Container (cargo) on:

[Wikipedia]

[Google]

[Amazon]

An intermodal container, often called a shipping container, is a large standardized

An intermodal container, often called a shipping container, is a large standardized

Shipping containers, explained by a historian. By Rebecca Heilweil Dec 14, 2021, vox.com. Two years after McLean's first container ship, the ''Ideal X'', started container shipping on the US East Coast,

Two years after McLean's first container ship, the ''Ideal X'', started container shipping on the US East Coast,

Ninety percent of the global container fleet consists of "dry freight" or "general purpose" containers – both of standard and special sizes.

And although lengths of containers vary from , according to two 2012 container census reports about 80% of the world's containers are either twenty or forty foot standard length boxes of the dry freight design. These typical containers are rectangular, closed box models, with doors fitted at one end, and made of corrugated

Ninety percent of the global container fleet consists of "dry freight" or "general purpose" containers – both of standard and special sizes.

And although lengths of containers vary from , according to two 2012 container census reports about 80% of the world's containers are either twenty or forty foot standard length boxes of the dry freight design. These typical containers are rectangular, closed box models, with doors fitted at one end, and made of corrugated  Although ISO standard 1496 of 1990 only required nine-high stacking, ''and only'' of containers rated at , current Ultra Large Container Vessels of the Post New Panamax and Maersk Triple E class are stacking them ten or eleven high. Moreover, vessels like the Marie Maersk no longer use separate stacks in their holds, and other stacks above deck – instead they maximize their capacity by stacking continuously from the bottom of the hull, to as much as twenty-one high. This requires automated planning, whereby heavy containers are systematically kept at the bottom of the stack, and light ones on top – not only to stabilize the ship, but also to prevent overloading and collapsing the bottom containers.

Regional intermodal containers, such as European, Japanese and U.S. domestic units however, are mainly transported by road and rail, and can frequently only be stacked up to two or three laden units high. Although the two ends are quite rigid, containers flex somewhat during transport.

Container capacity is often expressed in twenty-foot equivalent units (TEU, or sometimes ''teu''). A twenty-foot equivalent unit is a measure of containerized cargo capacity equal to one standard long container. This is an approximate measure, wherein the height of the box is not considered. For example, the tall high-cube, as well as containers are equally counted as one TEU. Similarly, extra long containers are commonly counted as just two TEU, no different than standard long units. Two TEU are equivalent to one forty-foot equivalent unit (FEU).

In 2014 the global container fleet grew to a volume of 36.6 million TEU, based on Drewry Shipping Consultants' Container Census. Moreover, in 2014 for the first time in history 40-foot High-Cube containers accounted for the majority of boxes in service, measured in TEU. In 2019 it was noted by global logistics data analysis

Although ISO standard 1496 of 1990 only required nine-high stacking, ''and only'' of containers rated at , current Ultra Large Container Vessels of the Post New Panamax and Maersk Triple E class are stacking them ten or eleven high. Moreover, vessels like the Marie Maersk no longer use separate stacks in their holds, and other stacks above deck – instead they maximize their capacity by stacking continuously from the bottom of the hull, to as much as twenty-one high. This requires automated planning, whereby heavy containers are systematically kept at the bottom of the stack, and light ones on top – not only to stabilize the ship, but also to prevent overloading and collapsing the bottom containers.

Regional intermodal containers, such as European, Japanese and U.S. domestic units however, are mainly transported by road and rail, and can frequently only be stacked up to two or three laden units high. Although the two ends are quite rigid, containers flex somewhat during transport.

Container capacity is often expressed in twenty-foot equivalent units (TEU, or sometimes ''teu''). A twenty-foot equivalent unit is a measure of containerized cargo capacity equal to one standard long container. This is an approximate measure, wherein the height of the box is not considered. For example, the tall high-cube, as well as containers are equally counted as one TEU. Similarly, extra long containers are commonly counted as just two TEU, no different than standard long units. Two TEU are equivalent to one forty-foot equivalent unit (FEU).

In 2014 the global container fleet grew to a volume of 36.6 million TEU, based on Drewry Shipping Consultants' Container Census. Moreover, in 2014 for the first time in history 40-foot High-Cube containers accounted for the majority of boxes in service, measured in TEU. In 2019 it was noted by global logistics data analysis

Other than the standard, general purpose container, many variations exist for use with different cargoes. The most prominent of these are

Other than the standard, general purpose container, many variations exist for use with different cargoes. The most prominent of these are

Basic terminology of globally standardized intermodal shipping containers is set out in standard:

* ISO 830:(1999) ''Freight containers – Vocabulary'', 2nd edition; last reviewed and confirmed in 2016.

From its inception, ISO standards on international shipping containers, consistently speak of them sofar as 'Series 1' containers – deliberately so conceived, to leave room for another such series of interrelated container standards in the future.

Basic dimensions and permissible gross weights of intermodal containers are largely determined by two ISO standards:

* ISO 668:2013–2020 Series 1 freight containers—Classification, dimensions and ratings

* ISO 1496-1:2013 Series 1 freight containers—Specification and testing—Part 1: General cargo containers for general purposes

Weights and dimensions of the most common (standardized) types of containers are given below. Forty-eight foot and fifty-three foot containers have not yet been incorporated in the latest, 2020 edition of the ISO 668. ISO standard maximum gross mass for all standard sizes except 10-ft boxes was raised to per Amendment 1 on ISO 668:2013, in 2016. Draft Amendment 1 of ISO 668: 2020 – for the eighth edition – maintains this.Draft Amendment ISO 668:2020/DAM 1

Basic terminology of globally standardized intermodal shipping containers is set out in standard:

* ISO 830:(1999) ''Freight containers – Vocabulary'', 2nd edition; last reviewed and confirmed in 2016.

From its inception, ISO standards on international shipping containers, consistently speak of them sofar as 'Series 1' containers – deliberately so conceived, to leave room for another such series of interrelated container standards in the future.

Basic dimensions and permissible gross weights of intermodal containers are largely determined by two ISO standards:

* ISO 668:2013–2020 Series 1 freight containers—Classification, dimensions and ratings

* ISO 1496-1:2013 Series 1 freight containers—Specification and testing—Part 1: General cargo containers for general purposes

Weights and dimensions of the most common (standardized) types of containers are given below. Forty-eight foot and fifty-three foot containers have not yet been incorporated in the latest, 2020 edition of the ISO 668. ISO standard maximum gross mass for all standard sizes except 10-ft boxes was raised to per Amendment 1 on ISO 668:2013, in 2016. Draft Amendment 1 of ISO 668: 2020 – for the eighth edition – maintains this.Draft Amendment ISO 668:2020/DAM 1

/ref> Given the average container lifespan, the majority of the global container fleet have not caught up with this change yet. Moreover, U.S. highways cannot handle such heavy fully laden containers yet, including the mass of truck (and trailer). Values vary slightly from manufacturer to manufacturer, but must stay within the tolerances dictated by the standards. Empty weight (''

/ref> (a gain of ~ over the ISO-usual ,Shipping Container Dimensions - Container Container.com

/ref> gives ''pallet-wide'' containers a usable internal floor width of , compared to in standard containers, because the extra width enables their users to either load two Euro-pallets end on end across their width, or three of them side by side (providing the pallets were neatly stacked, without overspill), whereas in standard ISO containers, a strip of internal floor-width of about cannot be used by Euro-pallets. As a result, while being virtually interchangeable: *A 20-foot PW can load 15 Euro-pallets – four more, or 36% better than the normal 11 pallets in an ISO-standard 20-foot unit *A 40-foot PW can load 30 Euro-pallets – five more, or 20% better than the 25 pallets in a standard 40-foot unit, and *A 45-foot PW can load 34 Euro-pallets – seven more, or 26% better than 27 in a standard 45-foot container. Some ''pallet-wides'' are simply manufactured with the same, ISO-standard floor structure, but with the side-panels welded in, such that the ribs/corrugations are embossed outwards, instead of indenting to the inside. This makes it possible for some ''pallet-wides'' to be just wide, but others can be wide. Many sea shipping providers in Europe allow these on board, as their external width overhangs over standard containers are sufficiently minor that they fit in the usual interlock spaces in ship's holds, as long as their corner-castings patterns (both in the floor and the top) still match with regular 40-foot units, for stacking and securing.

Although the below described sizes are not exclusively used in the U.S. (they are also used in cargo traffic across the borders, into Canada and Mexico), they are predominantly United States initiatives.

