ability to retain a cutting edge longer than steel knives, ceramic knives are suitable for slicing boneless meat, vegetables, fruit and bread. Since ceramics are brittle, blades may break if dropped on a hard surface, although improved manufacturing processes have reduced this risk. They are also unsuitable for chopping through hard foods such as bones or frozen foods, and for applications which require prying, which may cause breaking or chipping. Several brands offer either a black-coloured or a designed blade made through an additional

Ceramic knives are substantially harder than steel knives, will not corrode in harsh environments, are non-magnetic, and do not conduct electricity at room temperature. Because of their resistance to strong acid and caustic substances, and their ability to retain a cutting edge longer than steel knives, ceramic knives are suitable for slicing boneless meat, vegetables, fruit and bread. Since ceramics are brittle, blades may break if dropped on a hard surface, although improved manufacturing processes have reduced this risk. They are also unsuitable for chopping through hard foods such as bones or frozen foods, and for applications which require prying, which may cause breaking or chipping. Several brands offer either a black-coloured or a designed blade made through an additional

Unlike a steel blade that benefits from regular honing and resharpening in order to keep a sharp edge, a much harder ceramic blade will stay sharp and retain its cutting edge for much longer—at least ten times longer according to tests on a particular knife. However, the hardness of the ceramic material also makes it difficult to resharpen. Consequently, although a ceramic knife does not need regular sharpening in the same way as steel, when its blade eventually becomes blunt or chips specialized sharpening services are required for the ceramic edge.

Unlike a steel blade that benefits from regular honing and resharpening in order to keep a sharp edge, a much harder ceramic blade will stay sharp and retain its cutting edge for much longer—at least ten times longer according to tests on a particular knife. However, the hardness of the ceramic material also makes it difficult to resharpen. Consequently, although a ceramic knife does not need regular sharpening in the same way as steel, when its blade eventually becomes blunt or chips specialized sharpening services are required for the ceramic edge.

knife

A knife ( : knives; from Old Norse 'knife, dirk') is a tool or weapon with a cutting edge or blade, usually attached to a handle or hilt. One of the earliest tools used by humanity, knives appeared at least 2.5 million years ago, as evid ...

with a ceramic

A ceramic is any of the various hard, brittle, heat-resistant and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcelain, ...

blade typically made from zirconium dioxide (ZrO2; also known as zirconia), rather than the steel used for most knives. Ceramic knife blades are usually produced through the dry-pressing and firing of powdered zirconia using solid-state sintering

Clinker nodules produced by sintering

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction.

Sintering happens as part of a manufacturing ...

. The blades typically score 8.5 on the Mohs scale of mineral hardness

The Mohs scale of mineral hardness () is a qualitative ordinal scale, from 1 to 10, characterizing scratch resistance of various minerals through the ability of harder material to scratch softer material.

The scale was introduced in 1812 by t ...

, compared to 4.5 for normal steel and 7.5 to 8 for hardened steel and 10 for diamond

Diamond is a solid form of the element carbon with its atoms arranged in a crystal structure called diamond cubic. Another solid form of carbon known as graphite is the chemically stable form of carbon at room temperature and pressure, b ...

. The resultant blade has a hard edge that stays sharp for much longer than conventional steel blades. However, the blade is brittle

A material is brittle if, when subjected to stress, it fractures with little elastic deformation and without significant plastic deformation. Brittle materials absorb relatively little energy prior to fracture, even those of high strength. Br ...

, subject to chipping, and will break rather than flex if twisted. The ceramic blade is sharpened by grinding the edges with a diamond-dust-coated grinding wheel

Grinding wheels contains abrasive compounds for grinding and abrasive machining operations. Such wheels are also used in grinding machines.

The wheels are generally made with composite material . This consists of coarse-particle aggregate pres ...

.

Zirconium oxide

Zirconium oxide is used due to its polymorphism. It exists in three phases:

Zirconium oxide is used due to its polymorphism. It exists in three phases: monoclinic

In crystallography, the monoclinic crystal system is one of the seven crystal systems. A crystal system is described by three vectors. In the monoclinic system, the crystal is described by vectors of unequal lengths, as in the orthorhombic ...

, tetragonal

In crystallography, the tetragonal crystal system is one of the 7 crystal systems. Tetragonal crystal lattices result from stretching a cubic lattice along one of its lattice vectors, so that the cube becomes a rectangular prism with a squar ...

and cubic. Cooling to the monoclinic phase after sintering causes a large volume change, which often causes stress fractures in pure zirconia. Additives such as magnesia, calcia

Calcium oxide (CaO), commonly known as quicklime or burnt lime, is a widely used chemical compound. It is a white, caustic, alkaline, crystalline solid at room temperature. The broadly used term "'' lime''" connotes calcium-containing inorganic m ...

and yttria are used in manufacturing the knife material to stabilize the high-temperature phases and minimize this volume change. The highest strength and toughness is produced by the addition of 3 mol% yttrium oxide yielding partially stabilized zirconia. This material consists of a mixture of tetragonal and cubic phases with a bending strength of nearly 1,200 MPa. Small cracks allow phase transformations to occur, which essentially close the cracks and prevent catastrophic failure, resulting in a relatively tough ceramic material, sometimes known as TTZ (transformation-toughened zirconia).

Properties

Ceramic knives are substantially harder than steel knives, will not corrode in harsh environments, are non-magnetic, and do not conduct electricity at room temperature. Because of their resistance to strong acid and caustic substances, and their ability to retain a cutting edge longer than steel knives, ceramic knives are suitable for slicing boneless meat, vegetables, fruit and bread. Since ceramics are brittle, blades may break if dropped on a hard surface, although improved manufacturing processes have reduced this risk. They are also unsuitable for chopping through hard foods such as bones or frozen foods, and for applications which require prying, which may cause breaking or chipping. Several brands offer either a black-coloured or a designed blade made through an additional

Ceramic knives are substantially harder than steel knives, will not corrode in harsh environments, are non-magnetic, and do not conduct electricity at room temperature. Because of their resistance to strong acid and caustic substances, and their ability to retain a cutting edge longer than steel knives, ceramic knives are suitable for slicing boneless meat, vegetables, fruit and bread. Since ceramics are brittle, blades may break if dropped on a hard surface, although improved manufacturing processes have reduced this risk. They are also unsuitable for chopping through hard foods such as bones or frozen foods, and for applications which require prying, which may cause breaking or chipping. Several brands offer either a black-coloured or a designed blade made through an additional hot isostatic pressing

Hot isostatic pressing (HIP) is a manufacturing process, used to reduce the porosity of metals and increase the density of many ceramic materials. This improves the material's mechanical properties and workability.

The process can be used to p ...

step, which increases toughness.

Sharpening and general care

Unlike a steel blade that benefits from regular honing and resharpening in order to keep a sharp edge, a much harder ceramic blade will stay sharp and retain its cutting edge for much longer—at least ten times longer according to tests on a particular knife. However, the hardness of the ceramic material also makes it difficult to resharpen. Consequently, although a ceramic knife does not need regular sharpening in the same way as steel, when its blade eventually becomes blunt or chips specialized sharpening services are required for the ceramic edge.

Unlike a steel blade that benefits from regular honing and resharpening in order to keep a sharp edge, a much harder ceramic blade will stay sharp and retain its cutting edge for much longer—at least ten times longer according to tests on a particular knife. However, the hardness of the ceramic material also makes it difficult to resharpen. Consequently, although a ceramic knife does not need regular sharpening in the same way as steel, when its blade eventually becomes blunt or chips specialized sharpening services are required for the ceramic edge.

References

External links

* {{knives Knives Ceramic engineering