Although the below described sizes are not exclusively used in the U.S. (they are also used in cargo traffic across the borders, into Canada and Mexico), they are predominantly United States initiatives.

General purpose 53’ containers were introduced in the United States in 1989, and are used both in the US and Canada, mainly for domestic road and rail transport. They are considered High-Cubes, based on their ISO-standard height. Their width of however makes them wider than ISO-standard containers. These large boxes have 60% more capacity than 40’ containers, enabling shippers to consolidate more cargo into fewer containers.

Generally, North American 53-foot containers were not constructed strong enough to endure the rigors of ocean transport, but in 2007 container carrier American President Lines introduced the first 53-foot ocean-capable containers. All new, reinforced 53-foot boxes were built specifically for international trade and designed to withstand ocean voyages on its South China-to-Los Angeles service. In 2013 however, APL stopped offering vessel space for 53-foot containers on its trans-Pacific ships. Nevertheless, In 2015 both Crowley and TOTE Maritime each announced the construction of their respective second combined container and

General purpose 53’ containers were introduced in the United States in 1989, and are used both in the US and Canada, mainly for domestic road and rail transport. They are considered High-Cubes, based on their ISO-standard height. Their width of however makes them wider than ISO-standard containers. These large boxes have 60% more capacity than 40’ containers, enabling shippers to consolidate more cargo into fewer containers.

Generally, North American 53-foot containers were not constructed strong enough to endure the rigors of ocean transport, but in 2007 container carrier American President Lines introduced the first 53-foot ocean-capable containers. All new, reinforced 53-foot boxes were built specifically for international trade and designed to withstand ocean voyages on its South China-to-Los Angeles service. In 2013 however, APL stopped offering vessel space for 53-foot containers on its trans-Pacific ships. Nevertheless, In 2015 both Crowley and TOTE Maritime each announced the construction of their respective second combined container and

File:JR貨物【 鉄道代行船舶輸送 】岡山新港高島埠頭--③.jpg, the 19D-type container used by JR Freight in Japan

File:US Navy 051010-M-0596N-001 A tractor moves a quadcon container at Kin Red Port in Okinawa.jpg, U.S. Navy tractor moves Quadcon containers at Kin Red Port in Okinawa (2005)

File:US Navy 060831-N-3560G-052 Members of Naval Mobile Construction Battalion Four (NMCB-4) load Tricon Containers loaded with construction equipment destine for field testing in Iraq, into a U.S. Air Force, Air Mobility Command, C.jpg, U.S. Navy load Tricon containers into a Lockheed C-5 Galaxy transport aircraft (2006)

File:US Navy 070820-F-8678B-050 Construction Mechanic 1st Class Kenneth E. Terlaan drives a extendable boom forklift through the mud to position a CONEX box containing the field armory during setup for a field exercise.jpg, U.S. Navy moving a Bicon box. Note the forklift pockets only in the sides, not at the ends.

Each container is allocated a standardized

Each container is allocated a standardized

Containers are transferred between rail, truck, and ship by container cranes at

Containers are transferred between rail, truck, and ship by container cranes at

File:Container lashing bridge fitting.JPG, Containers can be horizontally connected with lashing bridge fittings

File:Dockworker team on a container ship.jpg, Dockworkers securing containers on a ship with steel lashing bars and

Container-sized units are also often used for moving large pieces of equipment to temporary sites. Specialised containers are particularly attractive to militaries already using containerisation to move much of their freight around. Shipment of specialized equipment in this way simplifies logistics and may prevent identification of high value equipment by enemies. Such systems may include command and control facilities, mobile operating theatres or even

Container-sized units are also often used for moving large pieces of equipment to temporary sites. Specialised containers are particularly attractive to militaries already using containerisation to move much of their freight around. Shipment of specialized equipment in this way simplifies logistics and may prevent identification of high value equipment by enemies. Such systems may include command and control facilities, mobile operating theatres or even

Half the containers that enter the United States leave empty. Their value in the US is lower than in China, so they are sometimes used for other purposes. This is typically but not always at the end of their voyaging lives. The US military often used its

Half the containers that enter the United States leave empty. Their value in the US is lower than in China, so they are sometimes used for other purposes. This is typically but not always at the end of their voyaging lives. The US military often used its

*

*

page 8page 14page 18page 20page 26

*

excerpt and text search

*

excerpt and text search

* Donovan, Arthur & Bonney, Joseph "The Box That Changed The World", East Windsor, New Jersey, Commonwealth Business Media, 2006

Bureau International des Containers et du Transport Intermodal

* ttp://wheremy.com/container-tracking/ Track and trace by Shipping Containersbr>Track and trace Container CargosFreight container types and sizes summary

– by GDV, the collective of German insurance companies

ISO Containers

– ISO Freight Containers {{DEFAULTSORT:Intermodal Container Modularity Port infrastructure

An intermodal container, often called a shipping container, is a large standardized

An intermodal container, often called a shipping container, is a large standardized shipping container

A shipping container is a container with strength suitable to withstand shipment, storage, and handling. Shipping containers range from large reusable steel boxes used for intermodal shipments to the ubiquitous corrugated boxes. In the context o ...

, designed and built for intermodal freight transport, meaning these containers can be used across different modes of transport – from ship

A ship is a large watercraft that travels the world's oceans and other sufficiently deep waterways, carrying cargo or passengers, or in support of specialized missions, such as defense, research, and fishing. Ships are generally distinguishe ...

to rail to truck

A truck or lorry is a motor vehicle designed to transport cargo, carry specialized payloads, or perform other utilitarian work. Trucks vary greatly in size, power, and configuration, but the vast majority feature body-on-frame constructi ...

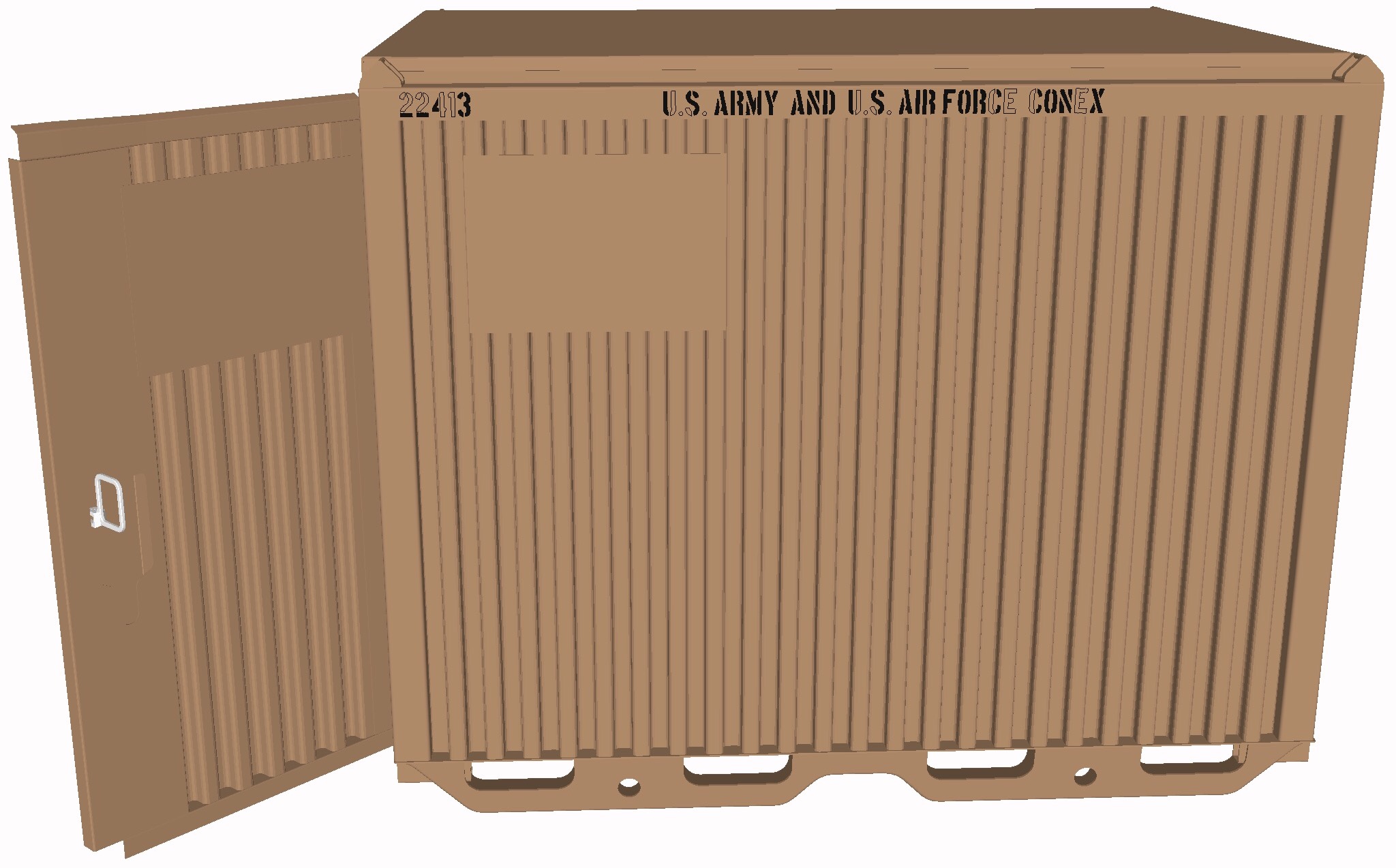

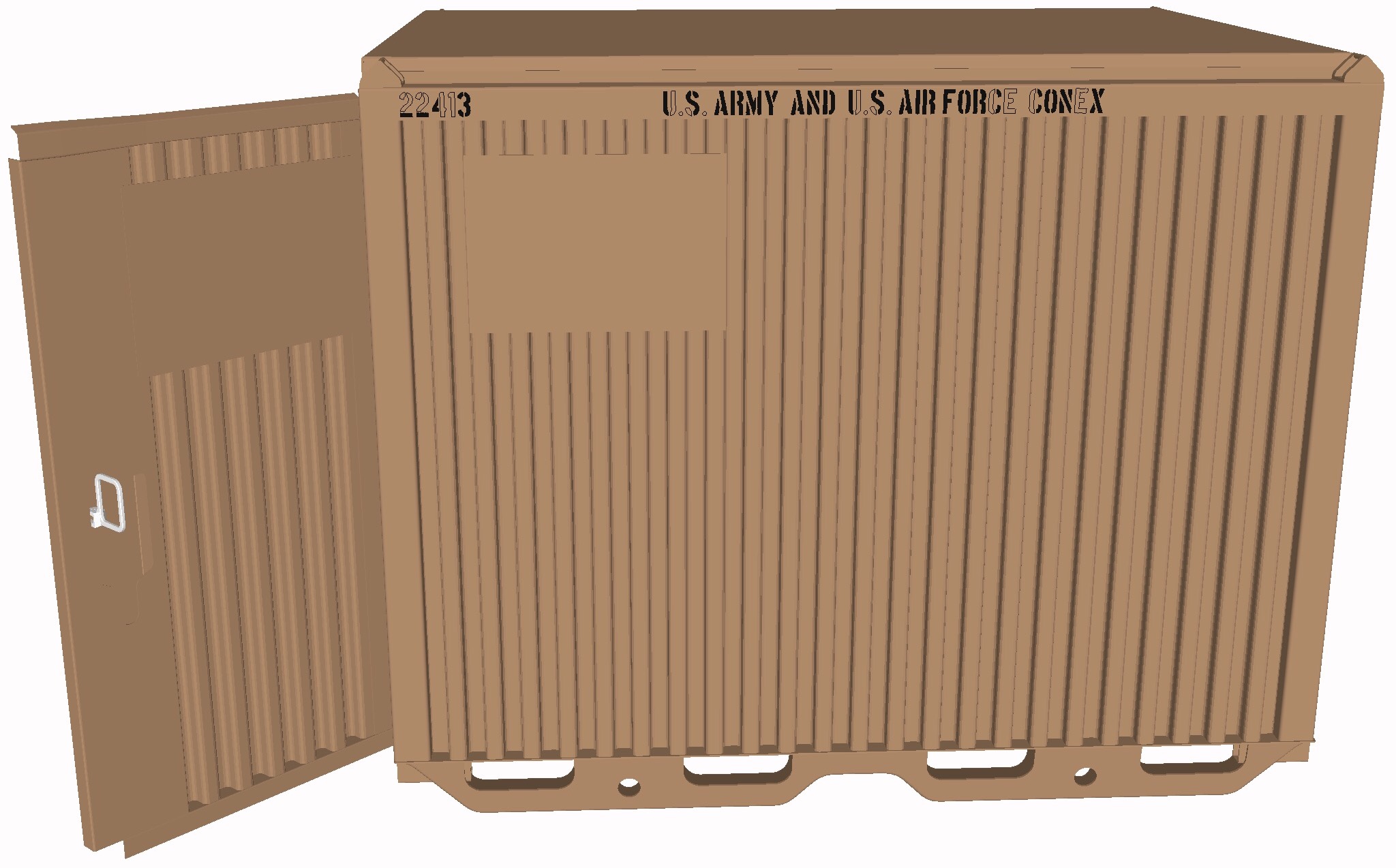

– without unloading and reloading their cargo. Intermodal containers are primarily used to store and transport materials and products efficiently and securely in the global containerized intermodal freight transport system, but smaller numbers are in regional use as well. These containers are known under a number of names. Based on size alone, up to 95% of intermodal containers comply with ISO standards, and can officially be called ISO containers. Many other names are simply: container, cargo or freight container, shipping, sea or ocean container, container van or sea van, sea can or C can, or MILVAN, SEAVAN, or RO/RO. The also used term CONEX (Box) is technically incorrect carry-over usage of the name of an important predecessor of the international ISO containers, namely the much smaller prior steel CONEX boxes used by the U.S. Army.

Intermodal containers exist in many types and a number of standardized sizes, but ninety percent of the global container fleet are so-called "dry freight" or "general purpose" containers – durable closed rectangular boxes, made of rust-retardant Corten steel; almost all wide, and of either standard length, as defined by International Organization for Standardization

The International Organization for Standardization (ISO ) is an international standard development organization composed of representatives from the national standards organizations of member countries. Membership requirements are given in Ar ...

(ISO) standard 668:2020. The worldwide standard heights are and – the latter are known as High Cube or Hi-Cube (HC or HQ) containers.

First invented in the early 20th century, modern 40-foot intermodal containers proliferated during the 1960s and 1970s under the containerization

Containerization is a system of intermodal freight transport using intermodal containers (also called shipping containers and ISO containers). Containerization is also referred as "Container Stuffing" or "Container Loading", which is the p ...

innovations of the American shipping company SeaLand. Just like cardboard boxes and pallet

A pallet (also called a skid) is a flat transport structure, which supports goods in a stable fashion while being lifted by a forklift, a pallet jack, a front loader, a jacking device, or an erect crane. A pallet is the structural found ...

s, these containers are a means to bundle cargo and goods into larger, unitized loads, that can be easily handled, moved, and stacked, and that will pack tightly in a ship or yard. Intermodal containers share a number of key construction features to withstand the stresses of intermodal shipping, to facilitate their handling and to allow stacking, as well as being identifiable through their individual, unique ISO 6346

ISO 6346 is an international standard covering the coding, identification and marking of intermodal (shipping) containers used within containerized intermodal freight transport by the International Organization for Standardization (ISO). T ...

reporting mark.

In 2012, there were about 20.5 million intermodal containers in the world of varying types to suit different cargoes. Containers have largely supplanted the traditional break bulk cargo

In shipping, break-bulk, breakbulk, or break bulk cargo, also called general cargo, refers to goods that are stowed on board ship in individually counted units. Traditionally, the large numbers of items are recorded on distinct bills of lading ...

– in 2010 containers accounted for 60% of the world's seaborne trade. The predominant alternative methods of transport carry bulk cargo

Bulk cargo is commodity cargo that is transported unpackaged in large quantities.

Description

Bulk cargo refers to material in either liquid or granular, particulate form, as a mass of relatively small solids, such as petroleum/ crude oil ...

whether gaseous, liquid, or solid; e.g., by bulk carrier

A bulk carrier or bulker is a merchant ship specially designed to transport unpackaged bulk cargo — such as grains, coal, ore, steel coils, and cement — in its cargo holds. Since the first specialized bulk carrier was built in 1852, ec ...

or tank ship, tank car

A tank car (International Union of Railways (UIC): tank wagon) is a type of railroad car (UIC: railway car) or rolling stock designed to transport liquid and gaseous commodities.

History

Timeline

The following major events occurred in the ...

, or truck

A truck or lorry is a motor vehicle designed to transport cargo, carry specialized payloads, or perform other utilitarian work. Trucks vary greatly in size, power, and configuration, but the vast majority feature body-on-frame constructi ...

. For air freight

Air cargo is any property carried or to be carried in an aircraft. Air cargo comprises air freight, air express and airmail.

Aircraft types

Different cargo can be transported by passenger, cargo or combi aircraft:

* Passenger aircraft use the ...

, the lighter weight IATA-defined unit load devices are used.

History

Origins

By the 1830s, railways across several continents were carrying containers that could be transferred to other modes of transport. TheLiverpool and Manchester Railway

The Liverpool and Manchester Railway (L&MR) was the first inter-city railway in the world. It opened on 15 September 1830 between the Lancashire towns of Liverpool and Manchester in England. It was also the first railway to rely exclusively ...

in the United Kingdom

The United Kingdom of Great Britain and Northern Ireland, commonly known as the United Kingdom (UK) or Britain, is a country in Europe, off the north-western coast of the European mainland, continental mainland. It comprises England, Scotlan ...

was one of these. "Simple rectangular timber boxes, four to a truck, they were used to convey coal from the Lancashire collieries to Liverpool, where they were transferred to horse-drawn carts by crane." Early versions of standardized containers were used in Europe before World War II. Construction of these containers had a steel frame with wooden walls, floor, roof and doors.

Creation of international standards

The first international standard for containers was established by the Bureau International des Containers et du Transport Intermodal (B.I.C.) in 1933, and a second one in 1935, primarily for transport between European countries. American containers at this time were not standardized, and these early containers were not yet stackable – neither in the U.S. nor Europe. In November 1932, the first container terminal in the world was opened by the Pennsylvania Rail Road Company inEnola, Pennsylvania

Enola is a census-designated place (CDP) located along the Susquehanna River in East Pennsboro Township, Cumberland County, Pennsylvania. The population was 6,111 at the 2010 census. Norfolk Southern operates Enola Yard, a large rail yard and ...

. Containerization was developed in Europe and the US as a way to revitalize rail companies after the Wall Street Crash of 1929

The Wall Street Crash of 1929, also known as the Great Crash, was a major American stock market crash that occurred in the autumn of 1929. It started in September and ended late in October, when share prices on the New York Stock Exchange coll ...

, in New York, which resulted in economic collapse and a drop in all modes of transport.

Mid 20th century innovations

In April 1951 at Zürich Tiefenbrunnen railway station, the Swiss Museum of Transport and the ''Bureau International des Containers'' (BIC) held demonstrations of container systems for representatives from a number of European countries, and from the United States. A system was selected for Western Europe, based on the Netherlands' system for consumer goods and waste transportation called ''Laadkisten'' (lit. "Loading chests"), in use since 1934. This system used roller containers for transport by rail, truck and ship, in various configurations up to capacity, and up to in size. This became the first post World War II European railway standard of theInternational Union of Railways

The International Union of Railways (UIC, french: Union internationale des chemins de fer) is an international rail transport industry body.

History

The railways of Europe originated as many separate concerns, and there were many border chang ...

– ''UIC-590'', known as "pa-Behälter". It was implemented in the Netherlands, Belgium, Luxembourg, West Germany, Switzerland, Sweden and Denmark.

The use of standardized steel shipping container

A shipping container is a container with strength suitable to withstand shipment, storage, and handling. Shipping containers range from large reusable steel boxes used for intermodal shipments to the ubiquitous corrugated boxes. In the context o ...

s began during the late 1940s and early 1950s, when commercial shipping operators and the US military started developing such units. In 1948 the U.S. Army Transportation Corps

The Transportation Corps is a combat service support branch of the U.S. Army. It is responsible for the movement of personnel and material by truck, rail, air, and sea. It is one of three U.S. Army logistics branches, the others being the ...

developed the "Transporter", a rigid, corrugated steel container, able to carry . It was long, wide, and high, with double doors on one end, was mounted on skids, and had lifting rings on the top four corners. After proving successful in Korea, the Transporter was developed into the Container Express (CONEX) box system in late 1952. Based on the Transporter, the size and capacity of the Conex were about the same, but the system was made modular, by the addition of a smaller, half-size unit of long, wide and high. CONEXes could be stacked three high, and protected their contents from the elements. By 1965 the US military used some 100,000 Conex boxes, and more than 200,000 in 1967, making this the first worldwide application of intermodal containers. Their invention made a major contribution to the globalization

Globalization, or globalisation (English in the Commonwealth of Nations, Commonwealth English; American and British English spelling differences#-ise, -ize (-isation, -ization), see spelling differences), is the process of foreign relation ...

of commerce in the second half of the 20th century, dramatically reducing the cost of transporting goods and hence of long-distance trade.

From 1949 onwards, engineer Keith Tantlinger repeatedly contributed to the development of containers, as well as their handling and transportation equipment. In 1949, while at Brown Trailers Inc. of Spokane, Washington

Spokane ( ) is the largest city and county seat of Spokane County, Washington, United States. It is in eastern Washington, along the Spokane River, adjacent to the Selkirk Mountains, and west of the Rocky Mountain foothills, south of the ...

, he modified the design of their stressed skin aluminum 30-foot trailer, to fulfil an order of two-hundred containers that could be stacked two high, for Alaska-based ''Ocean Van Lines''. Steel castings on the top corners provided lifting and securing points.

In 1955 trucking magnate Malcom McLean bought Pan-Atlantic Steamship Company, to form a container shipping enterprise, later known as Sea-Land. The first containers were supplied by Brown Trailers Inc, where McLean met Keith Tantlinger, and hired him as vice-president of engineering and research. Under the supervision of Tantlinger, a new x x Sea-Land container was developed, the length determined by the maximum length of trailers then allowed on Pennsylvanian highways. Each container had a frame with eight corner castings that could withstand stacking loads. Tantlinger also designed automatic spreaders for handling the containers, as well as the twistlock mechanism that connects with the corner castings.

Modern form

Containers in their modern 21st-century form first began to gain widespread use around 1956. Businesses began to devise a structured process to utilize and to get optimal benefits from the role and use of shipping containers. Over time, the invention of the modern telecommunications of the late 20th century made it highly beneficial to have standardized shipping containers and made these shipping processes more standardized, modular, easier to schedule, and easier to manage.The history of the metal box that’s wrecking the supply chainShipping containers, explained by a historian. By Rebecca Heilweil Dec 14, 2021, vox.com.

Two years after McLean's first container ship, the ''Ideal X'', started container shipping on the US East Coast,

Two years after McLean's first container ship, the ''Ideal X'', started container shipping on the US East Coast, Matson Navigation

Matson, Inc. is an American shipping and navigation services company headquartered in Honolulu, Hawaii. Founded in 1882, Matson, Inc.'s subsidiary Matson Navigation Company provides ocean shipping services across the Pacific to Hawaii, Alaska, ...

followed suit between California and Hawaii. Just like Pan-Atlantic's containers, Matson's were wide and high, but due to California's different traffic code Matson chose to make theirs long. In 1968, McLean began container service to South Vietnam for the US military with great success.

Modern ISO standards

ISO standards for containers were published between 1968 and 1970 by the International Maritime Organization. These standards allow for more consistent loading, transporting, and unloading of goods in ports throughout the world, thus saving time and resources. The International Convention for Safe Containers is a 1972 regulation by the Inter-governmental Maritime Consultative Organization on the safe handling and transport of containers. It decrees that every container travelling internationally be fitted with a CSC Safety-approval Plate. This holds essential information about the container, including age, registration number, dimensions and weights, as well as its strength and maximum stacking capability.Impact of industry changes on workers

Longshoremen and related unions around the world struggled with this revolution in shipping goods. For example, by 1971 a clause in the International Longshoremen's Association (ILA) contract stipulated that the work of "stuffing" (filling) or "stripping" (emptying) a container within of a port must be done by ILA workers, or if not done by ILA, that the shipper needed to pay royalties and penalties to the ILA. Unions for truckers and consolidators argued that the ILA rules were not valid work preservation clauses, because the work of stuffing and stripping containers away from the pier had not traditionally been done by ILA members. In 1980 theSupreme Court of the United States

The Supreme Court of the United States (SCOTUS) is the highest court in the federal judiciary of the United States. It has ultimate appellate jurisdiction over all U.S. federal court cases, and over state court cases that involve a point ...

heard this case and ruled against the ILA.

Impact in worldwide supply shortage of 2020 to present

Some experts have said that the shipping containers have proven to have a downside, as exacerbating some of the economic and societal damage from the 2021 global supply chain crisis of 2020 and 2021, and the resulting shortages related to the COVID-19 pandemic. One problem is that the centralized, continuous shipping process made possible by the containers has now proven to be a liability of sorts; the reason is that if there is just one bottleneck, delay, or other breakdown at any point in the process, it can easily cause major delays everywhere up and down the supply chain. In January 2021, a shortage of shipping containers at ports caused shipping to be backlogged. Marc Levinson, author of ''Outside the Box: How Globalization Changed from Moving Stuff to Spreading Ideas'' and '' The Box: How the Shipping Container Made the World Smaller and the World Economy Bigger'', noted in an interview:"Because of delays in the process, it’s taking a container longer to go from its origin to its final destination where it’s unloaded, so the container is in use longer for each trip. You’ve just lost a big hunk of the total capacity because the containers can’t be used as intensively. We've had in the United States an additional problem, which is that the ship lines typically charge much higher rates on services from Asia to North America than from North America to Asia. This has resulted in complaints, for example, from farmers and agricultural companies, that it’s hard to get containers in some parts of the country because the ship lines want to ship them empty back to Asia, rather than letting them go to South Dakota and load over the course of several days. So we’ve had exporters in the United States complaining that they have a hard time finding a container that they can use to send their own goods abroad."

Description

Ninety percent of the global container fleet consists of "dry freight" or "general purpose" containers – both of standard and special sizes.

And although lengths of containers vary from , according to two 2012 container census reports about 80% of the world's containers are either twenty or forty foot standard length boxes of the dry freight design. These typical containers are rectangular, closed box models, with doors fitted at one end, and made of corrugated

Ninety percent of the global container fleet consists of "dry freight" or "general purpose" containers – both of standard and special sizes.

And although lengths of containers vary from , according to two 2012 container census reports about 80% of the world's containers are either twenty or forty foot standard length boxes of the dry freight design. These typical containers are rectangular, closed box models, with doors fitted at one end, and made of corrugated weathering steel

Weathering steel, often referred to by the genericised trademark COR-TEN steel and sometimes written without the hyphen as corten steel, is a group of steel alloys which were developed to eliminate the need for painting, and form a stable r ...

(commonly known as CorTen) with a plywood floor. Although corrugating the sheet metal

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Sheet metal is one of the fundamental forms used in metalworking, and it can be cut and bent into a variety of shapes.

Thicknesses can vary significantly; ex ...

used for the sides and roof contributes significantly to the container's rigidity and stacking strength, just like in corrugated iron

Corrugated galvanised iron or steel, colloquially corrugated iron (near universal), wriggly tin (taken from UK military slang), pailing (in Caribbean English), corrugated sheet metal (in North America) and occasionally abbreviated CGI is a b ...

or in cardboard boxes

Cardboard boxes are industrially prefabricated boxes, primarily used for packaging goods and materials. Specialists in industry seldom use the term cardboard because it does not denote a specific material. The term ''cardboard'' may refer to a va ...

, the corrugated sides cause aerodynamic drag, and up to 10% fuel economy loss in road or rail transport, compared to smooth-sided vans.

Standard containers are wide by high, although the taller "High Cube" or "hi-cube" units measuring have become very common in recent years. By the end of 2013, high-cube 40 ft containers represented almost 50% of the world's maritime container fleet, according to Drewry's Container Census report.

About 90% of the world's containers are either nominal or long, although the United States and Canada also use longer units of , and . ISO containers have castings with openings for twistlock fasteners at each of the eight corners, to allow gripping the box from above, below, or the side, and they can be stacked up to ten units high.

startup

A startup or start-up is a company or project undertaken by an entrepreneur to seek, develop, and validate a scalable business model. While entrepreneurship refers to all new businesses, including self-employment and businesses that never intend t ...

Upply that China's role as 'factory of the world' is further incentivizing the use of 40-foot containers, and that the computational standard 1 TEU boxes only make up 20% of units on major east–west liner routes, and demand for shipping them keeps dropping. In the 21st century, the market has shifted to using 40-foot high-cube dry and refrigerated containers more and more predominantly. Forty-foot units have become the standard to such an extent that the sea freight industry now charges less than 30% more for moving a 40-ft unit than for a 1 TEU box. Although 20-ft units mostly have heavy cargo, and are useful for stabilizing both ships and revenue, carriers financially penalize 1 TEU boxes by comparison.

For container manufacturers, 40-foot High-Cubes now dominate market demand both for dry and refrigerated units. Manufacturing prices for regular dry freight containers are typically in the range of $1750–$2000 U.S. per CEU (container equivalent unit), and about 90% of the world's containers are made in China. The average age of the global container fleet was a little over 5 years from end 1994 to end 2009, meaning containers remain in shipping use for well over 10 years.

Gooseneck tunnel

A ''gooseneck tunnel'', an indentation in the floor structure, that meshes with the ''gooseneck'' on dedicated container semi-trailers, is a mandatory feature in the bottom structure of 1AAA and 1EEE (40- and 45-ft high-cube) containers, and optional but typical on standard height, forty-foot and longer containers.Types

Other than the standard, general purpose container, many variations exist for use with different cargoes. The most prominent of these are

Other than the standard, general purpose container, many variations exist for use with different cargoes. The most prominent of these are refrigerated container

A refrigerated container or reefer is an intermodal container (shipping container) used in intermodal freight transport that is capable of refrigeration for the transportation of temperature-sensitive, perishable cargo such as fruits, vegetabl ...

s (also called ''reefers'') for perishable goods, that make up 6% of the world's shipping boxes. Tanks in a frame, for bulk liquids, account for another 0.75% of the global container fleet.

Although these variations are not of the standard type, they mostly are ''ISO standard'' containers – in fact the ISO 6346

ISO 6346 is an international standard covering the coding, identification and marking of intermodal (shipping) containers used within containerized intermodal freight transport by the International Organization for Standardization (ISO). T ...

standard classifies a broad spectrum of container types in great detail. Aside from different size options, the most important container types are:

* General-purpose dry vans, for boxes, cartons, cases, sacks, bales, pallets, drums, etc., Special interior layouts are known, such as:

** rolling-floor containers, for difficult-to-handle cargo

** garmentainers, for shipping garments on hangers (GOH)

* Ventilated containers. Essentially dry vans, but either passively or actively ventilated. For instance for organic products requiring ventilation.

* Temperature controlled – either insulated, refrigerated, and/or heated containers, for perishable goods

* Tank containers, for liquids, gases, or powders. Frequently these are dangerous goods

Dangerous goods, abbreviated DG, are substances that when transported are a risk to health, safety, property or the environment. Certain dangerous goods that pose risks even when not being transported are known as hazardous materials ( syllabi ...

, and in the case of gases one shipping unit may contain multiple gas bottles

* Bulk containers (sometimes ''bulktainers''), either closed models with roof-lids, or hard or soft open-top units for top loading, for instance for bulk minerals. Containerized coal carriers and "bin-liners" (containers designed for the efficient road and rail transportation of rubbish from cities to recycling and dump sites) are used in Europe.

* Open-top and open-side containers, for instance for easy loading of heavy machinery or oversize pallets. Crane systems can be used to load and unload crates without having to disassemble the container itself. Open sides are also used for ventilating hardy perishables like apples or potatoes.

* Log cradles for cradling logs

* Platform based containers such as:

** flat-rack and bolster containers, for barrels, drums, crates, and any heavy or bulky out-of-gauge cargo, like machinery, semi-finished goods or processed timber. Empty flat-racks can either be stacked or shipped sideways in another ISO container

** collapsible containers, ranging from flushfolding flat-racks to fully closed ISO and CSC certified units with roof and walls when erected.

* trash containers, for carrying trash bags and cans to and from Recycling factories and landfills.

Containers for offshore

Offshore may refer to:

Science and technology

* Offshore (hydrocarbons)

* Offshore construction, construction out at sea

* Offshore drilling, discovery and development of oil and gas resources which lie underwater through drilling a well

* Off ...

use have a few different features, like pad eyes, and must meet additional strength and design requirements, standards and certification, such as the DNV2.7-1 by Det Norske Veritas

DNV (formerly DNV GL) is an international accredited registrar and classification society headquartered in Høvik, Norway. The company currently has about 12,000 employees and 350 offices operating in more than 100 countries, and provides serv ...

, LRCCS by Lloyd's Register

Lloyd's Register Group Limited (LR) is a technical and professional services organisation and a maritime classification society, wholly owned by the Lloyd’s Register Foundation, a UK charity dedicated to research and education in science and ...

, Guide for Certification of Offshore Containers by American Bureau of Shipping

American(s) may refer to:

* American, something of, from, or related to the United States of America, commonly known as the "United States" or "America"

** Americans, citizens and nationals of the United States of America

** American ancestry, pe ...

and the International standard ISO10855: ''Offshore containers and associated lifting sets'', in support of IMO MSC/Circ. 860

A multitude of equipment, such as generators, has been installed in containers of different types to simplify logistics – see for more details.

Swap body units usually have the same bottom corner fixtures as intermodal containers, and often have folding legs under their frame so that they can be moved between trucks without using a crane. However they frequently do not have the upper corner fittings of ISO containers, and are not stackable, nor can they be lifted and handled by the usual equipment like reach-stackers or straddle-carriers. They are generally more expensive to procure.

Specifications

Basic terminology of globally standardized intermodal shipping containers is set out in standard:

* ISO 830:(1999) ''Freight containers – Vocabulary'', 2nd edition; last reviewed and confirmed in 2016.

From its inception, ISO standards on international shipping containers, consistently speak of them sofar as 'Series 1' containers – deliberately so conceived, to leave room for another such series of interrelated container standards in the future.

Basic dimensions and permissible gross weights of intermodal containers are largely determined by two ISO standards:

* ISO 668:2013–2020 Series 1 freight containers—Classification, dimensions and ratings

* ISO 1496-1:2013 Series 1 freight containers—Specification and testing—Part 1: General cargo containers for general purposes

Weights and dimensions of the most common (standardized) types of containers are given below. Forty-eight foot and fifty-three foot containers have not yet been incorporated in the latest, 2020 edition of the ISO 668. ISO standard maximum gross mass for all standard sizes except 10-ft boxes was raised to per Amendment 1 on ISO 668:2013, in 2016. Draft Amendment 1 of ISO 668: 2020 – for the eighth edition – maintains this.Draft Amendment ISO 668:2020/DAM 1

Basic terminology of globally standardized intermodal shipping containers is set out in standard:

* ISO 830:(1999) ''Freight containers – Vocabulary'', 2nd edition; last reviewed and confirmed in 2016.

From its inception, ISO standards on international shipping containers, consistently speak of them sofar as 'Series 1' containers – deliberately so conceived, to leave room for another such series of interrelated container standards in the future.

Basic dimensions and permissible gross weights of intermodal containers are largely determined by two ISO standards:

* ISO 668:2013–2020 Series 1 freight containers—Classification, dimensions and ratings

* ISO 1496-1:2013 Series 1 freight containers—Specification and testing—Part 1: General cargo containers for general purposes

Weights and dimensions of the most common (standardized) types of containers are given below. Forty-eight foot and fifty-three foot containers have not yet been incorporated in the latest, 2020 edition of the ISO 668. ISO standard maximum gross mass for all standard sizes except 10-ft boxes was raised to per Amendment 1 on ISO 668:2013, in 2016. Draft Amendment 1 of ISO 668: 2020 – for the eighth edition – maintains this.Draft Amendment ISO 668:2020/DAM 1/ref> Given the average container lifespan, the majority of the global container fleet have not caught up with this change yet. Moreover, U.S. highways cannot handle such heavy fully laden containers yet, including the mass of truck (and trailer). Values vary slightly from manufacturer to manufacturer, but must stay within the tolerances dictated by the standards. Empty weight (''

tare weight

Tare weight , sometimes called unladen weight, is the weight of an empty vehicle or container.

By subtracting tare weight from gross weight ( laden weight), one can determine the weight of the goods carried or contained (the net weight).

Etym ...

'') is not determined by the standards, but by the container's construction, and is therefore indicative, but necessary to calculate a net load figure, by subtracting it from the maximum permitted gross weight.

The bottom row in the table gives the legal maximum cargo weights for U.S. highway transport, and those based on use of an industry common tri-axle chassis. Cargo must also be loaded evenly inside the container, to avoid axle weight violations. The maximum gross weights that U.S. railroads accept or deliver are for 20-foot containers, and for 40-foot containers, in contrast to the global ISO-standard gross weight for 20-footers having been raised to the same as 40-footers in the year 2005. In the U.S., containers loaded up to the rail cargo weight limit cannot move over the road, as they will exceed the U.S. highway limit.

Tests

Here are examples of tests from ISO 1496-1:2013 (Stacking, Lifting, Restraint, wall, roof and floor Strength, Rigidity).Other sizes

'Pallet wide' containers

Europe

European ''pallet wide'' (or 'PW') containers are minimally wider, and have shallow side corrugation, to offer just enough internal width, to allow common European '' Euro-pallets'' of long by wide, to be loaded with significantly greater efficiency and capacity. Having a typical internal width of ,Pallet wide containers – ShippingAndFreightResource.com/ref> (a gain of ~ over the ISO-usual ,Shipping Container Dimensions - Container Container.com

/ref> gives ''pallet-wide'' containers a usable internal floor width of , compared to in standard containers, because the extra width enables their users to either load two Euro-pallets end on end across their width, or three of them side by side (providing the pallets were neatly stacked, without overspill), whereas in standard ISO containers, a strip of internal floor-width of about cannot be used by Euro-pallets. As a result, while being virtually interchangeable: *A 20-foot PW can load 15 Euro-pallets – four more, or 36% better than the normal 11 pallets in an ISO-standard 20-foot unit *A 40-foot PW can load 30 Euro-pallets – five more, or 20% better than the 25 pallets in a standard 40-foot unit, and *A 45-foot PW can load 34 Euro-pallets – seven more, or 26% better than 27 in a standard 45-foot container. Some ''pallet-wides'' are simply manufactured with the same, ISO-standard floor structure, but with the side-panels welded in, such that the ribs/corrugations are embossed outwards, instead of indenting to the inside. This makes it possible for some ''pallet-wides'' to be just wide, but others can be wide. Many sea shipping providers in Europe allow these on board, as their external width overhangs over standard containers are sufficiently minor that they fit in the usual interlock spaces in ship's holds, as long as their corner-castings patterns (both in the floor and the top) still match with regular 40-foot units, for stacking and securing.

45-foot containers

The pallet-wide high-cube container has gained particularly wide acceptance, as these containers can replace the swap bodies that are common for truck transport in Europe. The EU has started a standardization for pallet wide containerization in the European Intermodal Loading Unit (EILU) initiative.Australia

Australian RACE containers are also slightly wider to optimise them for the use ofAustralia Standard Pallets

Australian standard pallets are square softwood or hardwood pallets that are standard in Australia and non-standard anywhere else in the world.

They are 1165 × 1165 mm in size and fit exactly in the RACE container of the Australian railw ...

, or are long and wide to be able to fit up to 40 pallets.

Although the below described sizes are not exclusively used in the U.S. (they are also used in cargo traffic across the borders, into Canada and Mexico), they are predominantly United States initiatives.

Although the below described sizes are not exclusively used in the U.S. (they are also used in cargo traffic across the borders, into Canada and Mexico), they are predominantly United States initiatives.

North America domestic containers

48-foot containers

The 48’ shipping container is a Very Uncommon High Cube container in that it is tall on the exterior. It is wide which makes it wider than ISO-standard containers. This size was introduced by container shipping company APL (formerly American President Lines) in 1986, and is used domestically in North America on road and rail, but can only be transported on deck by ships. This size being longer and wider has 29% more volume capacity than the standard 40-ft High-Cube, yet costs of moving it by truck or rail are almost the same.53-foot containers

roll-on/roll-off

Roll-on/roll-off (RORO or ro-ro) ships are cargo ships designed to carry wheeled cargo, such as cars, motorcycles, trucks, semi-trailer trucks, buses, Trailer (vehicle), trailers, and railroad cars, that are driven on and off the ship on their o ...

ships for Puerto Rico trade, with the specific design to maximize cubic cargo capacity by carrying 53-foot, containers.

Within Canada, Oceanex offers 53-foot-container ocean service to and from Newfoundland. Fifty-three-foot containers are also being used on some Asia Pacific international shipping routes.

60-foot containers

In May 2017, Canadian Tire andCanadian Pacific Railway

The Canadian Pacific Railway (french: Chemin de fer Canadien Pacifique) , also known simply as CPR or Canadian Pacific and formerly as CP Rail (1968–1996), is a Canadian Class I railway incorporated in 1881. The railway is owned by Canad ...

announced deployment of the first 60-foot intermodal containers in North America. The containers allow Canadian Tire to increase the volume of goods shipped per container by 13%.

Small containers

The ISO 668 standard has so far never standardized containers to be the same height as so-called "Standard-height", , 20- and 40-foot containers. By the ISO standard, 10-foot (and previously included 5-ft and 6-ft boxes) are only of unnamed, 8-foot (2.44 m) height. But industry makes 10-foot units more frequently of height, to mix, match (and stack) better in a fleet of longer, 8 ft 6 in tall containers. Smaller units, on the other hand, are no longer standardized, leading to deviating lengths, like or , with non-standard widths of 2.20 m / 86.6 in and 1.95 m / 76¾ in respectively, and non-standard heights of 2.26 m / 7 ft 5 in and 1.91 m / 6 ft 3.2 in respectively, for storage or off-shore use.U.S. military

The United States military continues to use small containers, strongly reminiscent of their Transporter and Conex boxes of the 1950s and 1960s. These mostly comply with (previous) ISO standard dimensions, or are a direct derivative thereof. Current terminology of the United States armed forces calls these small containers Bicon,Tricon Tricon may refer to:

* Tricon Global Restaurants, a spin-off company of PepsiCo that, after a merger, became known as Yum! Brands

* Tricon Residential, formerly Tricon Capital, a Canadian real estate company

* Tricon, an alternate name for the 24t ...

and Quadcon, with sizes that correspond with (previous) ISO 668 standard sizes 1D, 1E and 1F respectively. These containers are of a standard height, and with a footprint size either one half (Bicon), one third (Tricon) or one quarter (Quadcon) the size of a standard 20-foot, one TEU container. At a nominal length of , two Bicons coupled together lengthwise match one 20-foot ISO container, but their height is shy of the more commonly available 10-foot ISO containers of so-called 'standard' height, which are tall. Tricons and Quadcons however have to be coupled transversely – either three or four in a row – to be stackable with twenty foot containers. Their length of corresponds to the width of a standard 20-foot container, which is why there are forklift pockets at their ends, as well as in the sides of these boxes, and the doors only have one locking bar each. The smallest of these, the Quadcon, exists in two heights: or . Only the first conforms to ISO-668 standard dimensions (size 1F).

Japan: 12-foot containers

In Japan's domestic freight rail transport, most of the containers are long in order to fit Japan's unique standard pallet sizes.Reporting mark

ISO 6346

ISO 6346 is an international standard covering the coding, identification and marking of intermodal (shipping) containers used within containerized intermodal freight transport by the International Organization for Standardization (ISO). T ...

reporting mark

A reporting mark is a code used to identify owners or lessees of rolling stock and other equipment used on certain rail transport networks. The code typically reflects the name or identifying number of the owner, lessee, or operator of the equi ...

(ownership code), four letters long ending in either U, J or Z, followed by six digits and a check digit. The ownership code for intermodal containers is issued by the (International container bureau, abbr. B.I.C.) in France, hence the name "BIC-Code" for the intermodal container reporting mark. So far there exist only four-letter BIC-Codes ending in "U".

The placement and registration of BIC Codes is standardized by the commissions TC104 and TC122 in the JTC1 of the ISO which are dominated by shipping companies. Shipping container

A shipping container is a container with strength suitable to withstand shipment, storage, and handling. Shipping containers range from large reusable steel boxes used for intermodal shipments to the ubiquitous corrugated boxes. In the context o ...

s are labelled with a series of identification codes that includes the manufacturer code, the ownership code, usage classification code, UN placard for hazardous goods and reference codes for additional transport control and security.

Following the extended usage of pallet-wide containers in Europe the EU started the Intermodal Loading Unit (ILU) initiative. This showed advantages for intermodal transport of containers and swap bodies. This led to the introduction of ILU-Codes defined by the standard EN 13044 which has the same format as the earlier BIC-Codes. The International Container Office BIC agreed to only issue ownership codes ending with U, J or Z. The new allocation office of the UIRR (International Union of Combined Road-Rail Transport Companies) agreed to only issue ownership reporting marks for swap bodies ending with A, B, C, D or K – companies having a BIC-Code ending with U can allocate an ILU-Code ending with K having the same preceding letters. Since July 2011 the new ILU codes can be registered, beginning with July 2014 all intermodal ISO containers and intermodal swap bodies must have an ownership code and by July 2019 all of them must bear a standard-conforming placard.

Handling

container terminal

A container port or container terminal is a facility where cargo containers are transshipped between different transport vehicles, for onward transportation. The transshipment may be between container ships and land vehicles, for example train ...

s. Forklift

A forklift (also called lift truck, jitney, hi-lo, fork truck, fork hoist, and forklift truck) is a powered industrial truck used to lift and move materials over short distances. The forklift was developed in the early 20th century by various ...

s, reach stackers, straddle carriers, container jacks and cranes

Crane or cranes may refer to:

Common meanings

* Crane (bird), a large, long-necked bird

* Crane (machine), industrial machinery for lifting

** Crane (rail), a crane suited for use on railroads

People and fictional characters

* Crane (surname), ...

may be used to load and unload trucks or trains outside of container terminals. Swap bodies

A swap body, swop body, exchangeable container or interchangeable unit, is one of the types of standard freight intermodal container, containers for road and rail transport.

Based on and very similar to the more widespread Intermodal container, ...

, sidelifters, tilt deck trucks, and hook trucks allow transfer to and from trucks with no extra equipment.

ISO-standard containers can be handled and lifted in a variety of ways by their corner fixtures, but the structure and strength of 45-foot (type E) containers limits their tolerance of side-lifting, nor can they be forklifted, based on ISO 3874 (1997).

Transport

Containers can be transported bycontainer ship

A container ship (also called boxship or spelled containership) is a cargo ship that carries all of its load in truck-size intermodal containers, in a technique called containerization. Container ships are a common means of commercial intermoda ...

, truck and freight train

Rail freight transport is the use of rail transport, railroads and trains to transport cargo as opposed to human passengers.

A freight train, cargo train, or goods train is a group of Railroad car#Freight cars, freight cars (US) or goods wagon ...

s as part of a single journey without unpacking. Units can be secured in transit using " twistlock" points located at each corner of the container. Every container has a unique BIC code painted on the outside for identification and tracking, and is capable of carrying up to 20–25 tonnes

The tonne ( or ; symbol: t) is a unit of mass equal to 1000 kilograms. It is a non-SI unit accepted for use with SI. It is also referred to as a metric ton to distinguish it from the non-metric units of the short ton ( United States ...

. Costs for transport are calculated in twenty-foot equivalent units (TEU).

Rail

When carried by rail, containers may be carried onflatcar

A flatcar (US) (also flat car, or flatbed) is a piece of rolling stock that consists of an open, flat deck mounted on a pair of trucks (US) or bogies (UK), one at each end containing four or six wheels. Occasionally, flat cars designed to carry ...

s or well car

A well car, also known as a double-stack car (or also intermodal car/container car), is a type of railroad car specially designed to carry intermodal containers (shipping containers) used in intermodal freight transport. The "well" is a depress ...

s. The latter are specially designed for container transport, and can accommodate double-stacked containers. However, the loading gauge

A loading gauge is a diagram or physical structure that defines the maximum height and width dimensions in railway vehicles and their loads. Their purpose is to ensure that rail vehicles can pass safely through tunnels and under bridges, and ke ...

of a rail system may restrict the modes and types of container shipment. The smaller loading gauges often found in European railroads will only accommodate single-stacked containers. In some countries, such as the United Kingdom, there are sections of the rail network through which high-cube containers cannot pass, or can pass through only on well cars. On the other hand, Indian Railways

Indian Railways (IR) is a statutory body under the ownership of Ministry of Railways, Government of India that operates India's national railway system. It manages the fourth largest national railway system in the world by size, with a tot ...

runs double-stacked containers on flatcars under 25 kV overhead electrical wires. The wires must be at least above the track. China Railway

China State Railway Group Company, Ltd., doing business as China Railway (CR), is the national passenger and freight railroad corporation of the People's Republic of China.

China Railway operates passenger and freight transport throughout Ch ...

also runs double-stacked containers under overhead wires, but must use well cars to do so, since the wires are only above the track.

Sea

About 90% of non-bulk cargo worldwide is transported by container, and the largest container ships can carry over 19,000 TEU (Twenty-Foot Equivalent, or how many 20 foot containers can fit on a ship). Between 2011 and 2013, an average of 2,683 containers were reported lost at sea. Other estimates go up to 10,000; of these 10% are expected to contain chemicals toxic to marine life. Various systems are used for securing containers on ships. Losses of containers at sea are low.Air

Containers can also be transported in planes, as seen within intermodal freight transport. However, transporting containers in this way is typically avoided due to the cost of doing such and the lack of availability of planes which can accommodate such awkwardly sized cargo. There are special aviation containers, smaller than intermodal containers, called unit load devices.Securing and security

Securing containers and contents

There are many established methods and materials for stabilizing and securing intermodal containers loaded on ships, as well as the internal cargo inside the boxes. Conventional restraint methods and materials such as steel strapping and wood blocking and bracing have been around for decades and are still widely used. Polyester strapping and lashing, and synthetic webbings are also common today. Dunnage bags (also known as "air bags") are used to keep unit loads in place. Flexi-bags can also be directly loaded, stacked in food-grade containers. Indeed, their standard shape fills the entire ground surface of a 20 ft ISO container.turnbuckle

A turnbuckle, stretching screw or bottlescrew is a device for adjusting the tension or length of ropes, cables, tie rods, and other tensioning systems. It normally consists of two threaded eye bolts, one screwed into each end of a small meta ...

s

Image:Lashing application flat rack.jpg, Polyester lashing application

Image:Lashing and dunnage bag application.JPG, Polyester strapping and dunnage bag application

Image:Stabilizing capabilities Cordstrap dunnage bags.jpg, Application in container

Security

Intermodal containers which contain valuables can be the target of break-ins and burglary when left unattended. In these cases, the container may be fitted with a security system consisting of a motion detector and panel inside the container. The panel can trigger a siren, strobe, or light to deter intruders, or use a radio signal to alert security guards. Items that were packed incorrectly may come loose and cause a false response from an inside motion detector. If criminals break in by cutting through a wall of the container, the obstructed motion detector becomes useless. Tomographic motion detectors work well in intermodal containers because they do not require a line of sight to detect motion. The entire container is covered by a volumetric sensing mesh that is not blocked by equipment or inventory. Tomographic motion detection is not prone to misdetection due to dirt buildup as is the case for beams and infrared sensors.Non-shipping uses

Containerized equipment

Container-sized units are also often used for moving large pieces of equipment to temporary sites. Specialised containers are particularly attractive to militaries already using containerisation to move much of their freight around. Shipment of specialized equipment in this way simplifies logistics and may prevent identification of high value equipment by enemies. Such systems may include command and control facilities, mobile operating theatres or even

Container-sized units are also often used for moving large pieces of equipment to temporary sites. Specialised containers are particularly attractive to militaries already using containerisation to move much of their freight around. Shipment of specialized equipment in this way simplifies logistics and may prevent identification of high value equipment by enemies. Such systems may include command and control facilities, mobile operating theatres or even missile launcher

In military terminology, a missile is a guided airborne ranged weapon capable of self-propelled flight usually by a jet engine or rocket motor. Missiles are thus also called guided missiles or guided rockets (when a previously unguided rocket ...

s (such as the Russian 3M-54 Klub

The 3M-54 Kalibr, (Калибр, caliber), also referred to it as 3M54-1 Kalibr, 3M14 Biryuza (Бирюза, turquoise), (NATO reporting name SS-N-27 Sizzler and SS-N-30A) is a family of Russian cruise missiles developed by the Novator Design Bur ...

surface-to-surface missile

A surface-to-surface missile (SSM) or ground-to-ground missile (GGM) is a missile designed to be launched from the ground or the sea and strike targets on land or at sea. They may be fired from hand-held or vehicle mounted devices, from fixed ins ...

).

Complete water treatment systems can be installed in containers and shipped around the world.

Electric generators can be permanently installed in containers to be used for portable power.

Repurposing

Half the containers that enter the United States leave empty. Their value in the US is lower than in China, so they are sometimes used for other purposes. This is typically but not always at the end of their voyaging lives. The US military often used its

Half the containers that enter the United States leave empty. Their value in the US is lower than in China, so they are sometimes used for other purposes. This is typically but not always at the end of their voyaging lives. The US military often used its Conex container

The CONEX box (Container, express) was a type of cargo container developed during the Korean War that was used to transport and store supplies during the Korean and Vietnam wars. It was reinvented by Malcom McLean to form the standard Intermod ...

s as on-site storage, or easily transportable housing for command staff and medical clinics. Nearly all of the more than 150,000 Conex containers shipped to Vietnam remained in the country, primarily as storage or other mobile facilities. Permanent or semi-permanent placement of containers for storage is common. A regular forty-foot container has about of steel, which takes of energy to melt down. Repurposing used shipping containers is increasingly a practical solution to both social and ecological problems. The global ISO Container industry valued at 686.6 thousand units in 2021 and 743.0 thousand units in 2022 respectively.

Shipping container architecture

Shipping container architecture is a form of architecture using steel intermodal containers ( shipping containers) as the main structural element. It is also referred to as cargotecture, a portmanteau of cargo with architecture, or "arkitai ...

employs used shipping containers as the main framing of modular home designs, where the steel may be an integrated part of the design, or be camouflaged into a traditional looking home. They have also been used to make temporary shops, cafes, and computer datacenters, e.g. the Sun Modular Datacenter.

Intermodal containers are not strong enough for conversion to underground bunkers without additional bracing, as the walls cannot sustain much lateral pressure and will collapse. Also, the wooden floor of many used containers could contain some fumigation residues, rendering them unsuitable as confined spaces, such as for prison cells or bunkers. Cleaning or replacing the wood floor can make these used containers habitable, with proper attention to such essential issues as ventilation and insulation.

See also

* * Mall * Conflat * Container chassis * * * * * Double-stack rail transport * * Inter-box connector * * * * * * Mall * * * * * * *International standards

ASTM

ASTM International, formerly known as American Society for Testing and Materials, is an international standards organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, a ...

D5728-00 Standard Practices for Securement of Cargo in Intermodal and Unimodal Surface Transport

* ISO 668:2013 Series 1 freight containers – Classification, dimensions and ratings

* ISO 830:1999 Freight containers – Vocabulary

* ISO 1161:1984 Series 1 freight containers – Corner fittings – Specification

* ISO 1496 – Series 1 freight containers – Specification and testing

** ISO 1496-1:2013 – Part 1: General cargo containers for general purposes

** ISO 1496-2:2008 – Part 2: Thermal containers

** ISO 1496-3:1995 – Part 3: Tank containers for liquids, gases, and pressurized dry bulk

** ISO 1496-4:1991 – Part 4: Non-pressurized container for dry bulk

** ISO 1496-5:1991 – Part 5: Platform and platform based containers

* ISO 2308:1972 Hooks for lifting freight containers of up to 30 tonnes capacity – Basic requirements

* ISO 3874:1997 Series 1 freight containers – Handling and securing

* ISO 6346

ISO 6346 is an international standard covering the coding, identification and marking of intermodal (shipping) containers used within containerized intermodal freight transport by the International Organization for Standardization (ISO). T ...

:1995 Freight containers – Coding, identification and marking

* ISO 9897:1997 Freight containers – Container equipment data exchange (CEDEX) – General communication codes

* ISO/TS 10891:2009 Freight containers – Radio frequency identification (RFID) – Licence plate tag

* ISO 14829:2002 Freight containers – Straddle carriers for freight container handling – Calculation of stability

* ISO 17363:2007 Supply chain applications of RFID – Freight containers

* ISO/PAS 17712:2006 Freight containers – Mechanical seals

* ISO 18185-2:2007 Freight containers – Electronic seals

Notes

References

page 8

*

Further reading

* George, Rose. '' Ninety Percent of Everything: Inside Shipping, the Invisible Industry That Puts Clothes on Your Back, Gas in Your Car, and Food on Your Plate'' (2013), describes typical sea voyagexcerpt and text search

*

International Organization for Standardization

The International Organization for Standardization (ISO ) is an international standard development organization composed of representatives from the national standards organizations of member countries. Membership requirements are given in Ar ...

(ISO), ''Freight containers'', Volume 34 of ISO standards handbook, International Organization for Standardization, 4th edition, 2006.

* Levinson, Marc. '' The Box: How the Shipping Container Made the World Smaller and the World Economy Bigger'', Princeton, N.J. : Princeton University Press, 2006.excerpt and text search

* Donovan, Arthur & Bonney, Joseph "The Box That Changed The World", East Windsor, New Jersey, Commonwealth Business Media, 2006

External links

Bureau International des Containers et du Transport Intermodal

* ttp://wheremy.com/container-tracking/ Track and trace by Shipping Containersbr>Track and trace Container Cargos

– by GDV, the collective of German insurance companies

ISO Containers

– ISO Freight Containers {{DEFAULTSORT:Intermodal Container Modularity Port infrastructure